Preparation method of damping cork PVC floor

A cork flooring and flooring technology, applied in the direction of floors, coverings/linings, insulation layers, etc., can solve the problems of reducing the environmental protection degree of PVC flooring, high labor and equipment costs, and low peeling strength between cork and flooring, so as to avoid harmful Material, improve sound insulation effect, save the effect of hot melt adhesive bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

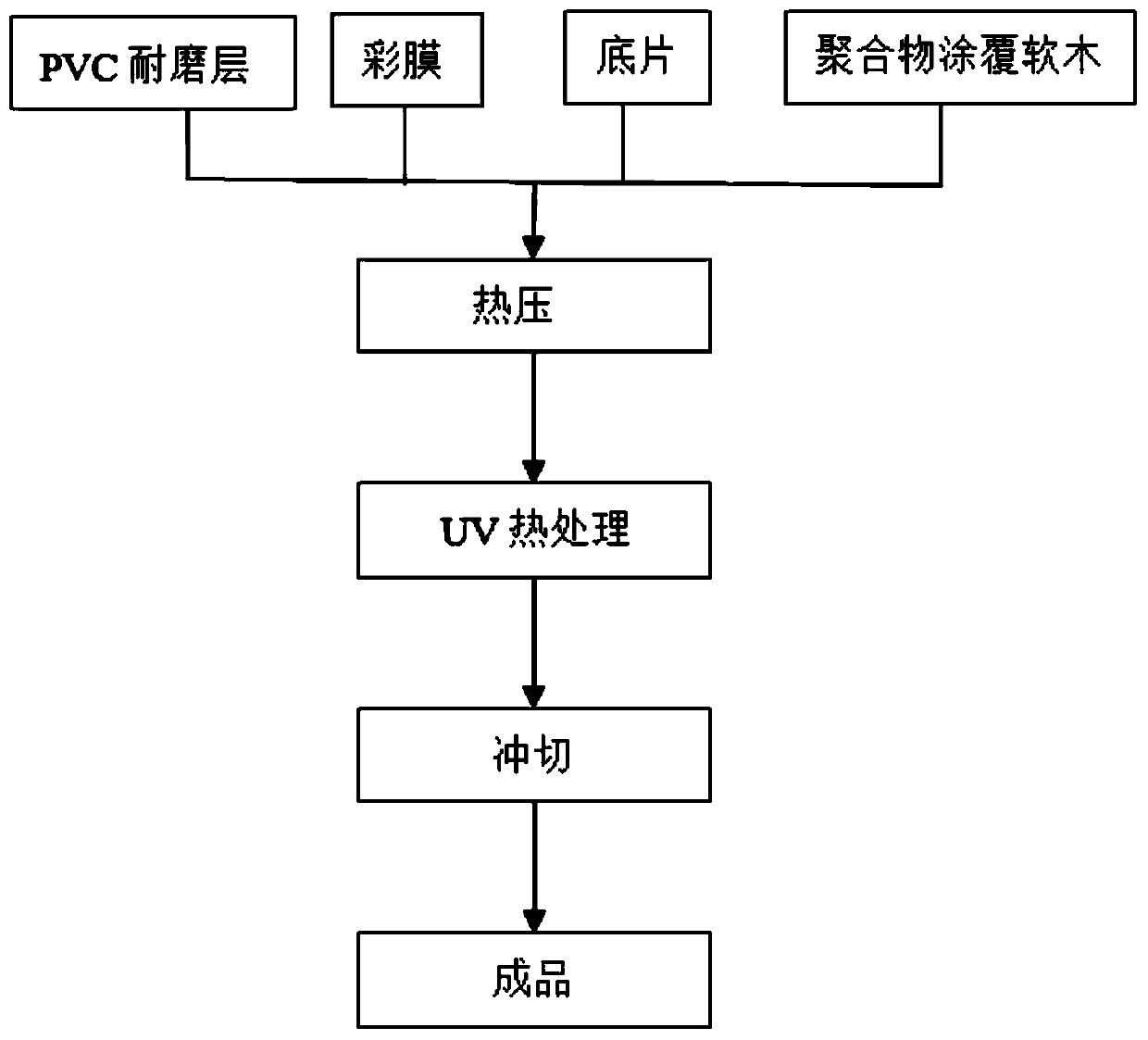

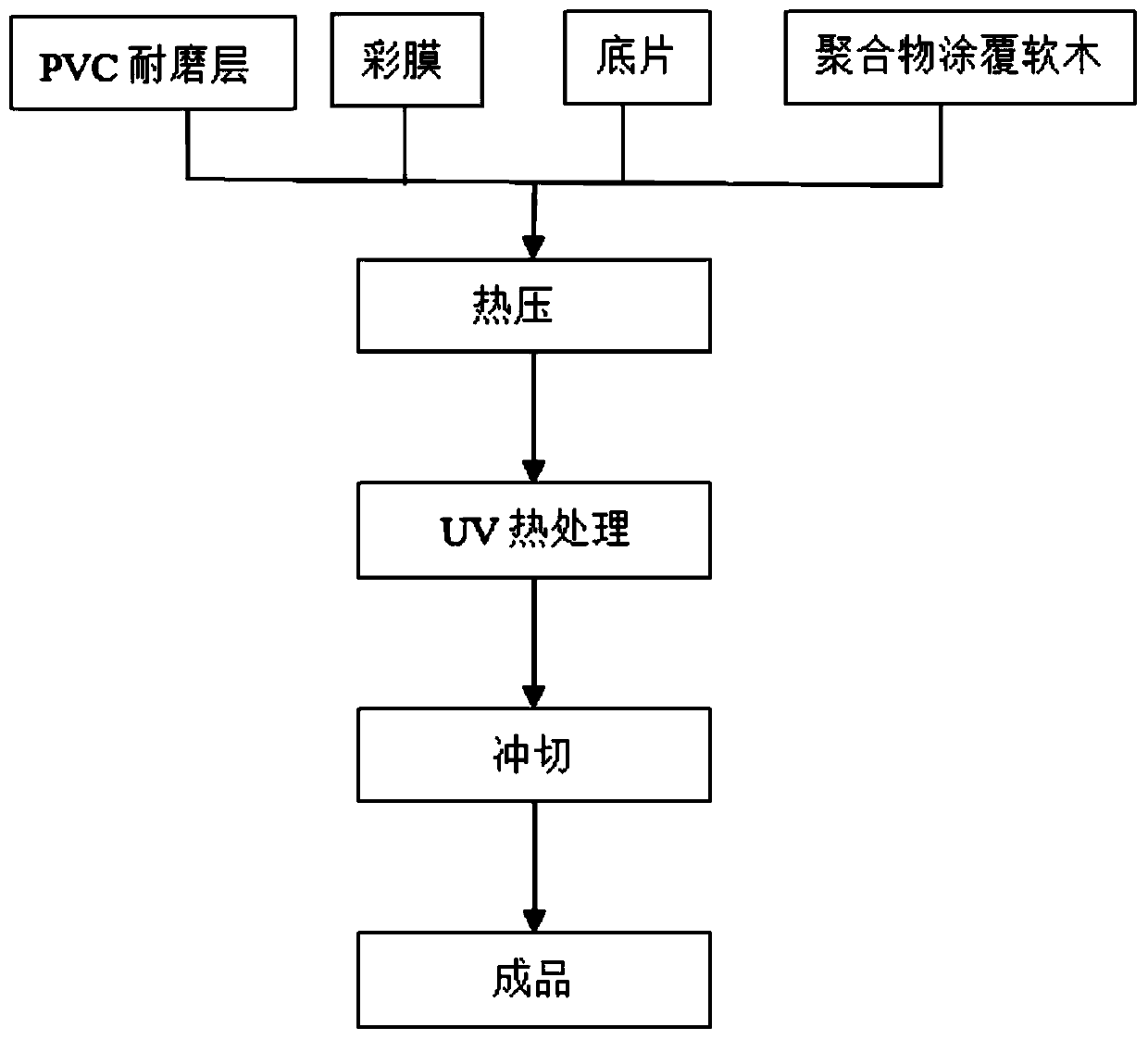

[0025] Please refer to figure 1 , a kind of preparation method of silent cork PVC floor, adopts the cork floor and PVC floor coated with polymer as raw material so as to save the bonding process of hot melt adhesive, specifically comprises the following steps:

[0026] (1) Lamination: Composite lamination of the cork floor coated with polymer, PVC wear-resistant layer, PVC color film, and PVC film; wherein the film is a stone-plastic substrate; the polymer-coated cork, its The polymer comprises the following components in terms of mass: 20 parts of polyvinyl chloride, 1 part of plasticizer, and 0.3 parts of stabilizer;

[0027] (2) Press: Push the stacked material into the press, hot pressing temperature is 150°C, hot pressing time is 40min, cold pressing temperature is lower than 40°C, cold pressing time is 40min, unloading;

[0028] (3) UV heat treatment: the temperature in the hot water zone is 90°C, the speed is 14m / min; the temperature in the cold water zone is 30°C, the...

Embodiment 2

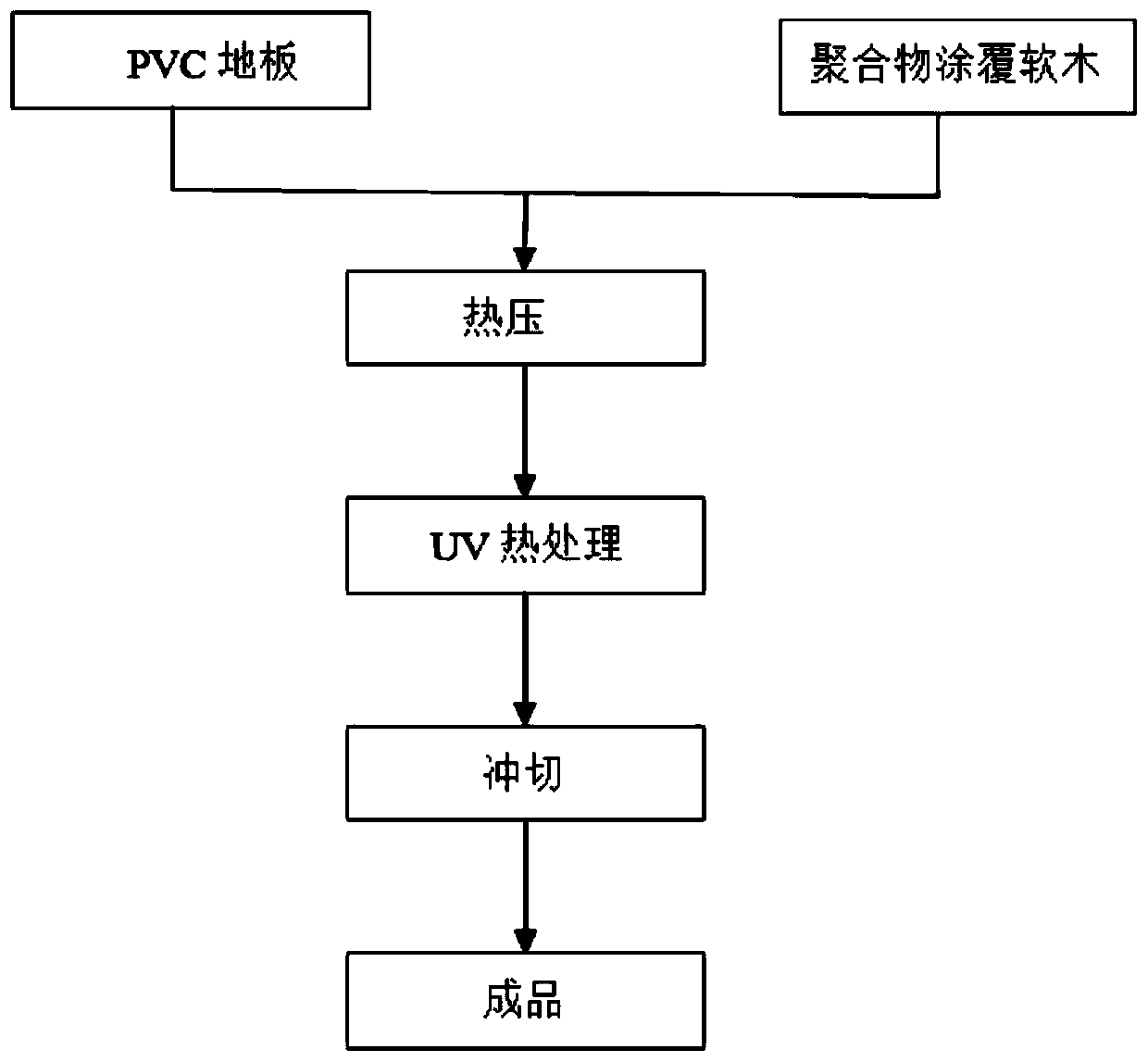

[0033] Please refer to figure 2 , a method for preparing a silent cork PVC floor, using a polymer-coated cork floor and a PVC floor finished product as raw materials so as to save the bonding process of hot melt adhesive, specifically comprising the following steps:

[0034] (1) Lamination: Composite lamination of the polymer-coated cork floor and the finished PVC stone-plastic floor at one time; wherein the negative is the stone-plastic substrate; the polymer-coated cork is calculated by mass Including the following components: 30 parts of polyvinyl chloride, 1.5 parts of plasticizer, and 0.5 parts of stabilizer;

[0035] (2) Press machine: Push the stacked material into the press, hot pressing temperature is 130°C, hot pressing time is 8min, cold pressing temperature is lower than 40°C, cold pressing time is 30min, and unloading;

[0036] (3) UV heat treatment: the temperature in the hot water zone is 90°C, the speed is 14m / min; the temperature in the cold water zone is 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com