Plastic-frame-free backlight module

A backlight module, frame technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as influence, and achieve the effect of reducing problems, stable structure, and reducing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

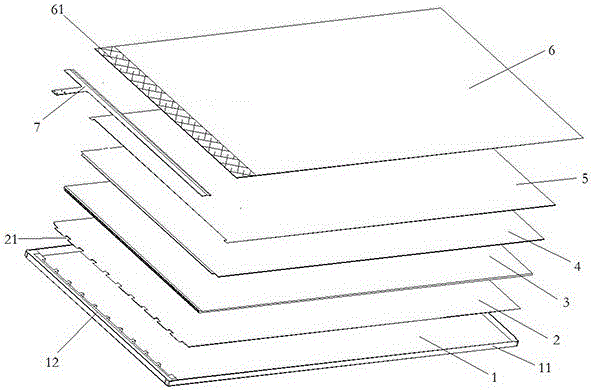

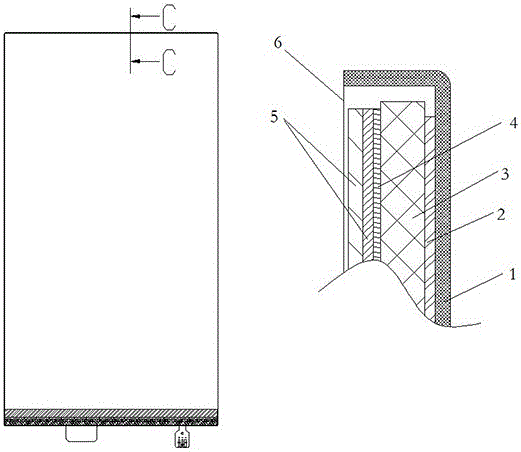

[0025] as attached figure 1 with attached figure 2 As shown, what this embodiment shows is a backlight module with three sides and no frame, and the specific structure is as follows:

[0026] On one side of the light bar 7 on the iron shell 1, a tooth-shaped protrusion 12 is provided. Firstly, a small hole is provided on the iron shell 1, and the iron shell 1 is placed in the injection mold, and the iron shell is directly placed on the iron shell through the injection mold. Serrated protrusions 12 are formed on the top of the body, because during the injection molding process, part of the molten colloid will enter the engaging holes, and after the overall colloid is cooled, the molten colloid remaining in the engaging holes will form the engaging protrusions , the protrusion can make the integral tooth-shaped protrusion 12 fixed on the iron shell, and the inner side of the iron shell frame 11 is coated with a reflective layer. One side of the light bar 7 of the reflector 2 ...

Embodiment 2

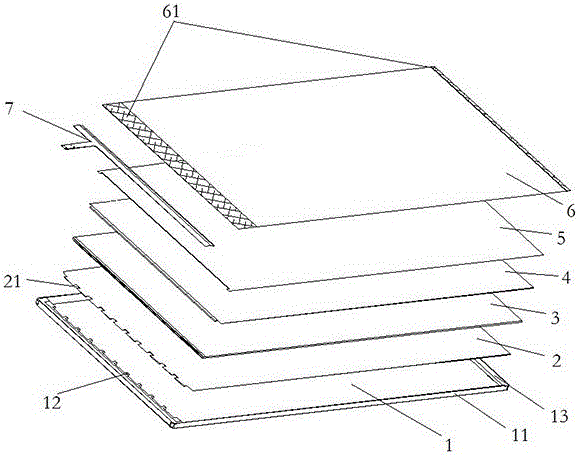

[0030] as attached figure 1 And attached figure 2 As shown, what this embodiment shows is a backlight module with no borders on both sides, and the specific structure is as follows:

[0031] One side of the light bar 7 on the iron shell 1 is provided with tooth-shaped protrusions 12, the inner side of the iron shell frame 11 is coated with an oil reflective layer, and an upper cushion frame 13 is arranged on the opposite side of the light bar 7 sides, and the tooth-shaped protrusions Both the riser 12 and the upper cushion frame 13 are formed by injection molding on the iron shell 1, specifically, the iron shell is placed on the injection mold, and the tooth-shaped protrusions 12 are directly formed on the iron shell through the injection mold, because in the injection molding process In the process, part of the molten colloid will enter into the engaging hole. After the whole colloid is cooled, the molten colloid remaining in the engaging hole will form an engaging protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com