Semiconductor manufacturing method and multi-piece deposition equipment

A technology of deposition equipment and manufacturing method, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of shortening radio frequency generation time, long radio frequency generation time, reducing substrate production efficiency, etc. Radio frequency generation time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

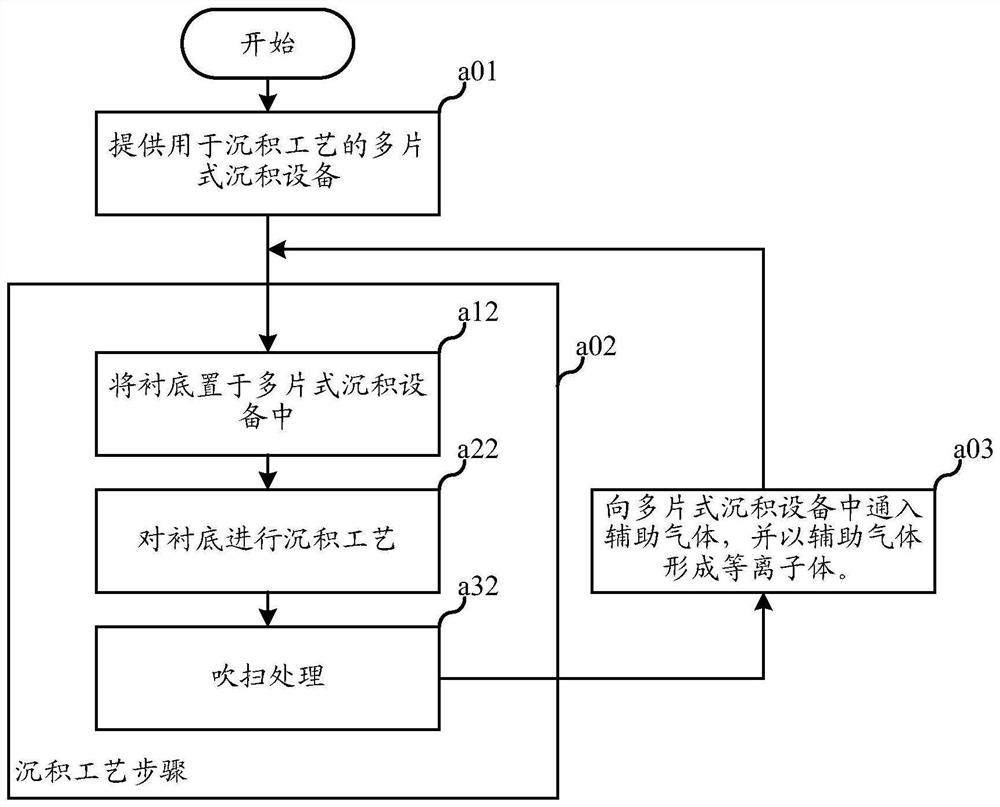

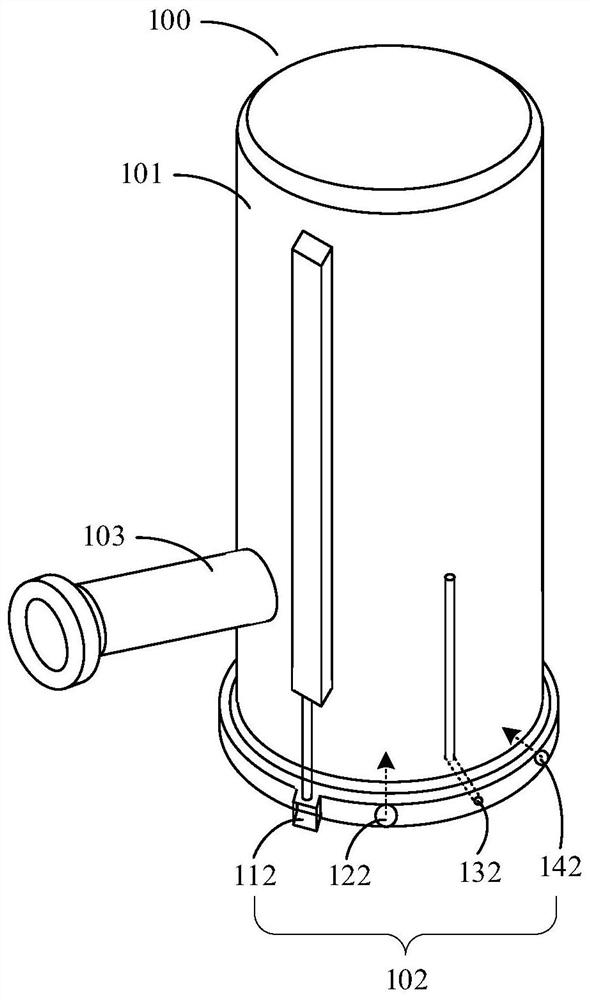

[0030] At present, the equipment used for substrate deposition is divided into single-chip deposition equipment and multi-chip deposition equipment. Compared with single-chip deposition equipment, multi-chip deposition equipment can perform deposition processes on a large number of substrates at a time. The deposition efficiency is higher. In the prior art, the radio frequency compensation function is usually used to shorten the generation time of radio frequency in the multi-chip deposition equipment.

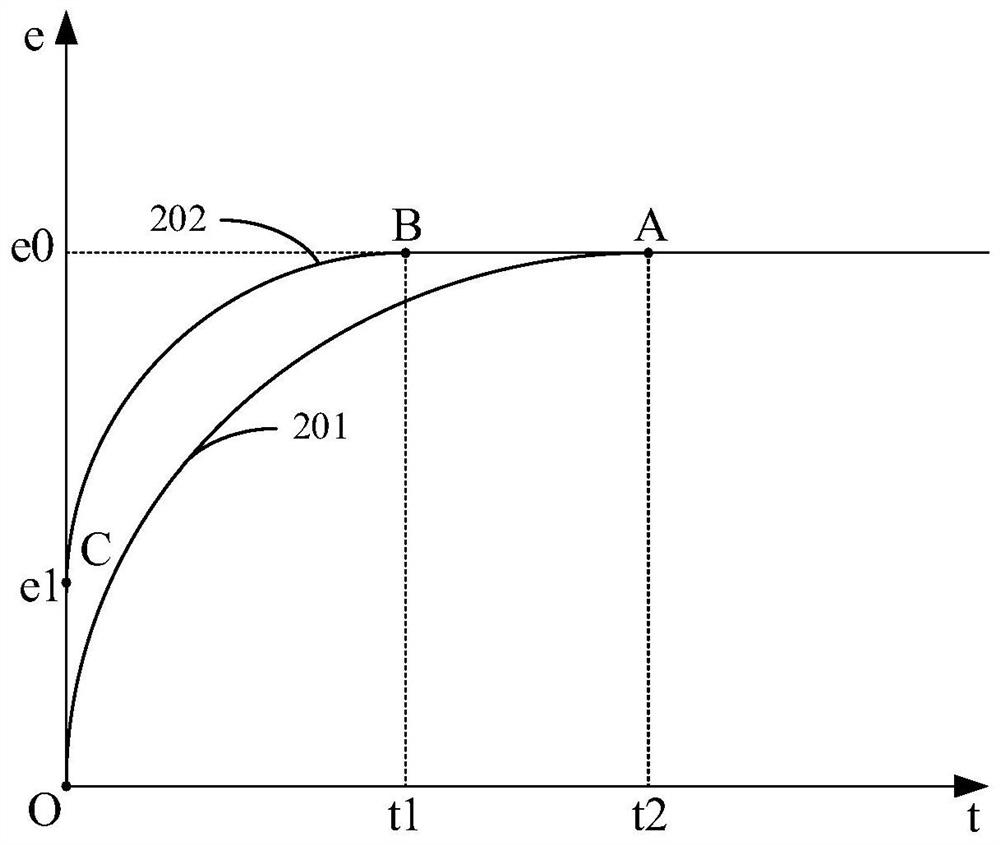

[0031] However, the inventors have found that the reaction space of multi-chip deposition equipment is much larger than that of general single-chip deposition equipment. Therefore, compared with single-chip deposition equipment, multi-chip deposition equipment is a large-volume deposition equipment. And for the multi-chip deposition equipment, even if the deposition process of each batch of substrates is carried out continuously, the interval time between the deposition proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com