Slag-release anti-explosion tube mold for dry-type material tundish working lining of reserved weir plate groove

A dry material and tundish technology, applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems that the staff are difficult to perceive intuitively, the output pressure increases, etc., and achieve the effect of reducing pipe bursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

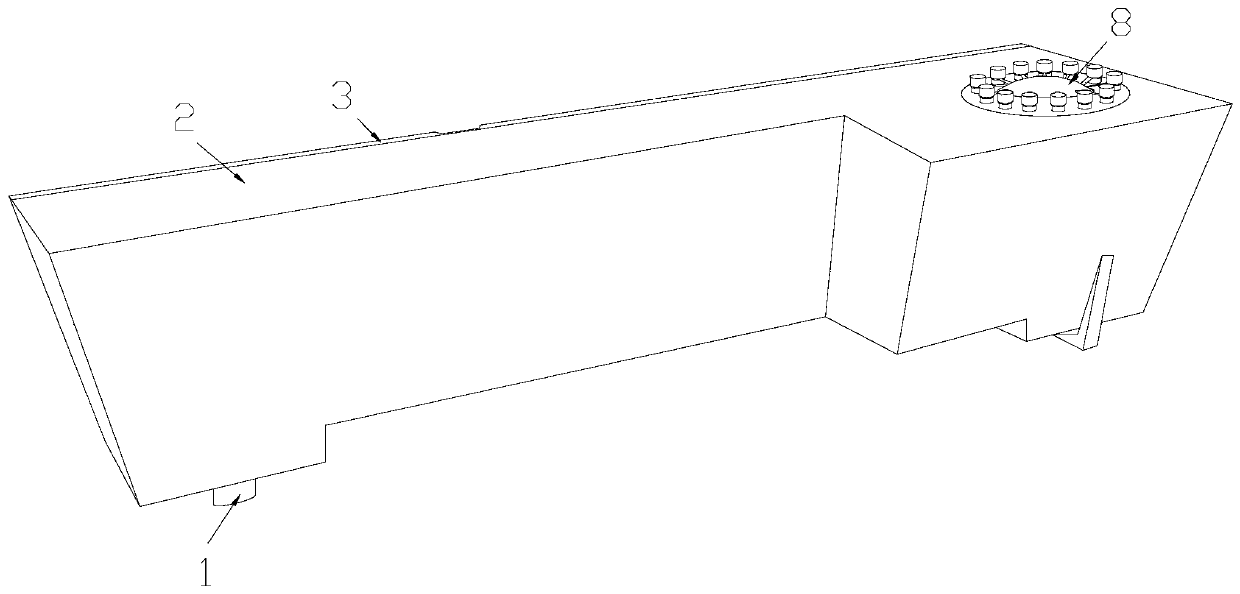

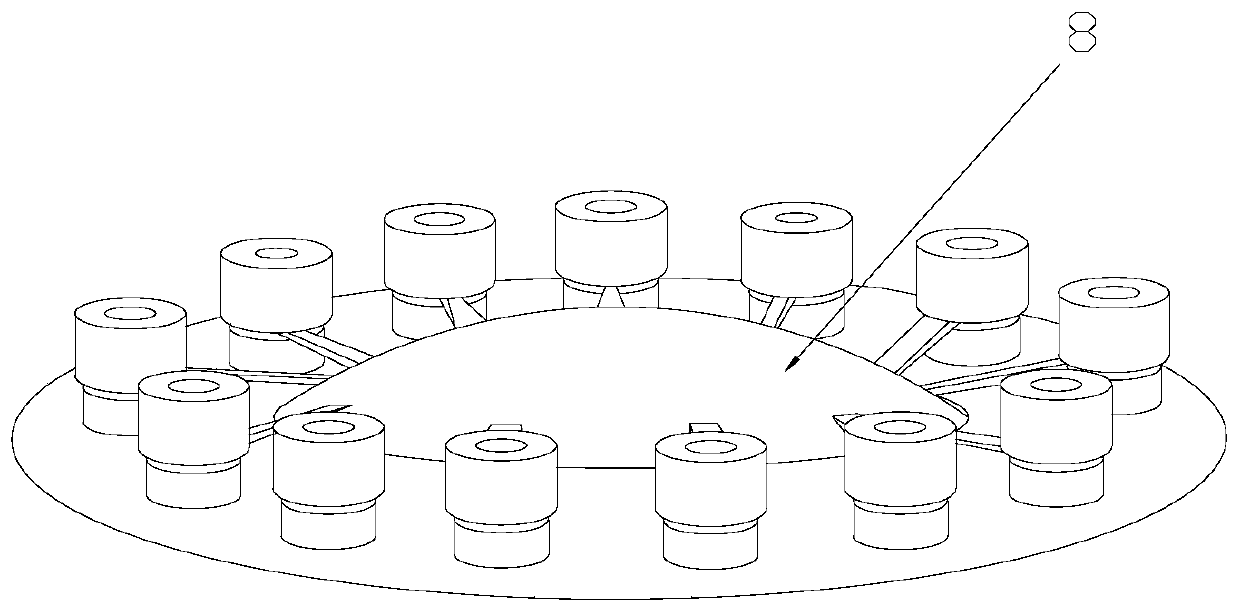

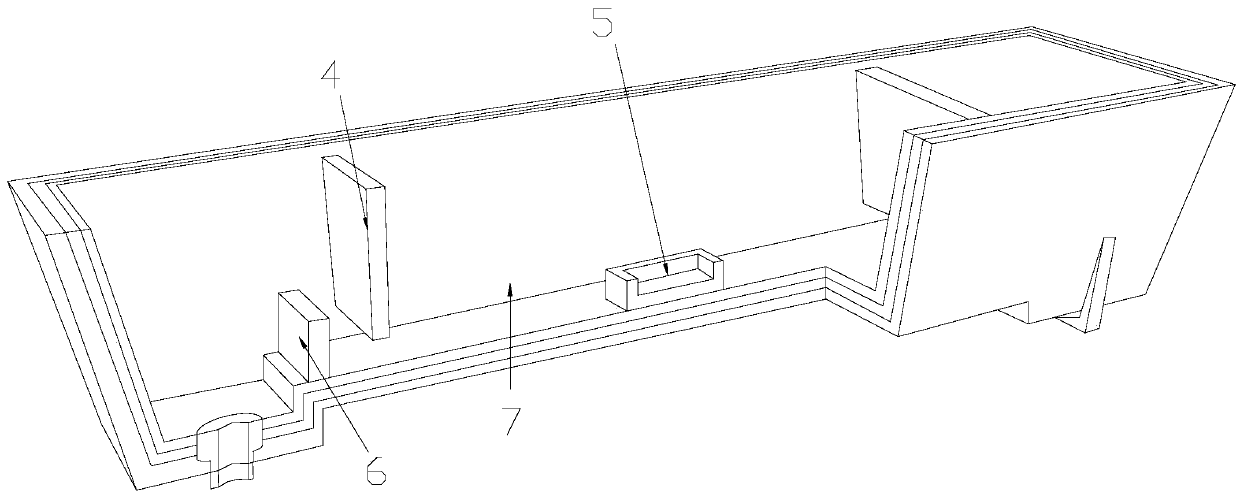

[0029] as attached figure 1 to attach Figure 9 Shown:

[0030] The invention provides a slag-releasing explosion-proof pipe mold for dry-type material tundish working lining with reserved weir plate grooves. Slag wall 4, impact pad 5, working layer 6, slag retaining dam 7, diversion slag release device 8, the shroud 1 is fixedly connected to the left bottom end of the dry-type material insulation lining 2 of the mold by electric welding, and the weir The installation groove plate 3 is fixedly installed on the back of the mold dry-type material insulation lining 2, and the slag retaining wall 4 is provided with two installed on the left and right sides of the mold dry-type material insulation lining 2 respectively. The inside of the material insulation lining 2 is coated with a working layer 6, and the bottom end of the slag retaining dam 7 is fixedly connected to the inner bottom end of the mold dry material insulation lining 2 by means of electric welding, and the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com