Plunger pump for pumping ultralow-temperature liquid nitrogen

A technology of ultra-low temperature and plunger pumps, applied in the field of plunger pumps, can solve problems such as pressure reduction and impact on fracturing operations, and achieve the effect of stable fracturing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

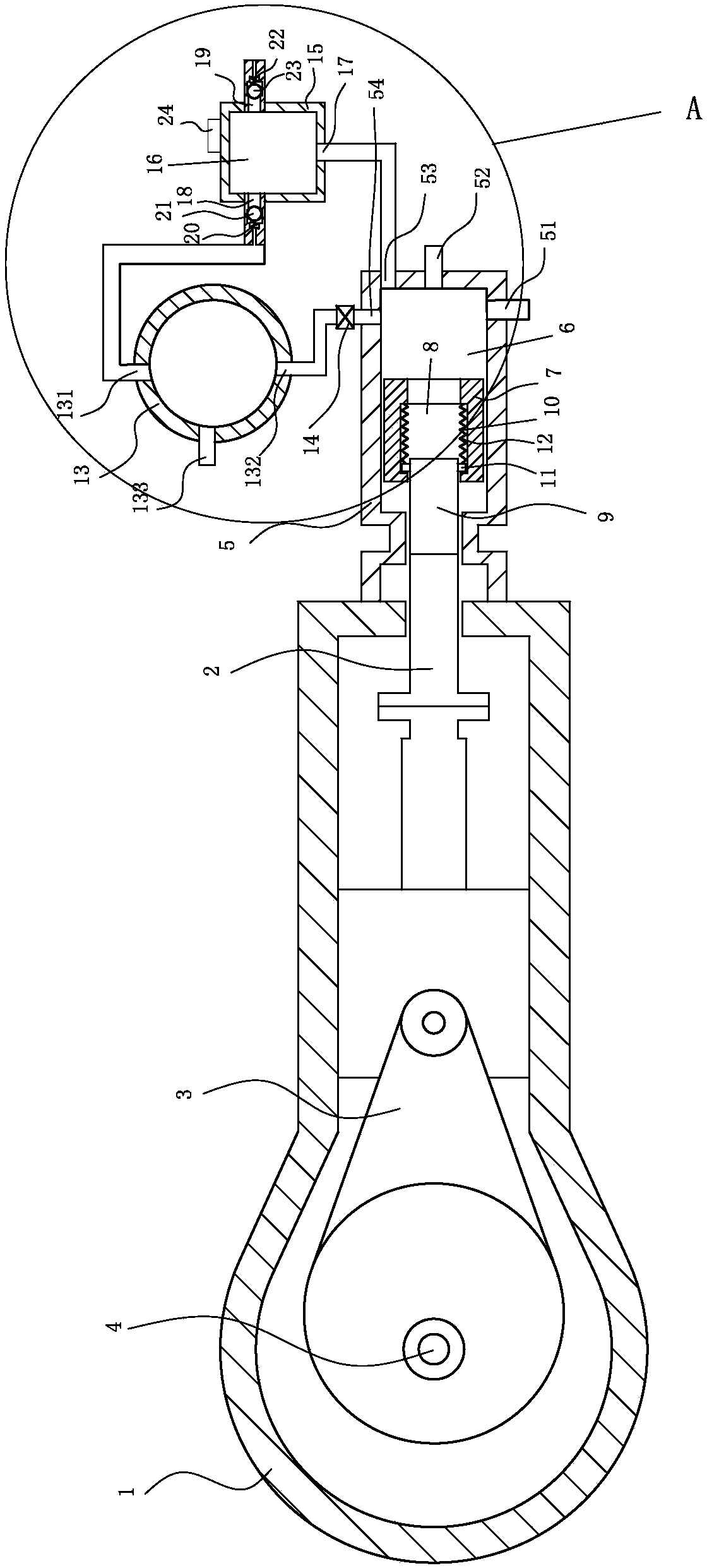

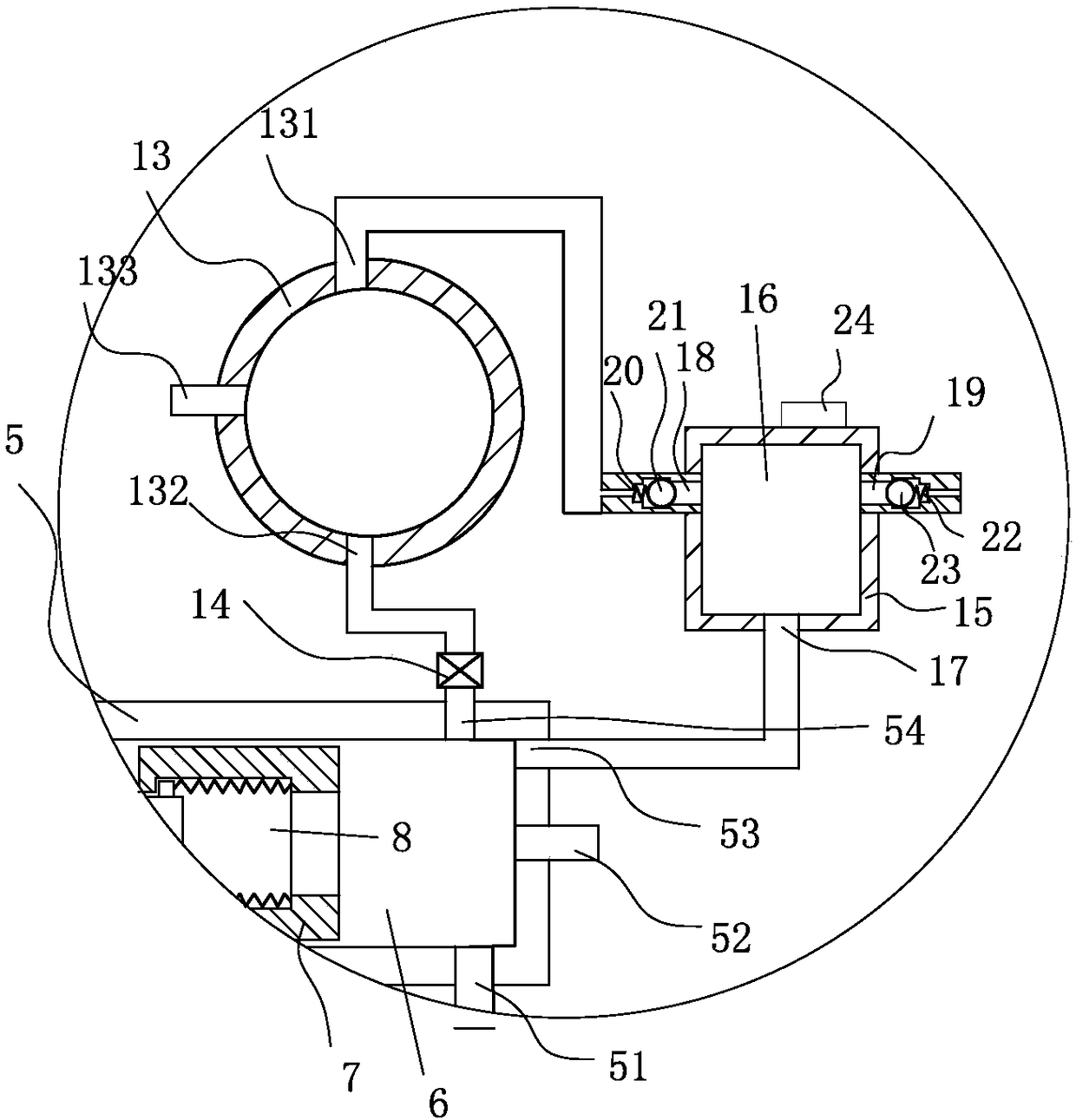

[0013] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0014] Embodiments of the invention are:

[0015] refer to figure 1 and figure 2 , a plunger pump for pumping ultra-low temperature liquid nitrogen, including a box body 1, a plunger 2 is slidably arranged on the box body 1, one end of which passes through the box body 1, and the inside of the box body 1 is located The inner end of the plunger 2 is provided with a crank linkage mechanism 3, the input end of the crank linkage mechanism 3 is connected with a motor 4, and the outer end of the plunger 2 on the box body 1 is provided with a pumping device, the The pumping device includes a housing 5 fixedly arranged on the box body 1, a chamber 6 is arranged in the housing 5, and a liquid inlet 51 and a liquid outlet 52 are arranged on the housing 5 in communication with the chamber 6 , a pressure measuring port 53 and a supply port 54, the chamber 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com