A hydraulic type high stability rubber hose joint

A high-stability, rubber hose joint technology, applied in the field of pipe joints, can solve the problems of joints falling off and bursting, easy leakage, joint leakage, etc., and achieves the effect of reducing pipe bursting, high connection stability, and improving connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

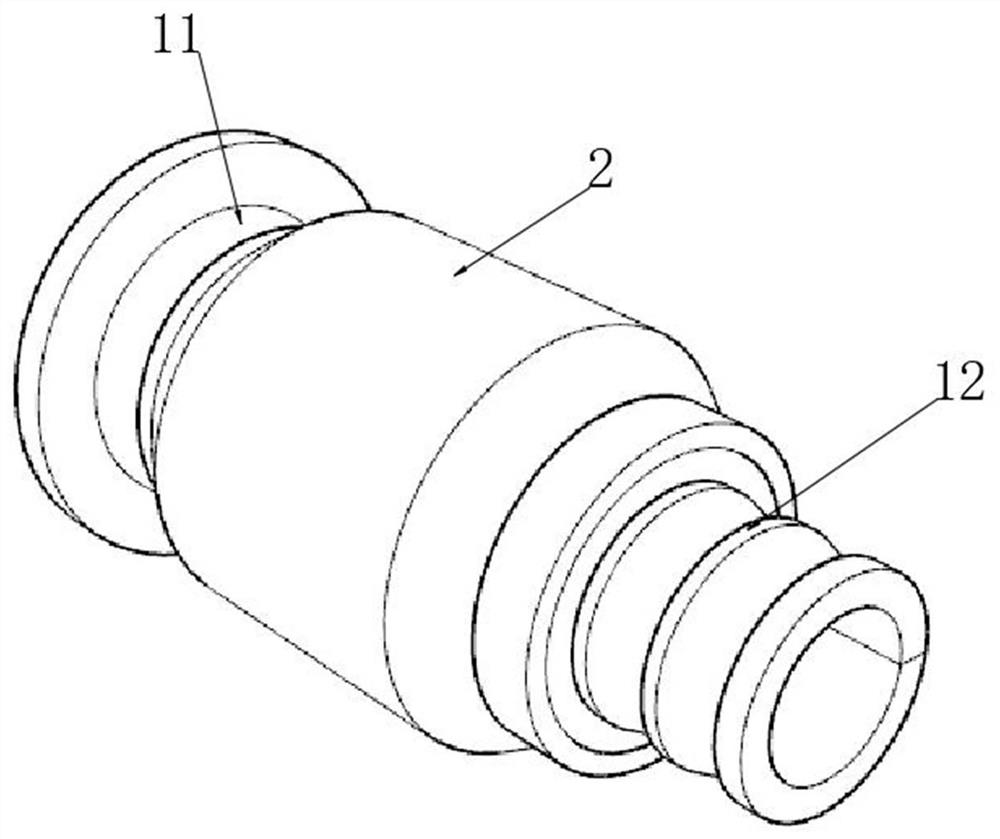

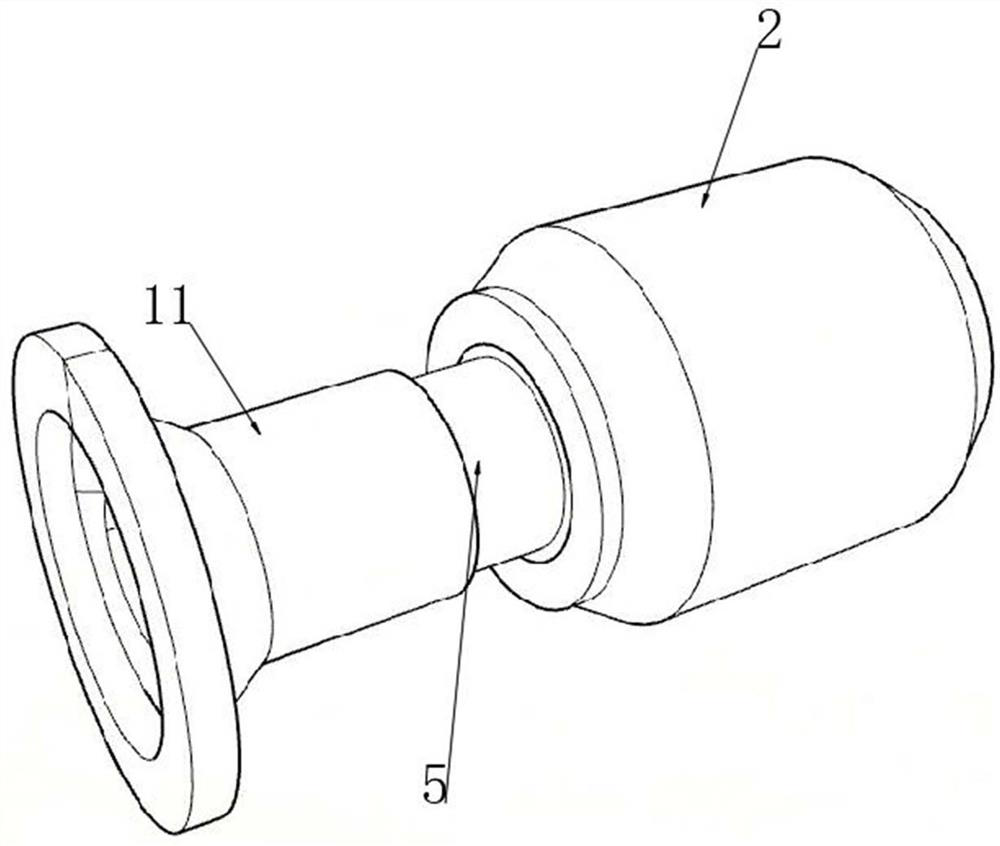

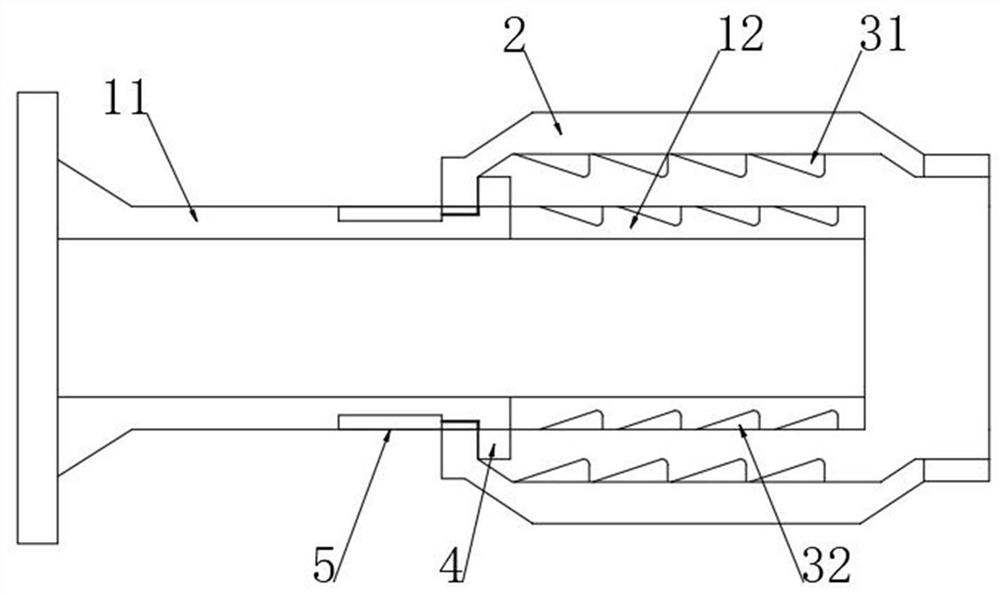

[0047] see Figure 2-3 , a hydraulic high-stability rubber hose joint, including a hydraulic variable tube and an outer casing 2 sleeved outside the hydraulic variable tube, the hydraulic variable tube includes a fixed rod 11 and a pressure variable tube 12 fixedly connected to the right end of the fixed rod 11, Both the fixed rod 11 and the outer casing 2 are of hard structure, and the pressure variable tube 12 is an elastic sealing structure, so that the pressure variable tube 12 can change to the shape under the pressure of the fluid, squeeze the rubber tube, and make the gap between the rubber tube and the joint The connection strength of the fixed rod 11 close to the outer end of the pressure variable tube 12 is fixedly connected to the limit washer 4, the sliding end of the pressure variable tube 12 is located on the left side of the limit washer 4, and the outer end of the pressure variable tube 12 is excavated with a A plurality of evenly distributed inset ring wedge g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com