Inserted-type automobile ignition coil iron core provided with air gap magnetic steel disc

An automotive ignition coil, plug-in technology, applied in transformer/inductor magnetic cores, electrical components, inductive energy storage devices, etc. The effect of improving the working environment, increasing the high-voltage output, and increasing the stored energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

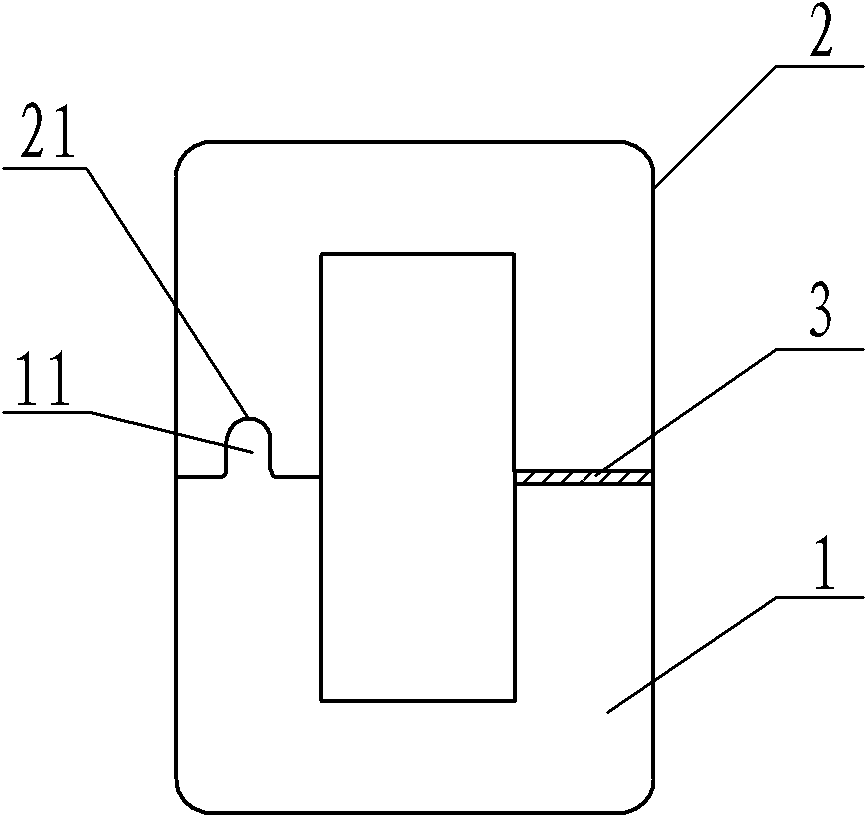

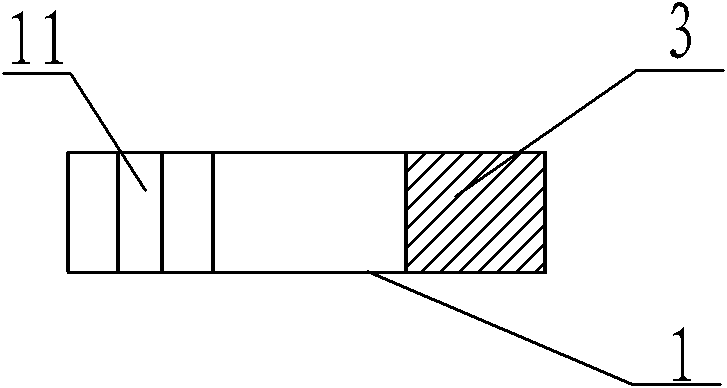

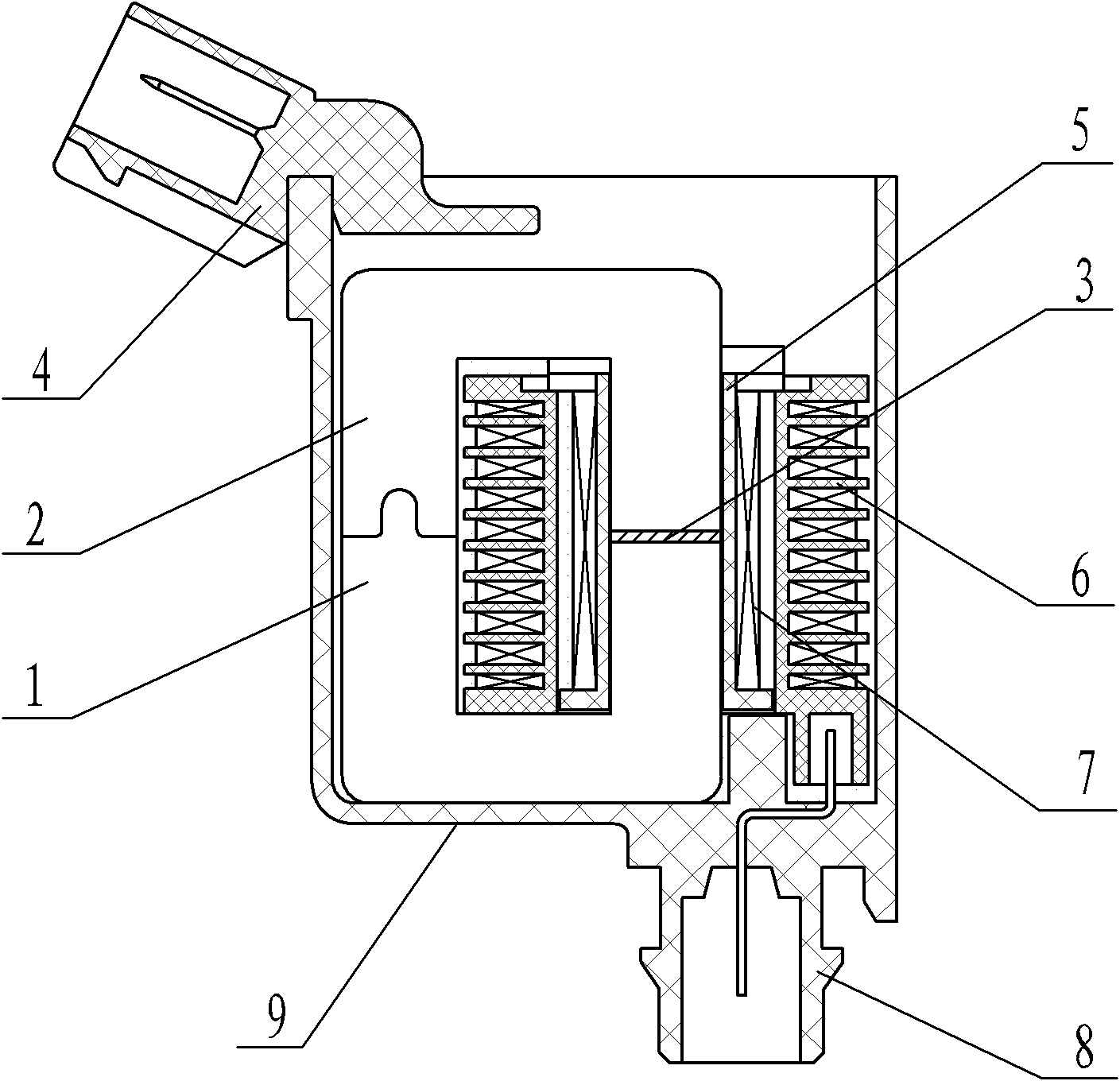

[0014] Figure 1 ~ Figure 2 It shows a plug-in automobile ignition coil iron core with air gap magnetic steel sheets, including a first U-shaped iron core 1 and a second U-shaped iron core 2 formed by butting to form an annular iron core, the first U-shaped iron core One side of 1 and the second U-shaped iron core 2 is a fixed connection end, and an air gap is provided between the end faces of the other side, which is characterized in that a magnetic steel sheet 3 with a polarity opposite to the magnetization direction of the iron core is inserted into the air gap . The above-mentioned magnetic steel sheet 3 can be made of ordinary magnetic steel, such as N30UH. The material of the first U-shaped iron core and the second U-shaped iron core is grain-oriented electrical steel with relatively high magnetic permeability. In this example, 30Q130 grain-oriented electrical steel is used to increase the magnetic permeability μ of the iron core.

[0015] The fixed connection end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com