A control device for flat platen printing platform

A control device, flattening technology, applied to general parts of printing machinery, printing, printing machines, etc., can solve the problems of high manufacturing cost, difficult manufacturing, complex coordination, etc., to save operating time, simple structure, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

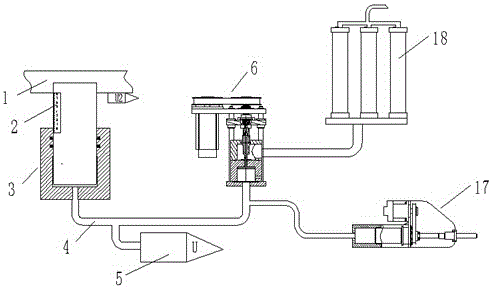

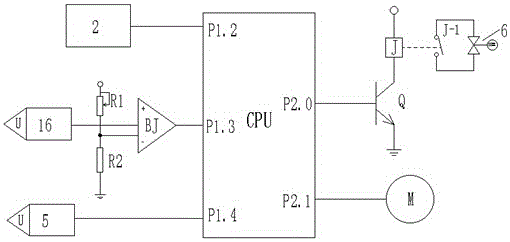

[0022] see figure 1 and figure 2 , the present invention includes executive hydraulic cylinder 3, pressurized hydraulic cylinder 17, electric control valve 6, gas-liquid converter 18 and driving part; The pipeline 4 is connected; the pressurized hydraulic cylinder 17 is connected with the driving part; the electric control valve 6 is connected with the gas-liquid converter 18 .

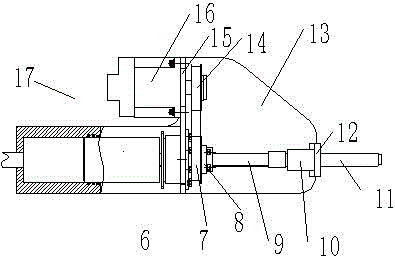

[0023] The driving part in the present invention includes a servo motor M, a screw transmission pair, a guide sleeve 12 and a frame; the frame is composed of a fixed plate 13 and a bracket 15 fixedly connected thereto; Cylinder 17 is fixed by support 15; The plunger part of described pressurization hydraulic cylinder 17 is connected with lead screw 9 one end; The other end of described lead screw 9 is sleeved on the guide sleeve 12; Press the limiting end of the hydraulic cylinder 17, and be threadedly connected with the lead screw 9; one side of the screw nut 8 is also provided with a driven synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com