Mortar pumping system and pumping pipeline

A technology for pumping pipes and mortar, which is applied to parts, pumps, and pump controls of elastic fluid pumping devices. It can solve the problems of difficult control of the pumping height of mortar, achieve good sealing, convenient installation, and economical Affordable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

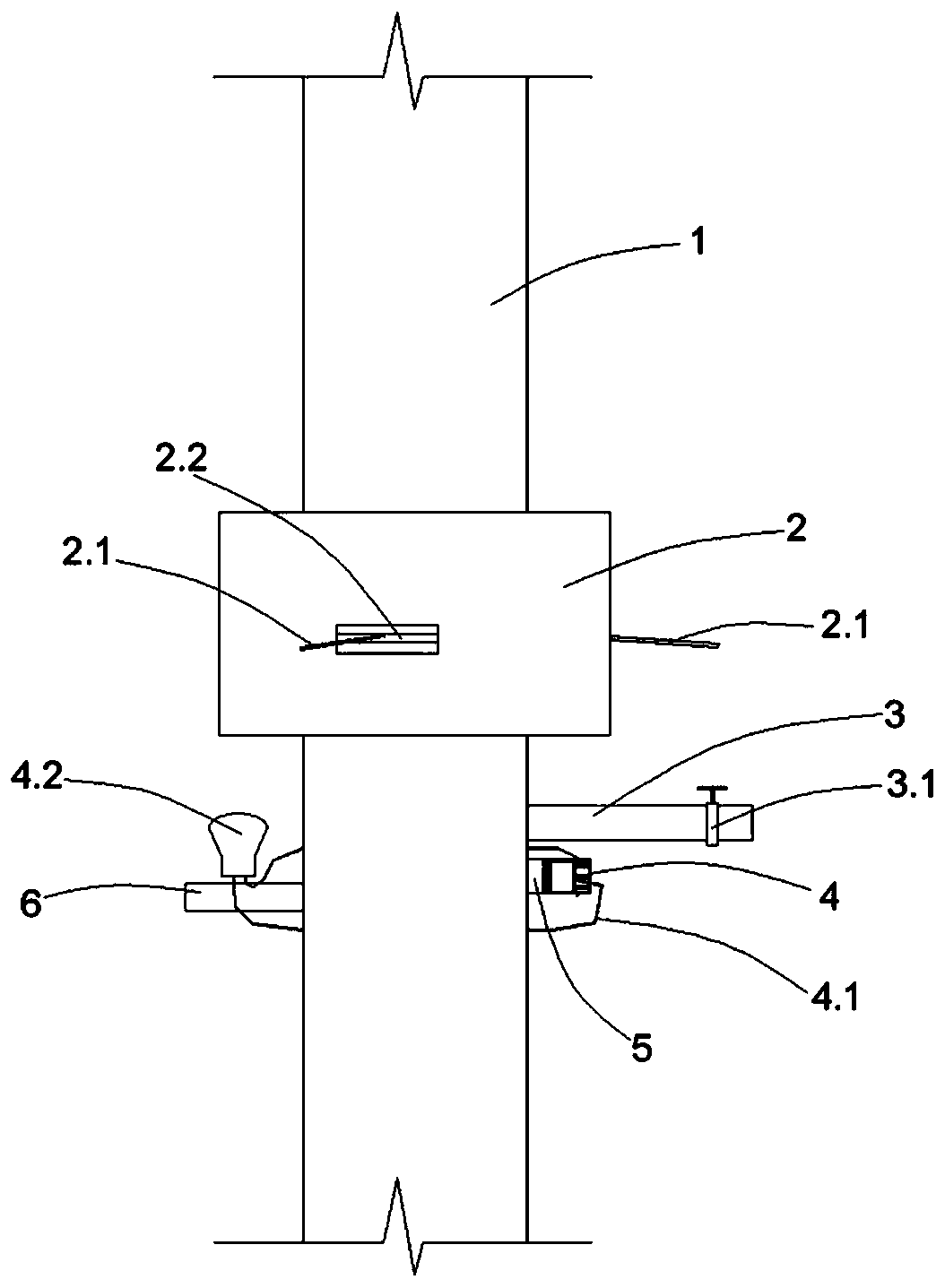

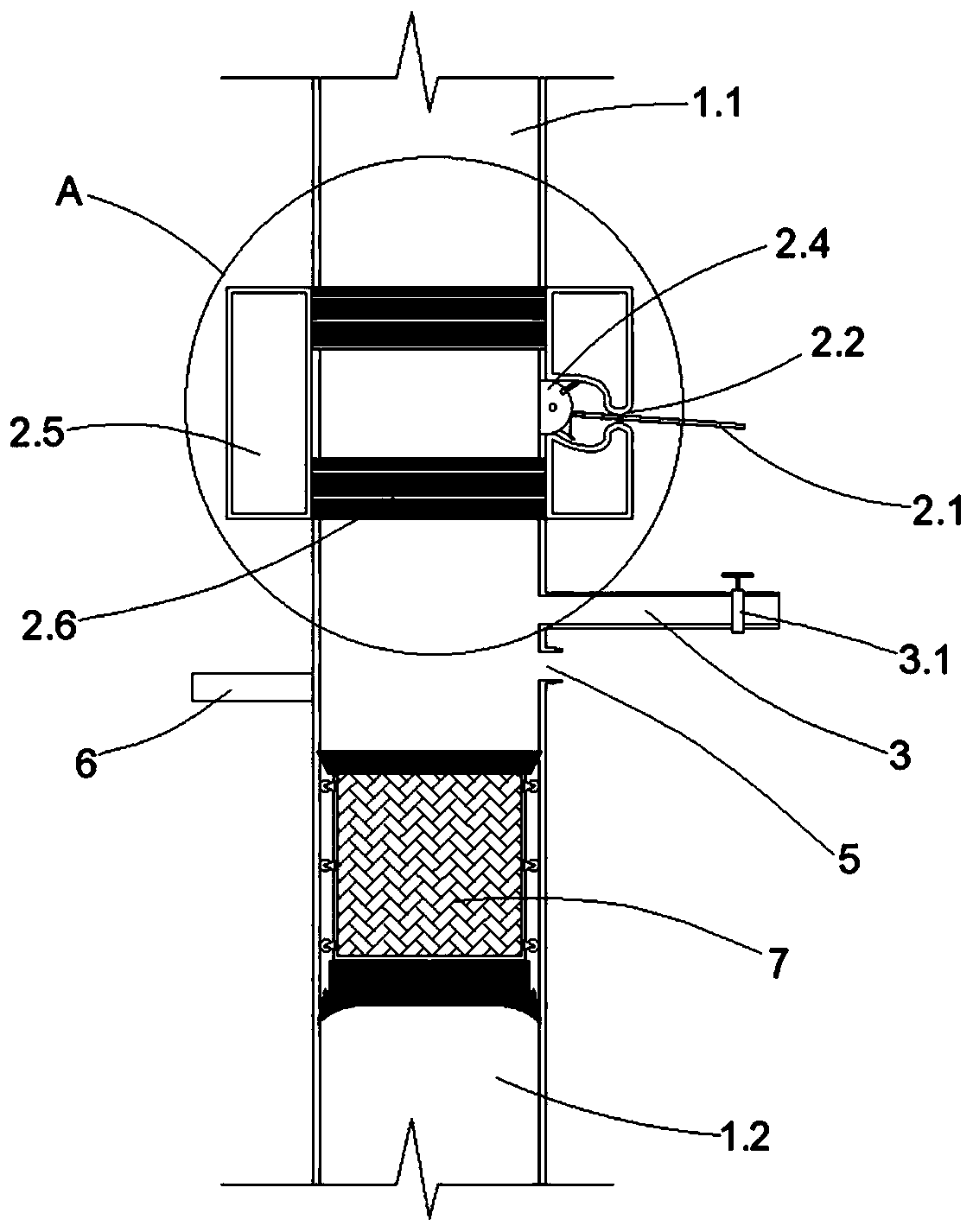

[0041] Such as Figure 1 to Figure 7 As shown, the mortar pumping system includes a delivery pump and a pumping pipeline. In this embodiment, the pumping pipeline is laid along the floor height, and the mortar 8 on the ground is powered by the delivery pump, and then transported to corresponding floor locations.

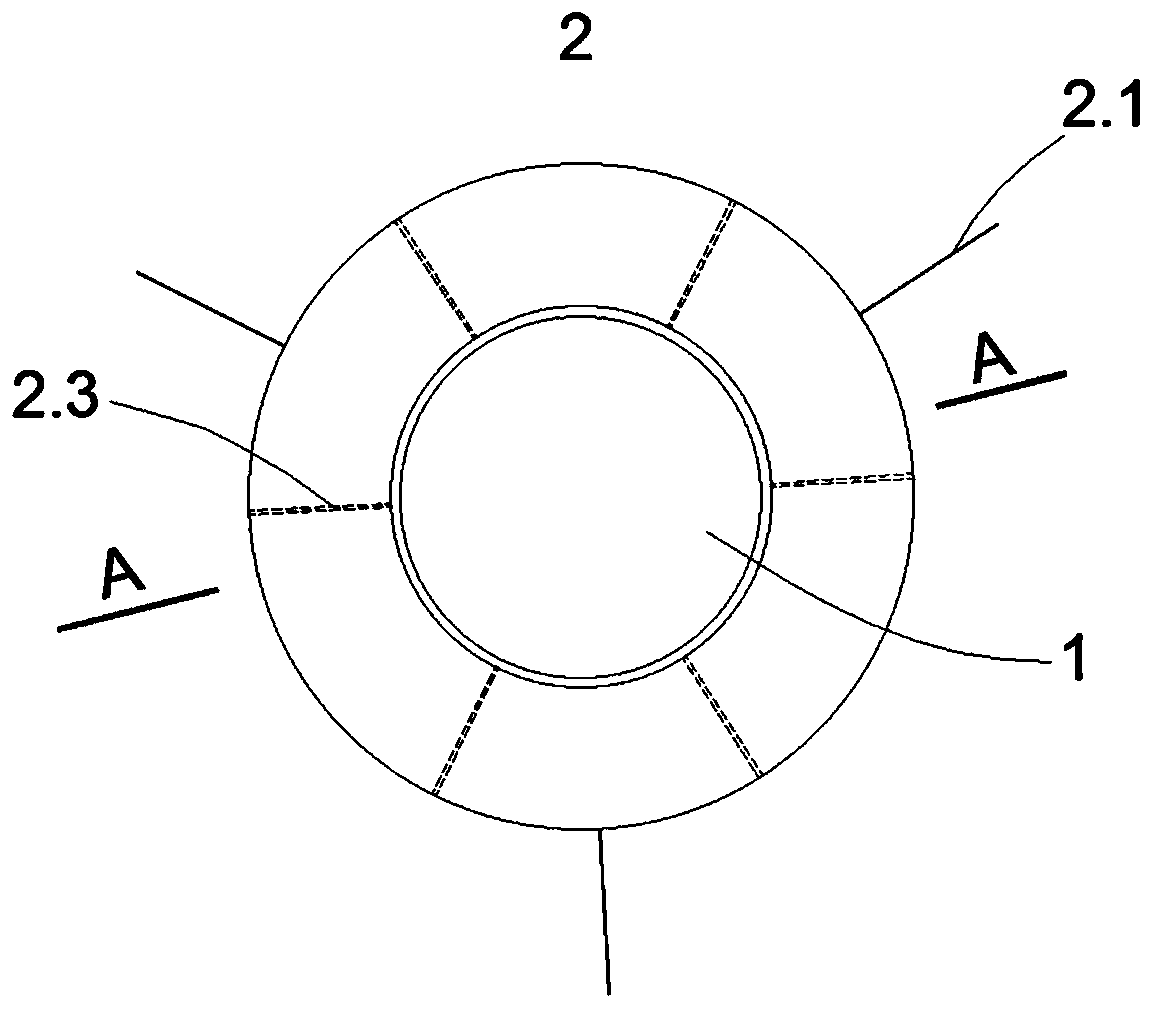

[0042] The specific details of the pumping pipeline are as follows: figure 1 and image 3 As shown, the pumping pipeline in this embodiment includes a delivery main pipe 1, a delivery branch pipe 3 communicated with the delivery main pipe 1 (the delivery branch pipe 3 is provided with a valve 3.1), and a sliding unit 7 that is sealed and slidably assembled in the delivery main pipe 1 , the intercepting unit 2 arranged on the conveying main pipe 1 and the monitoring unit 4 arranged on the conveying main pipe 1 . In this embodiment, the conveying main pipe 1 is arranged in sections, that is, the conveying main pipe 1 includes a plurality of sectioned conveying main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com