Production method for textile reinforced compound stone plate

A technology of reinforced composite and manufacturing method, applied in building construction, covering/lining, construction, etc., can solve problems such as poor interlayer shear strength, decreased mechanical properties, complicated process, etc., to reduce weight and improve safety in use , The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

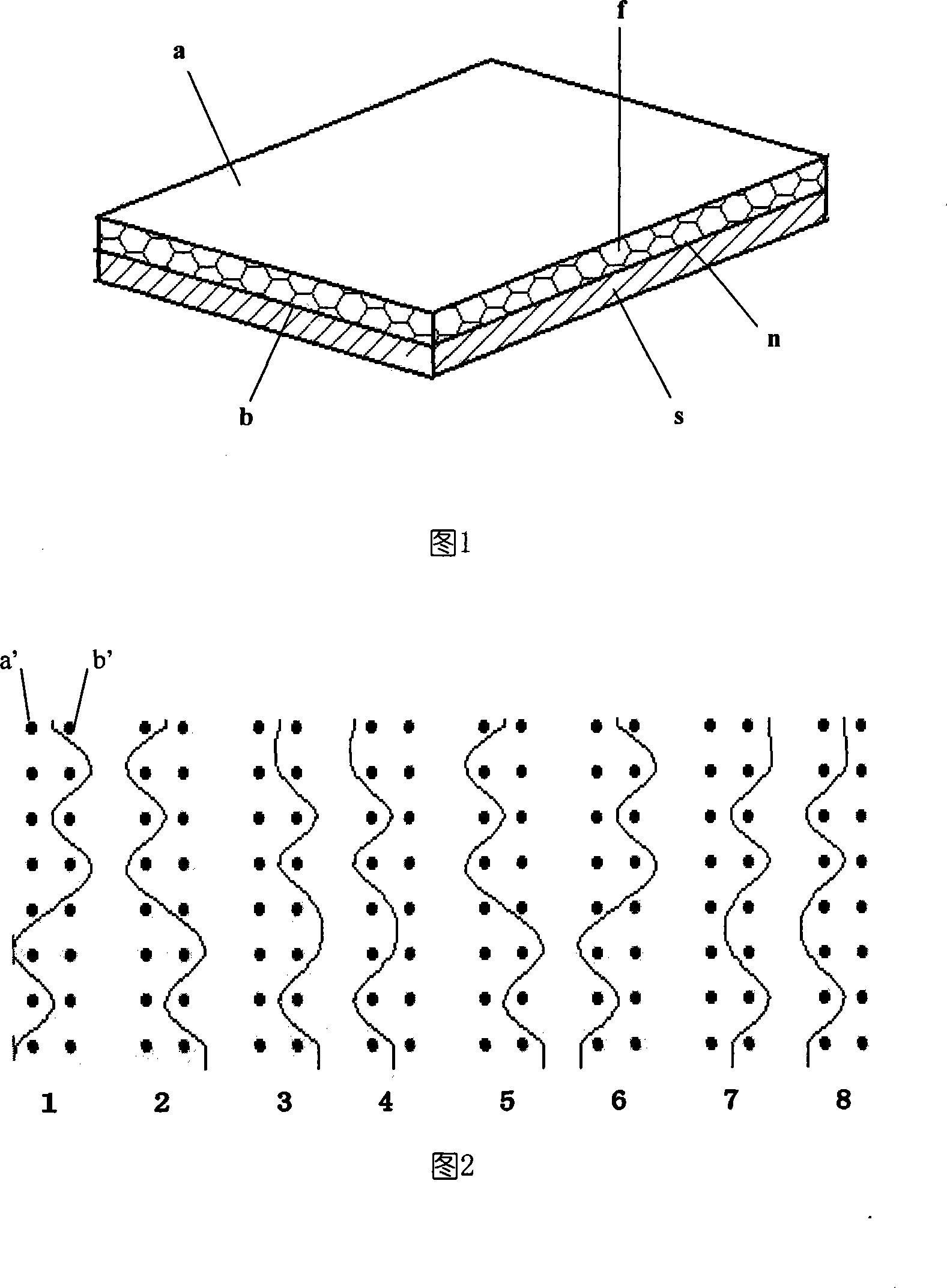

[0012] The embodiment uses marble as the stone board and glass fiber spacer woven fabric resin board as the reinforcement, consisting of five steps.

[0013] In the first step, a 22 mm thick spacer fabric is woven from glass fibers on a rapier loom.

[0014] Use glass fiber (produced by Chongqing International Composite Materials Co., Ltd., product code G75) that is formed by merging three yarns with a linear density of 67.5 g / km per share as a raw material. On a rapier loom with two let-off mechanisms, in a fully weaved weave, all warp yarns are divided into three groups, and all weft yarns are divided into upper and lower layers a' and b'; the first group of warp yarns 4, 8 and the The two groups of warp yarns 3 and 7 share a set of tension-sensing warp let-off mechanism, which is let off at a speed of 1.2 mm / machine per revolution. The first group of warp yarns 4 and 8 only appear on the upper layer a of the woven spacer fabric, and the upper layer of weft yarn a' is inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com