Flip LED (light-emitting diode) substrate structure

A technology for LED substrates and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as a large amount of solder and high consumption of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

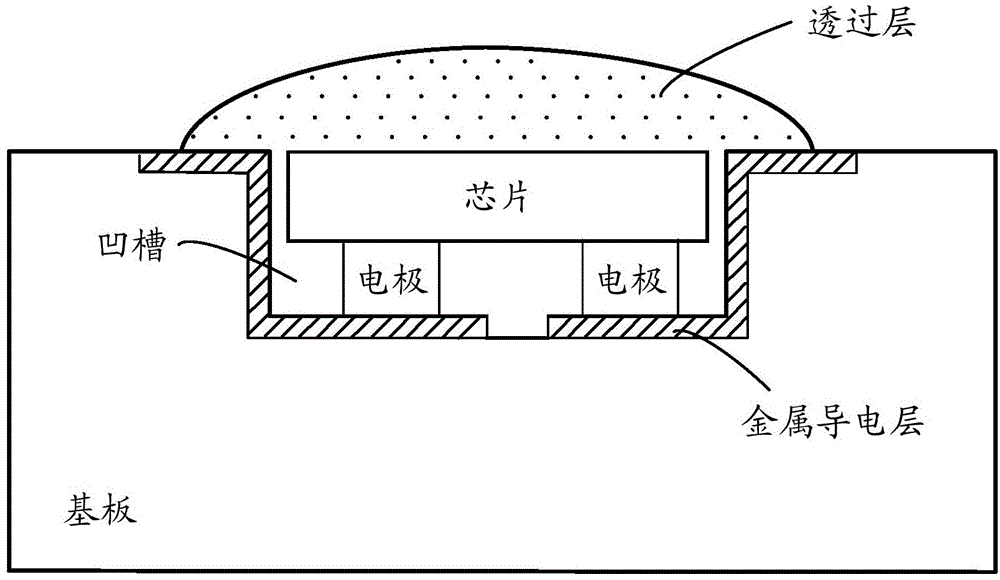

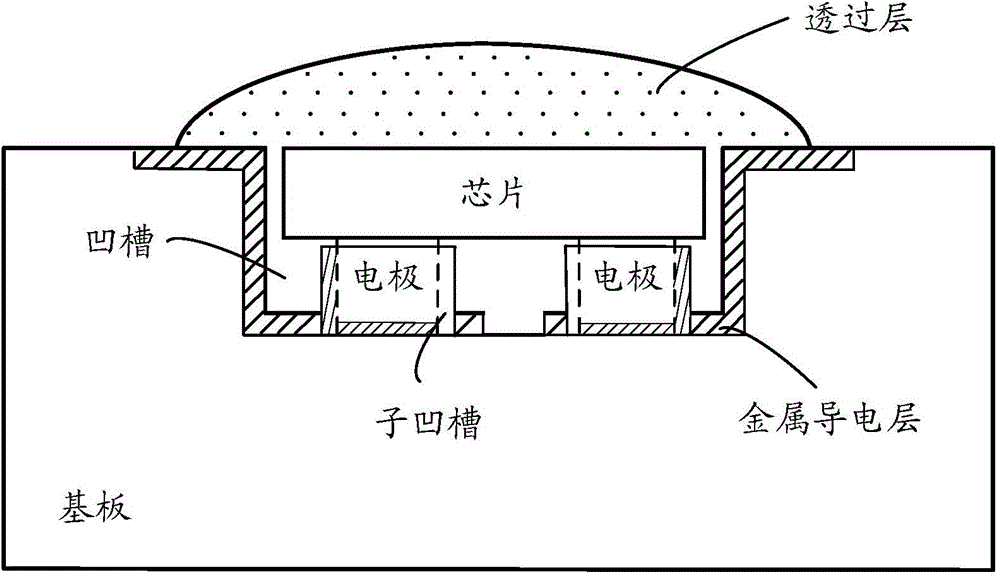

[0022] The structure of the flip-chip LED substrate will be further described in detail below with reference to the implementation manner and the accompanying drawings.

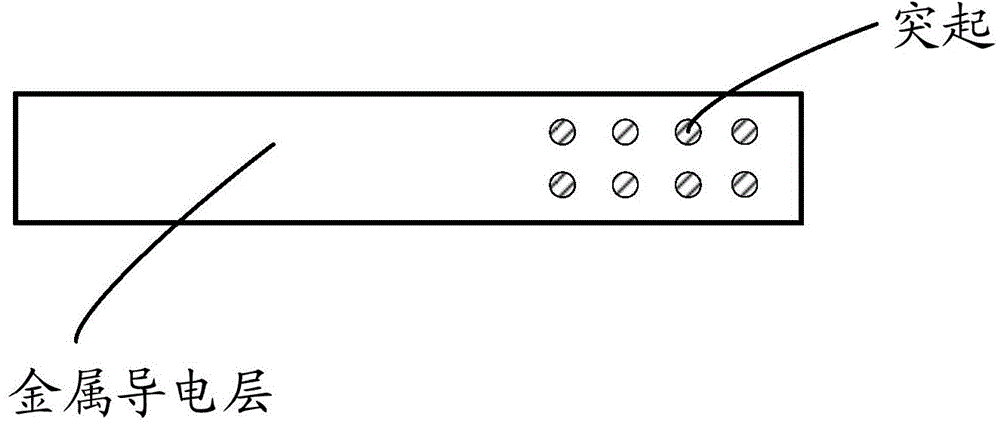

[0023] combined with figure 1 , In the flip-chip LED substrate structure according to one embodiment, grooves are provided on the substrate, and the grooves can accommodate LED chips. The conductive metal layer is arranged in the groove and extends to the surface of the substrate. In addition, the conductive metal layer is divided into two parts, which are respectively connected to two electrodes of the LED chip. A light-transmitting layer is covered on the top of the LED chip, and the light-transmitting layer can be made of highly transparent materials such as epoxy resin, polycarbonate, polymethyl methacrylate, glass, and organic silicon materials. The flip-chip LED substrate structure of this scheme cleverly uses the light-transmitting layer to cover and press down on the LED chip, and makes the LED chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com