Cable tube type stranding device for hardware alternating current equipment processing

A technology of alternating current and equipment, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of easy loosening of cables, inability to adjust the tightness of cable strands, affecting people's normal use, etc., to improve the effect of stranding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

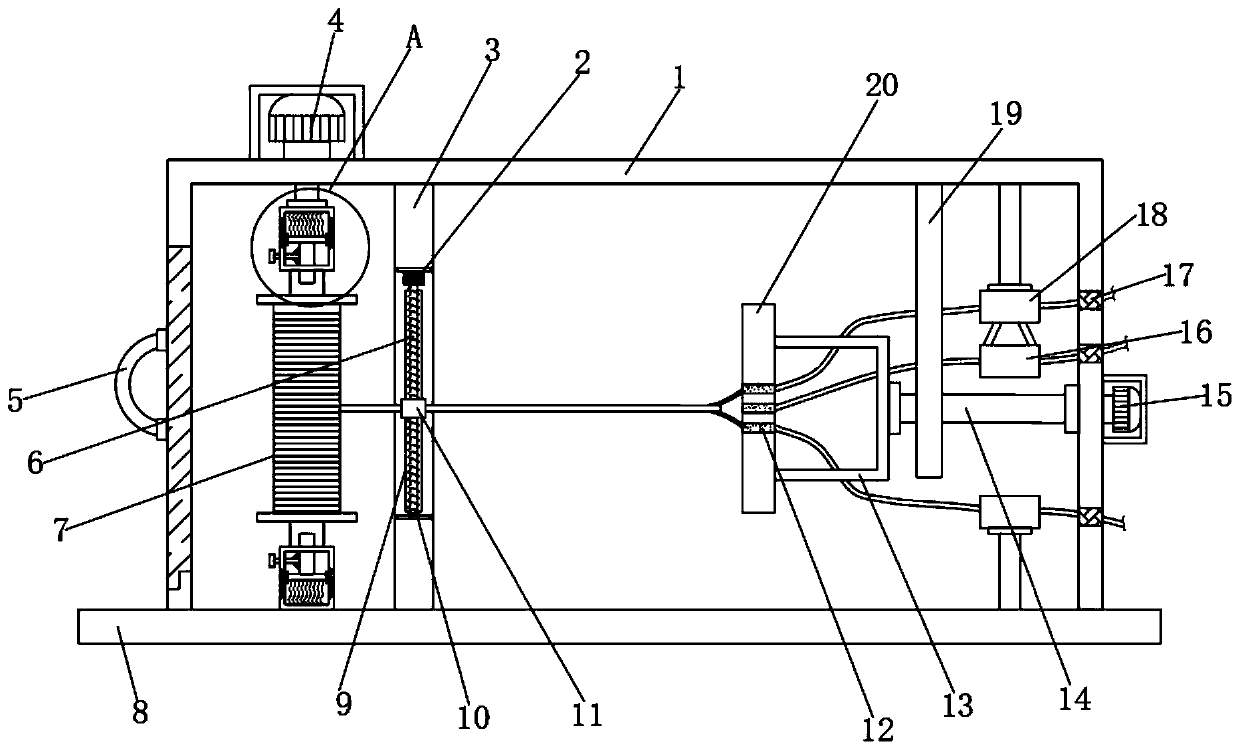

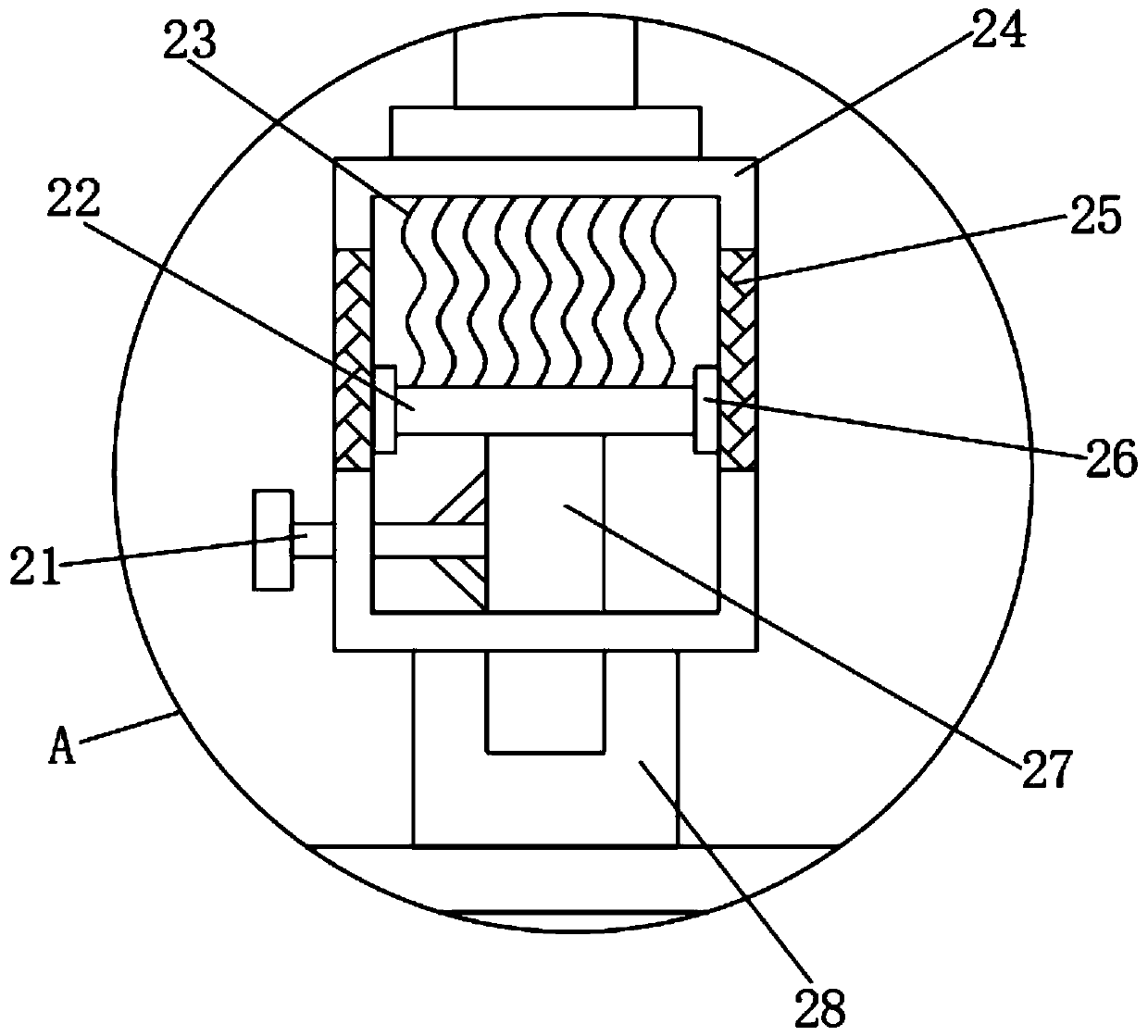

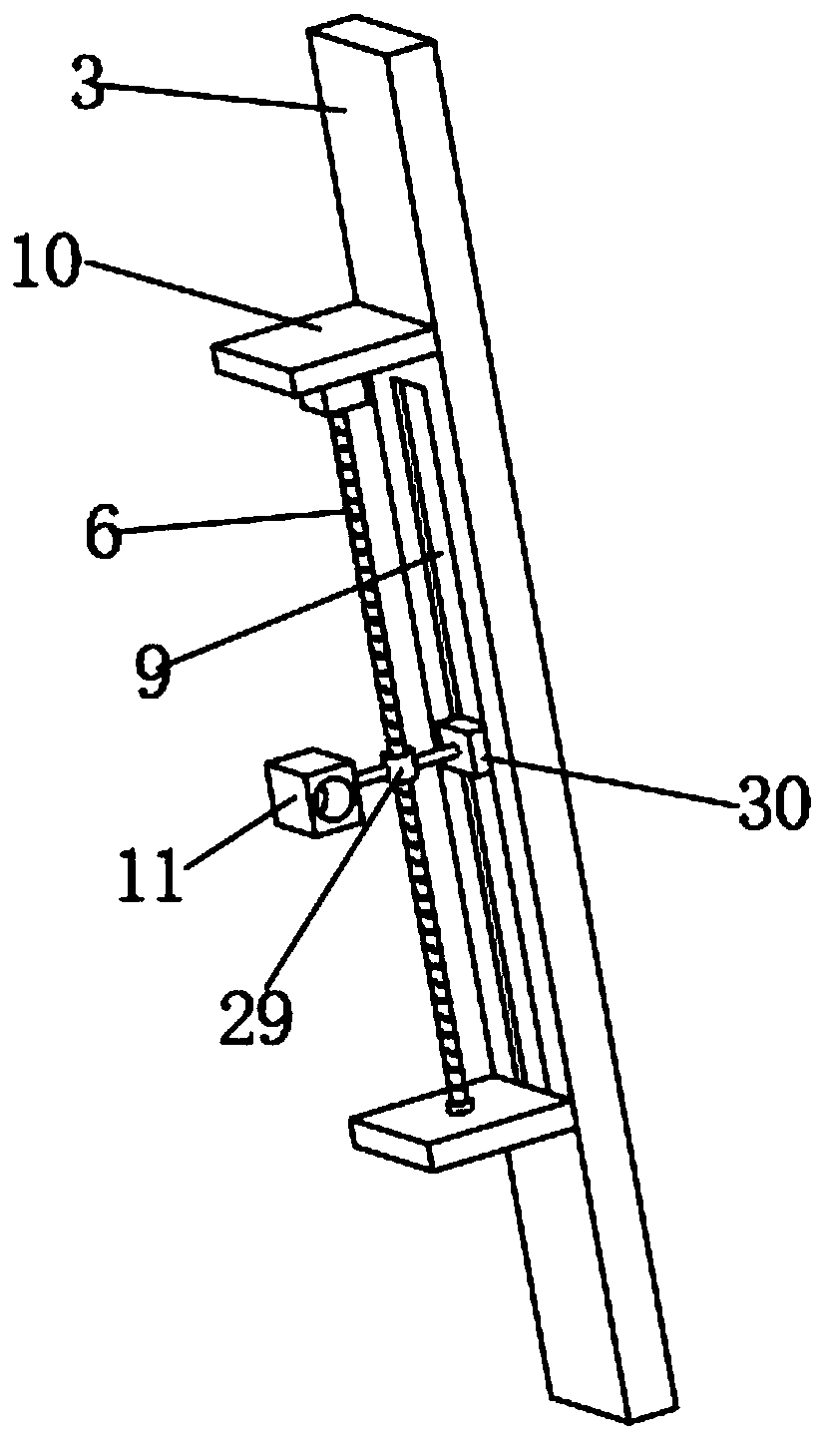

[0031] refer to Figure 1-3 , a cable tube type twisting device for Wujinjiaodian equipment processing, including a box body 1, a second motor 4 is connected to the top outer wall of the box body 1 by bolts, and the outer wall of one end of the output shaft of the second motor 4 is connected by bolts. Sleeve 24, one side inner wall of sleeve 24 is welded with spring 23, and the outer wall of one end of spring 23 is welded with connection disc 22, and the outer wall of both sides of connection disc 22 is all connected with second slide block 26 by bolt, and connection disc 22 One side of the outer wall of the card column 27 is connected with a clamping post 27 by bolts, and one side of the card post 27 is connected with a handle 21 by bolts, and one end of the clamping post 27 is clamped with a fixing seat 28, and one side of the fixing seat 28 The outer wall is connected with a Take-up roller 7, one side outer wall of box body 1 is connected with third motor 15 by bolt, and on...

Embodiment 2

[0035] refer to Figure 4-5 , a cable tube type stranding device for Wujinjiaodian equipment processing. Compared with Embodiment 1, the outer wall of one side of the twisting reel 20 is connected with a fixing plate by bolts, and the bottom outer wall of the fixing plate is connected by bolts. There is an electric push rod 31, the outer wall of one end of the electric push rod 31 is connected with a fixed plate by bolts, and the outer wall of one end of the fixed plate is connected with a snap ring 32 by bolts.

[0036] Working principle: when in use, when people twist the cable body 33, people pass a plurality of cables through the through slot 12, and when the cables pass through the through slot 12, people start the third motor 15, and the third The motor 15 drives the twisting reel 20 to rotate, so that the twisting work of the cable can be completed. At the same time, people can start the electric push rod 31 when the cable is twisted, and the electric push rod 31 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com