Sprayed product, and production method and special die thereof

A production method and product technology, applied in the fields of spraying products, production methods and special molds, can solve the problems of low tensile strength of needle-punched or tufted carpets, consumption of hot melt adhesive and reinforcing tape, and peeling of carpets, etc. To achieve the effect of highlighting the substantive features, reducing the bonding process, and facilitating mold processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1, see Figure 8 , processed into a surface layer mold 42 and a back layer mold 41, the two positions are corresponding, there is an extrusion cutter 43 on the back layer mold 41, the surface layer mold 42 is a plane, and there is no protrusion on the back layer mold 41. There is a gap of 0.5-3 mm between the cutter 43 and the surface layer mold 42, which is specifically related to the thickness of the reinforcing belt used, the weight of the glass fiber felt, the thickness of the honeycomb paper, etc.; thus the special mold of the present invention is made.

Embodiment 2

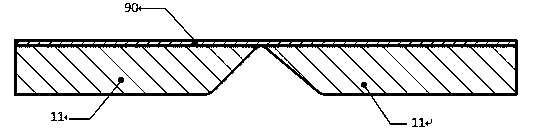

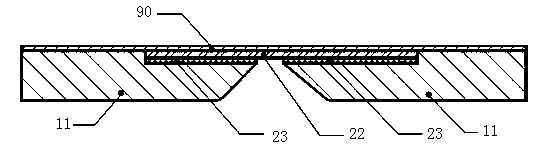

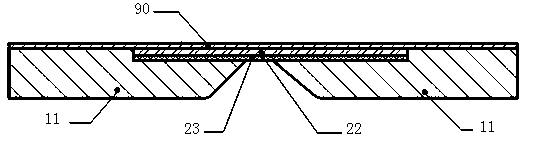

[0027] Example 2, see Figure 9 , Figure 5 , during production, the reinforcement strip 22 is pre-placed on the designated position of the surface layer mold 42. After the glass fiber felt, honeycomb paper and other materials sprayed with polyurethane material are put into the mold, the back layer mold 41 and the surface layer mold 42 are combined together. , most of the polyurethane foam under the edge of the extrusion cutter 43 is squeezed to both sides, so the final product only has reinforcement band 22, fiberglass felt, honeycomb paper, and a small amount of polyurethane foam at the folded position; After the product is removed, the substrate 11 composed of polyurethane material, glass fiber felt and honeycomb paper can be turned over, and the reinforcing belt 22 is fixed on the substrate 11 through the polyurethane material forming a glass fiber reinforced polyurethane structure during the molding process of the substrate 11. Reinforcing strip 22 plays a connecting rol...

Embodiment 3

[0028] Example 3, see Figure 6 , as in Embodiment 2, the surfaces of the two substrates 11 that have been connected together through the reinforcing belt 22 are bonded with the fabric 90 by hot-melt adhesive to form the sprayed product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com