Method of representing gelation nucleating kinetics process of waxy crude oil emulsion

A technology for emulsion and crude oil, which is applied in the field of characterizing the nucleation dynamics process of waxy crude oil emulsion gelation, which can solve problems such as difficult identification, limited qualitative analysis, and unrealized quantitative characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Below in conjunction with accompanying drawing, the present invention will be further described:

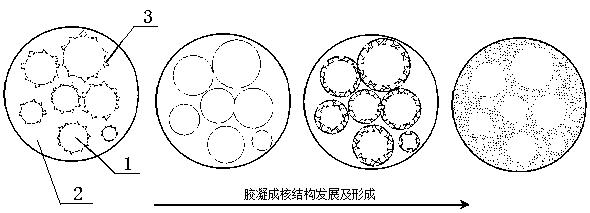

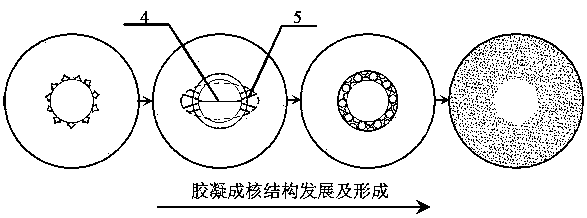

[0091] like figure 1 As shown, in the cooling process of the waxy crude oil emulsion, when the temperature is lower than the waxing point of crude oil, the wax crystal 3 is first precipitated and adsorbed on the surface of the dispersed phase water drop 1, and the wax crystal 3 is formed on the surface of the dispersed phase water drop 1 The aggregated bonding points make the surface of the dispersed phase water droplets 1 gradually covered by wax crystals 3, and then, as the cooling continues, the network flocs formed by the aggregation of wax crystals 3 continue to grow, and the gelation nucleation effect appears. , because the van der Waals attraction between the dispersed phase water droplets 1 in the waxy crude oil emulsion promotes the flocculation of the dispersed phase water droplets 1, so the gelation nucleation structure is based on the common structure of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com