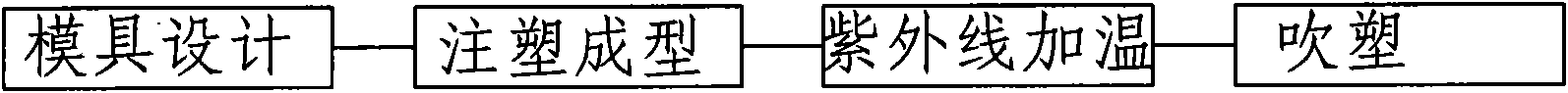

Process for moulding goblet

A molding process and technology for goblets, applied in the field of plastics, can solve problems such as easy bubbles and easy bending of the cup body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

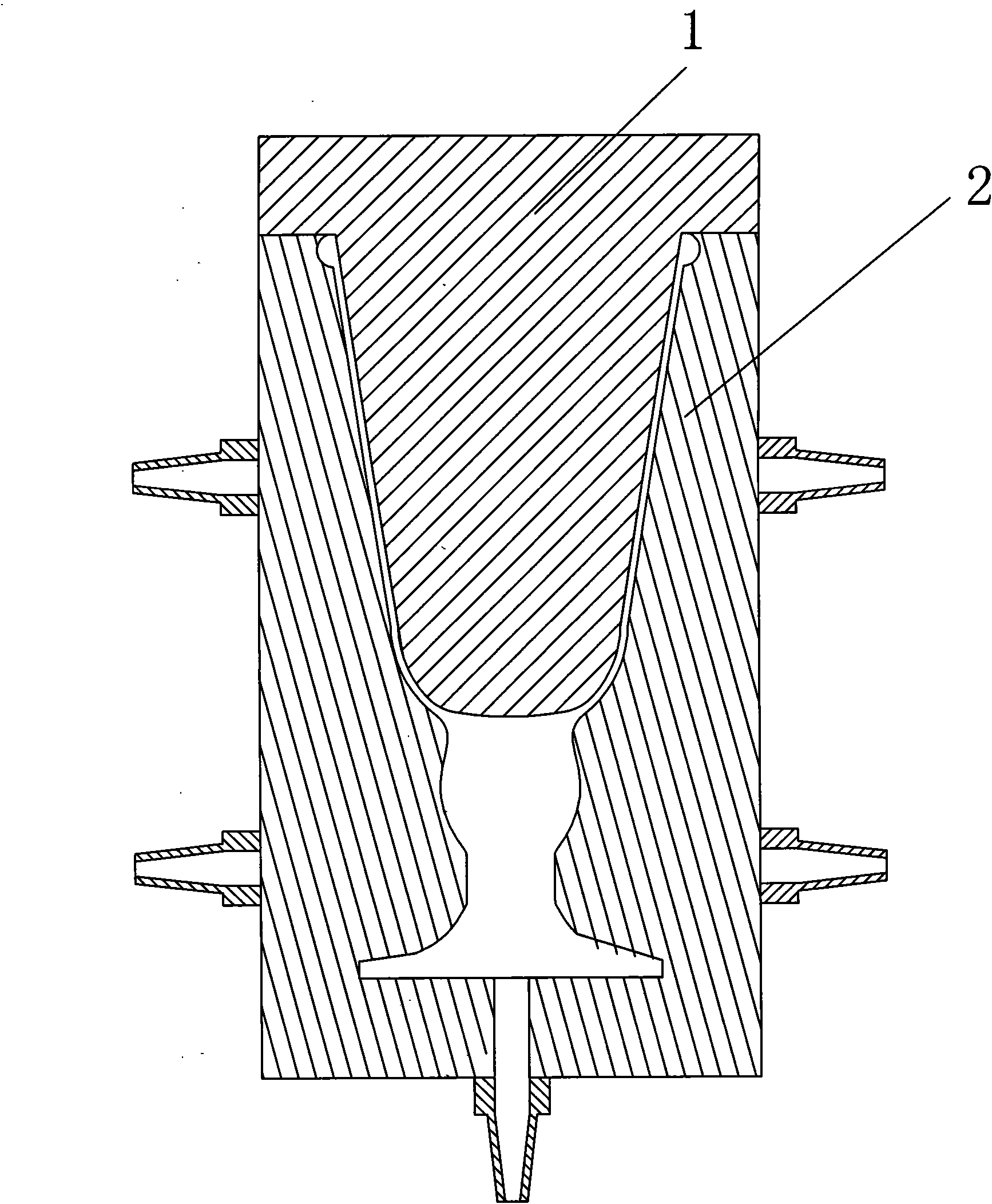

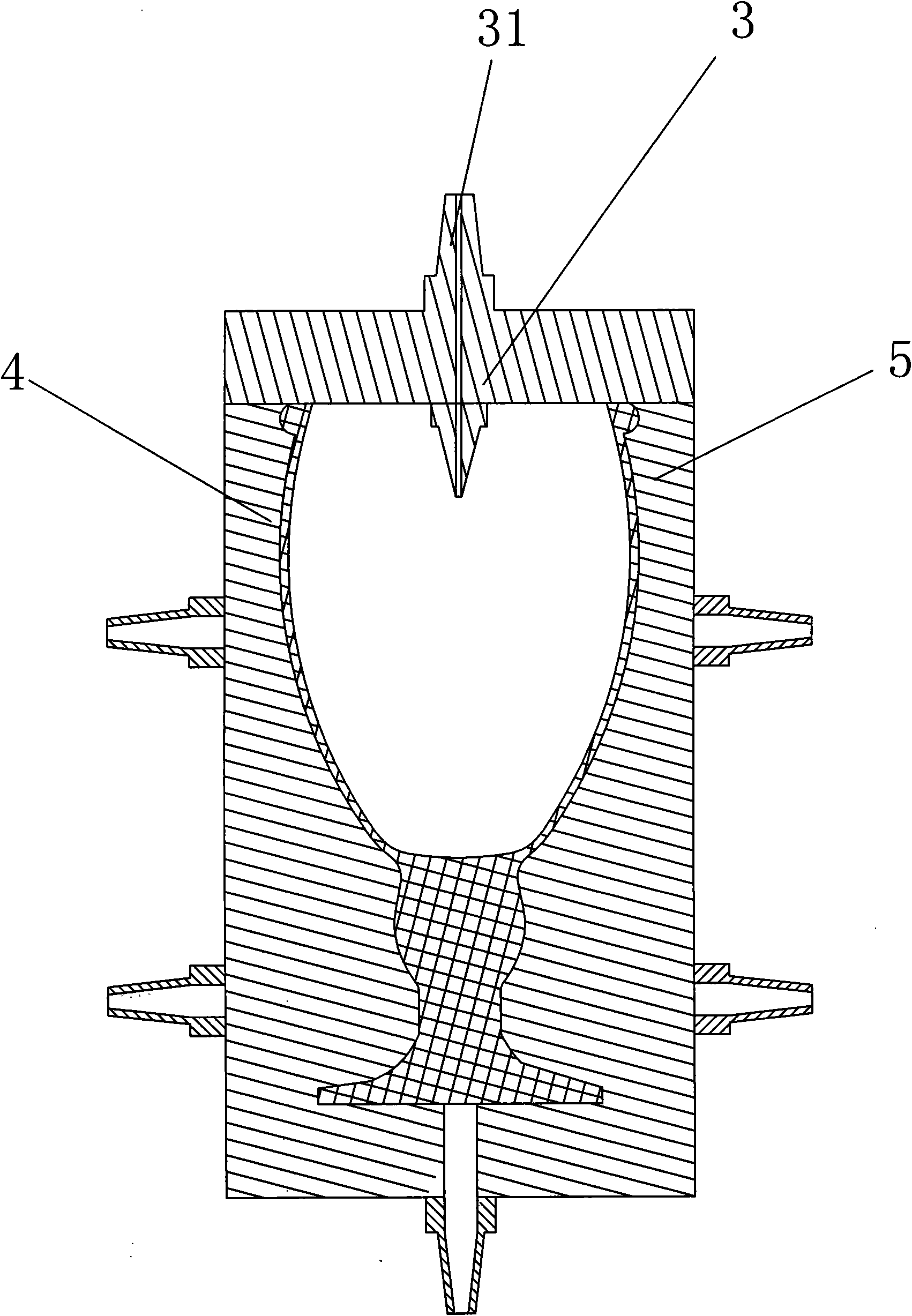

[0011] Such as figure 1 , figure 2 , image 3 As shown, a goblet molding process: a. According to the design of the product injection mold, the cup body of the primary product is wide on the outside and narrow on the inside, which is easy to demould; The top is wide and the bottom is narrow, and the outer edge of the primary product is 0.5 to 0.8 mm more exposed than the actual product; C. Ultraviolet heating, heating the primary product at 180 ° C to 260 ° C for 10 to 30 seconds to soften the primary product, and then place it In the blow mold; d, blow molding, blowing air for 8-12 seconds after closing the mold, the air pressure is kept at 25-28Mpa, to obtain a cup body with a wide middle and narrow ends, stop blowing, and demould to obtain a product. The injection mold is composed of an upper mold 1 and a lower mold 2. The gap formed after the upper mold 1 and the lower mold 2 are closed is the molding space of the primary product. The cup body of the primary product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com