Gas circulating system for preparing high-quality diamond and application method thereof

A technology of gas circulation and circulation system, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems affecting the quality of diamond film, reduce the production cost, improve the purity of hydrogen, and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

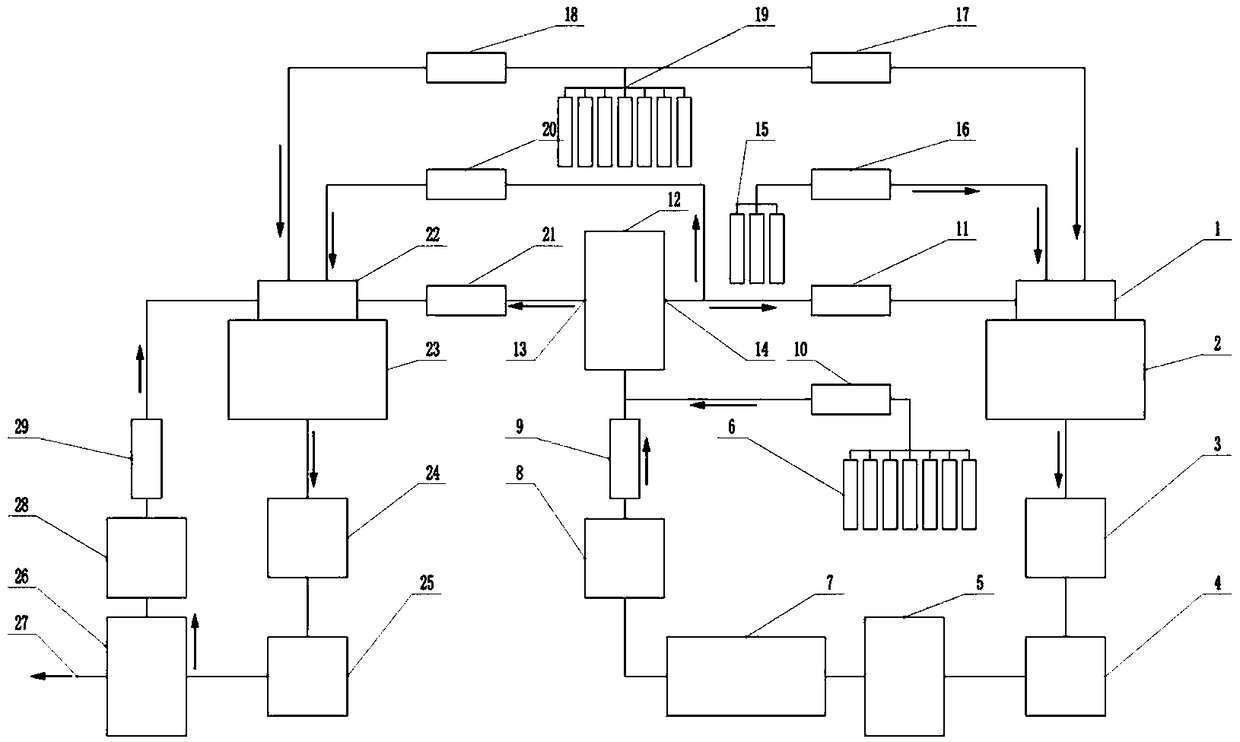

[0020] The invention relates to a gas circulation system and a use method for preparing high-quality diamond. The system mainly includes DC jet plasma deposition system, heat exchanger, filter, Roots pump, gas booster pump, oil-water separator, flow meter, hydrogen purifier, ordinary hydrogen, high-purity methane, high-purity argon, etc. .

[0021] Firstly, ordinary hydrogen 6 passes through the flow meter 2 10 to control the flow rate of the hydrogen purifier 12. After being purified by the purifier, the hydrogen in the form of high-purity hydrogen, high-purity methane 15 and high-purity argon 19 is passed into No. 1 DC arc injection Plasma torch 1. After the raw material gas is used for the deposition of the diamond film, the tail gas is pumped out of the No. 1 DC arc jet plasma deposition chamber 2 by the Roots pump 1 5 . Afterwards, the tail gas is cooled down through the heat exchanger one 3, the filter one 4 and the oil-water separator one 8 filter oil gas, water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com