Patents

Literature

48results about How to "Reduce bonding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

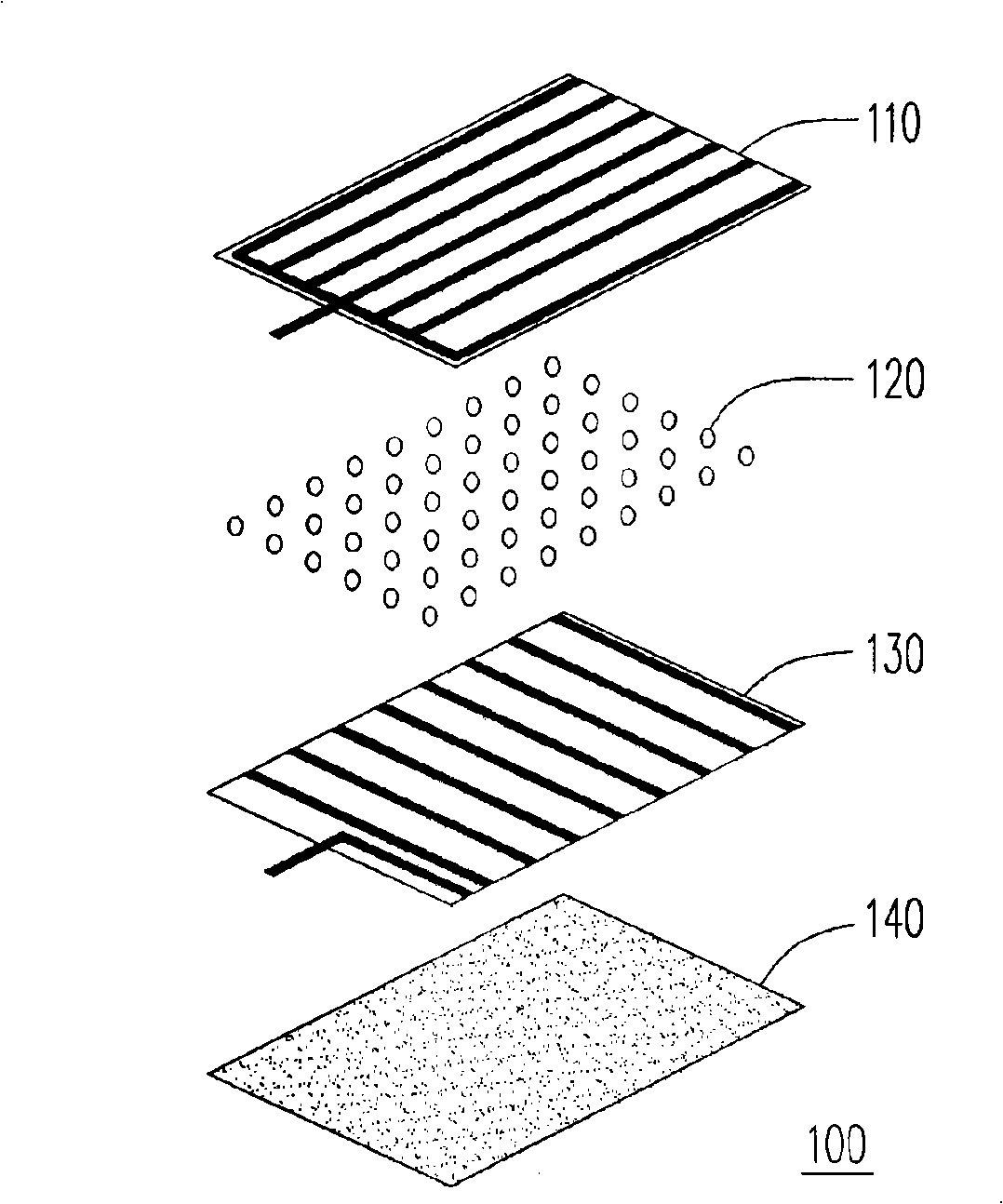

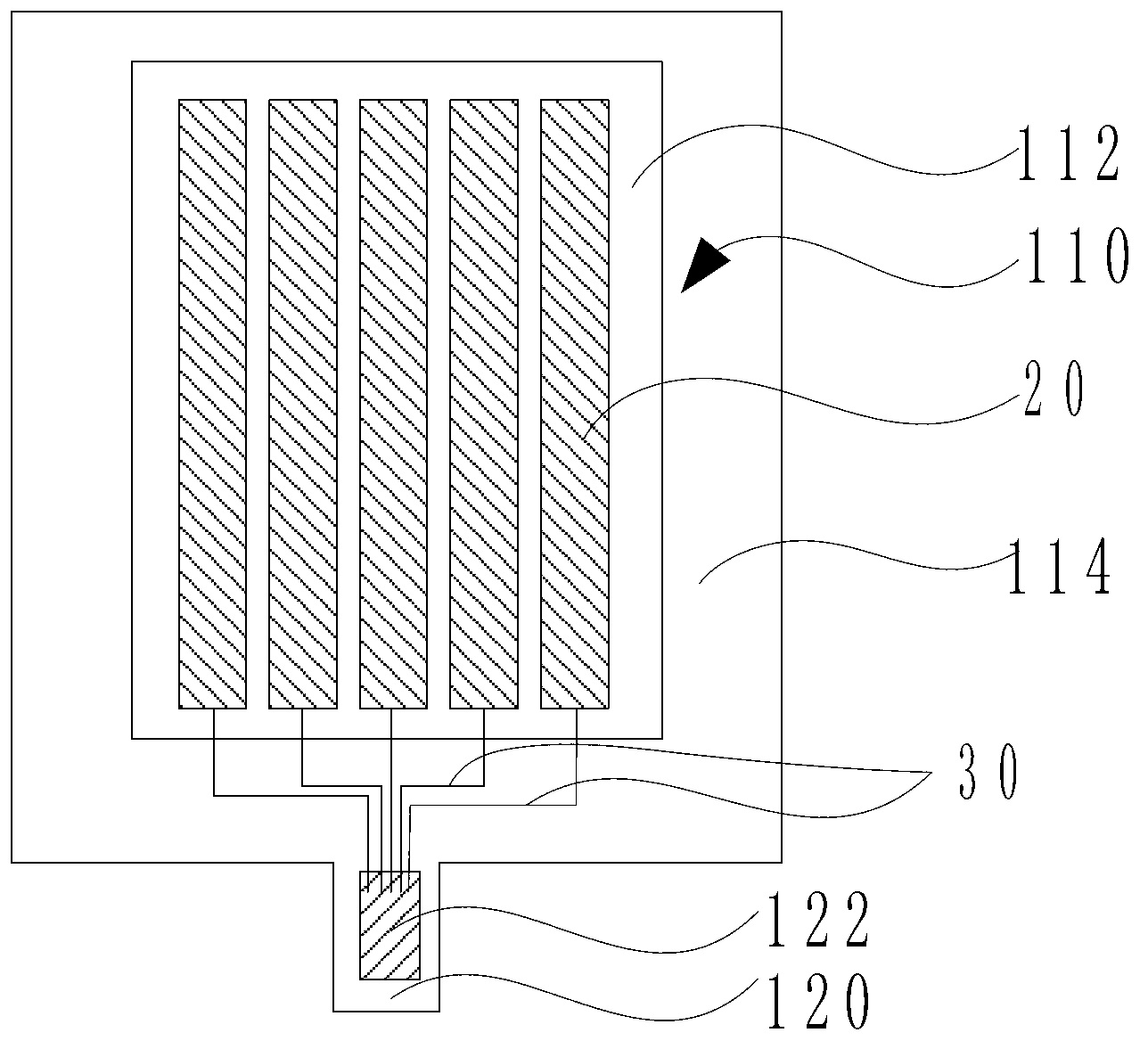

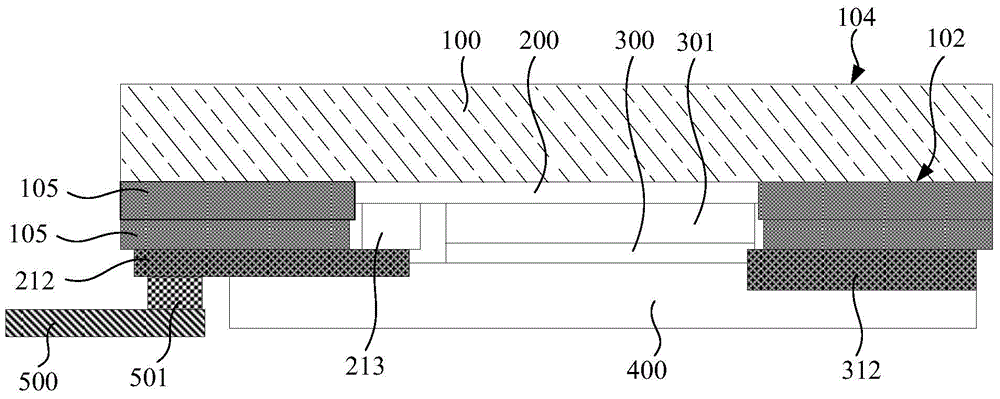

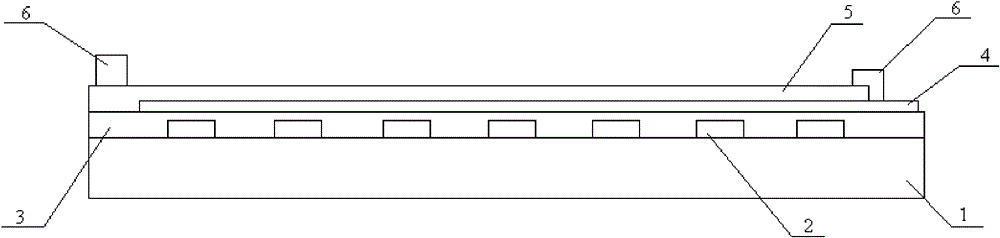

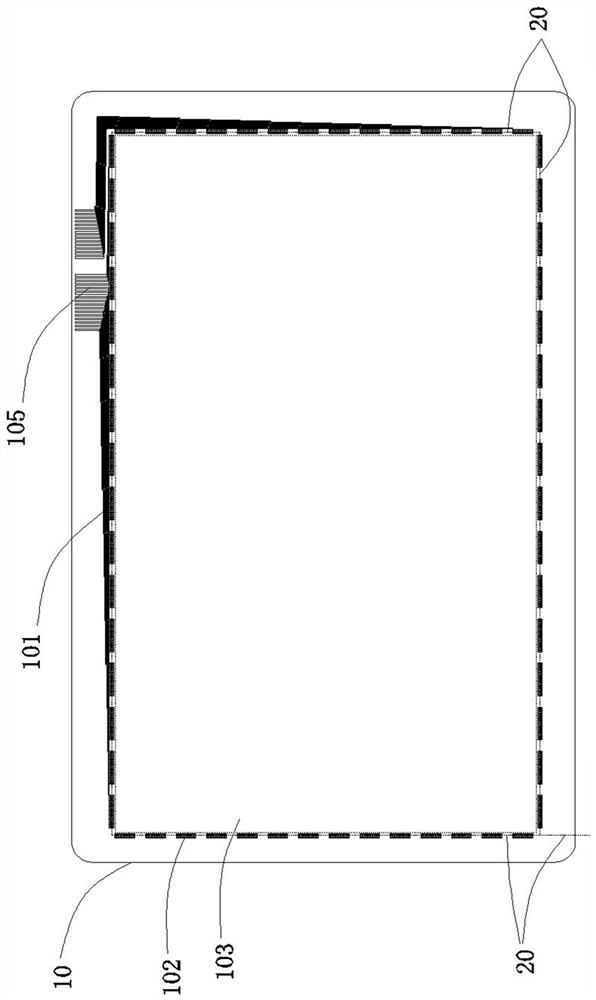

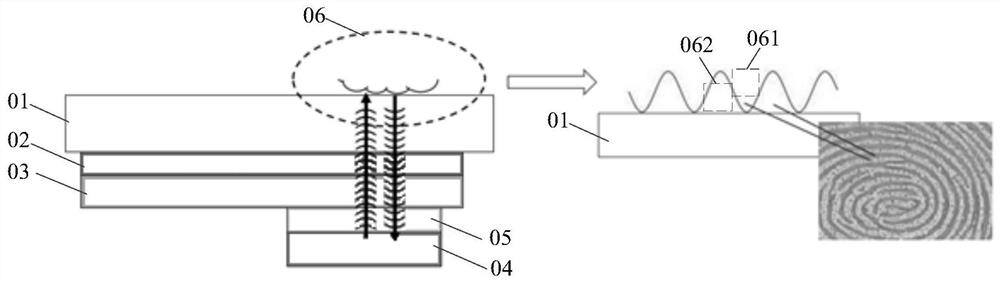

Touch control panel and touch control type LCD device

InactiveCN101408685AReduce usageReduce bonding processStatic indicating devicesInput/output processes for data processingLiquid-crystal displayInter layer

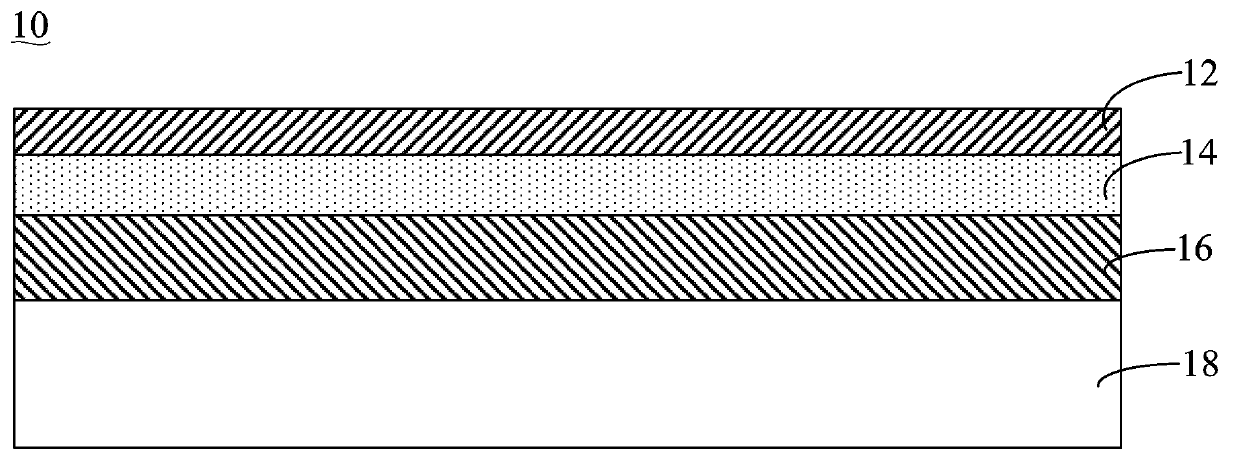

The invention relates to a touch panel and a touch-control liquid crystal display; wherein, the touch panel comprises a polarizing plate which is provided with a plurality of first electrodes, a contact layer which is provided with a plurality of second electrodes and an intermediate layer which is arranged between the polarizing plate and the contact layer. The touch panel utilizes an upper polarizing plate on the liquid crystal displaying panel to replace a glass substrate and can form the structure of the touch panel on the upper polarizing plate directly. Therefore, the integrated process of the touch panel and the liquid crystal displaying panel can be simplified, and the use of the glass substrate is reduced, so that the cost is lowered, and the thickness and weight of the touch-control liquid crystal display are reduced.

Owner:CHUNGHWA PICTURE TUBES LTD

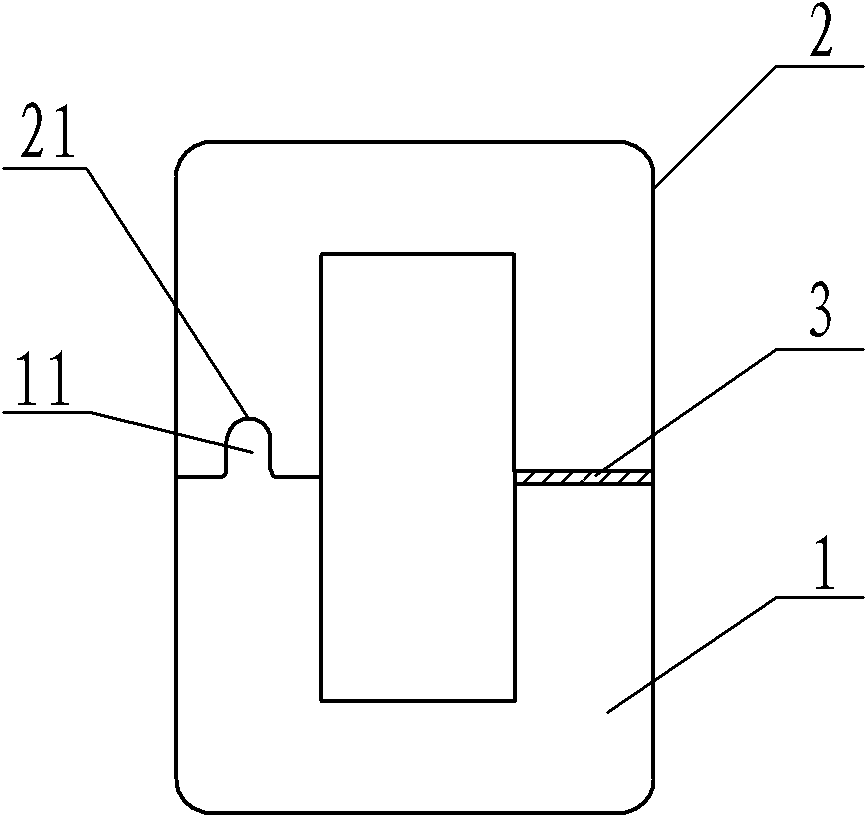

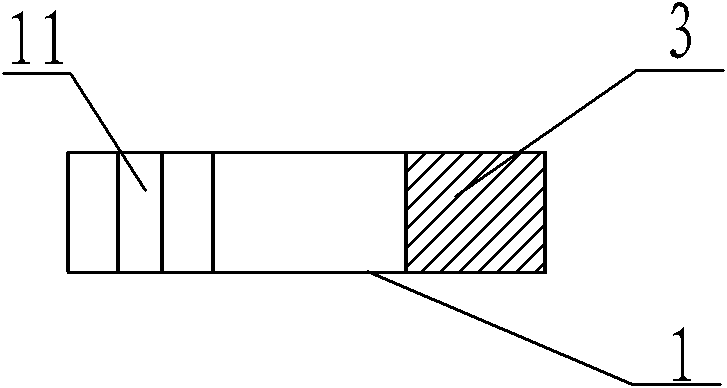

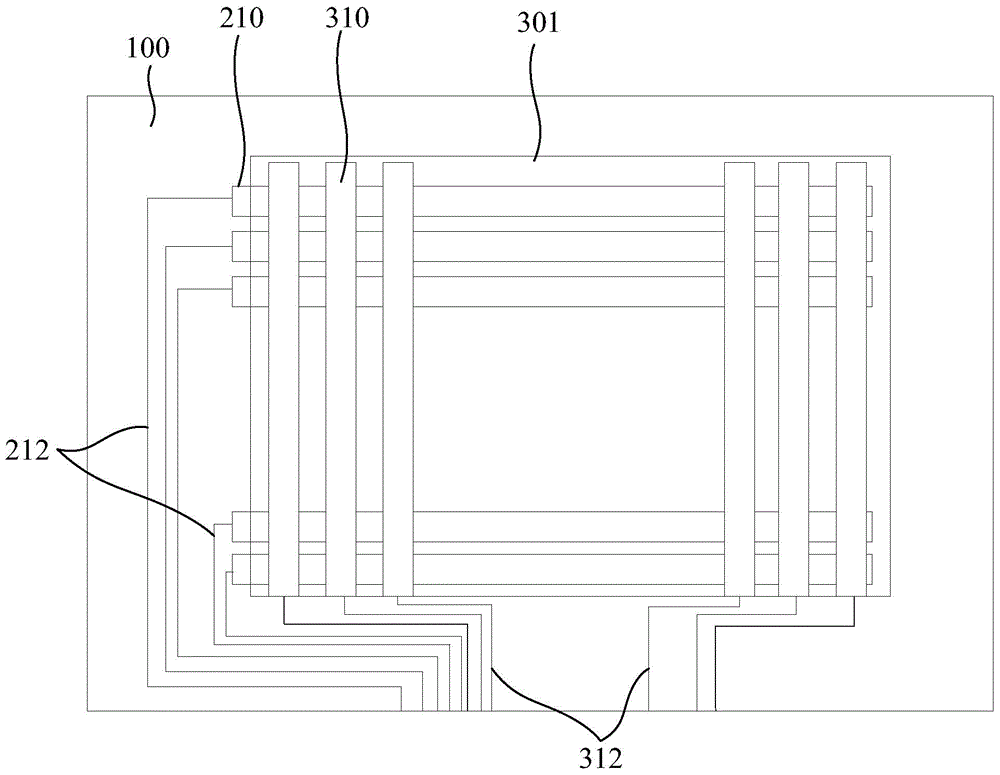

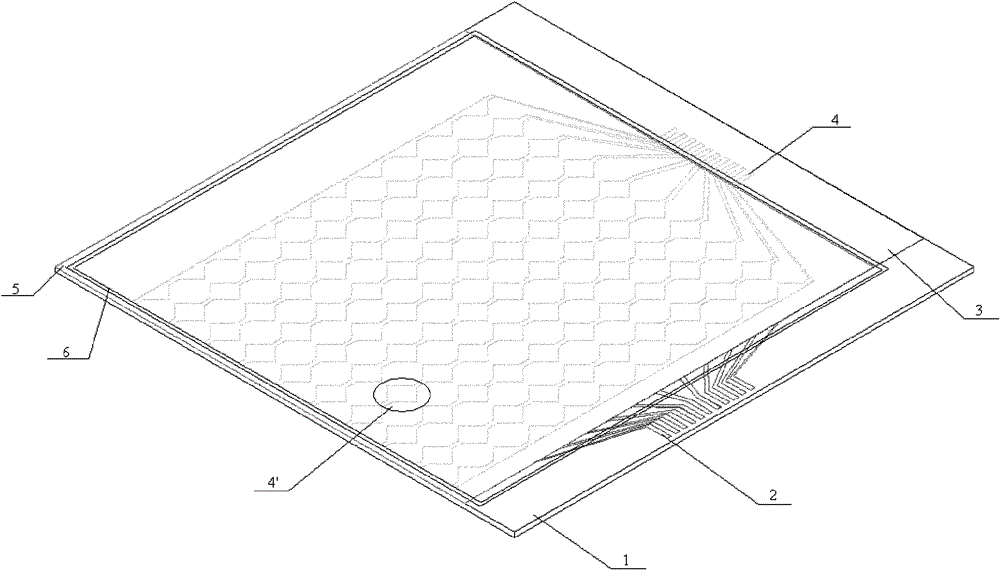

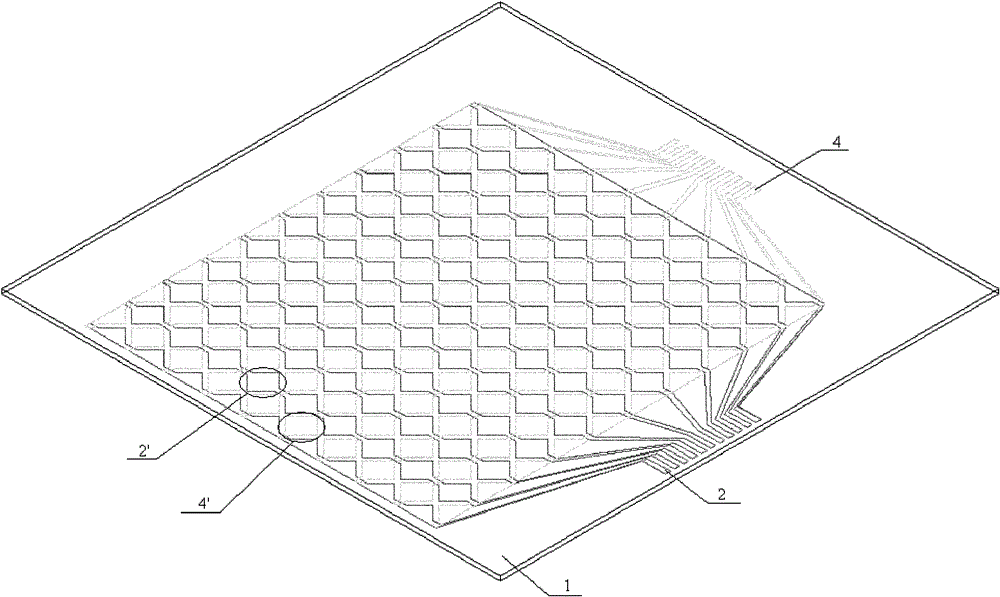

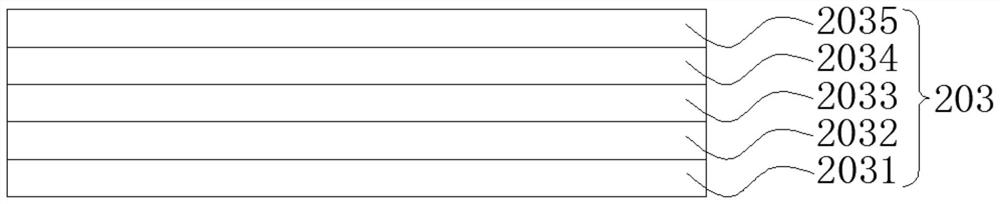

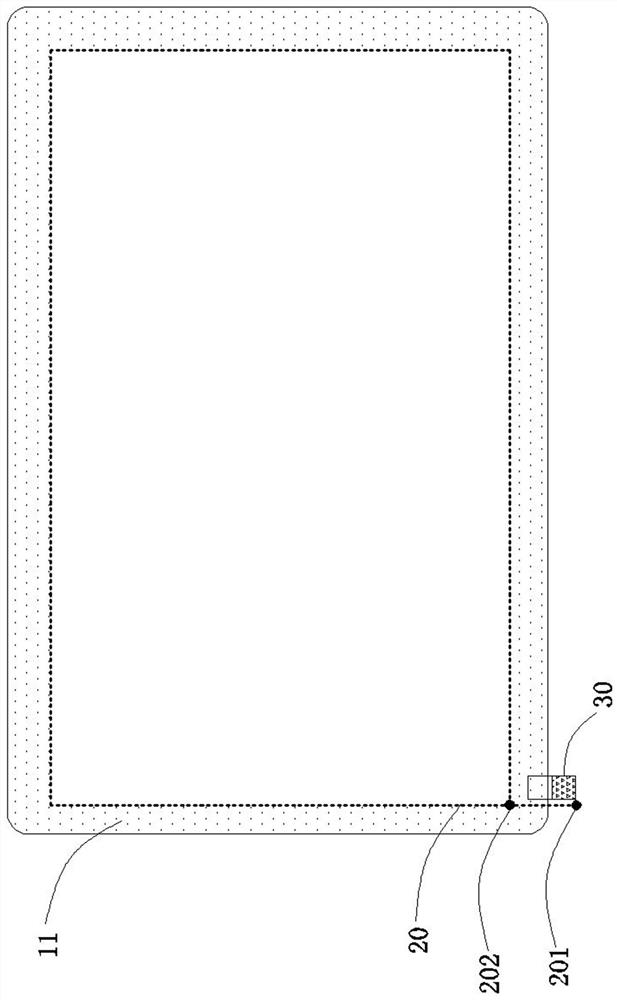

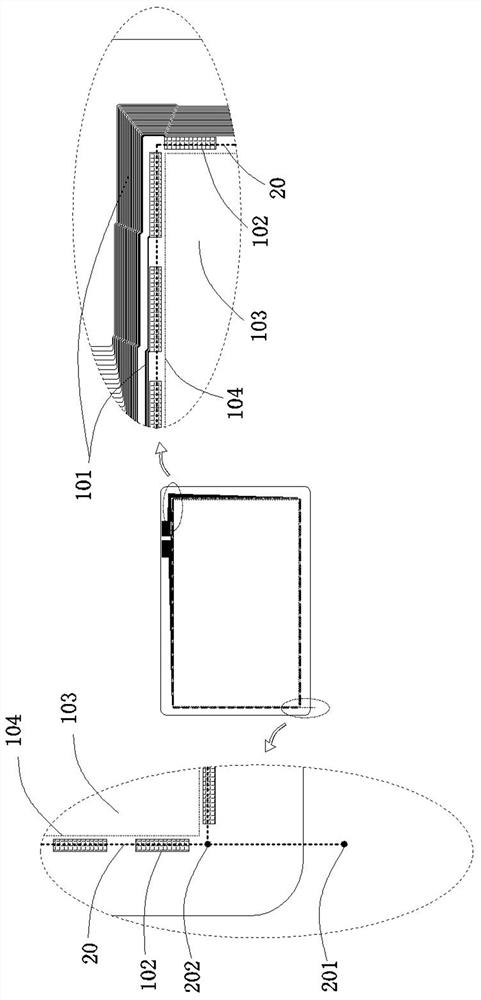

Transparent conducting film

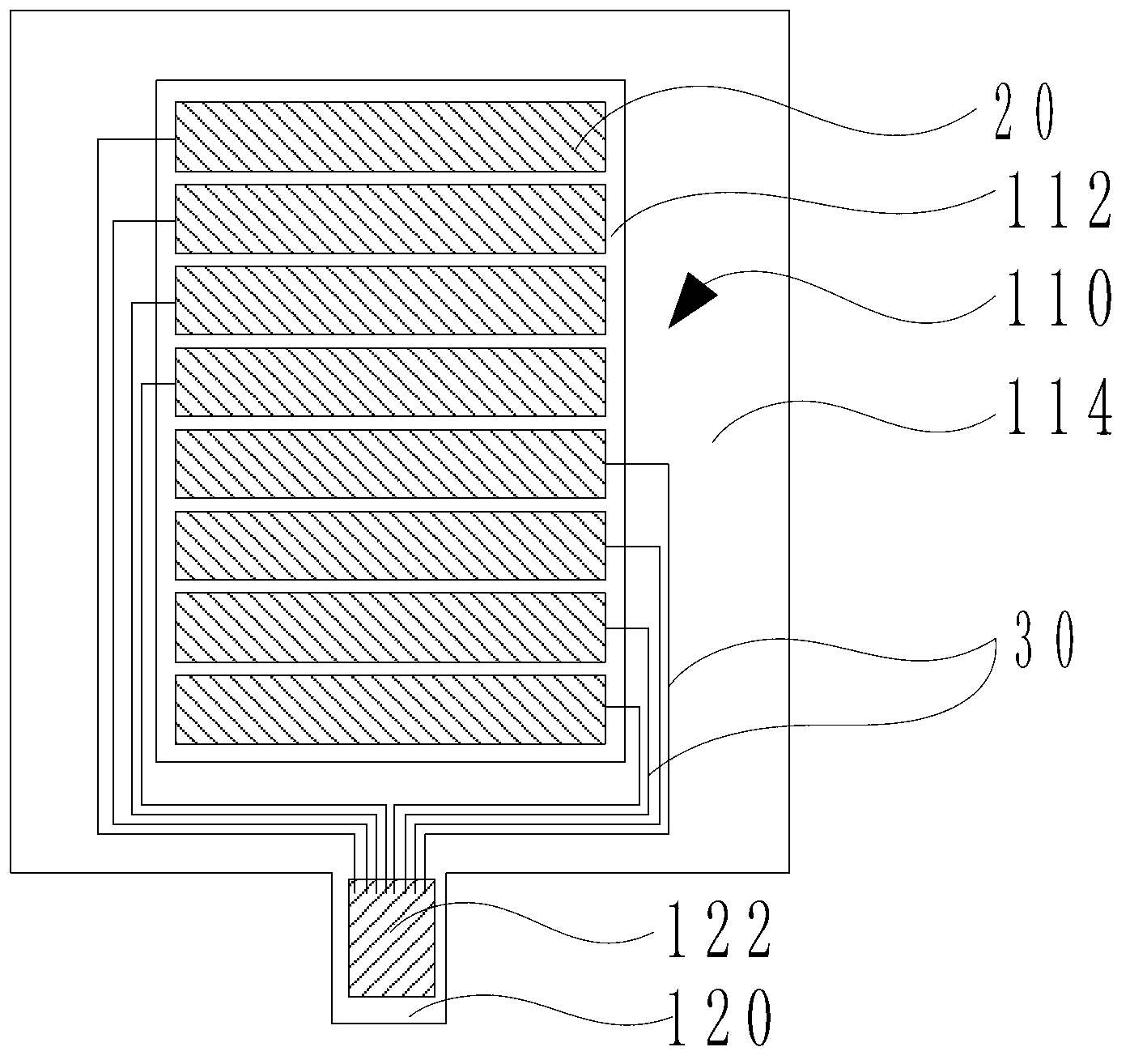

ActiveCN103295671AReduce bonding processIncrease productivityConductive layers on insulating-supportsTransparent dielectricsTransparent conducting filmLead electrode

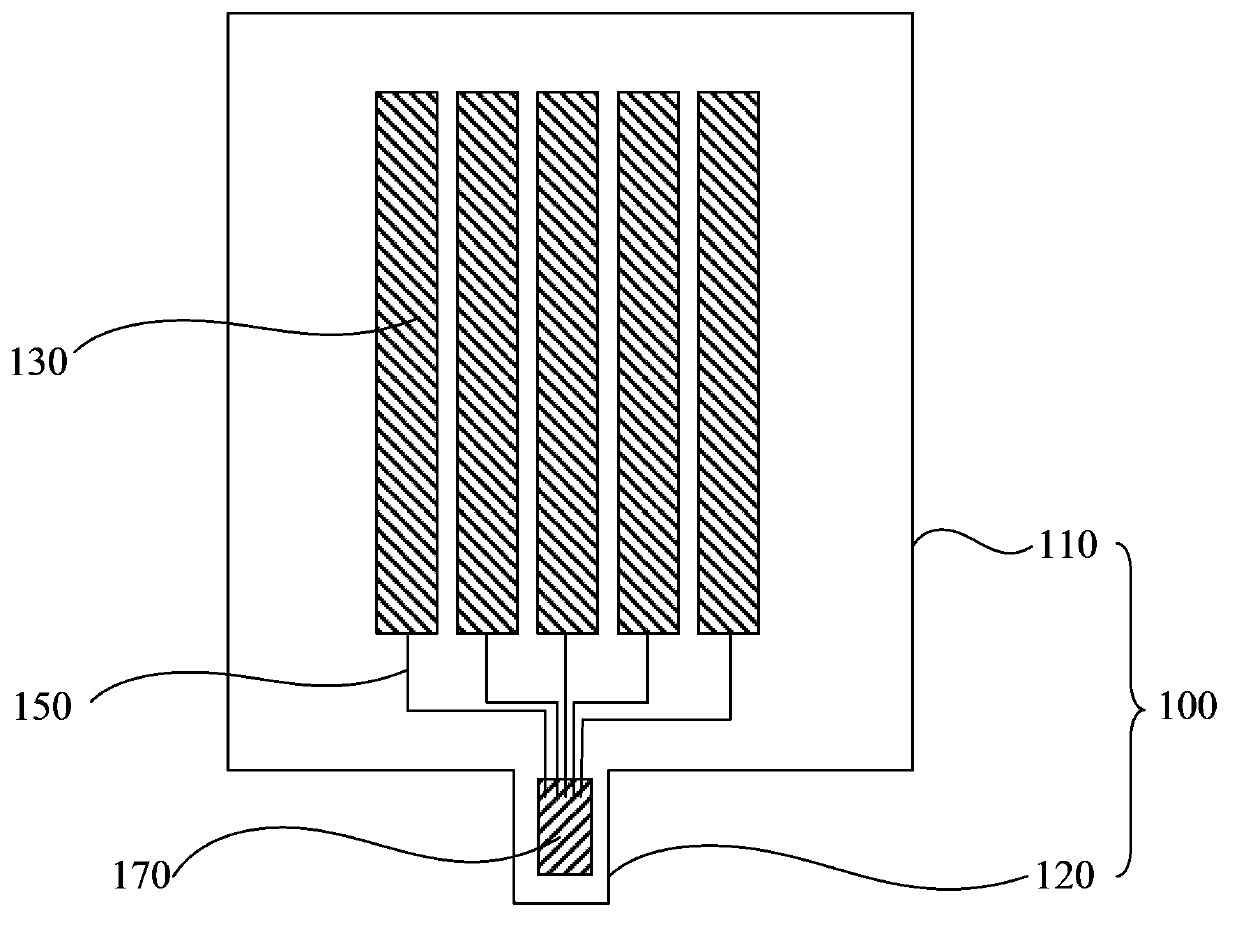

A transparent conducting film comprises a transparent substrate. The transparent substrate comprises a body and a flexible connection part formed by extending from one side of the body, the width of the flexible connection part is smaller than that of the side, extended with the flexible connection part, of the body, the flexible connection part is provided with a conducting circuit, the body comprises a sensing area, a border area positioned at edges of the sensing area, a latticed conducting layer and lead electrodes, the latticed conducting layer is arranged on one side of the sensing area of the body and comprises conducting wires which are crossed with each other, the lead electrodes are arranged on one side of the border area of the body, and the conducting layer is electrically connected with the conducing circuit via the lead electrodes. Since the flexible connection part is formed by extending from one side of the transparent substrate body and is integrated with the body, the flexible connection part does not need to be glued with the transparent conducting film extra, gluing process is omitted, and production efficiency is improved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

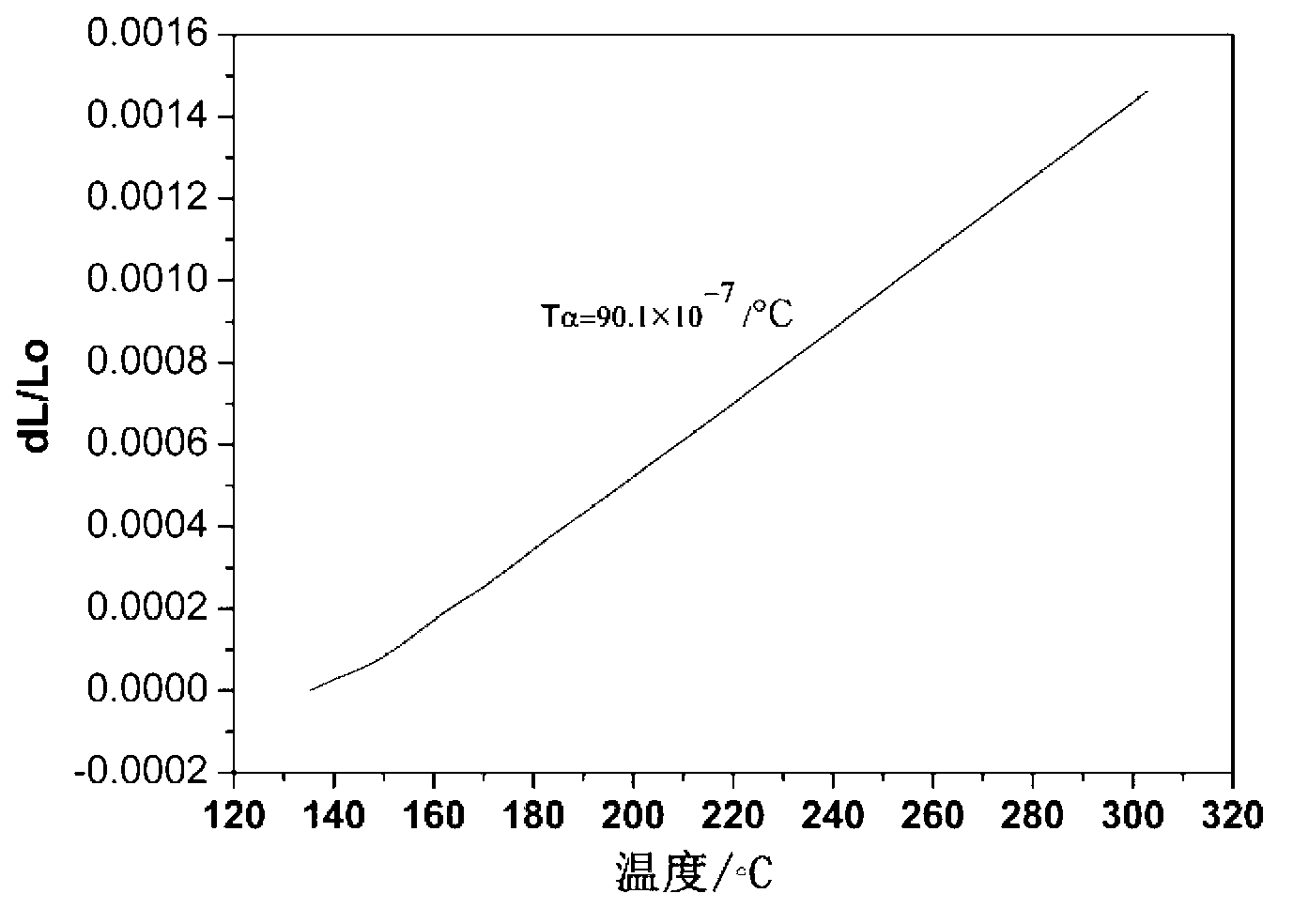

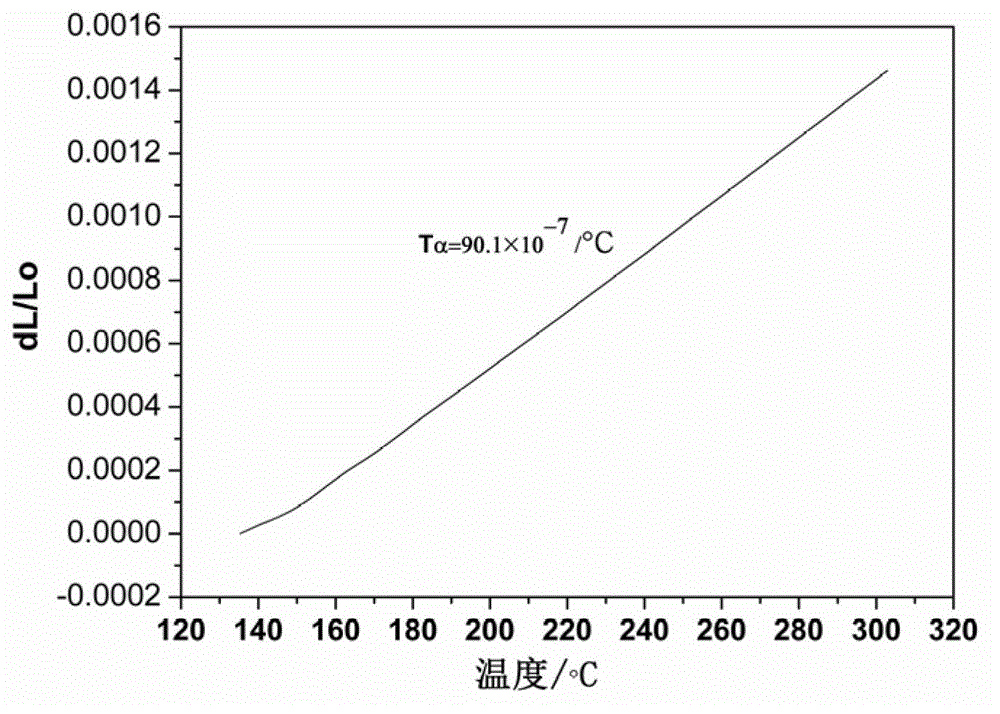

Preparation method of thermal insulation composite material

InactiveCN103317796AReduce usageReduce the use of cement mortar bonding processHeat proofingGlass/slag layered productsThermal insulationBonding process

A preparation method of a thermal insulation composite material comprises the following steps: firstly, mixing foaming thermal insulation material batch and carrying out compression moulding; secondly, preparing a microcrystalline glass sheet material through fusion; thirdly, taking out the prepared foaming thermal insulation material, putting the material on the upper surface of the prepared microcrystalline glass sheet material of 880 DEG C, and compounding the foaming thermal insulation material and the microcrystalline glass sheet material; fourthly, sending the composite sheet material into a foaming furnace of 850 DEG C through a mesh belt, foaming and insulating at 850 DEG C for 25-45 min, cooling at the cooling rate of 10-20 DEG C / min to 600 DEG C, and standing at constant temperature for 30 min; and finally, cooling at the cooling speed of 1-2 DEG C / min from 600 DEG C to room temperature so as to obtain the thermal insulation composite board. According to the invention, the thermal insulation foam glass material and the microcrystalline glass building material are bonded at high temperature into an integral body; the bonding process by the use of cement mortar during the construction process is reduced; material usage is minimized; and construction procedure is simplified. Meanwhile, the prepared thermal insulation composite board's thermal insulation material has advantages of high strength, low water absorption, low density and low heat conductivity coefficient.

Owner:承德新通源新型环保材料有限公司

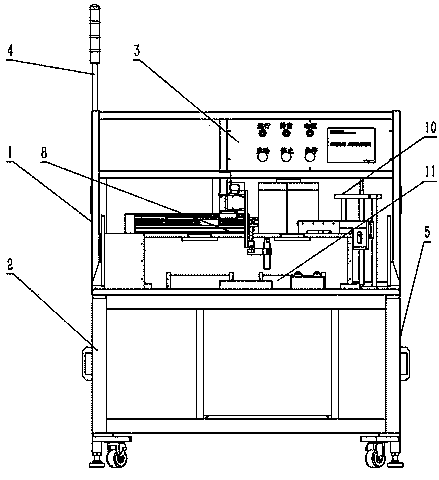

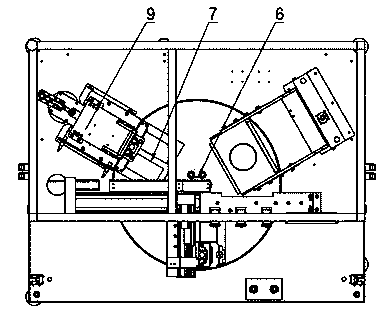

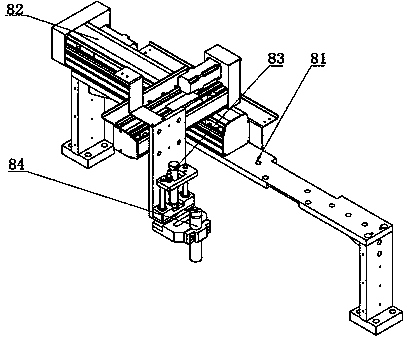

Turntable type UV laminator

InactiveCN103846191AGuaranteed Segmentation AccuracyGuaranteed uptimeLaminationPretreated surfacesBiochemical engineeringRaw material

Owner:HUNAN TENYUM INTELLIGENT EQUIP

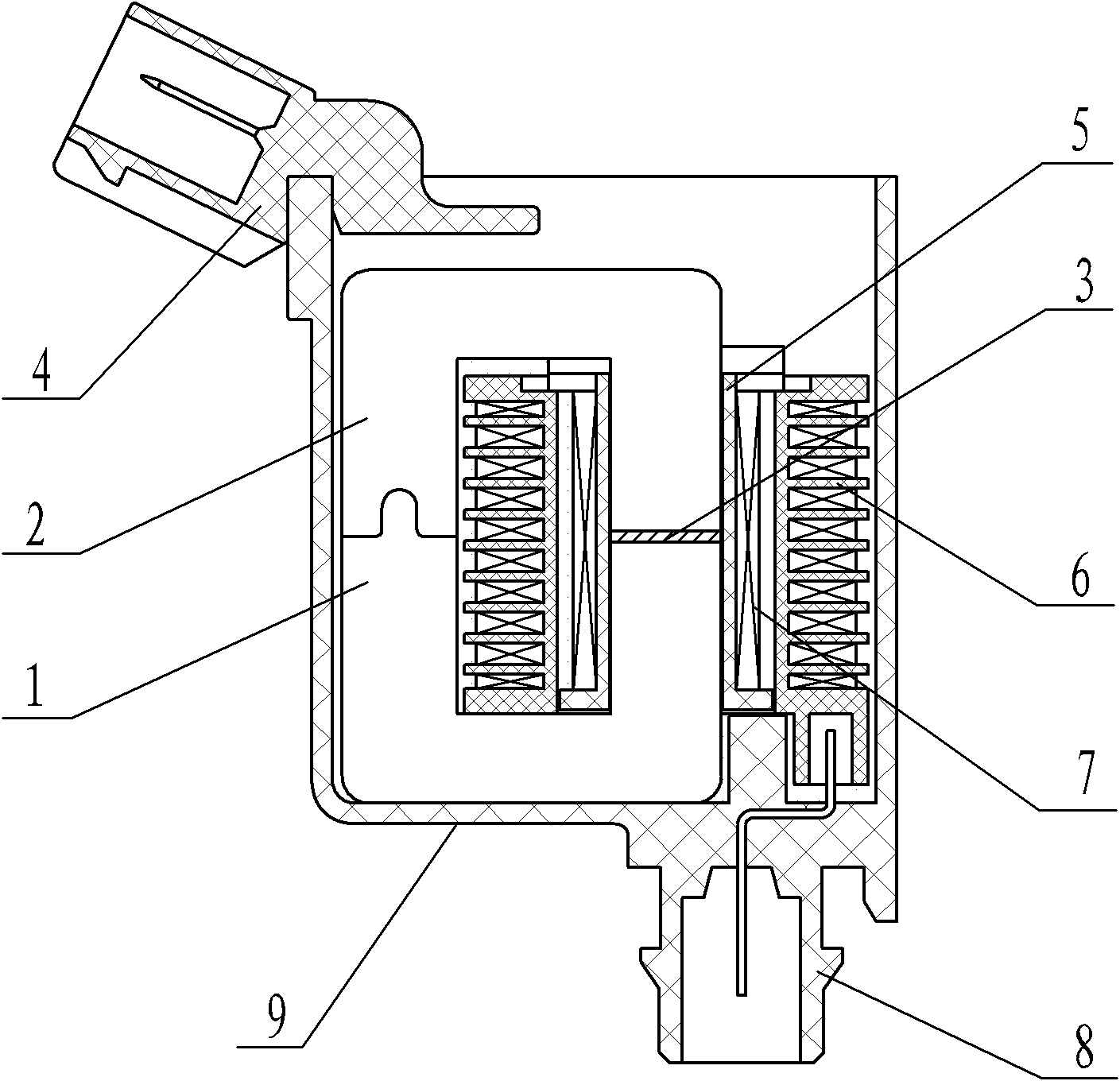

Inserted-type automobile ignition coil iron core provided with air gap magnetic steel disc

InactiveCN102376425ALarge energy storageReduce bonding processTransformersTransformers/inductances magnetic coresEpoxyStored energy

The invention relates to an inserted-type automobile ignition coil iron core provided with an air gap magnetic steel disc, which comprises a first U-shaped iron core and a second U-shaped iron core forming an annular iron core through butt joint; one sides of the first U-shaped iron core and the second U-shaped iron core are permanent connection ends; and an air gap is arranged between the end faces of the other sides of the first U-shaped iron core and the second U-shaped iron core. The inserted-type automobile ignition coil iron core provided with the air gap magnetic steel disc is characterized in that the magnetic steel disc of which the polarity is opposite to the magnetizing direction of the iron core is inserted into the air gap; the permanent connection end of the first U-shaped iron core is provided with a bead; the permanent connection end of the second U-shaped iron core is provided with a groove which corresponds to the bead; and the first U-shaped iron core and the second U-shaped iron core are mutually and fixedly connected after being inserted into the groove through the bead in the manner of transition fit. The inserted-type automobile ignition coil iron core provided with the air gap magnetic steel disc has the beneficial effect that the stored energy of the iron core is increased, the high-voltage input of an automobile ignition coil is improved, and an epoxy resin splicing process is not needed, so that the working environment is improved, and the physical health of operating personnel is ensured.

Owner:天津市新阳电子有限公司

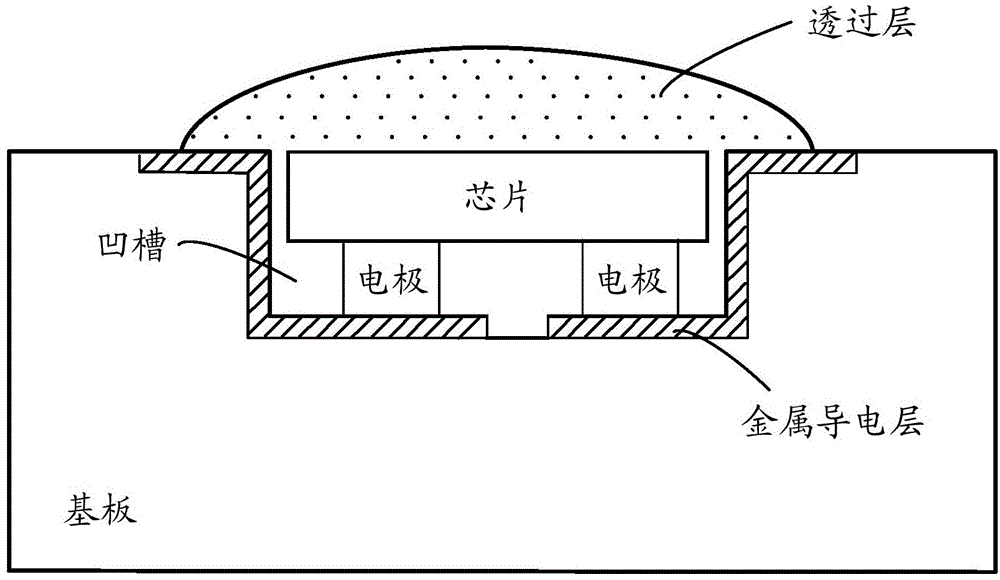

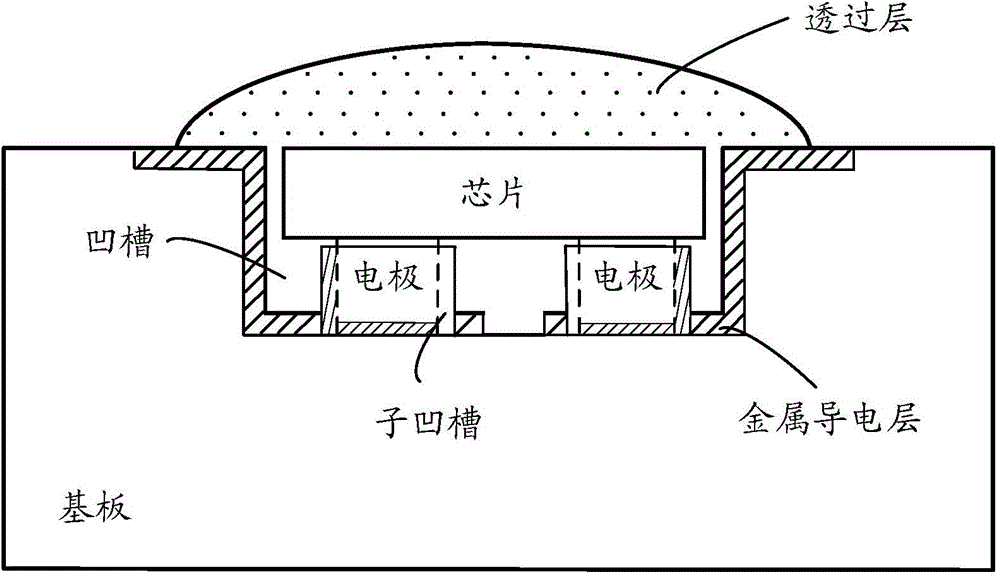

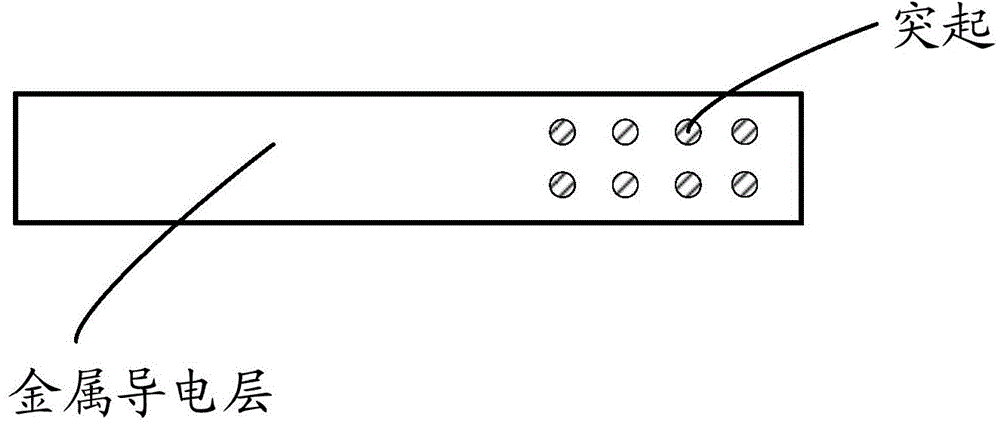

Flip LED (light-emitting diode) substrate structure

InactiveCN104600176AReduce bonding processImprove processing efficiencySemiconductor devicesScreen printingEngineering

The invention discloses a flip LED (light-emitting diode) substrate structure. The flip LED substrate includes a groove which is arranged on a substrate and used for holding LED chips; conductive metal layers which are arranged on the groove and extended to the surface of the substrate, wherein there are two conductive metal layers which are respectively connected with two electrodes of the LED chips; a transparent layer which covers the LED chips. According to the flip LED substrate structure, the transparent layer is ingeniously utilized to cover and press on the LED chips, the LED chips are electrically connected with the metal layers, soldering flux is coated without a silk-screen printing process, and the LED chips are directly placed in the groove; moreover, the procedure of gold line bonding is reduced, and the LED packaging efficiency is improved; meanwhile, a lot of money is saved and cost is reduced.

Owner:SHANGHAI UNIV

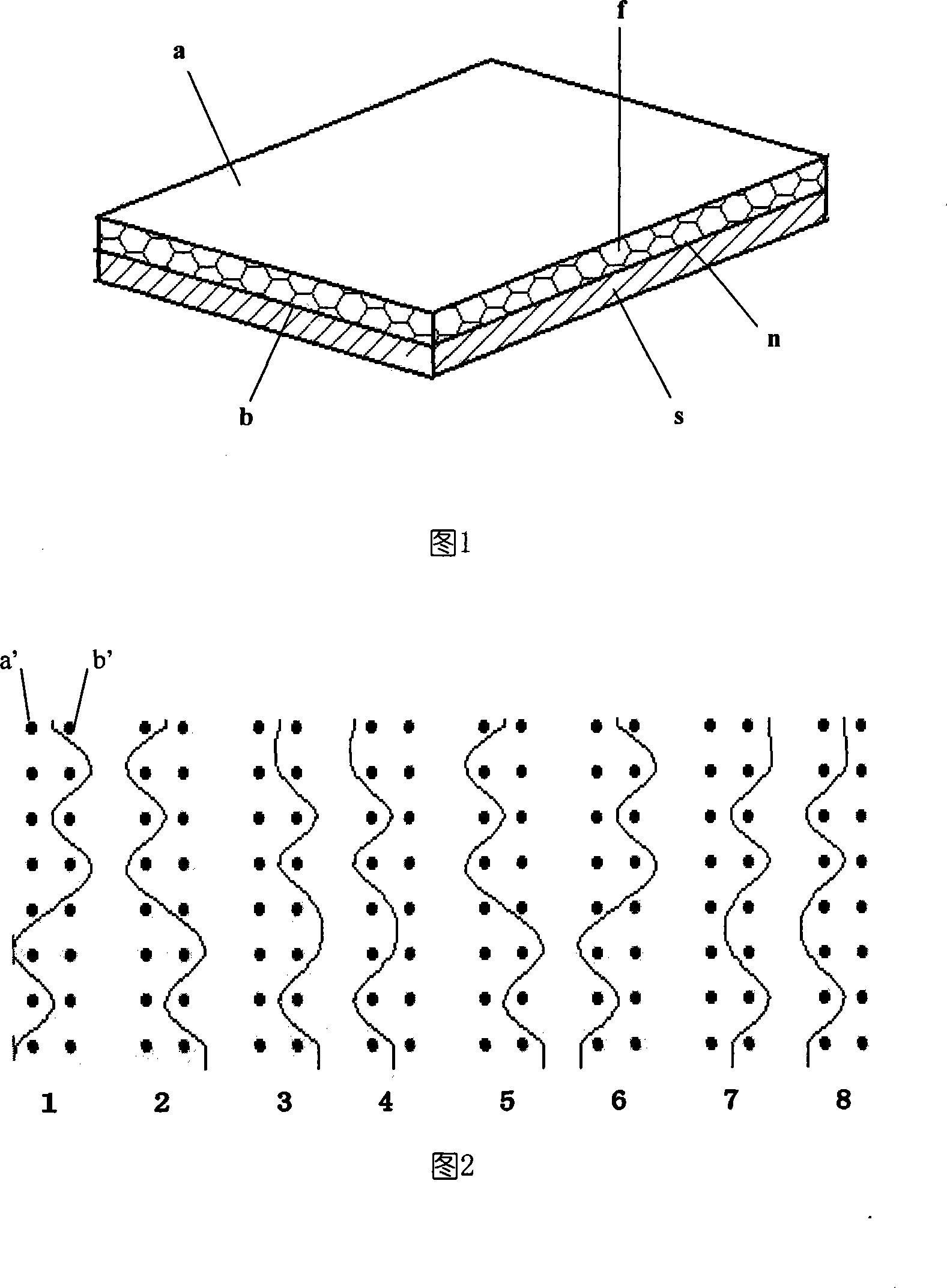

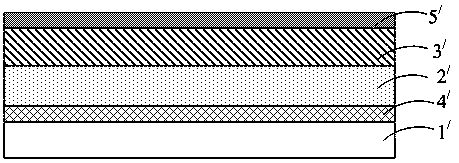

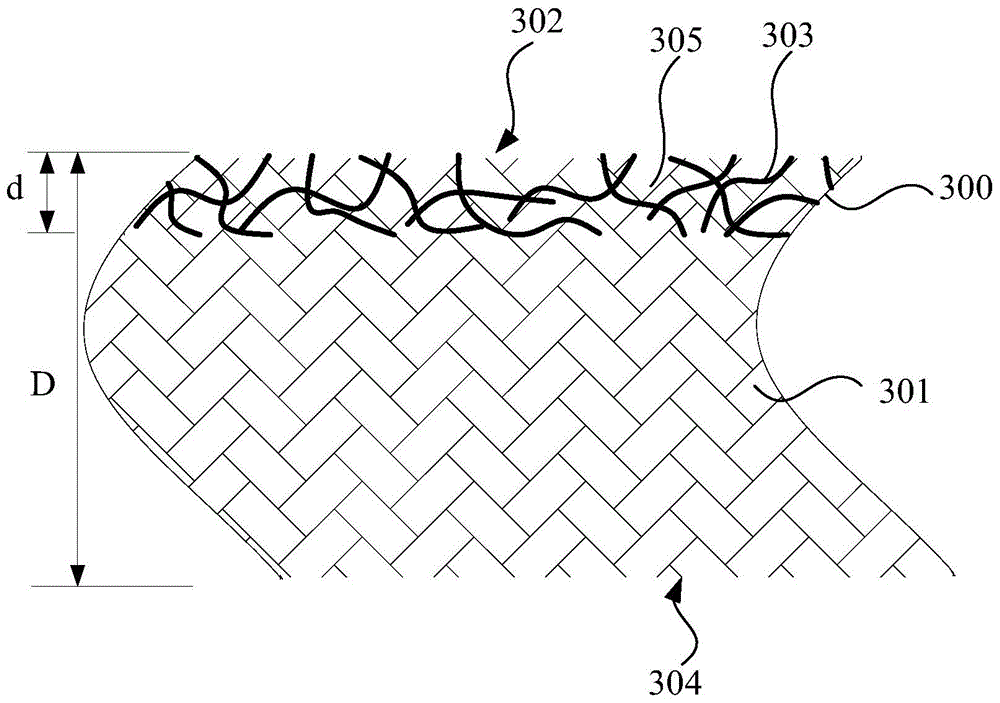

Production method for textile reinforced compound stone plate

InactiveCN101245657AThe overall thickness is thinThe thickness can be thinner, not only saving natural resourcesCovering/liningsNatural resourceBreaking strength

The invention discloses a manufacturing method for fabric-reinforced composite stone plates, which is characterized in that: on the premise that the natural patterns and colours of the stone plates are maintained and the weights of the stone plates are reduced as much as possible, a woven spacer fabric-reinforced composite plate is bonded on the back face of the stone, to manufacture the fabric-reinforced composite stone plate. The fabric-reinforced composite stone plate has the advantages of improving the structural performance of the existing stone plates, and relatively enhancing the rigidity, the anti-break strength, the shearing strength among the layers and the impact endurance of the composite stone plates, and improving the use safety of the composite stone plates, while the manufacturing method has the advantages of short process flow, saving natural resources, reducing labor intensity, and improving production efficiency, and is helpful to the development of the application fields of the composite stone plates.

Owner:CHANGZHOU BOLONG THREE DIMENSIONAL COMPOSITES

Photosensitive developed special line transfer glue for sapphire glass base material and preparation method thereof

InactiveCN108517196AImprove performanceGood synergyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhosphate

The invention discloses photosensitive developed special line transfer glue for a sapphire glass base material and a preparation method thereof. The photosensitive developed special line transfer glueis prepared from an acrylic ester active monomer, a photoinitiator, an acrylic acid phosphate assistant, a silane coupling agent, polyester acrylate, and urethane acrylate. The transfer glue does notcontain an organic solvent, and is environmentally friendly. A transfer technology is used as the foundation, and the advantages of a photosensitive developing technology are organically fused, the advantages are adopted and the defects are avoided. Especially, a product of the transfer glue not only can use the organic solvent for developing, but also can use pure water for developing, and is environmentally friendly, non-inflammable and non-explosible, and is a future tendency. The transfer glue has the excellent properties of solvent corrosion resistance, cold and thermal shock resistanceand the like after curing, and an adhesive force of a glue layer and the sapphire glass base material is excellent, especially, the adhesive force of the glue layer and the sapphire glass base material is greater than or equal to 4B after a water boiling test. The transfer glue is capable of solving problems of current UV glue that the adhesive force on the sapphire glass base material is poor, the water boiling is not resistant, and the solvent is not resistant.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

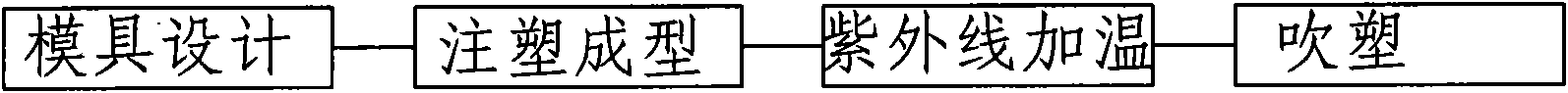

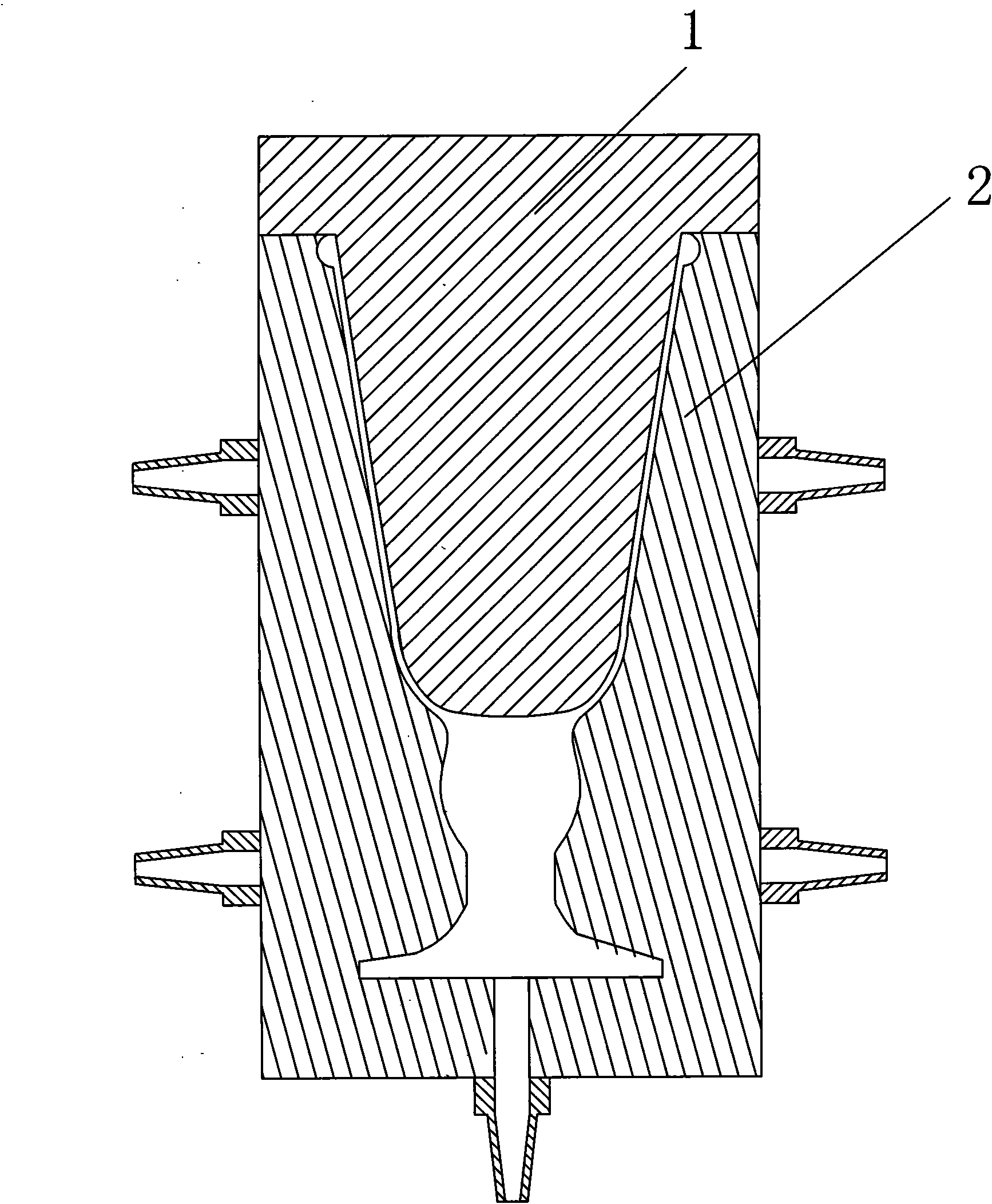

Process for moulding goblet

InactiveCN102069591AReduce bonding processSimple processingHollow articlesAtmospheric pressureInjection moulding

The invention relates to the field of plastics, in particular to a process for moulding a goblet. The process comprises the following steps of: a. designing an injection mold according to a product, wherein the goblet body part of a primary product is of a structure with a wide outer part and a narrow inner part and is convenient for demoulding; b. injecting for moulding and demoulding to obtain the primary product, wherein the goblet body is of a shape which is wide in the upper part and is narrow in the lower part, and the outer edge of the primary product is 0.5-0.8mm longer than that the practical product; c. ultraviolet heating: heating the primary product at 180-260 DEG C for 10-30 seconds so that the primary product is softened and then introducing the primary product into a blowing mould; d. blowing for moulding: blowing air for 8-12 seconds after compounding and maintaining the pressure to 25-28MPa to obtain the goblet body which is wide in the middle and is narrow at both ends; and stopping blowing air, demoulding and moulding to obtain a product. The moulding process can be used for producing the goblet for integrating the goblet body and the goblet; and the goblet body of the goblet is wide in the middle and is narrow at both ends, thus the processing operation is simple and the processing cost is low and the bonding procedure of the goblet body and the high foot body is reduced.

Owner:林聪实

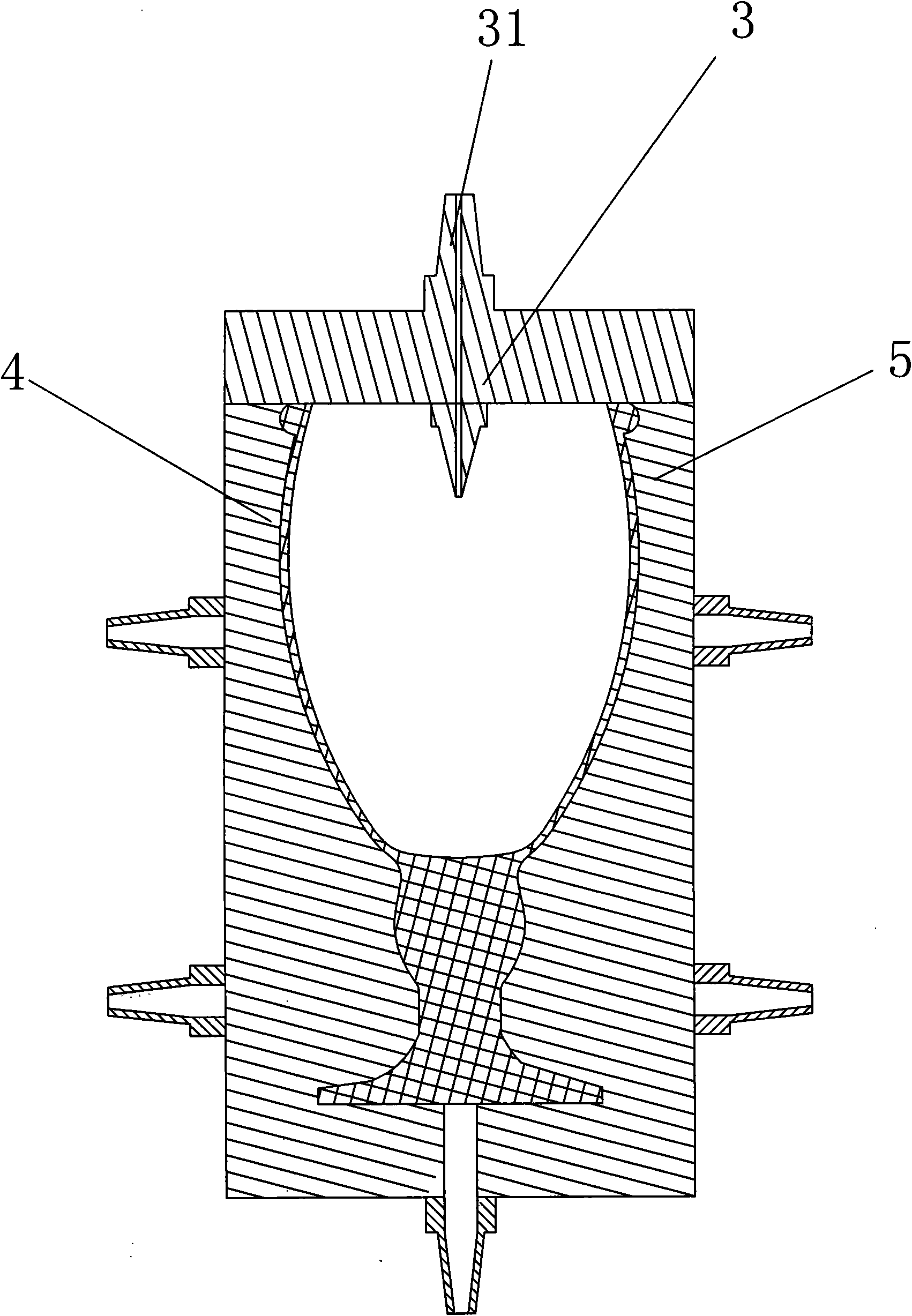

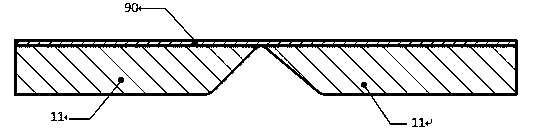

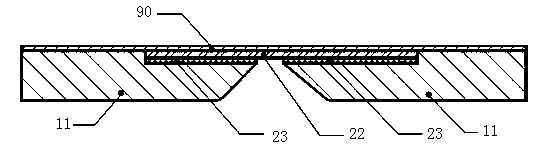

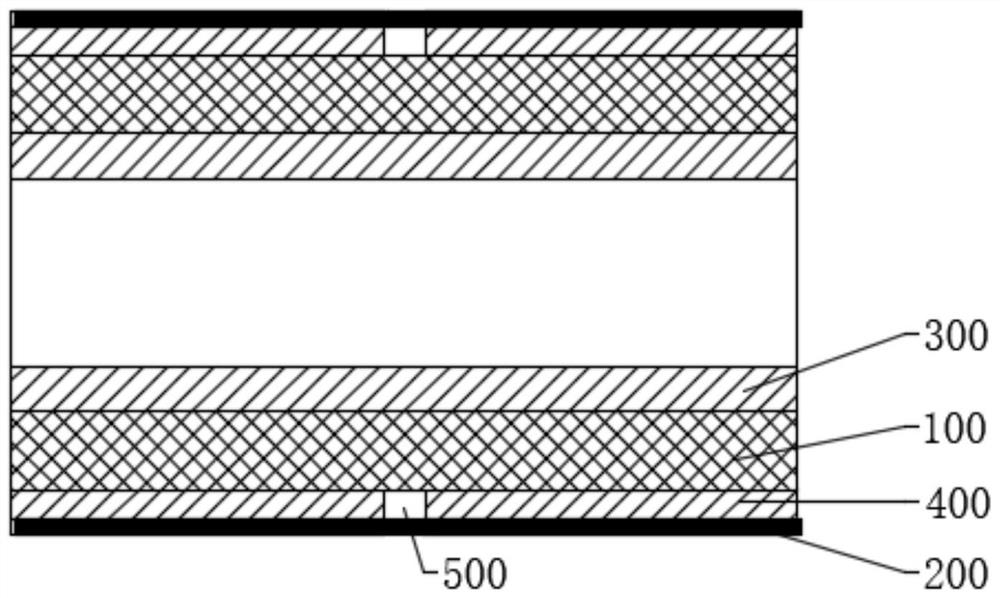

Sprayed product, and production method and special die thereof

The invention discloses a sprayed product, and a production method and a special die thereof. The product comprises two substrates (11), each of the substrates (11) has a honeycomb paper sandwiched glass fiber reinforced polyurethane structure, the substrates (11) are connected through a reinforcing band (22), and the reinforcing band (22) is fixed on the substrates (11) through a polyurethane material forming the glass fiber reinforced polyurethane structure in the molding process of the substrates (11). The production method comprises the following steps: putting the reinforcing band in a die, putting glass fiber felt and honeycomb paper sprayed with the polyurethane material into the die, and molding. The die comprises a surface layer die (42) and a back layer die (41), the back layer die (41) is provided with an extrusion cutter (43), the surface layer die (42) is a plane, and a gap of 0.5-3mm is maintained between the extrusion cutter (43) on the back layer die (41) and the surface layer die (42). The production method of the product has the advantages of simplicity, low cost, improvement of the reliability of the product, and convenient die processing.

Owner:YANTAI ZHENGHAI HIGH TECH

Special rubber roll material for pipeline thermal preserving heat insulating sound-proof and its production tech.

InactiveCN1861672AReduce bonding processReduce trafficThermal insulationPipe protection by thermal insulationElastomerPetroleum

This invention relates to a specialty elastomer web used for pipe warming, thermal insulating and noise insulating. It contains odor-free specialty elastomer, tackifying resin, white, light calcium carbonate, pottery clay, carbon black, age resister. The method includes (1) compound, (2) initial refine, (3)warm, (4)calender and compound, (5)press under low temperature,(6) appearance and dimension detect, (7)collect and coil. It can be used for enveloping and wrapping pipe in industry and civilian architectural, and petroleum or natural gas pipe, to prevent water freezing and pipe cracking under 0 deg.C, special -20deg.C or below. It can reduce noise to 10dB or below.

Owner:何霖

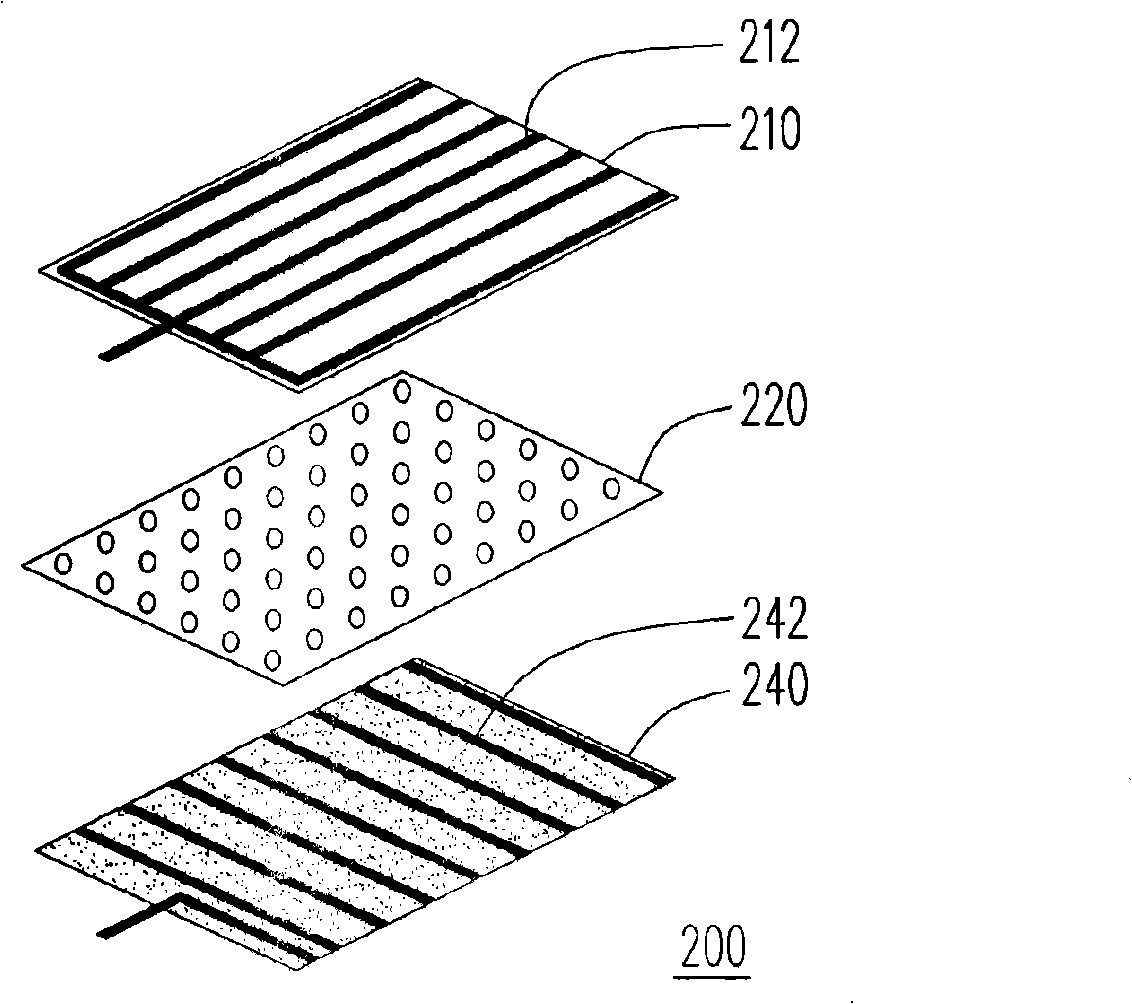

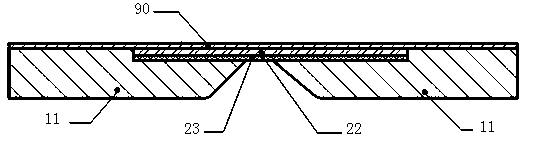

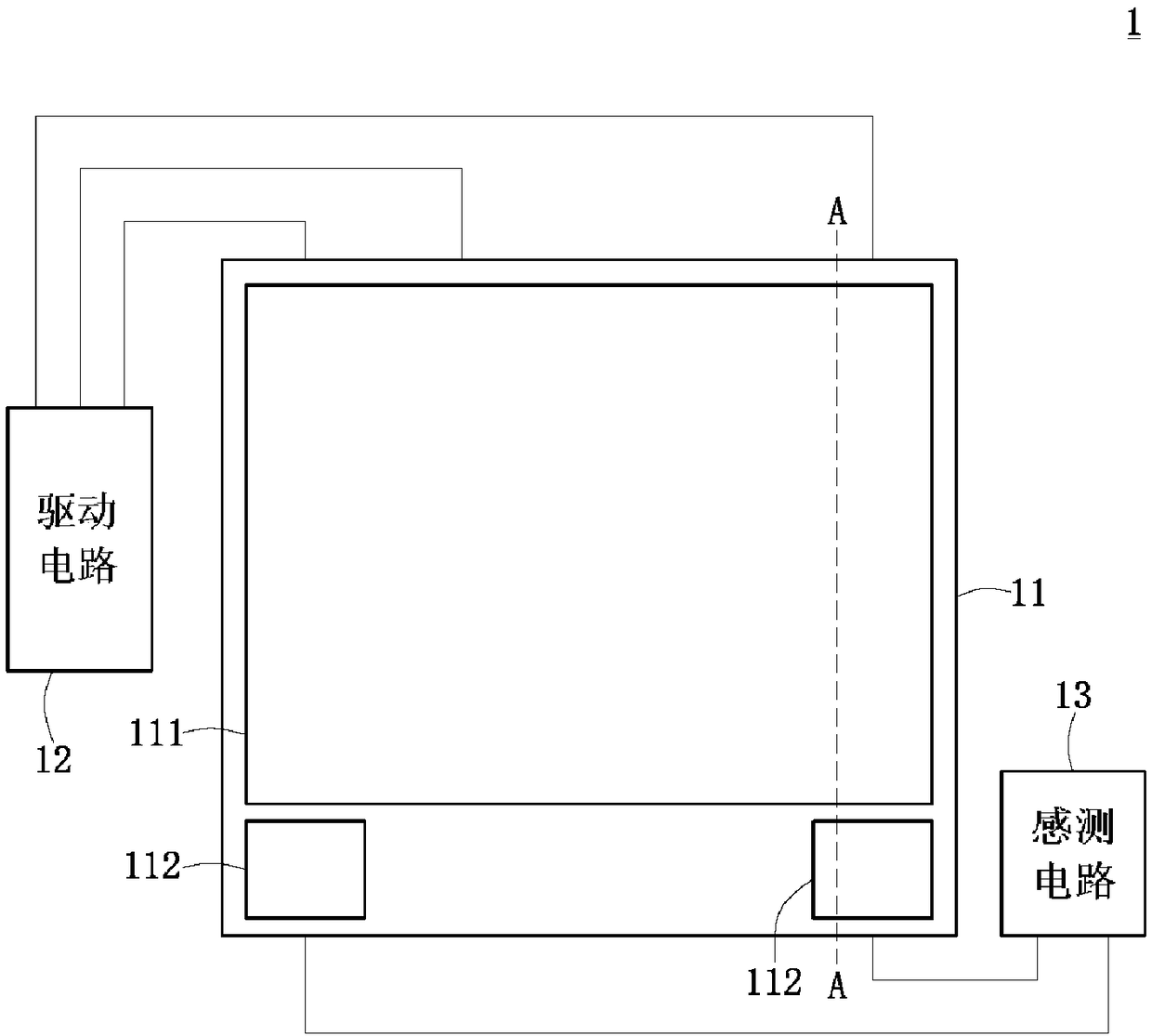

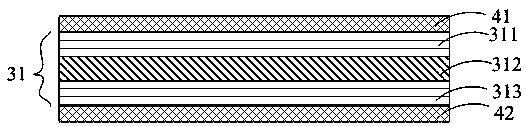

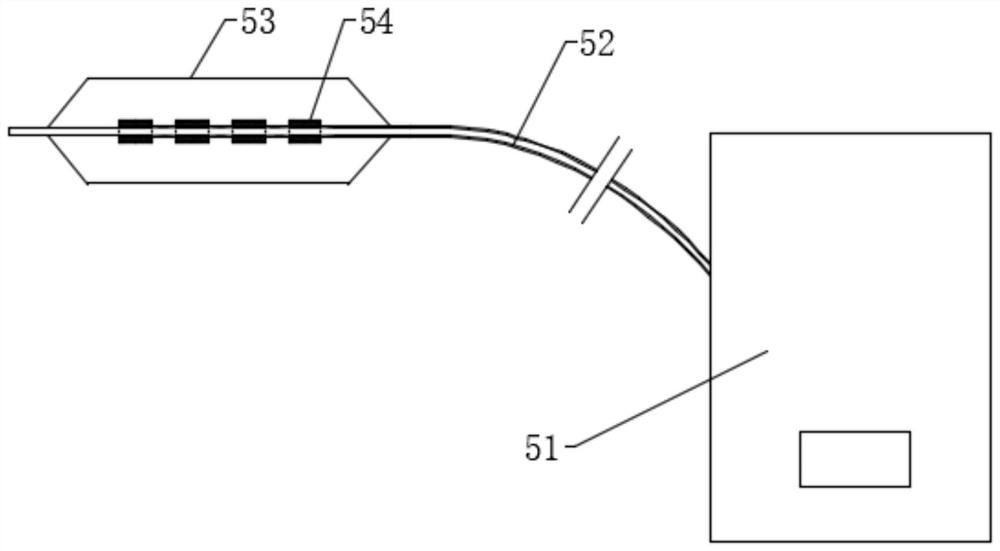

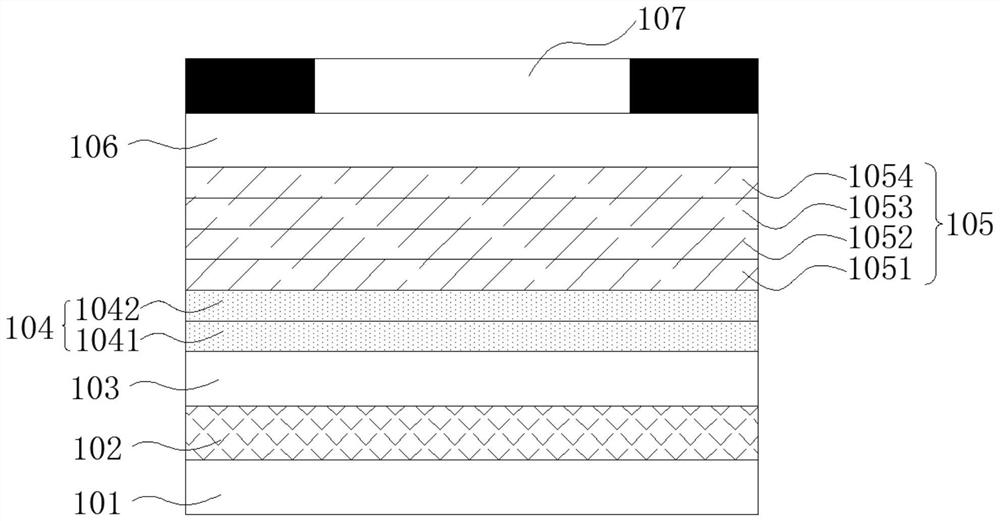

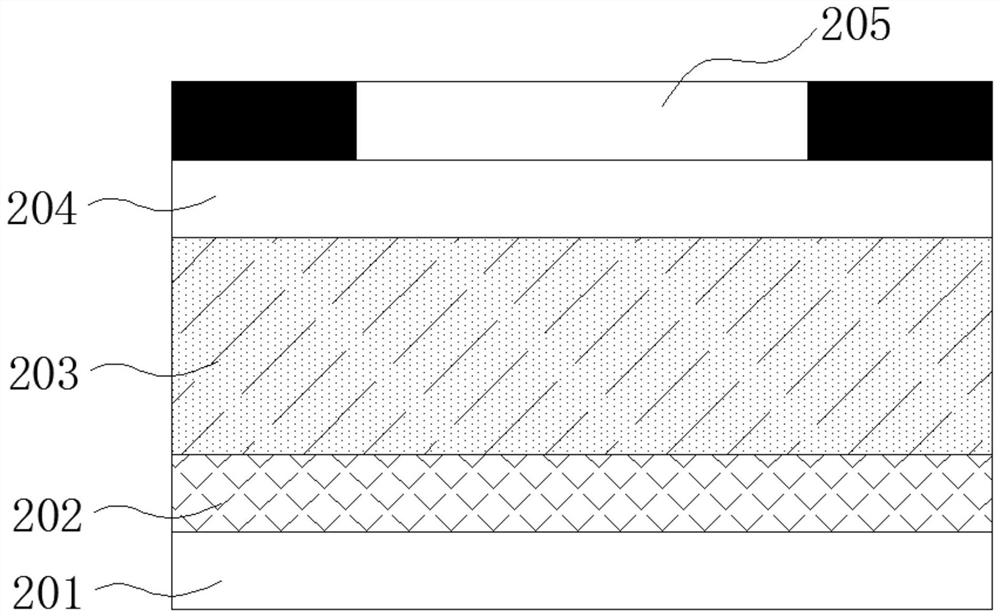

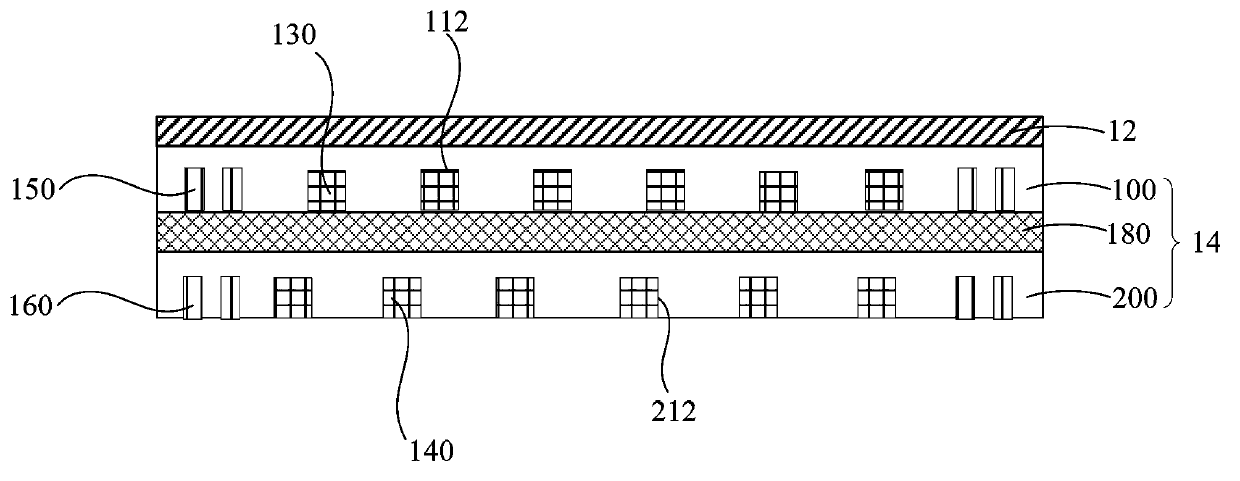

Liquid crystal display panel with operation sensing function and display device thereof

InactiveCN108089358AImprove processing yieldReduce bonding processNon-linear opticsInput/output processes for data processingManufacturing cost reductionLiquid-crystal display

The invention provides a liquid crystal display panel with an operation sensing function and a display device thereof. The liquid crystal display panel includes a display area and at least one operation sensing area not used for display. The operation sensing area includes at least one first electrode and at least one second electrode, wherein the first electrode of the operation sensing area doesnot receive pixel voltages, and the second electrode of the operation sensing area does not receive common voltages, so that the first electrode and / or the second electrode of the operation sensing area are used for sensing a sensing signal generated when a touch object touches or approaches the operation sensing area. According to the liquid crystal display panel, a touch control key function can be provided for the liquid crystal panel by only changing wiring layout, and an additional transparent touch control electrode layer does not need to be attached on an insulating substrate so that the yield of manufacture procedures of the touch control liquid crystal display panel can be improved, and manufacturing costs can be reduced.

Owner:TENX (SHENZHEN) TECH LTD +1

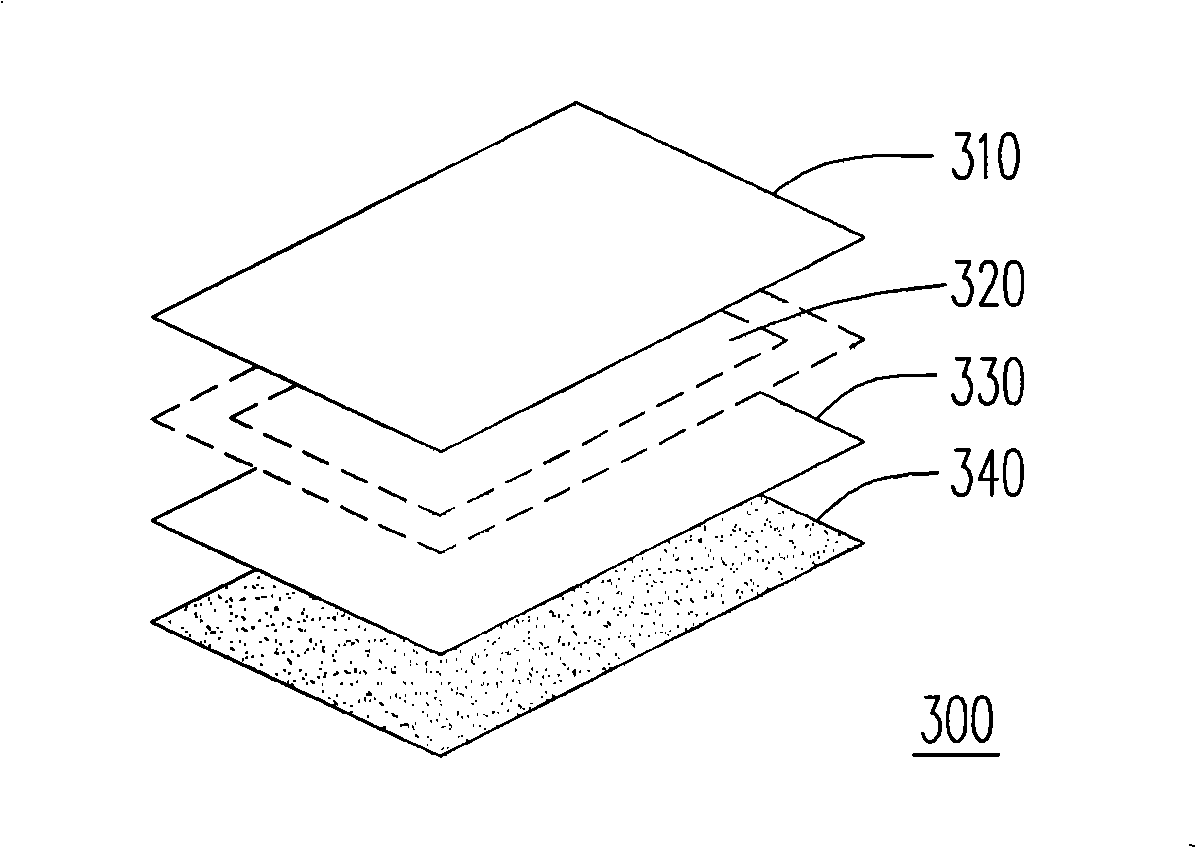

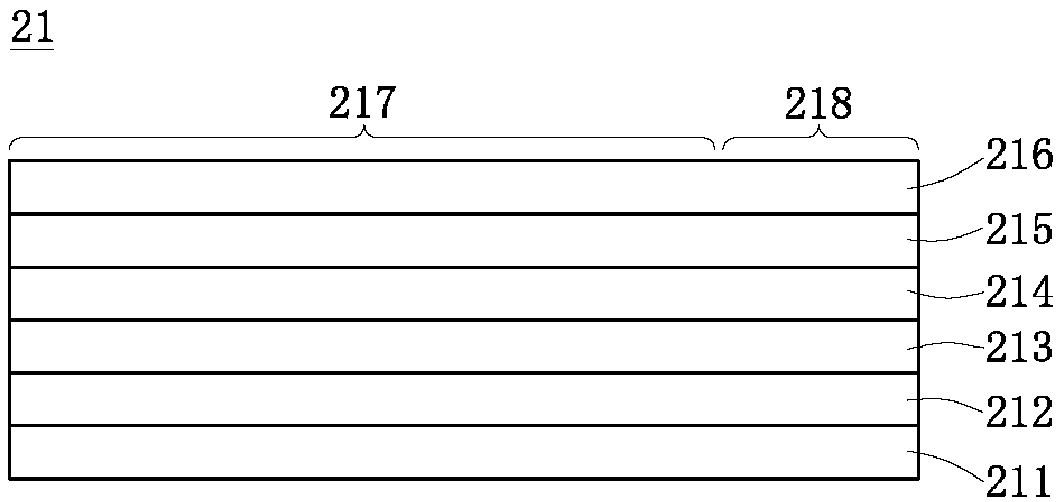

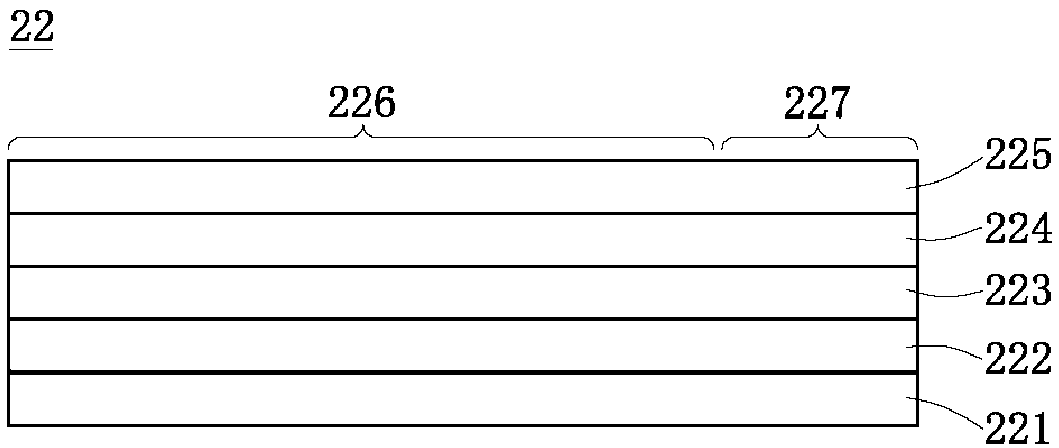

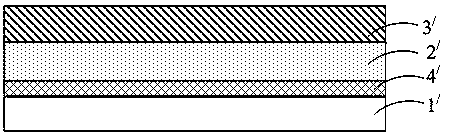

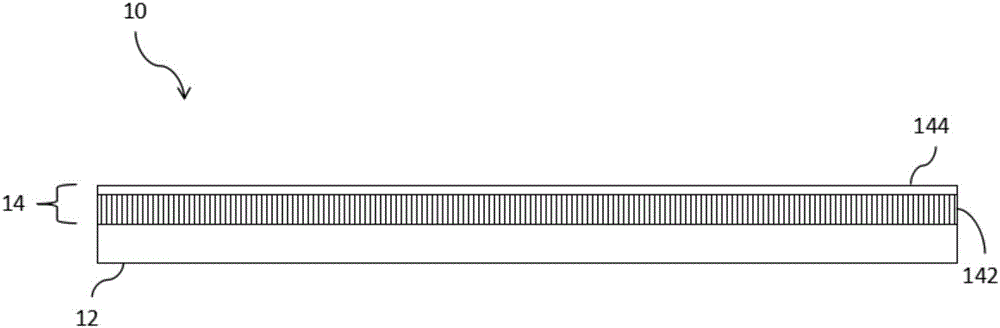

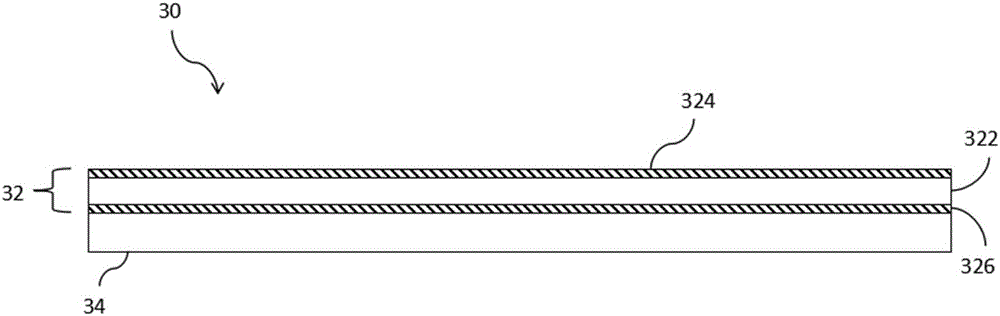

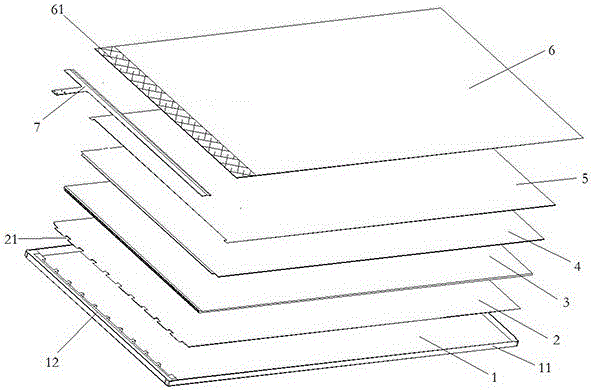

Polarizer and display device

InactiveCN108646334AReduce bonding processSimple production processSolid-state devicesPolarising elementsDisplay devicePolarizer

The invention provides a polarizer comprising a linear polarizer; a first optical cement layer which is arranged on the upper surface of the linear polarizer; and a second optical cement layer which is arranged on the lower surface of the linear polarizer. With application of the polarizer, the upper and lower surfaces of the polarizer are enabled to be equipped with the optical cement layer so that the fitting process of one surface of the upper and lower surfaces of the conventional polarizer can be reduced, the production technology process can be greatly simplified, the cost can be saved and the risk of cement overflow and cement drawing can be reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

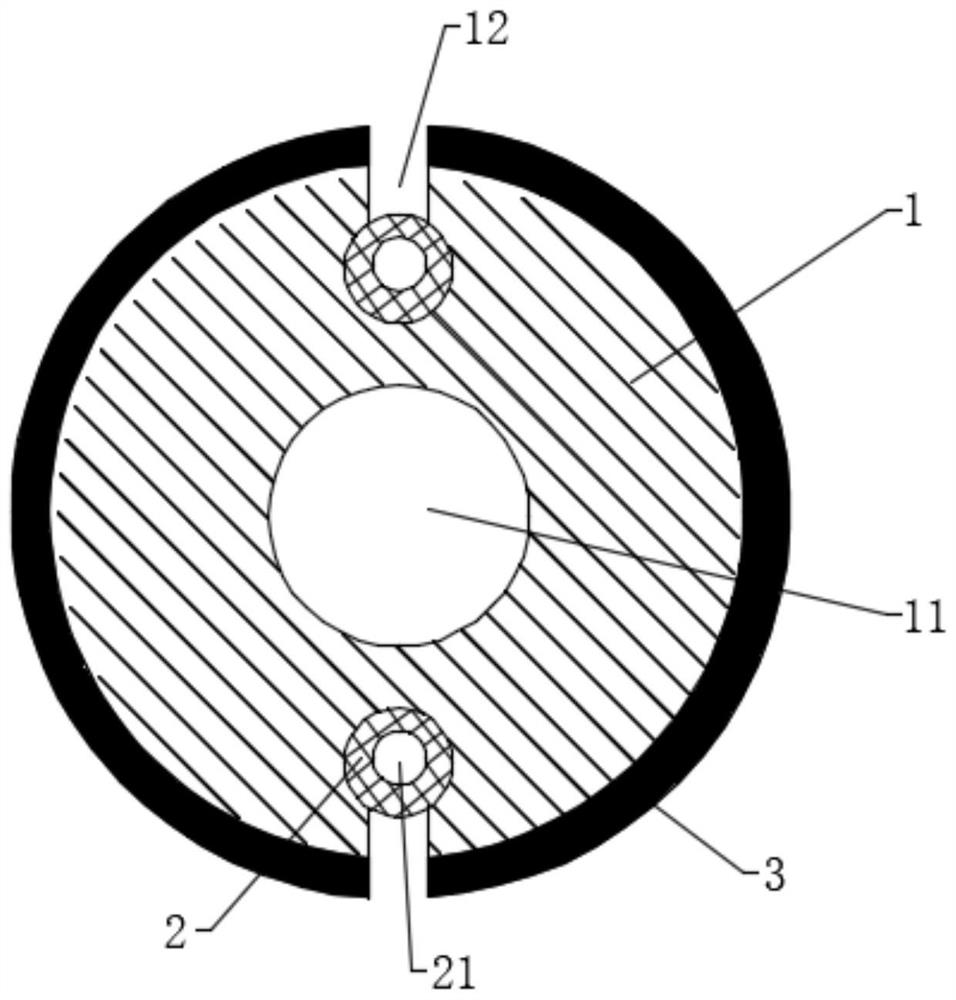

Electrode structure and balloon

The invention relates to the technical field of medical instruments, and discloses an electrode structure and a balloon. The electrode structure comprises a tube body, an inner electrode and an outer electrode, a tube body cavity is formed in the tube body, and a discharge channel which extends in the axis direction of the tube body and is communicated with the peripheral wall of the tube body is formed in the tube body; the inner electrode is arranged in the discharge channel; the outer electrodes are arranged on the outer peripheral walls of the two sides of the discharge channel, and the inner electrodes and the outer electrodes are conducted in a closed loop; the inner electrode, the outer electrode and the tube body are integrally formed. When the inner electrode and the outer electrode are conducted, breakdown can be carried out at the discharge channel, and then shock waves are generated and used for a focus part needing to be treated; the inner electrode, the outer electrode and the tube body are integrally formed, so that the bonding procedure in the prior art is reduced, machining is more convenient, meanwhile, the connection firmness of the inner electrode and the outer electrode is guaranteed, and then the stability of generated shock waves is guaranteed.

Owner:SONOSEMI MEDICAL CO LTD

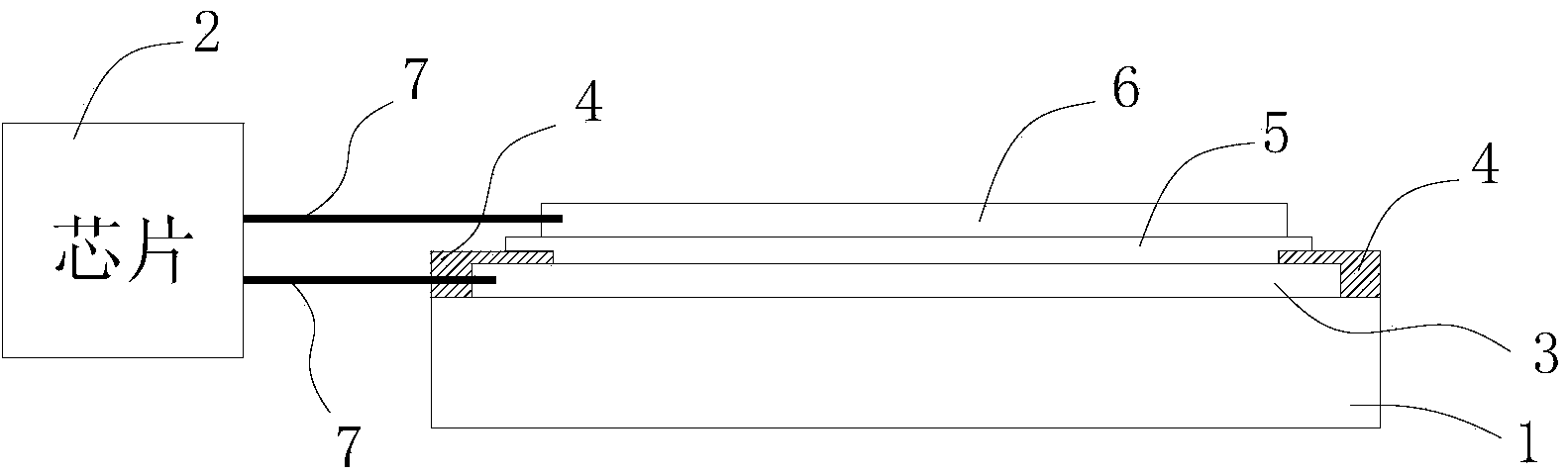

Monolithic glass capacitive touch screen structure and processing method thereof

InactiveCN103914201AHigh light transmittanceReduce thicknessInput/output processes for data processingCapacitanceFlexible circuits

The invention discloses a monolithic glass capacitive touch screen structure which comprises a glass substrate and a chip. The glass substrate is provided with a first ITO (indium-tin oxide) film, ink covers the edge of the first ITO film, the first ITO film is covered with an insulation transparent layer, the insulation transparent layer is covered with a second ITO film, and ITO wires are etched on the first ITO film and the second ITO film and are electrically connected with the chip via flexible circuit boards. The monolithic glass capacitive touch screen structure can meet the requirements of large size, low cost, high transmittance, thinness and light weight and the like.

Owner:SHENZHEN SANXIN JMT GLASS

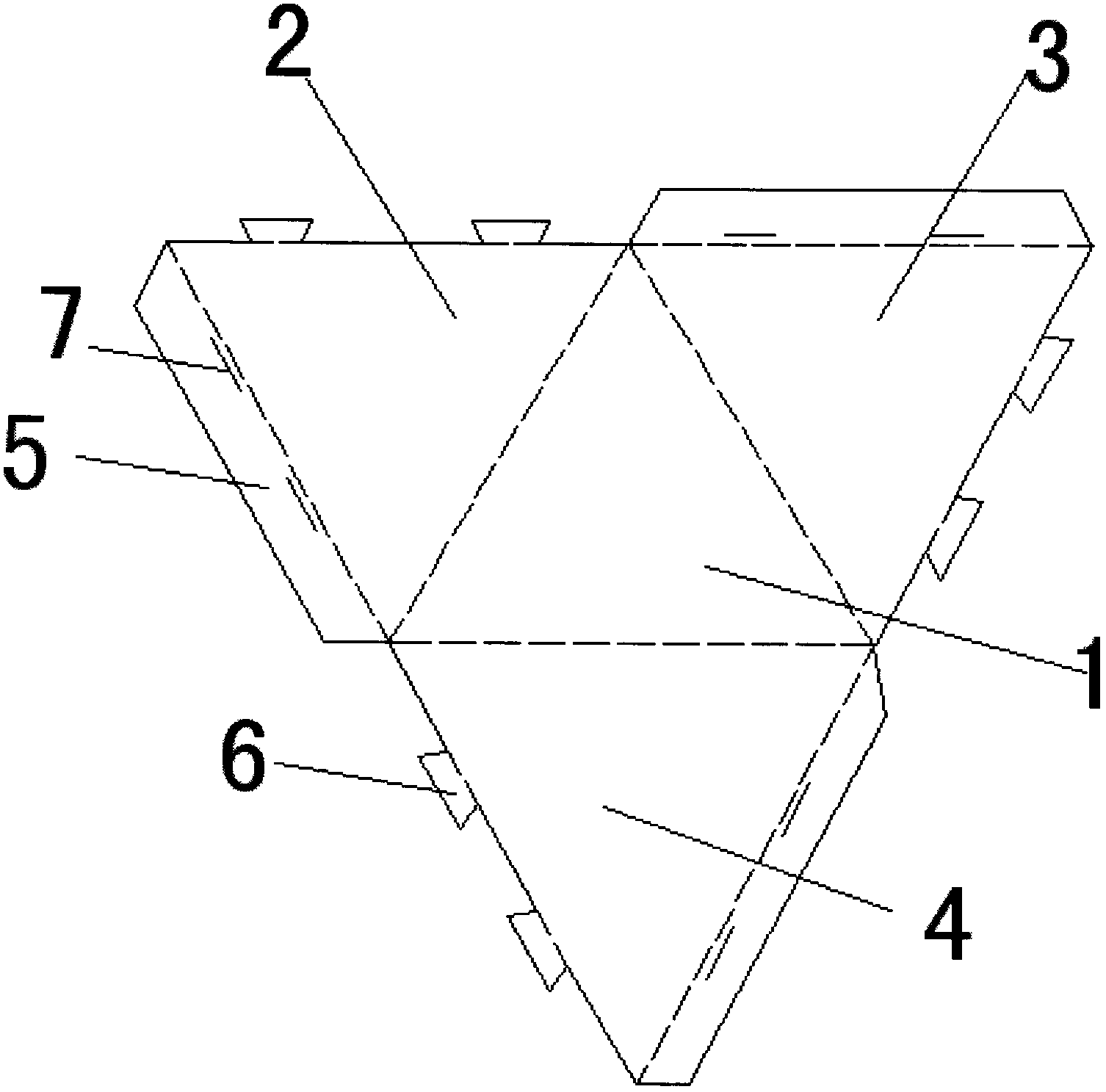

Folded-type triangular box structure

The invention relates to the field of packaging tools, in particular to a folded-type triangular box structure. A box body is formed by four equilateral triangles, three triangles serve as lateral surfaces, surround a central surface serving as the bottom surface and are buckled with corresponding kerfs through plugging tongues at end edges of the three lateral surfaces, and therefore a triangular box is stereoscopically formed. The folded-type triangular box structure is manufactured by cutting one paper board and does not need to be bonded, thereby being low in cost, easy to manufacture and use, and convenient to store and transport.

Owner:李富贵

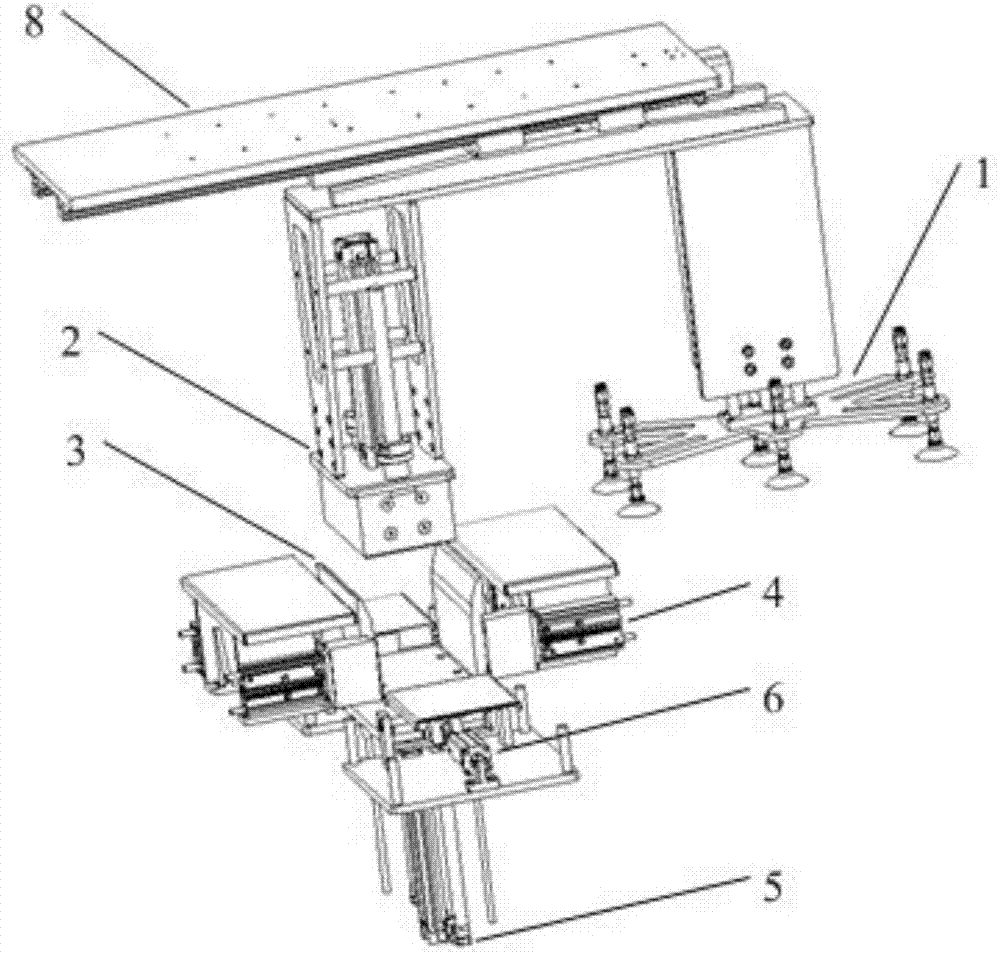

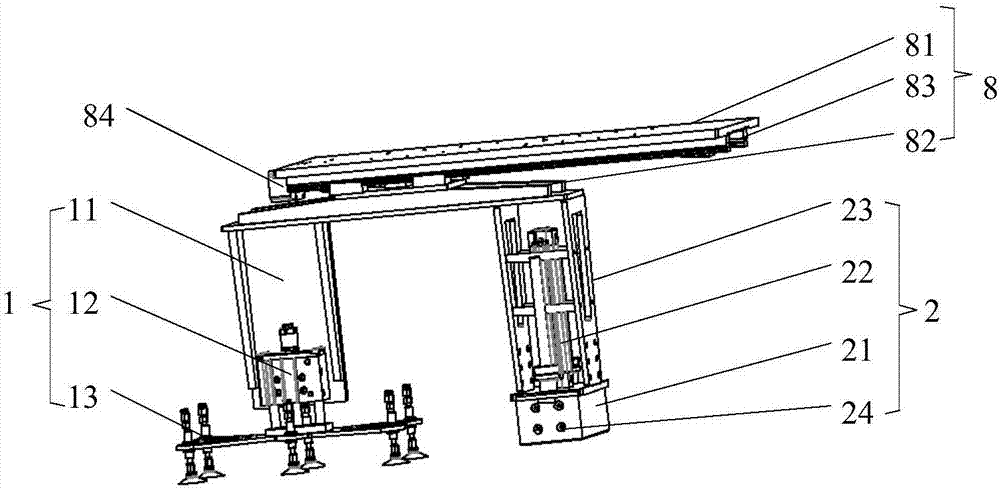

Forming mechanism of folded boxes

The invention discloses a forming mechanism of folded boxes, comprising a feeding device, a male die pressing device, a female die pressing device, two inner lug folding devices, a jacking device, and two turnover devices; the feeding device is used for placing a box to be folded at the top of the female die device; the male die pressing device and the jacking device move relatively along a first direction to clamp the box to be folded and move along the first direction to the bottom of the female die device; the two inner lug folding devices are arranged on two relative sides of the female die device respectively, and one turnover device is arranged correspondingly at the outer side of the corresponding inner lug folding device. The step of folding four edges, the step of folding a bottom cover and a step of maintaining pressure for the sides having double-sided adhesive are integrated herein for the forming mechanism; the forming mechanism is compact in structure and greatly reduced space of use; in addition, the requirement on material incoming for a box body is low, time for shifting the box body and adjusting the state is saved, and working efficiency is improved.

Owner:深圳市昇茂科技有限公司

Making method of comfortable polyurethane foam

The invention discloses a simple-operating process and low-cost making method of comfortable polyurethane foam. The method comprises the following steps: (1) producing a polyurethane foaming die according to a predetermined shape; (2) cutting a polyurethane hot-melt film to form the predetermined shape, and thermally compounding the cut polyurethane hot-melt film with a foam slice to form a thermally-compounded foam slice; and (3) cooling the thermally-compounded foam slice obtained in step (2), placing the cooled thermally-compounded foam slice in the polyurethane foaming die obtained in step(1), then pouring a polyurethane foam raw material, and taking out the obtained material 6-8 min later in order to obtain the comfortable polyurethane foam. The method improves the comfortableness ofthe polyurethane foam, and has the advantages of simple operating process, low cost, suitableness for large-scale production, and great practical significance.

Owner:JILIN UNIV +1

Touch screen and making method thereof

PendingCN106155369AReduce thicknessReduce bonding processInput/output processes for data processingEngineeringAdhesive

The invention relates to a touch screen. The touch screen comprises a protective cover plate, a first conducting layer, a substrate and a second conducting layer; the first conducting layer is arranged on the bottom face of the protective cover plate and comprises patterned first electrodes; the substrate is bonded to the first conducting layer; the second conducting layer comprises a carrier and nano conductive threads arranged in the carrier in an embedded mode, the material of the carrier is the same as that of the substrate, the nano conductive threads are connected in a lapped and staggered mode, the second conductive layer is patterned to form second electrodes, and the substrate makes the first electrodes and the second electrodes electrically isolated. According to the touch screen, an optical adhesive is not needed with the help of the substrate, and the thickness can be decreased; in addition, matching of different types of the first conducting layer and the second conducting layer can improve the optical effect. The invention further provides a making method of the touch screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Touch panel and display screen integrated OLED display device

InactiveCN101937285BTouch function hasSimple structureInput/output for user-computer interactionSolid-state devicesTouch SensesDisplay device

The invention discloses a touch panel and display screen integrated OLED display device, which comprises an anode substrate and an encapsulation cover plate which are stuck and connected and functional layers which are arranged in turn between the anode substrate and the encapsulation cover plate, wherein the inner surface of the encapsulation cover plate of the display is provided with touch functional layers, and the touch functional layers comprise a first transparent electrode layer, a first transparent electric insulating layer, a second transparent electrode layer and a second transparent electric insulating layer which are arranged in turn on the inner surface of the encapsulation cover plate; and the first transparent electrode layer, the first electric insulating layer and the second transparent electrode layer form a flat capacitor array. The touch sensing functional layers are integrated on the encapsulation cover plate, so display and touch functions can be realized without sticking a touch module to the exterior of the display screen, and the structure of the device is more compact and favorable for reducing the appearance size and weight of the device.

Owner:IRICO

Preparation method of thermal insulation composite material

InactiveCN103317796BReduce usageReduce the use of cement mortar bonding processHeat proofingGlass/slag layered productsThermal insulationBonding process

A preparation method of a thermal insulation composite material comprises the following steps: firstly, mixing foaming thermal insulation material batch and carrying out compression moulding; secondly, preparing a microcrystalline glass sheet material through fusion; thirdly, taking out the prepared foaming thermal insulation material, putting the material on the upper surface of the prepared microcrystalline glass sheet material of 880 DEG C, and compounding the foaming thermal insulation material and the microcrystalline glass sheet material; fourthly, sending the composite sheet material into a foaming furnace of 850 DEG C through a mesh belt, foaming and insulating at 850 DEG C for 25-45 min, cooling at the cooling rate of 10-20 DEG C / min to 600 DEG C, and standing at constant temperature for 30 min; and finally, cooling at the cooling speed of 1-2 DEG C / min from 600 DEG C to room temperature so as to obtain the thermal insulation composite board. According to the invention, the thermal insulation foam glass material and the microcrystalline glass building material are bonded at high temperature into an integral body; the bonding process by the use of cement mortar during the construction process is reduced; material usage is minimized; and construction procedure is simplified. Meanwhile, the prepared thermal insulation composite board's thermal insulation material has advantages of high strength, low water absorption, low density and low heat conductivity coefficient.

Owner:承德新通源新型环保材料有限公司

Folding display panel and preparation method of folding display panel

InactiveCN111768696AReduce design thicknessIncreased upper layer hardnessInput/output processes for data processingIdentification meansMaterials sciencePhysics

The invention discloses a folding display panel and a preparation method of the folding display panel. The folding display panel comprises a first substrate; the second substrate arranged opposite tothe first substrate; a display layer arranged on the surface of one side of the first substrate; and a composite functional layer and an optical adhesive layer which are arranged between the display layer and the second substrate, wherein the composite functional layer comprises at least one protective layer and a touch electrode layer, and the touch electrode layer is arranged on the surface of one side of the protective layer. Compared with an existing folding display panel, a polarizing layer and a touch layer are integrated into the composite functional layer in the folding display panel,the touch electrode layer is arranged on the surface of the protective layer, a layer of stacked optical adhesive layer is omitted, the hardness of the upper layer of the stacked structure can be improved, the overall stacking design thickness is reduced, the bending radius can be reduced, the laminating process is reduced, and the process flow is simplified.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Compound structure with low stress line

ActiveCN106827757AImprove featuresInsufficient improvementSynthetic resin layered productsElectrical equipmentRainbowOptoelectronics

The invention provides a compound structure with a low stress line. The compound structure comprises a compound film and an acryl ejection layer, wherein the compound film comprises a thermoplastic material layer with a first surface and a second surface; a first acryl hard layer is arranged on the first surface; a second acryl hard layer is arranged on the second surface; the acryl ejection layer is jointed with the second acryl hard layer in the manner of intra-mode forming, so that the generation of the stress line can be reduced. The compound structure with low stress line can reduce the stress line, has excellent shock resistance and is capable of providing a firm cover plate structure without a rainbow line.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Touch screen sensor back protection laser process

PendingCN114237428AAvoid damageDoes not affect functionalityInput/output processes for data processingComputer hardwareTouchscreen

The invention relates to the field of touch display, in particular to a touch screen sensor back protection laser process which mainly comprises the steps of designing a laser drawing file, adjusting laser parameters of a laser machine, performing laser and removing back protection residual parts. According to the touch screen sensor back protection laser process provided by the invention, before the touch screen sensor is manufactured and formed, the back protection of the touch screen sensor is subjected to laser treatment, so that the yield loss caused by addition of an attaching process and replacement of the back protection is solved, the attaching process is reduced, the working efficiency is improved, the cost is saved, and the product competitiveness is improved. Moreover, the back protection laser process of the touch screen sensor can avoid line damage to a touch screen sensor product caused by laser energy fluctuation, does not affect the functions of the touch screen sensor product, is high in feasibility, and can be used for mass production, product cost reduction and product competitiveness improvement.

Owner:烟台正海科技股份有限公司

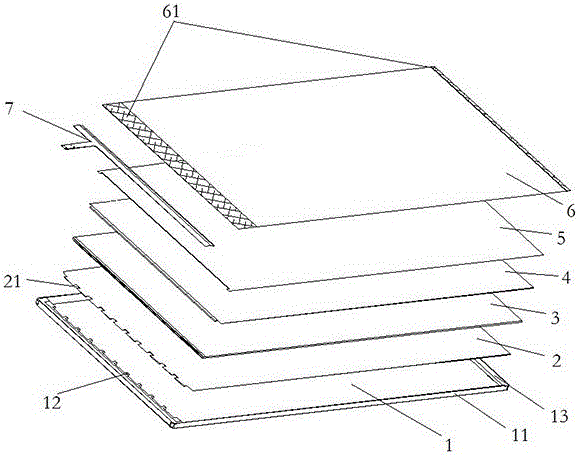

Flexible touch device

InactiveCN103425346AIncrease productivityImprove scratch resistanceInput/output processes for data processingTransparent conducting filmEngineering

A flexible touch device comprises a scratch-proof layer, a transparent conductive film layer and a flexible display screen, wherein the scratch-proof layer, the transparent conductive film layer and the flexible display screen are sequentially arranged in a stacked mode. The transparent conductive film layer comprises a first substrate, an induction conductive layer, a lead electrode and a conductive line, wherein the first substrate comprises a body and a flexible connection component which extends from one side of the body and forms, the body comprises an induction area located in the middle of the body and a frame area surrounding the induction area, the induction conductive layer, the lead electrode and the conductive line are arranged on the induction area, the frame area and the flexible connection component respectively, the induction conductive layer is in electric connected with the conductive line through the lead electrode, the side, opposite to the induction conductive layer, of the first substrate is arranged on the scratch-proof layer, and the flexible display screen is arranged on the induction conductive layer. According to the flexible touch device, the induction conductive layer, the lead electrode and the conductive line are all arranged on the first substrate, attachment processes are reduced, and accordingly high production efficiency is achieved.

Owner:NANCHANG O FILM TECH CO LTD +2

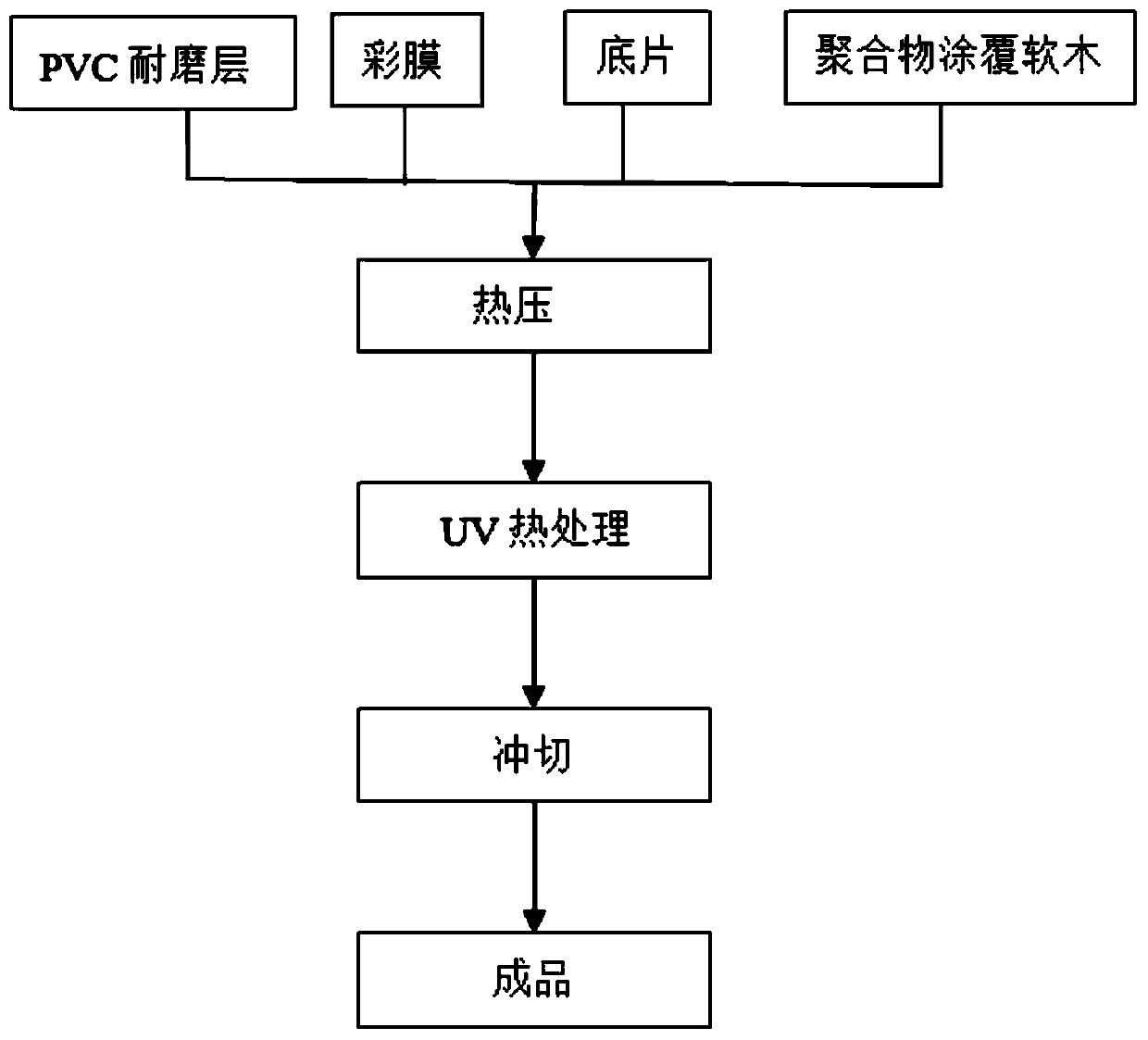

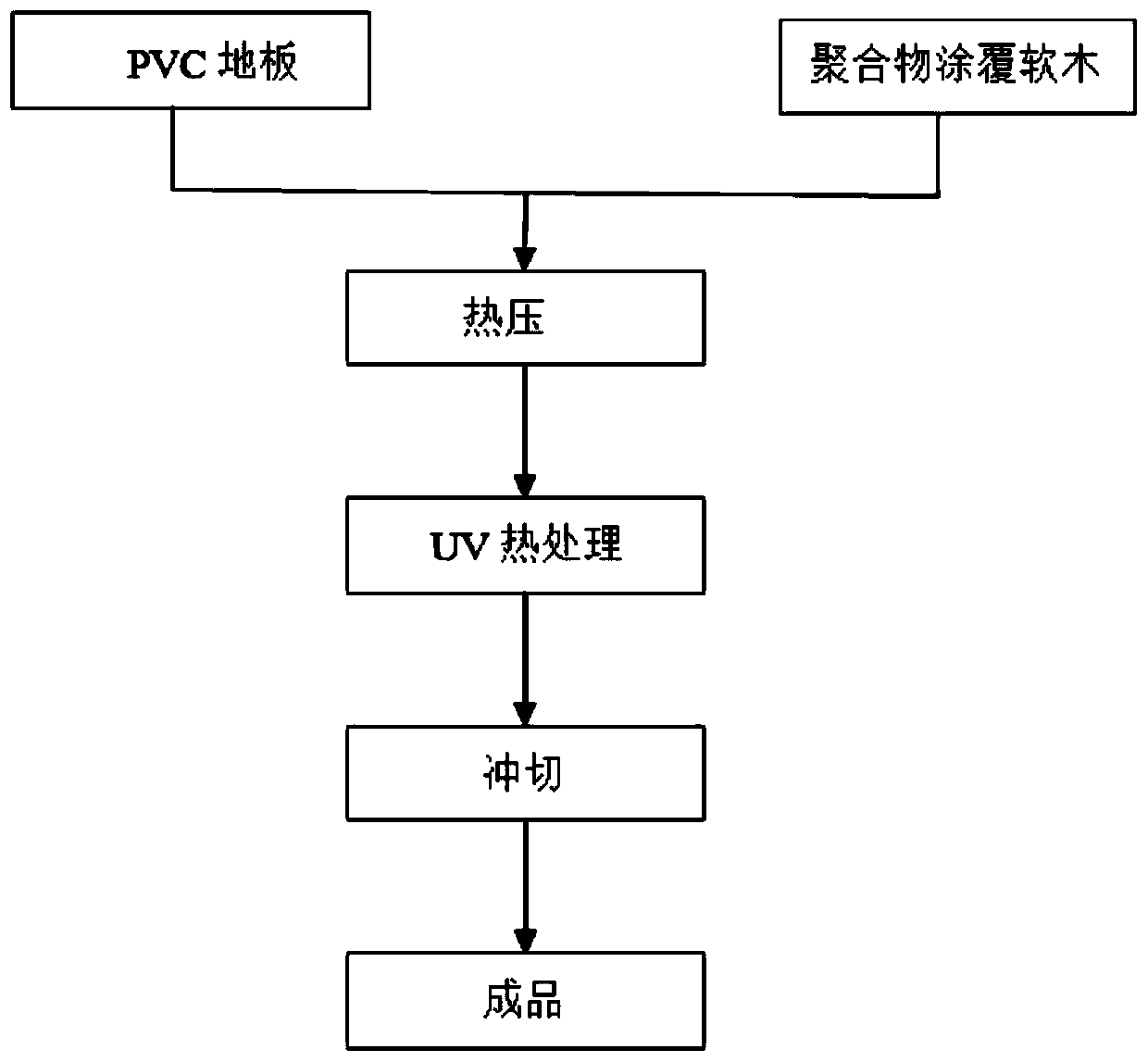

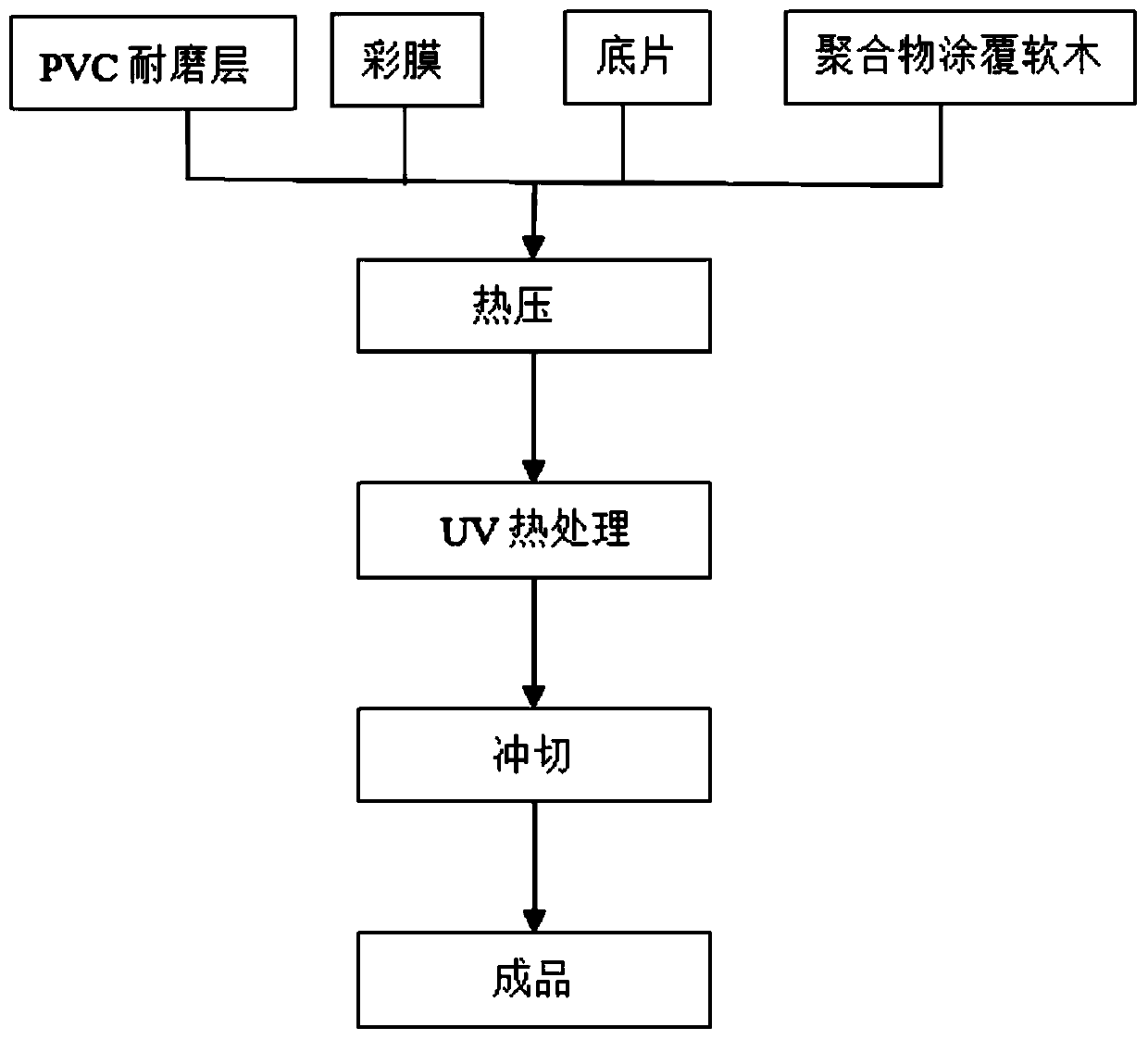

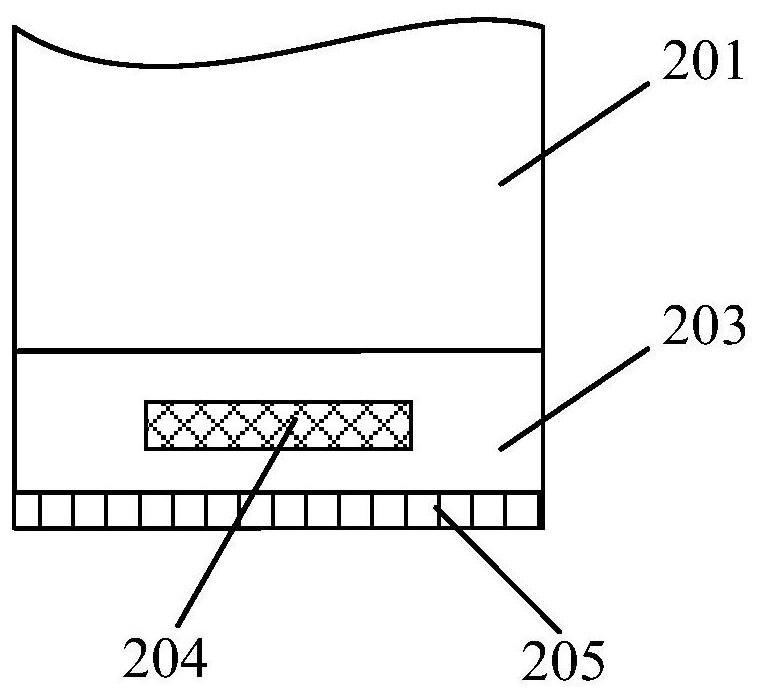

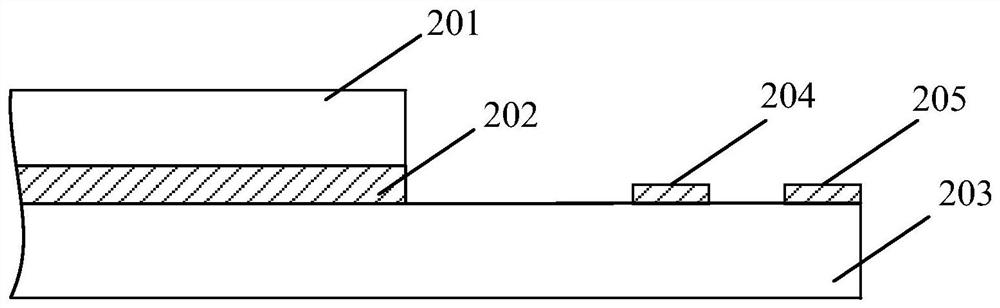

Preparation method of damping cork PVC floor

InactiveCN109989553ASimple processReduce bonding processCovering/liningsFlooring insulationsEngineeringHot-melt adhesive

The invention discloses a preparation method of a damping cork PVC (polyvinyl chloride) floor. Coated polymer cork is used as a raw material, an improvement is made by combining a process, so that a cork bonding process is omitted, a hot-pressing bonding process of a hot melt adhesive is omitted, and the cork PVC damping floor is prepared. The floor prepared by the method not only has the advantages of the traditional PVC floor, but also can effectively improve the sound insulation effect, the flatness is good, the peeling strength and warping meet the relevant national or industrial standards, the cork bonding procedure is simplified, the production efficiency is improved, the production cost is reduced, a hot melt adhesive attaching process is omitted, generation of harmful substances isavoided, and safety and environmental protection are achieved.

Owner:DECORIA MATERIALS JIANGSU CO LTD

Display module and electronic equipment

PendingCN112614874AReduce fit damageReduce thicknessSolid-state devicesPrint image acquisitionComputer hardwareEmbedded system

The embodiment of the invention provides a display module and electronic equipment and belongs to the technical field of communication. The display module comprises a packaging layer, a base layer, a light-emitting layer, a light-emitting circuit, a functional chip, an FPC and a fingerprint module, wherein the base layer comprises a first area and a second area, and the packaging layer covers the first area of the base layer; the light-emitting layer and the light-emitting circuit are arranged between the packaging layer and the base layer and located in the first area of the base layer; a functional chip binding area, an FPC binding area and a fingerprint module area are arranged in the second area of the base layer; the functional chip is arranged in the functional chip binding area, the FPC is arranged in the FPC binding area, and the fingerprint module is arranged in the fingerprint module area; the fingerprint module is electrically connected with the FPC. The display module is advantaged in that the fingerprint module is directly manufactured on the base layer, an original mode of attaching the fingerprint module to the back surface of the base layer is replaced, the overall thickness of the display module is greatly reduced, the attaching process is reduced, the attaching damage to the display module is reduced, and an under-screen fingerprint recognition function is realized.

Owner:VIVO MOBILE COMM CO LTD

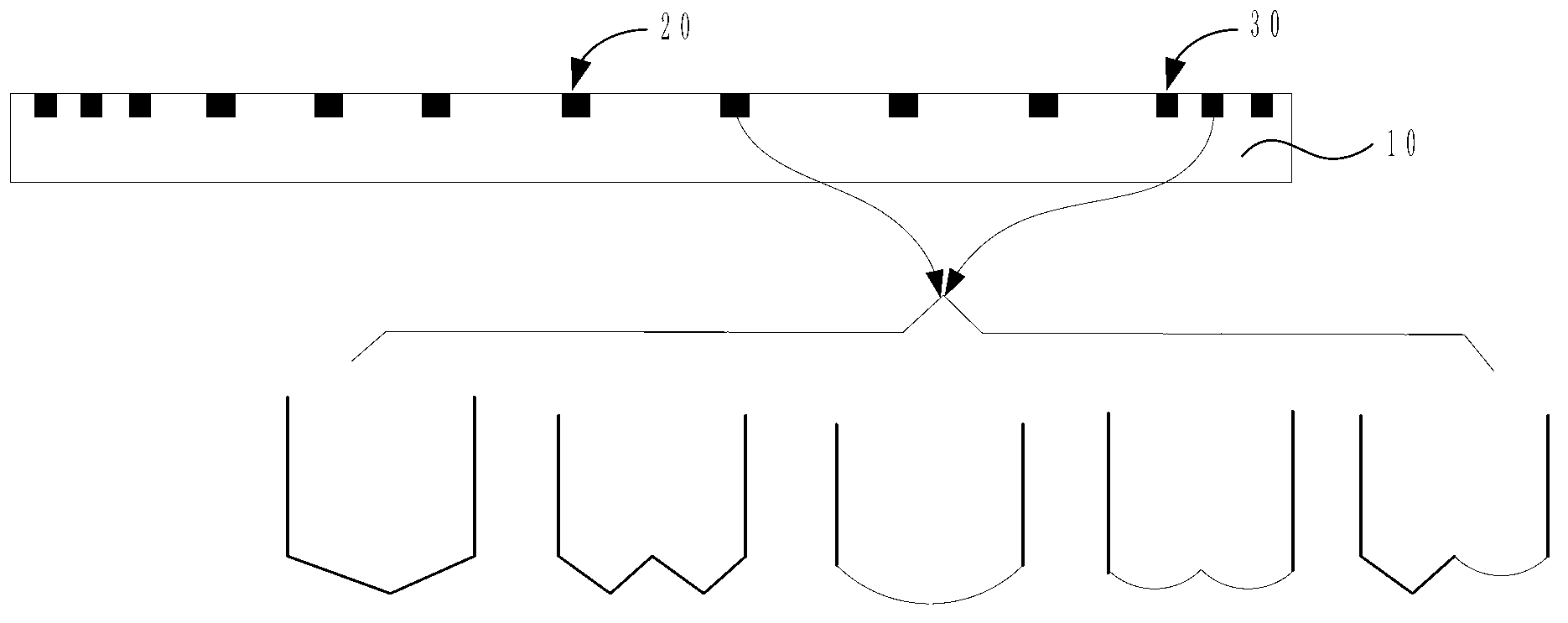

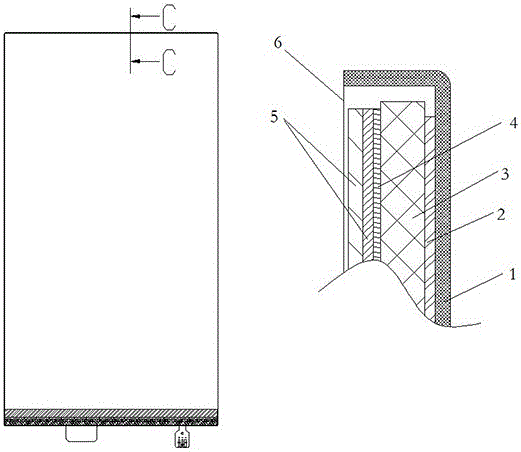

Plastic-frame-free backlight module

PendingCN106773307ASatisfy narrow edge requirementsStable structureNon-linear opticsLight guideOptoelectronics

The invention discloses a plastic-frame-free backlight module which comprises an iron shell, a reflection piece, a light guide plate, a diffusion piece, a light intensifying piece and a lamp strip. An iron shell frame is arranged at the edge of the iron shell, the reflection piece is arranged in the iron shell, the light guide plate is arranged on the reflection piece, the diffusion piece is arranged on the light guide plate, the light intensifying piece is arranged on the diffusion piece, and the lamp strip is arranged on the reflection piece. The plastic-frame-free backlight module is characterized in that tooth-shaped protrusions are arranged on the iron shell, tooth-shaped notches are arranged on the reflection piece, and the tooth-shaped protrusions and the tooth-shaped notches can be mutually buckled. A plastic frame structure in an existing backlight module can be omitted, so that size of the frame is greatly reduced, a frame-free integral structure can be stably maintained, and the plastic-frame-free backlight module has excellent using effect.

Owner:SHENZHEN BAOMING TECH

Preparation method of disc type multichannel ceramic membrane

PendingCN114249584ALower development requirementsLower manufacturing requirementsCeramic shaping apparatusWater/sewage treatment bu osmosis/dialysisCompression moldingCeramic membrane

The invention discloses a preparation method of a disc-type multi-channel ceramic membrane, which comprises the following steps: firstly, filling a mold cavity with a proper amount of granulation pug and paving, then carrying out injection molding on a plurality of plastic rubber blocks with the same shape as a channel, uniformly placing the plastic rubber blocks on the flattened powder surface, then filling a proper amount of granulation pug and paving, and finally, carrying out injection molding on the plastic rubber blocks to obtain the disc-type multi-channel ceramic membrane. And carrying out compression molding by using a molding press, demolding and sintering to obtain the support body with the channel inside. A mold with a flow guide groove is not needed, the forming difficulty is greatly reduced, the mold cost is reduced, the biscuit is integrally formed through a forming press, the filling plastic rubber block is decomposed and discharged in the high-temperature sintering process, an internal channel of the supporting body is formed, the attaching process of two biscuits is omitted, and the production efficiency is improved. And the integrity and the strength reliability of the support body are ensured.

Owner:SANDA FILM SCI & TECH XIAMEN

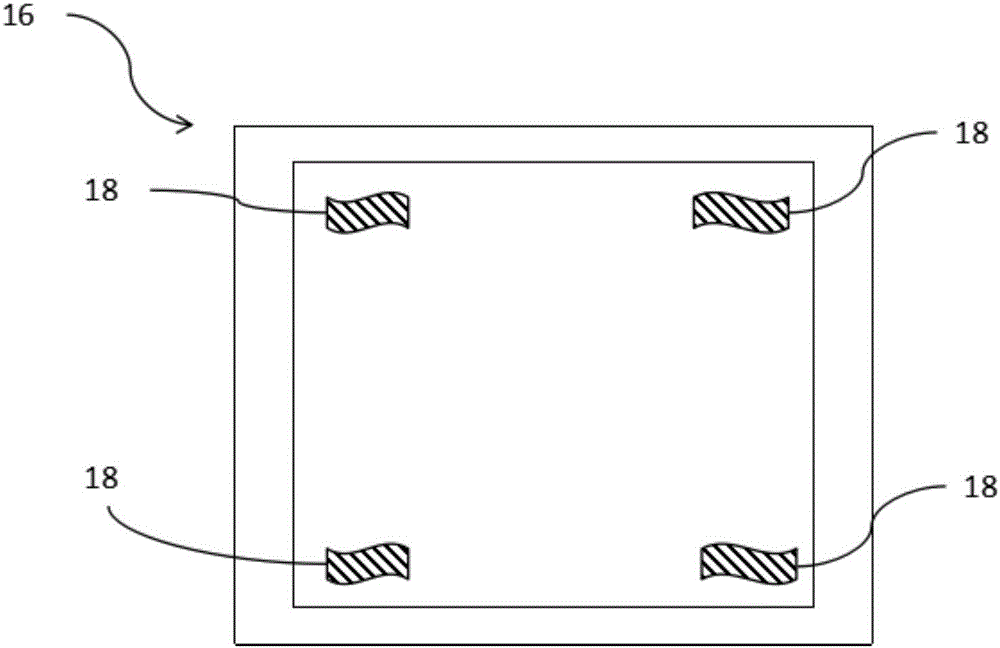

Pressure touch structure and display device

ActiveCN107562269BAvoid the problem of poor force touch effectLow costDigital data processing detailsPrinted circuitsCapacitanceDisplay device

The invention discloses a pressure touch control structure and a display device. The pressure touch structure includes a pressure sensor and a reference layer, a capacitor is formed between the pressure sensor and the reference layer, the pressure sensor includes a first pattern layer and a second pattern layer, and the second pattern layer includes a heat dissipation structure . In the technical solution of the pressure touch control structure and display device provided by the present invention, the pressure sensor includes a first pattern layer and a second pattern layer, and the second pattern layer includes a heat dissipation structure. In the present invention, the heat dissipation structure is arranged in the pressure sensor without The heat sink is installed separately from the pressure sensor, which avoids the problem of poor pressure touch effect caused by the uneven heat sink, thereby improving the pressure touch effect; there is no need to set the heat sink separately from the pressure sensor, thereby reducing a problem. The bonding process of the heat sink is separately set, and the material cost is reduced.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com