Patents

Literature

76results about How to "Meet winding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

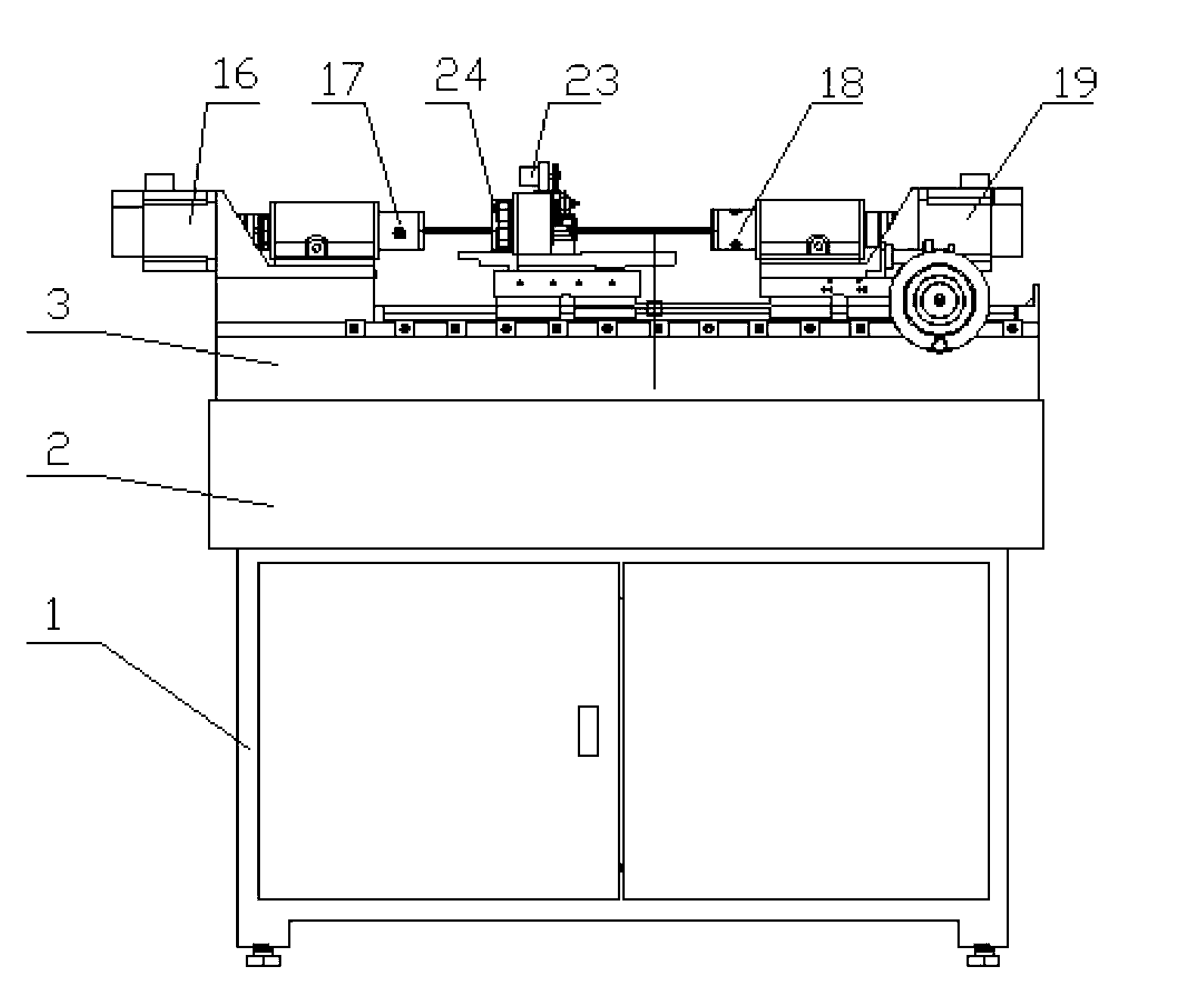

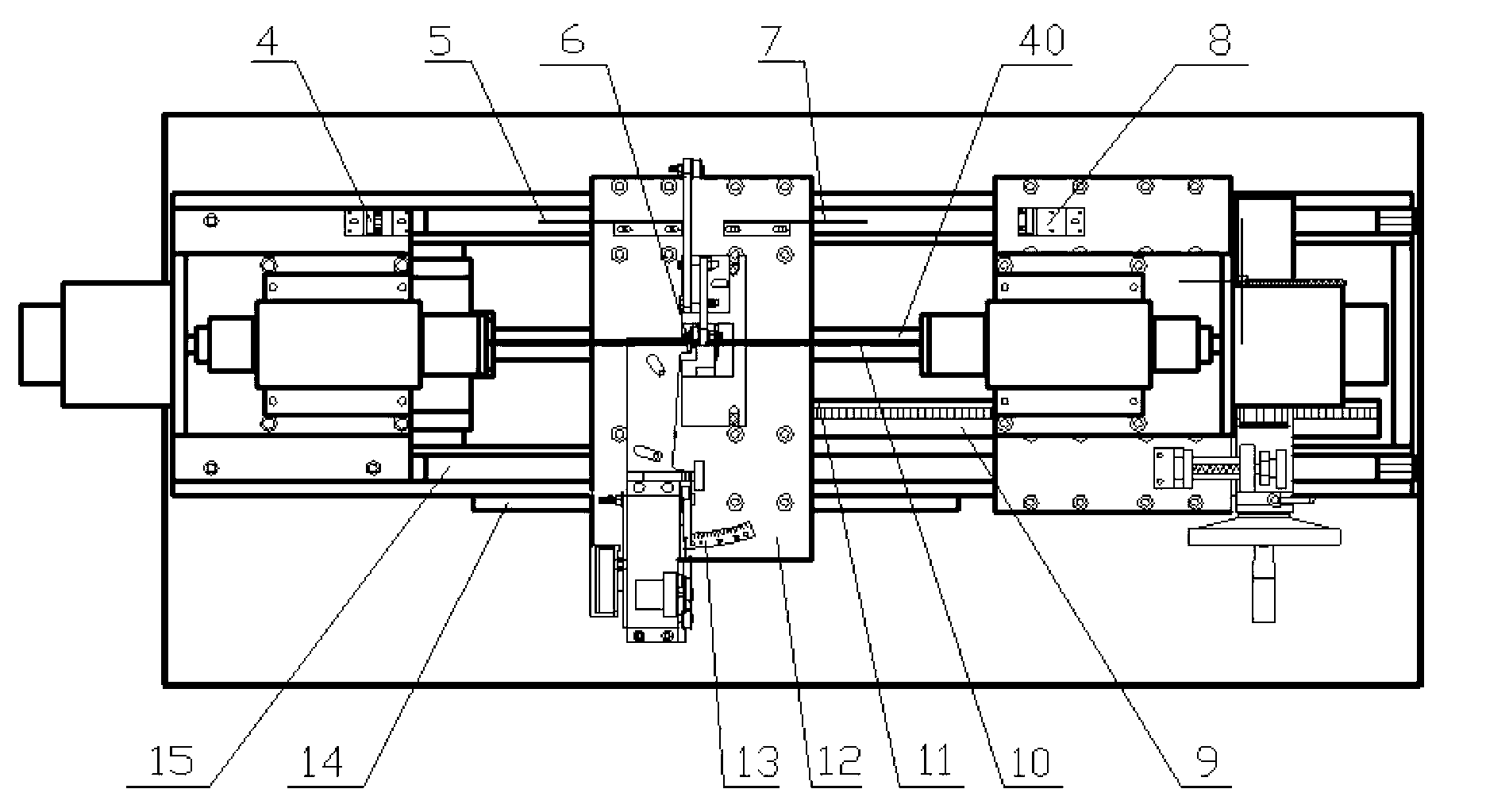

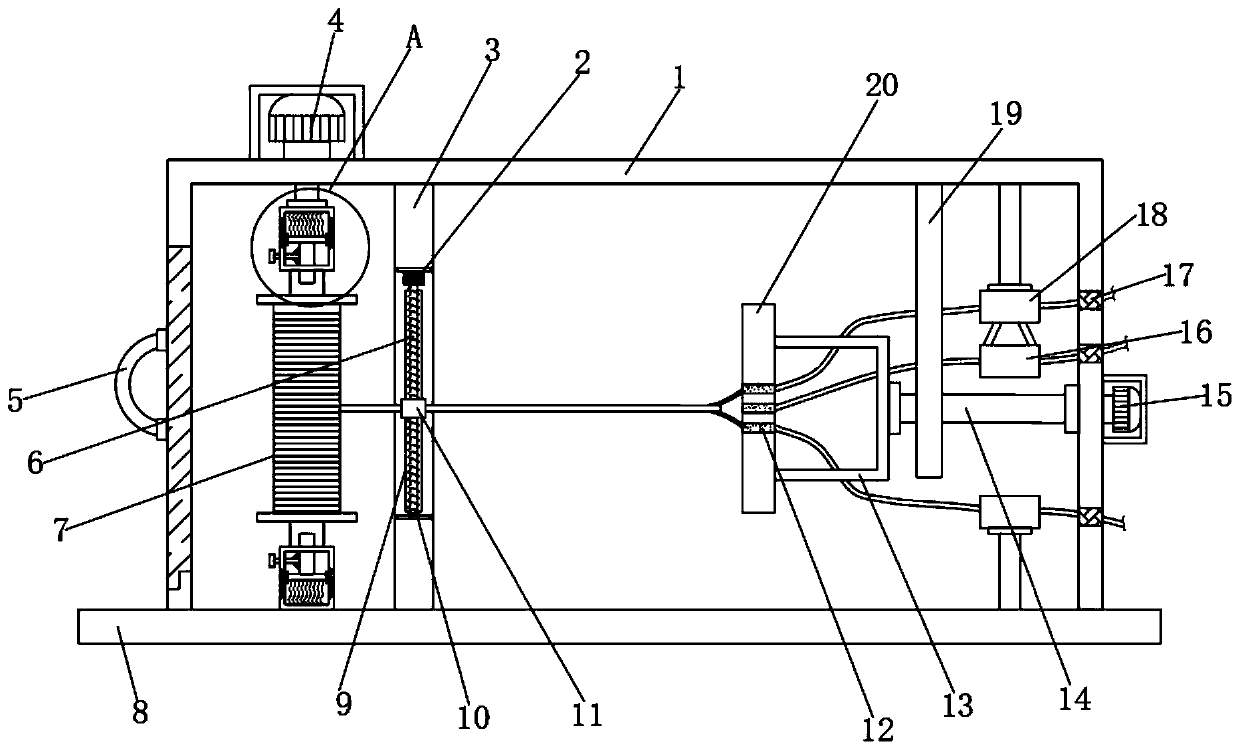

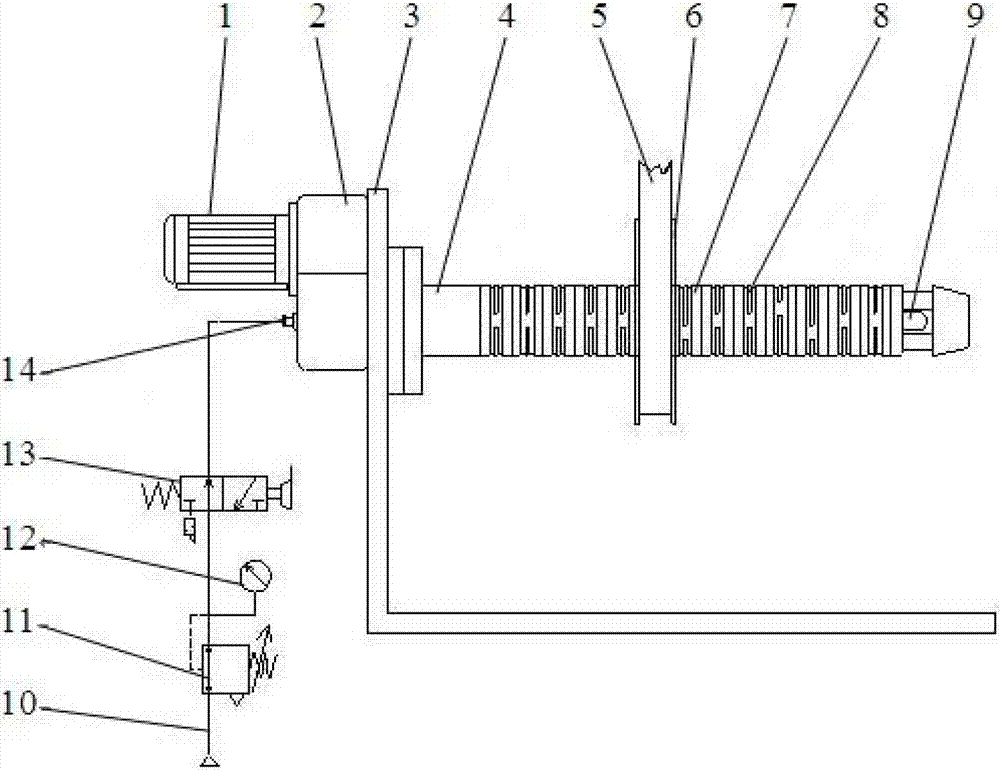

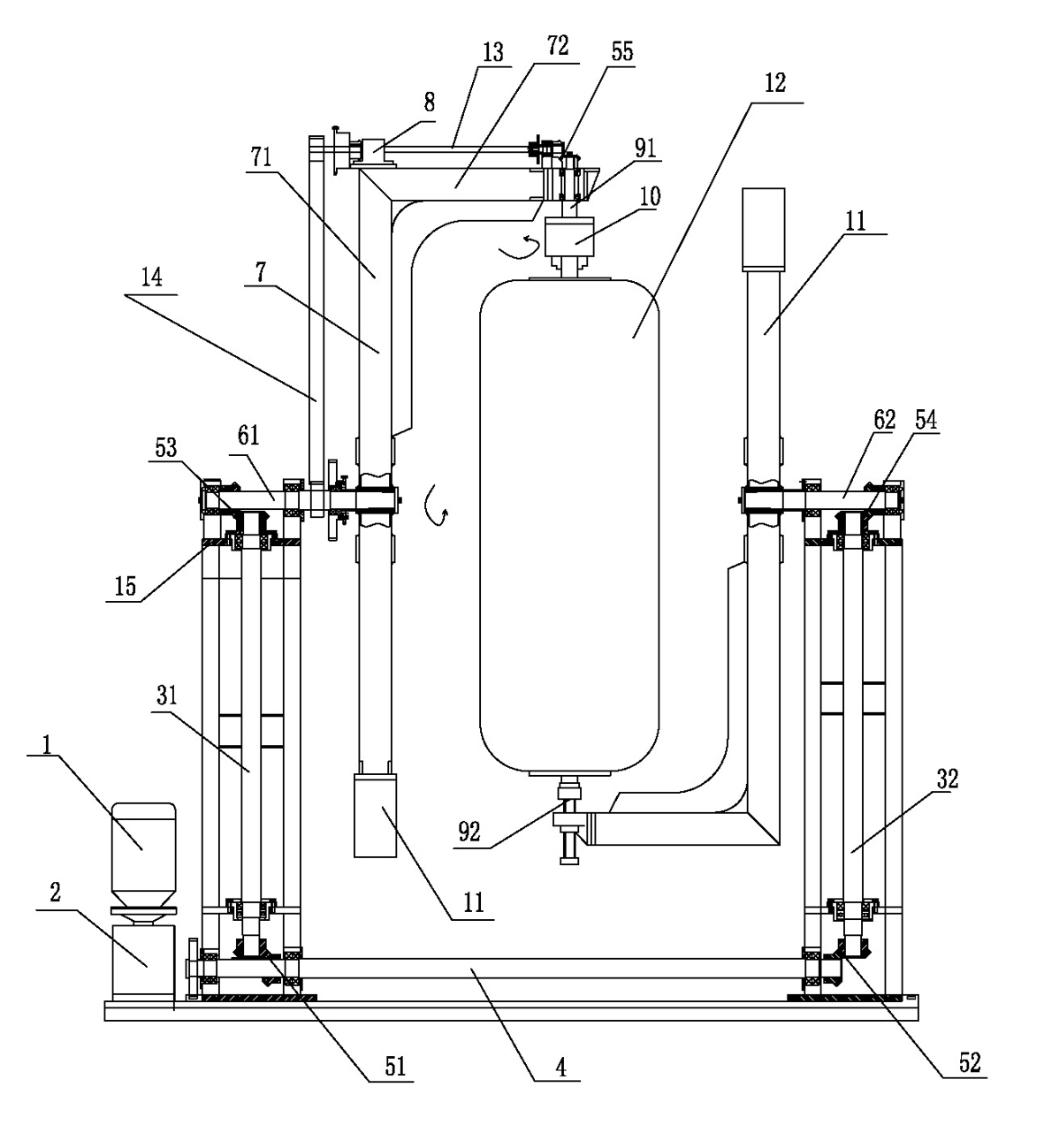

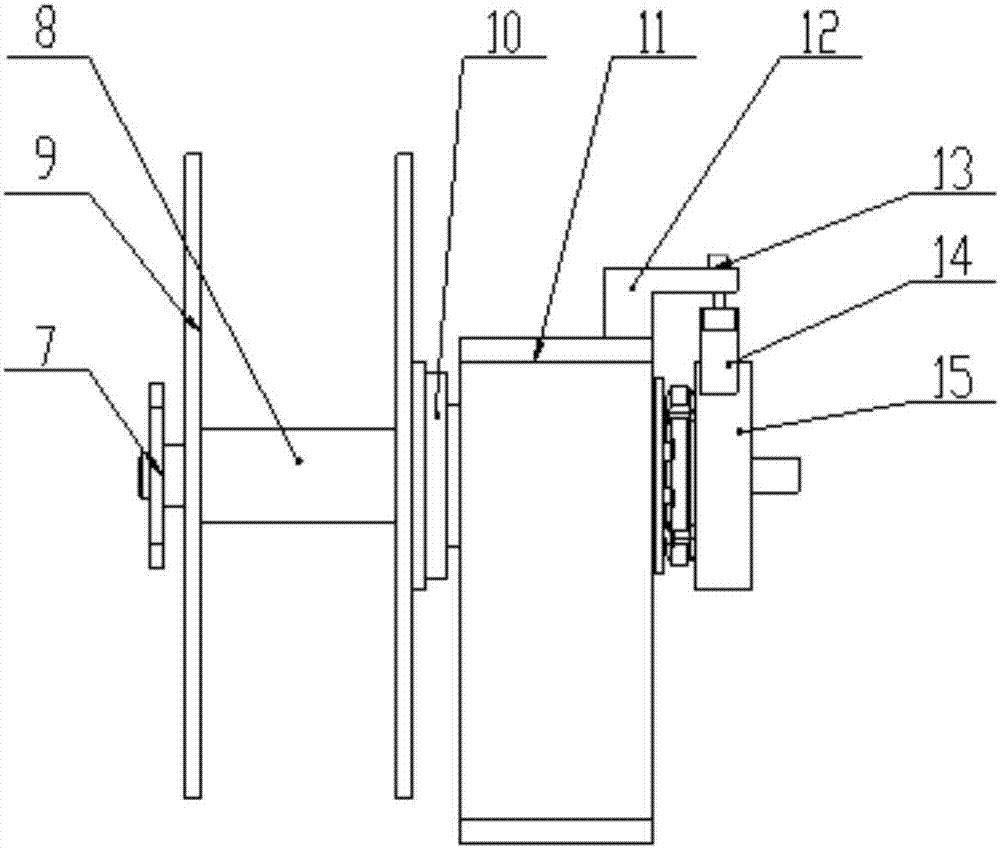

High-precision spiral wire winding machine

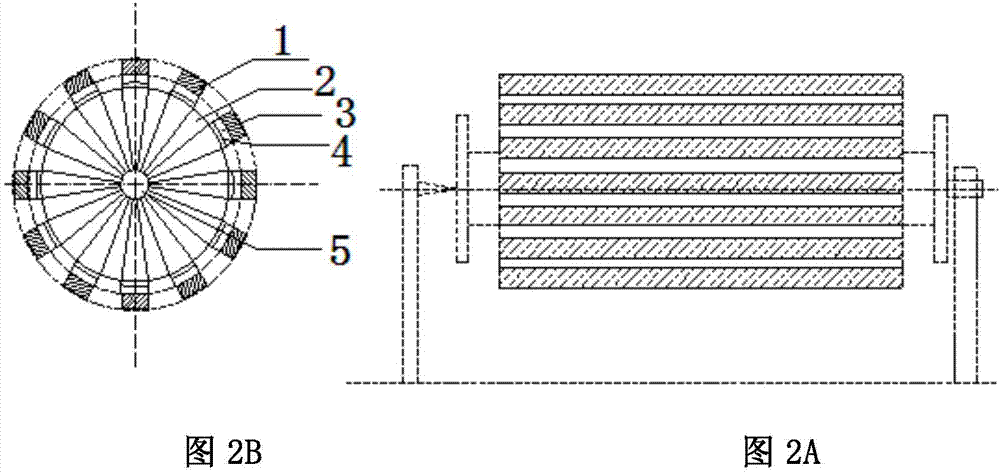

InactiveCN103317063AEasy to transformDeformation reachesMetal-working feeding devicesPositioning devicesWinding machineClosed loop feedback

The invention discloses a high-precision spiral wire winding machine. By coordinated movement of a wire winding mechanism, a wire guiding mechanism, a wire discharging mechanism with a torque motor and a magnetic powder brake in combined action, a working table driving mechanism, a locking mechanism with a mandrel tension adjusting device, a position detection system used for accurately controlling working table movement and detecting and monitoring the closed loop feedback position and an electrical control system, a wire or a strip spiral wire is wound at a high precision, the spiral wire types comprise equal screw pitch, gradual change screw pitch, jumping screw pitch and mixed screw pitch of the wire or a strip and edgewise winding of the strip, and the screw pitch error is smaller than 2 mu m. The high-precision spiral wire winding machine is further provided with a heating device for the wire or the strip, the wire or the strip which is hard is deformed easily by heating before wound on a mandrel, and the goal of winding is achieved. The spiral wire winding machine is low in cost and meets the multi-mode high-precision spiral wire production requirements of communication enterprises and national defense industries.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

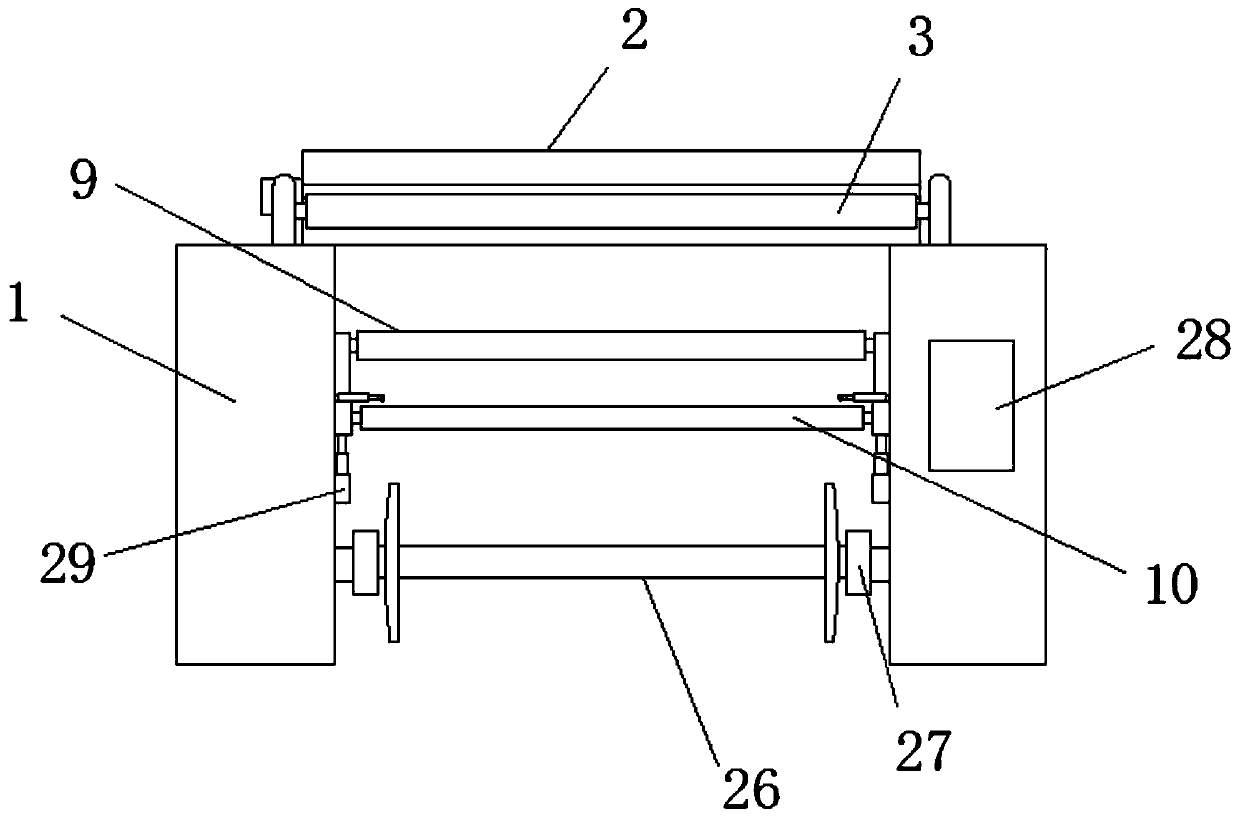

Winding device for textile machine

InactiveCN110550487AImprove flatnessAvoid affecting the winding effectWebs handlingWrinkle skinDrive motor

The invention provides a winding device for a textile machine. The winding device comprises a winding frame; a destaticizing box is fixedly connected with the top end of the winding frame; a smoothingroll is arranged on one side of the destaticizing box; ion fans are fixedly connected with the top end in the destaticizing box; a press roll is rotationally connected into the destaticizing box; a pull roll is arranged at the bottom end of the press roll; spiral pull belts are arranged at the inner parts of the two ends of the pull roll; the spiral directions of the spiral pull belts at the twoends of the pull roll are opposite; a driving motor is fixedly connected to one side of the destaticizing box; a tension regulating roll is rotationally connected into the winding frame; a transfer roll is arranged at the bottom end of the tension regulating roll; and movable blocks are arranged at the two ends of the transfer roll. The phenomenon that when being wound, textile cloth wrinkles canbe effectively prevented, meanwhile, the movement position of the textile cloth can be adjusted, so that the textile cloth is not likely to deviate, and the winding effect of the winding device on thetextile cloth is improved.

Owner:黄山佳诺化纤纺织有限公司

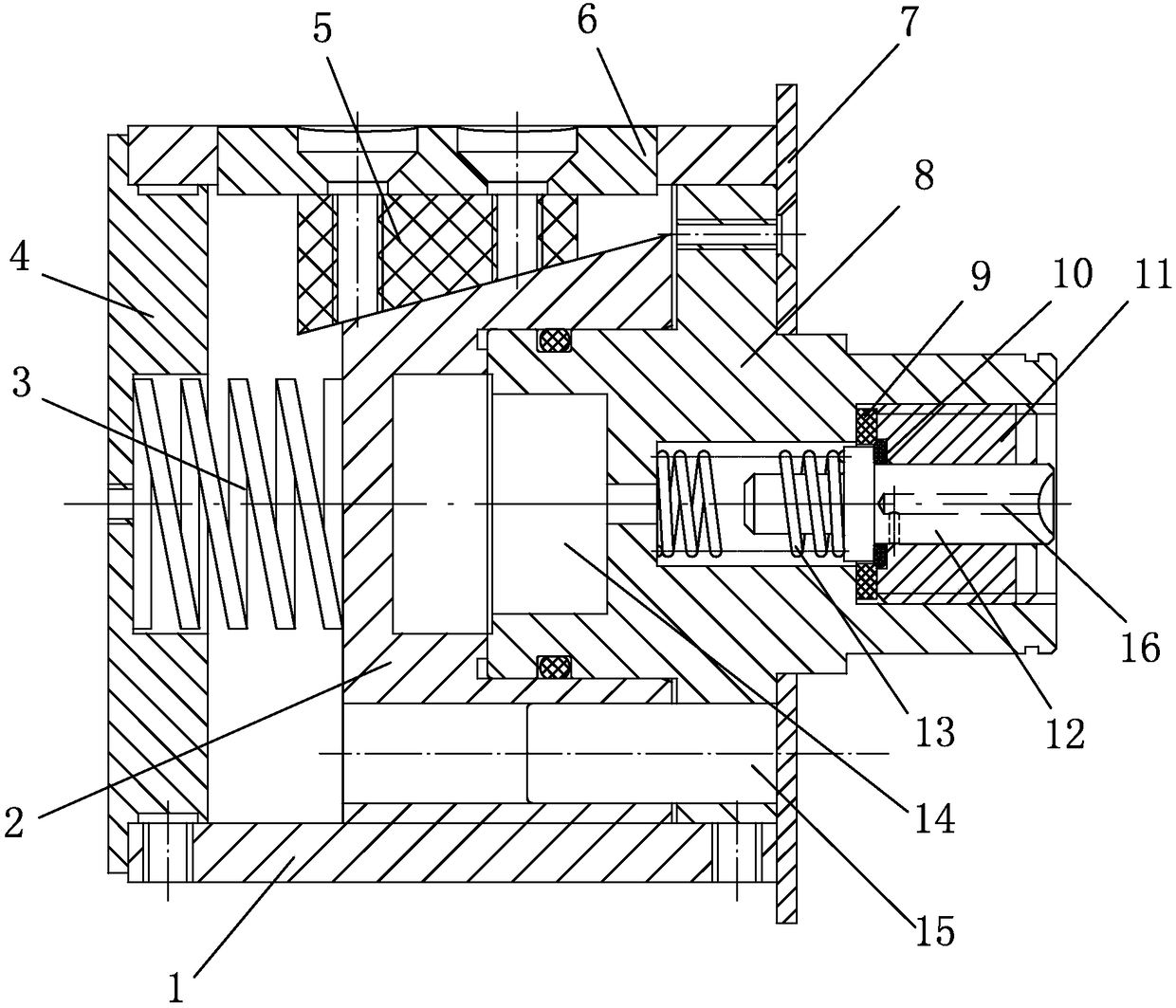

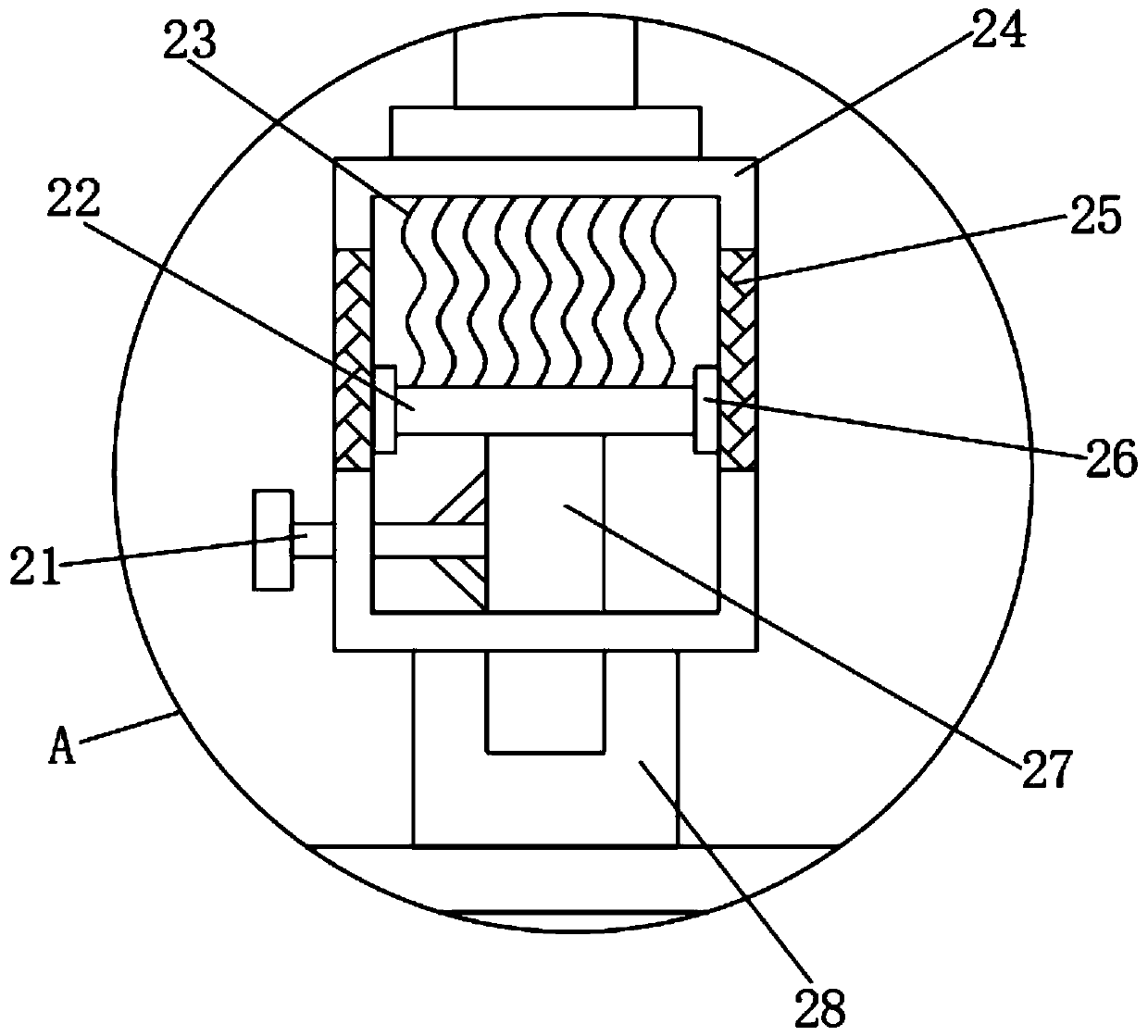

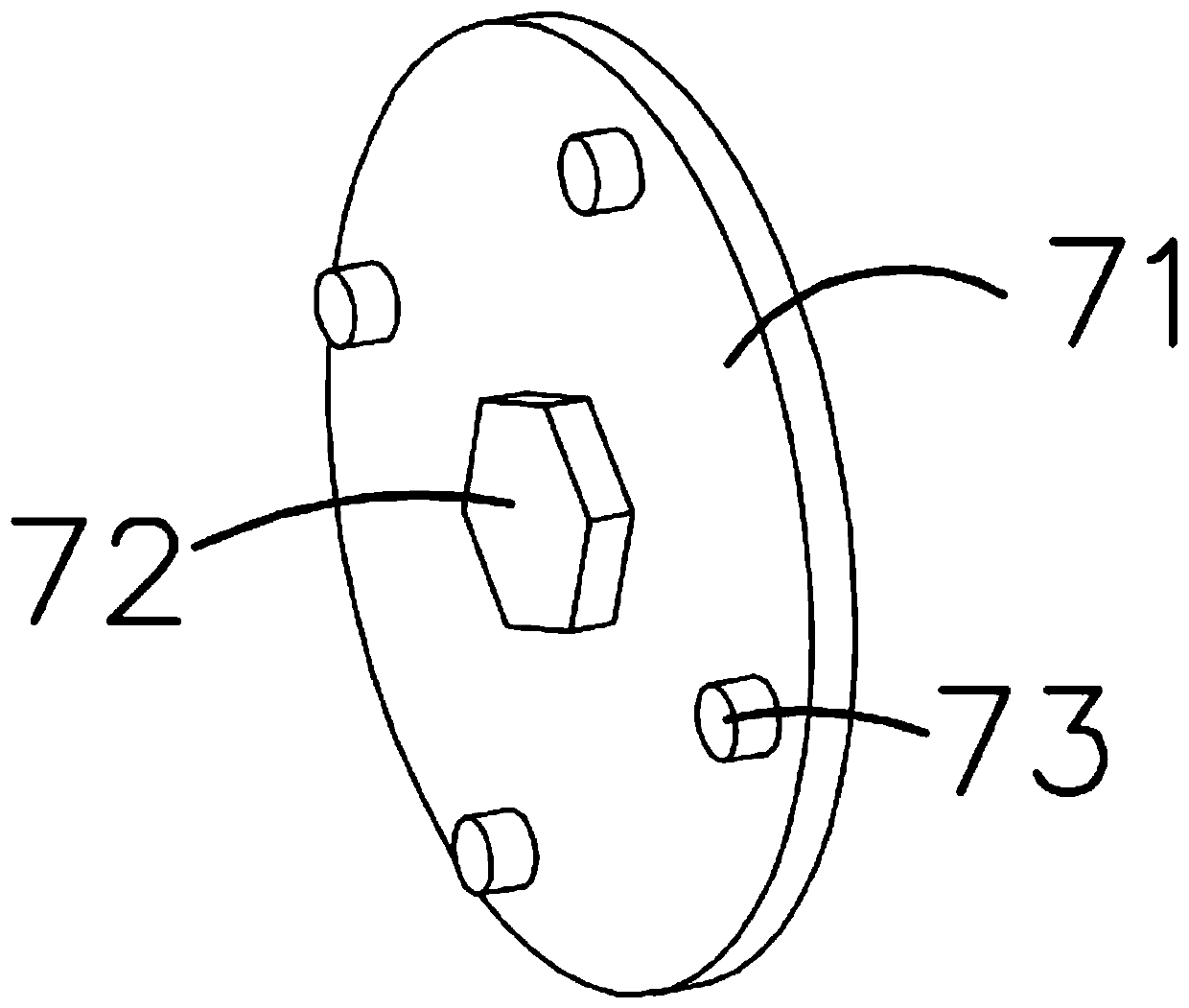

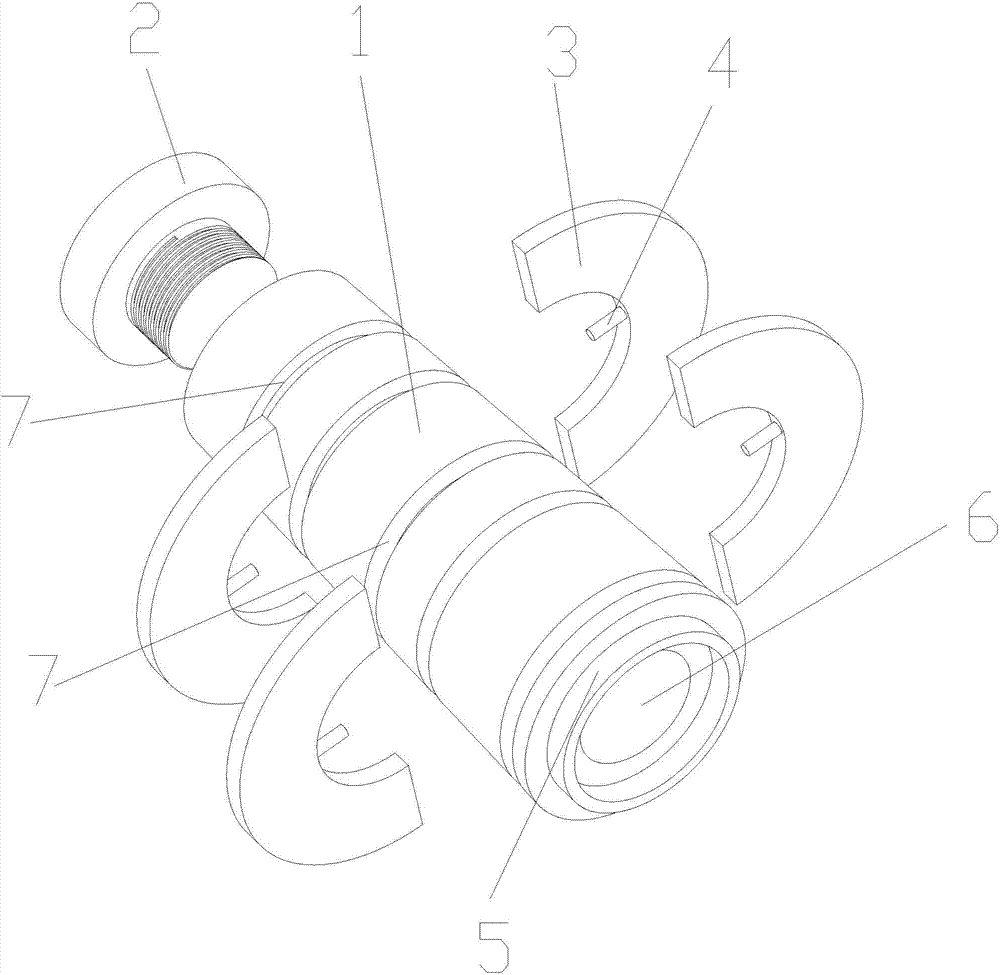

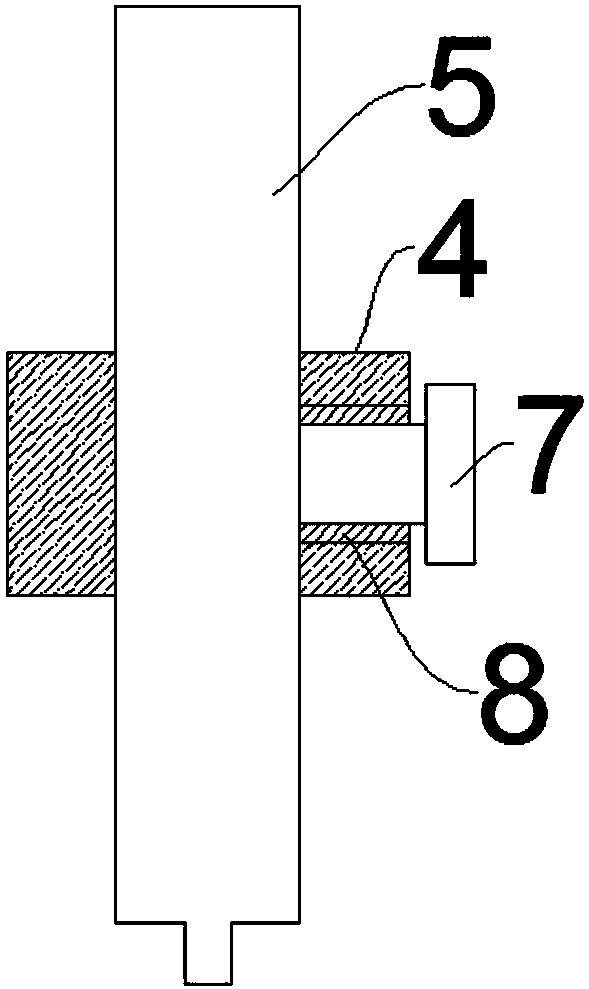

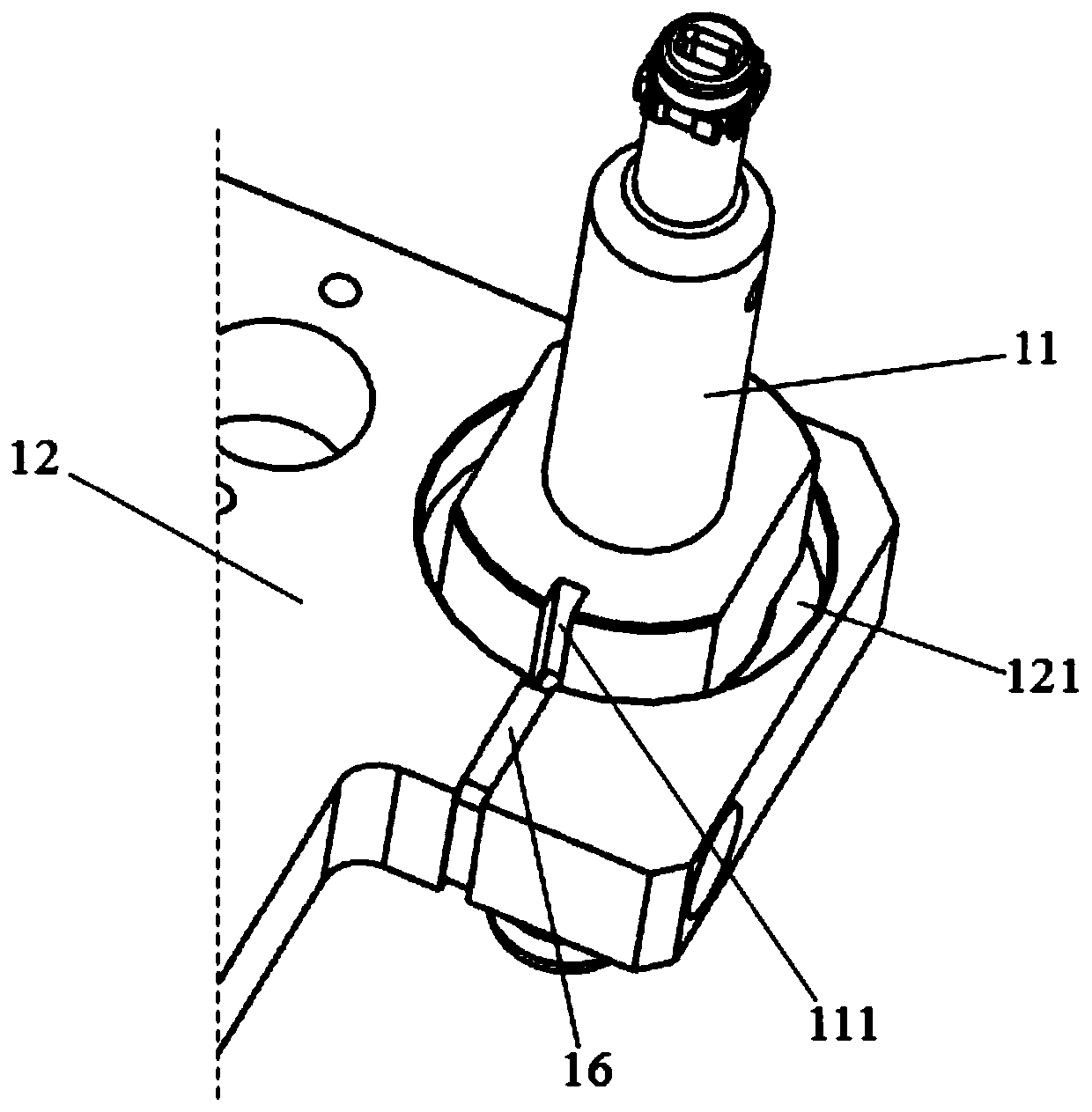

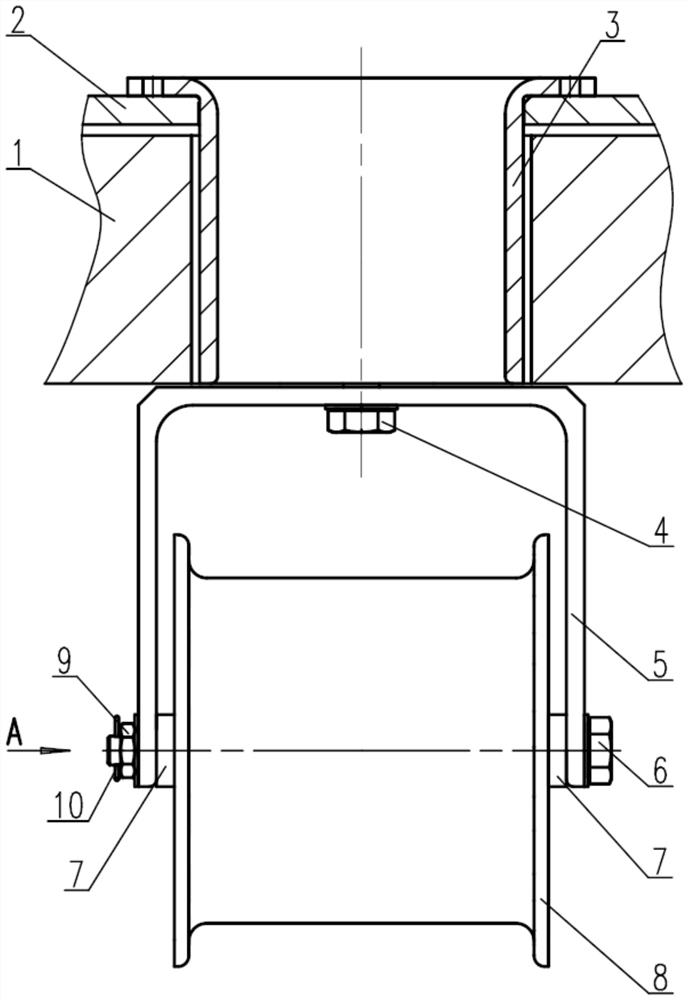

Inflatable winding chuck of slitting machine

The invention relates to an inflatable winding chuck of a slitting machine, comprising: a jacket; an end shaft partially extended into the jacket, wherein the extension end is in shrinking-end steppedstructure, the end shaft is axially provided with a three-segment stepped hole, a nozzle / gasket and a lock collar / O-shaped ring are arranged in the three-segment stepped hole, the outer edge of the O-shaped ring is abutted to the corners of the peripheral wall of a bore of the gasket, the nozzle is provided with a first spring at its left shaft segment, a right shaft segment of the nozzle is in sliding fit with the lock collar, the right shaft segment is provided with an intake passage, an inlet of the intake passage is positioned at the end of the right shaft segment, and an outlet of the intake passage is positioned on the outer periphery on the right of the O-shaped ring; a steel core, wherein the middle of the right end of the steel core is provided with a groove, the left end of thesteel core is provided with a second spring, and the outer peripheral face of the spring end is provided with a plurality of slants; and a plurality of expansion blocks. A cavity is arranged between the bottom of the groove of the steel core and the end face of the end shaft and is communicated with a left part of the three-segment stepped hole. After inflating, pressure can be automatically held;overall size is greatly reduced, the radial size of the whole structure can be reduced particularly, and the need for winding barrels having small inner diameter is met.

Owner:杭州大华工控技术有限公司

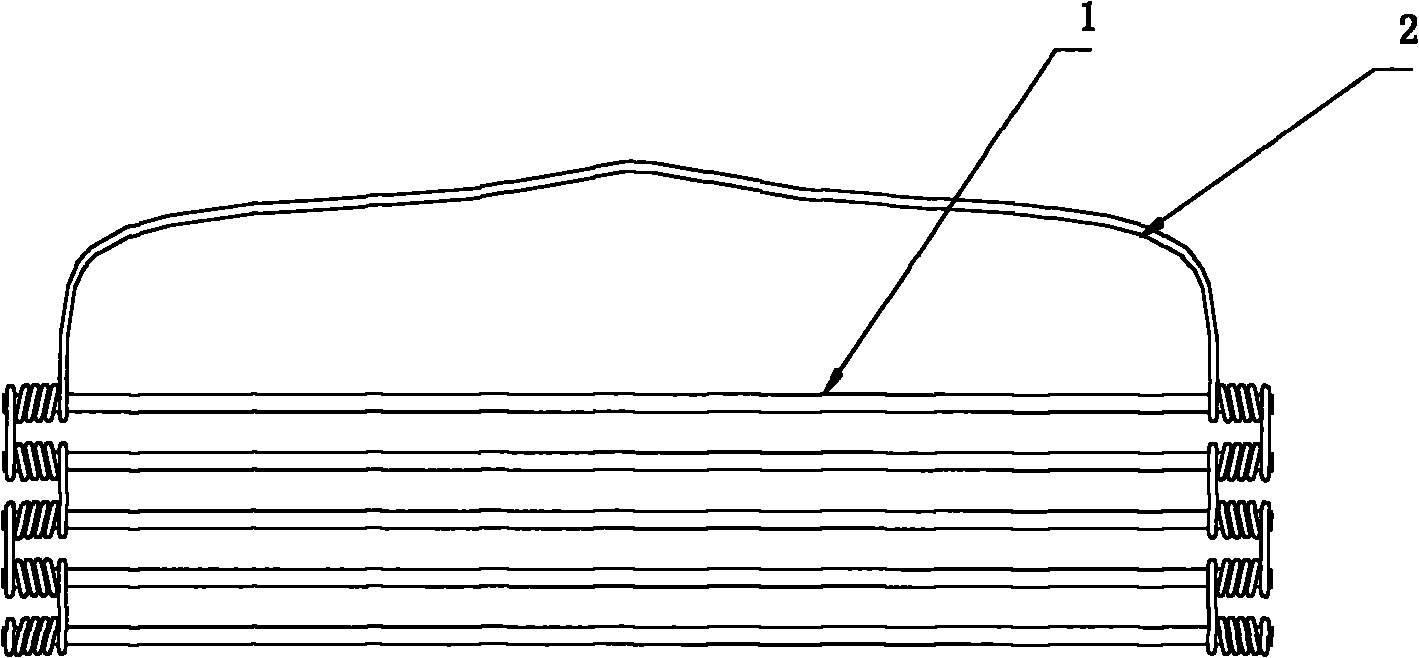

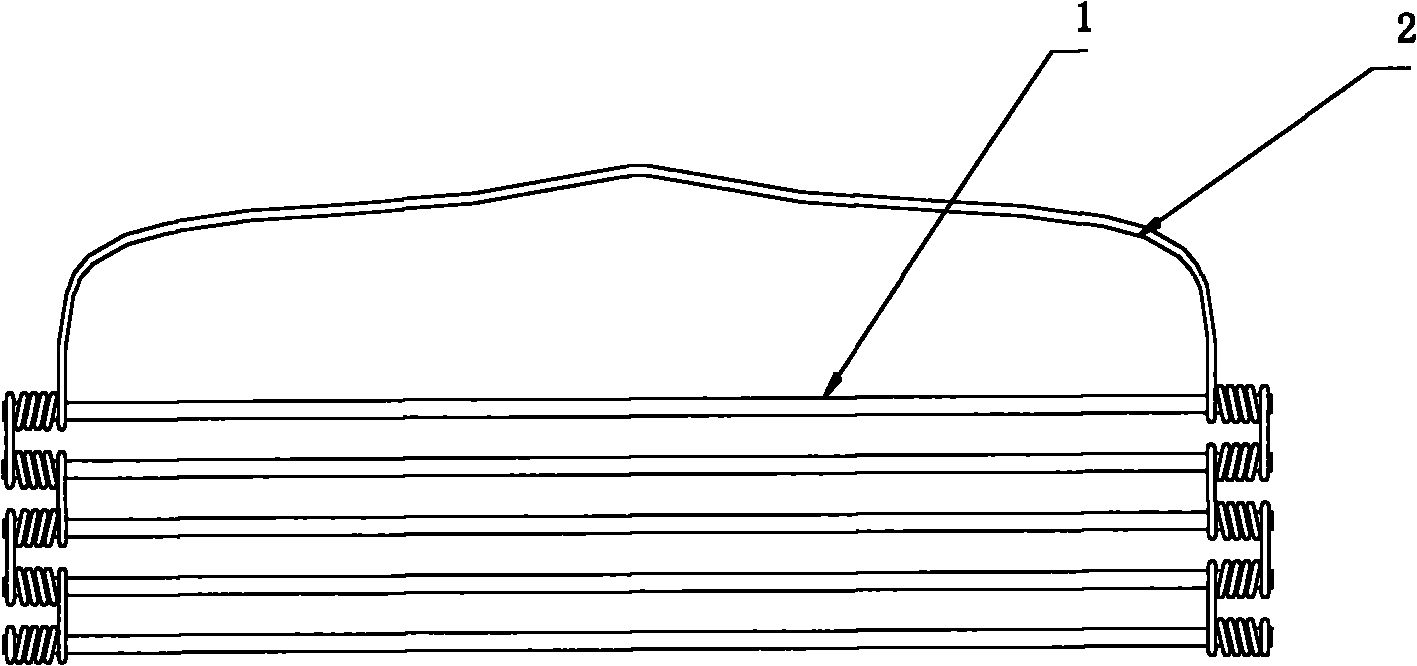

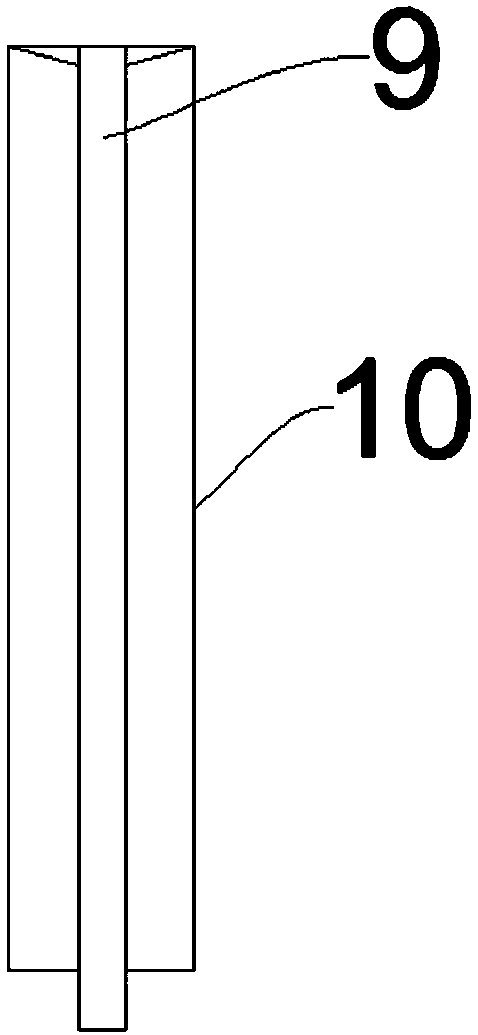

Method for plating chromium on molybdenum core rod

The invention discloses a method for plating chromium on a molybdenum core rod, which comprises the following steps: 1) closely winding the two ends of a metal wire (2) on the two ends of the molybdenum core rod (1) and fully cleaning the molybdenum core rod by a chemical method; 2) turning on a plating power supply, immediately connecting the molybdenum core rod (1) with the negative electrode of the plating power supply and placing the molybdenum core rod into a plating tank in which chromium plating solution is accommodated so as to start to electroplate, wherein the anode is made of the lead-antimony alloy containing 10 percent of antimony; 3) controlling the temperature of the chromium plating solution within the range from 40 to 70 DEG C during the electroplating, wherein the power cannot be interrupted during the electroplating process; and 4) taking the molybdenum core rod (1) out and then turning off the plating power supply after the electroplating. The method for plating the chromium ensures bright and clean, compact and non-scaling surface with high adhesion of the metal chromium layer plated on the molybdenum core rod by selecting the optimal plating process, matching the shape of a workpiece with that of the anode and completely cleaning the molybdenum core rod before plating so as to meet the winding requirements of a helix traveling-wave tube on a helix line.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

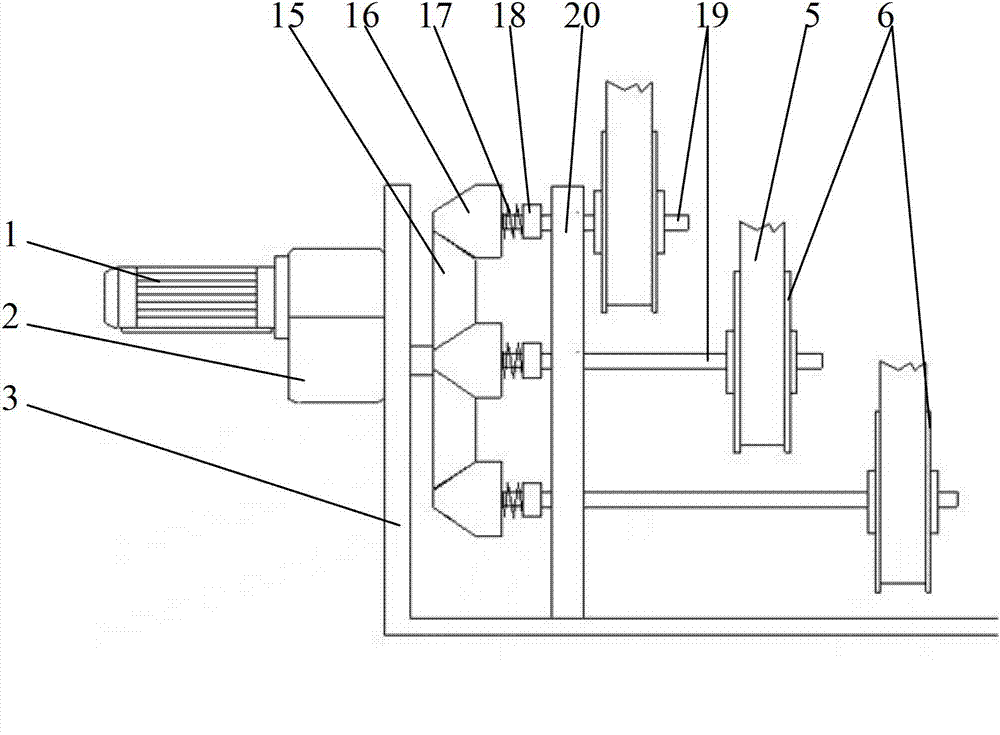

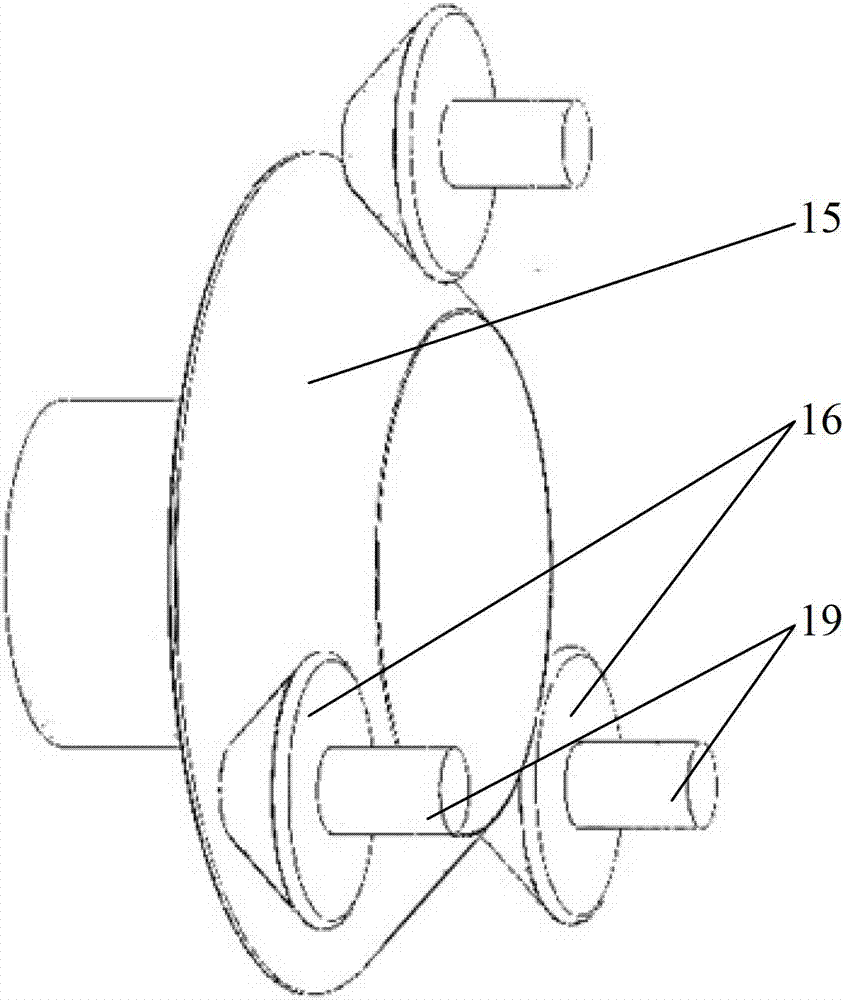

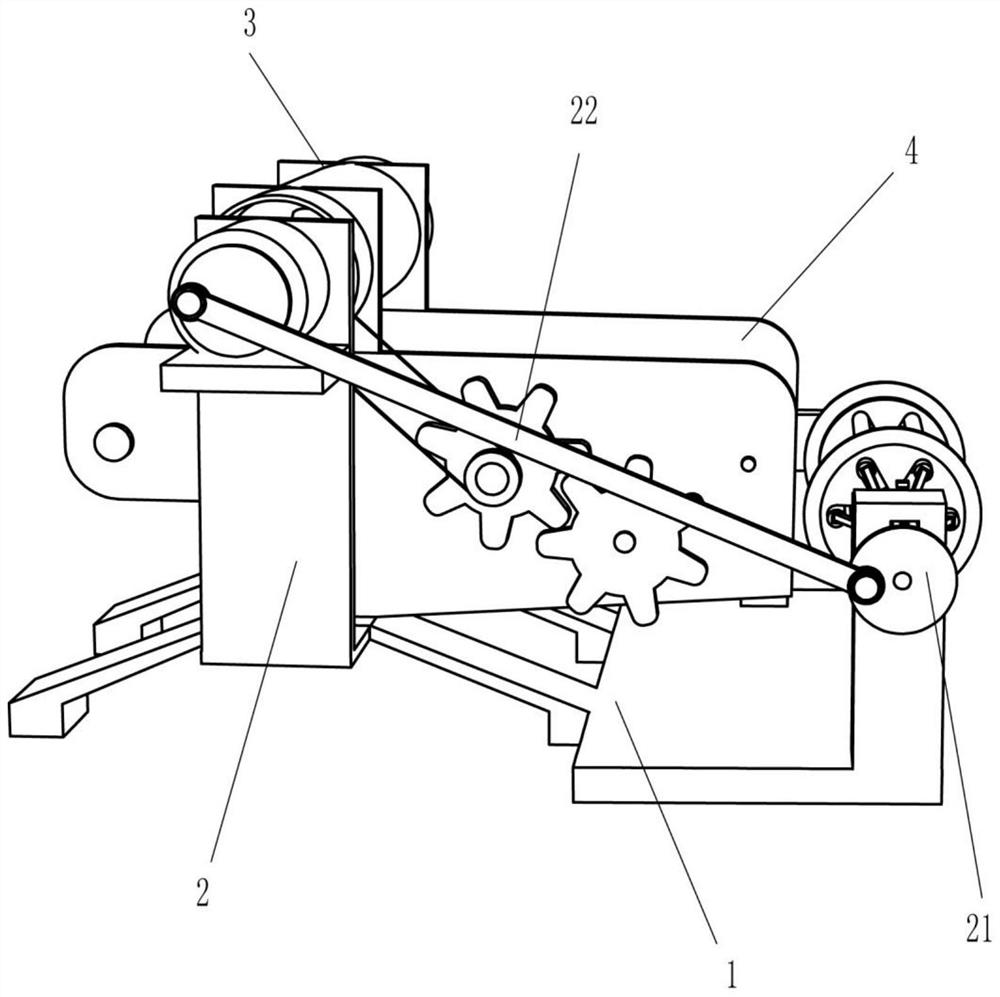

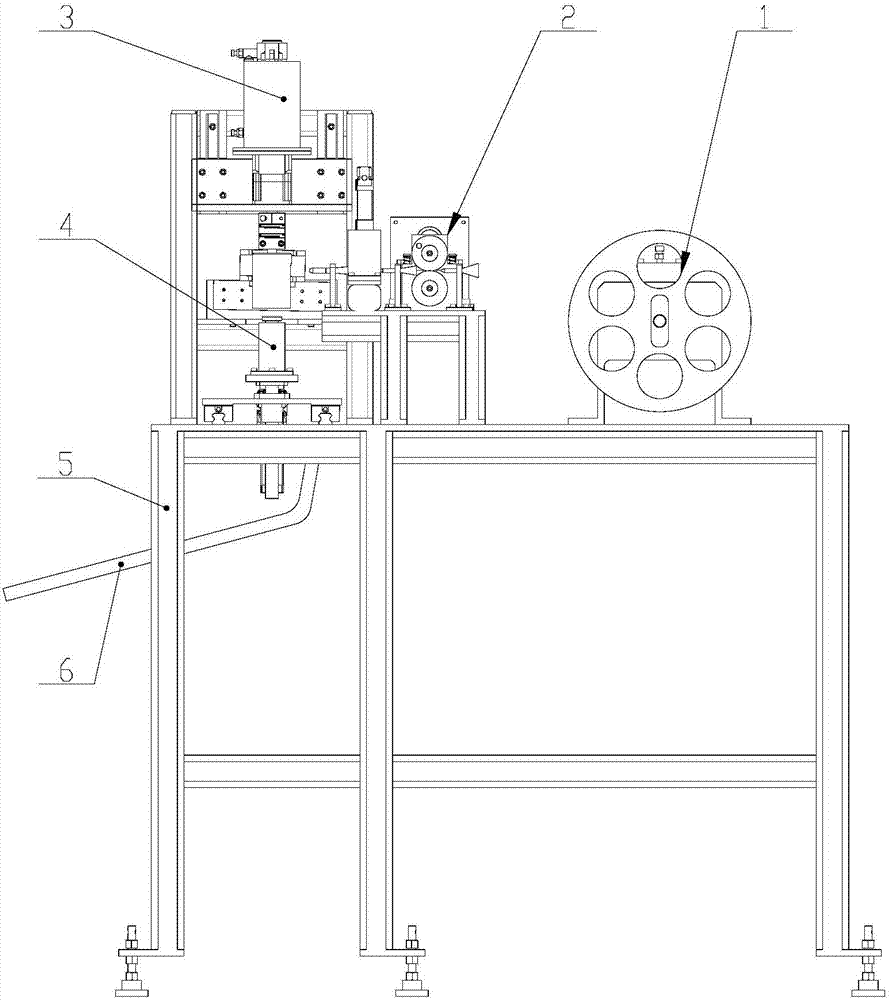

Coil winding machine for large power three-phase stator coils

InactiveCN102694442AIncrease productivityImprove coil performanceManufacturing dynamo-electric machinesWinding machineThree-phase

The invention discloses a coil winding machine for large power three-phase stator coils, comprising a shaft box, a wire laying mechanism, a wire hanging mechanism and a coiling die mechanism, and characterized in that the coiling die mechanism comprises an upper die and a lower die. The upper die and the lower die are symmetrically arranged to the center of a rotary main shaft. The bottom of the upper die and the bottom of the lower die are respectively provided with a pedestal. The upper die and the lower die are connected with a rotating table by a demoulding apparatus through the corresponding pedestal. The demoulding apparatus comprises a contraction cylinder, a central shaft in connection with the contraction cylinder, a contraction linkage in connection with the tip of the central shaft and a guiding mechanism vertically arranged to the rotary main shaft. The central shaft is in sliding connection with the rotary main shaft. The coil winding machine is formed by the upper die and the lower die arranged symmetrically and the dies are connected with the rotary table by the demoulding apparatus, realizing the coiling and automatic demoulding for large power coils with improved production efficiency and coil performance and mitigated labor intensity.

Owner:NIDE MECHANICAL EQUIP

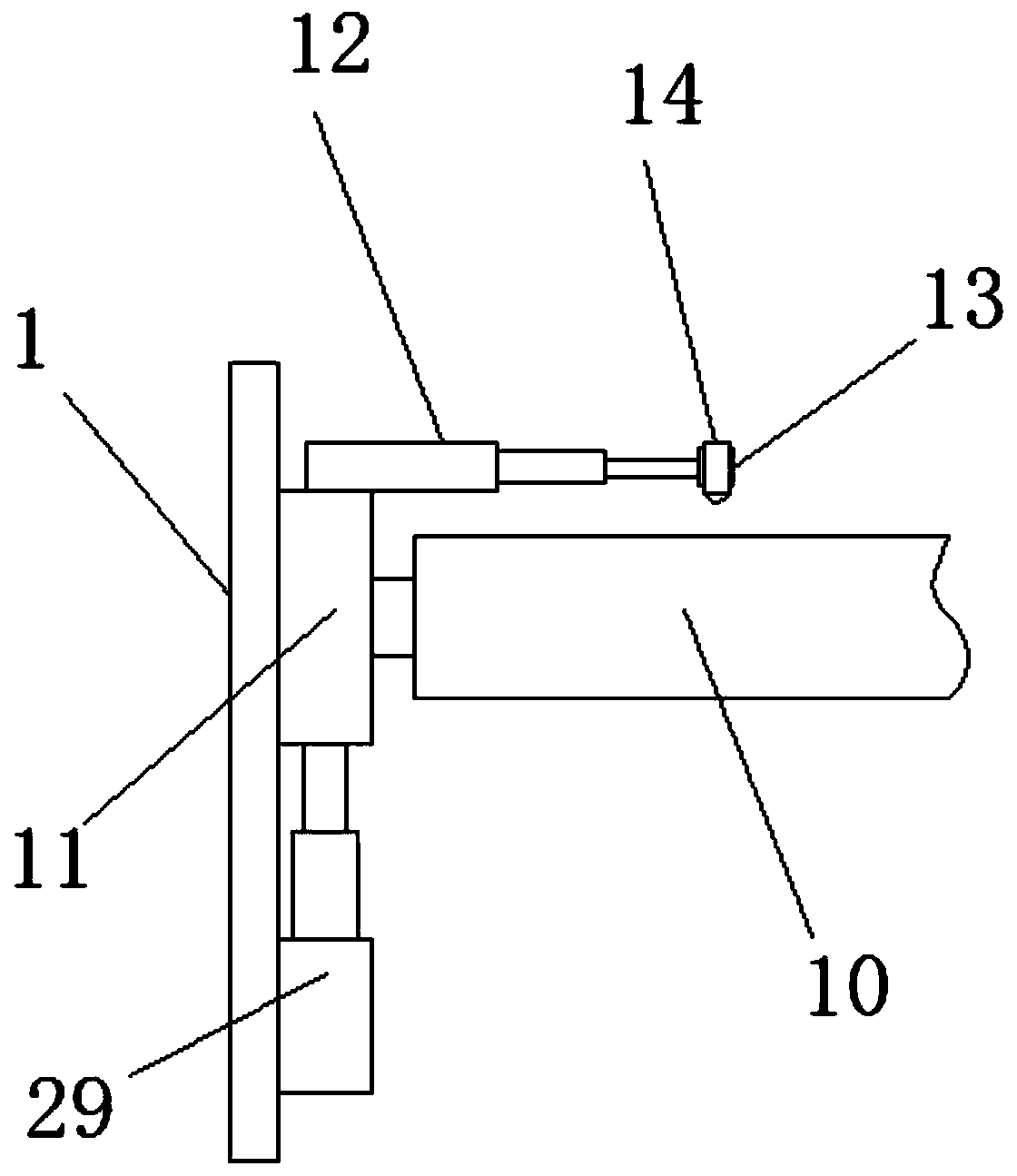

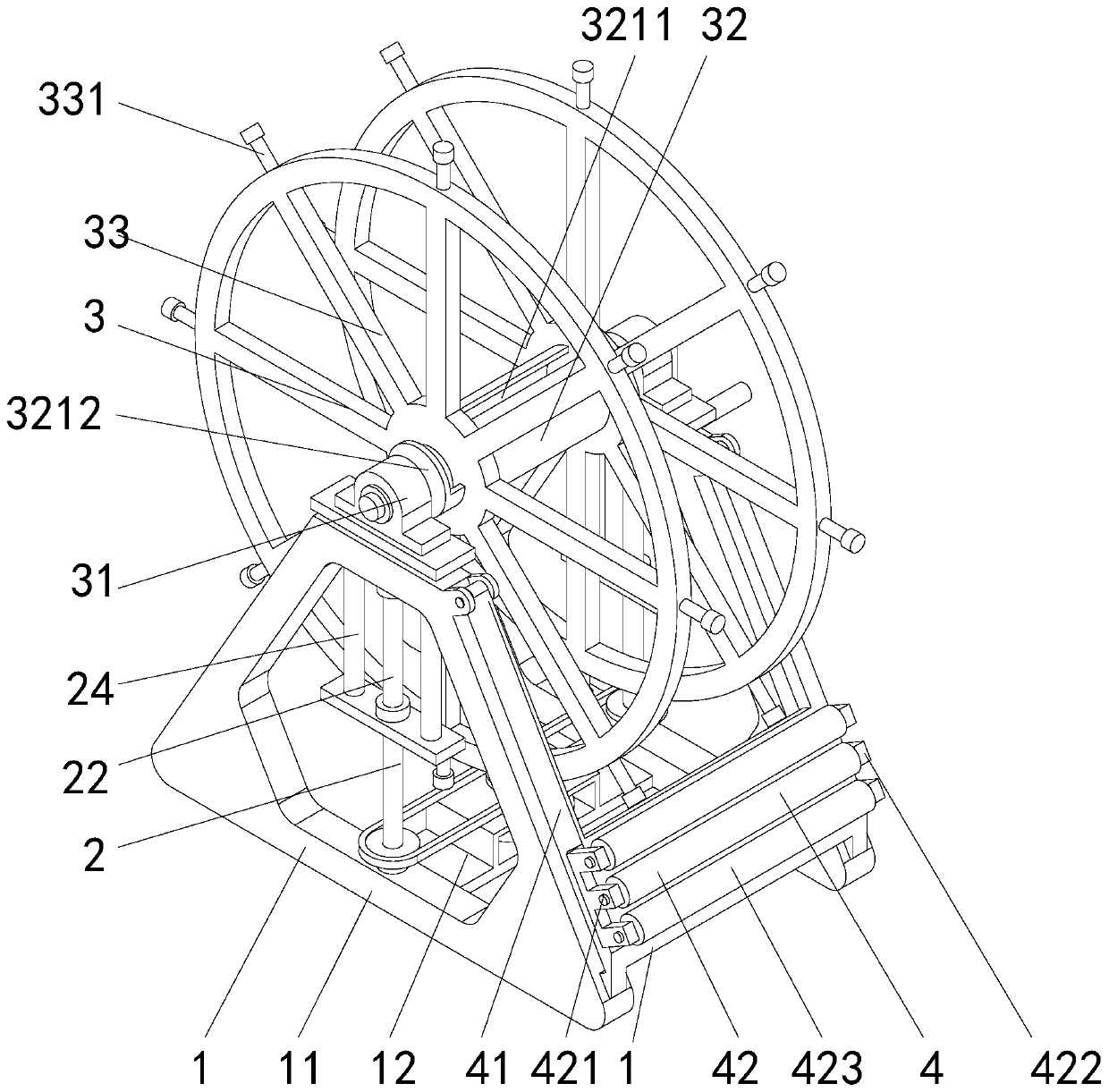

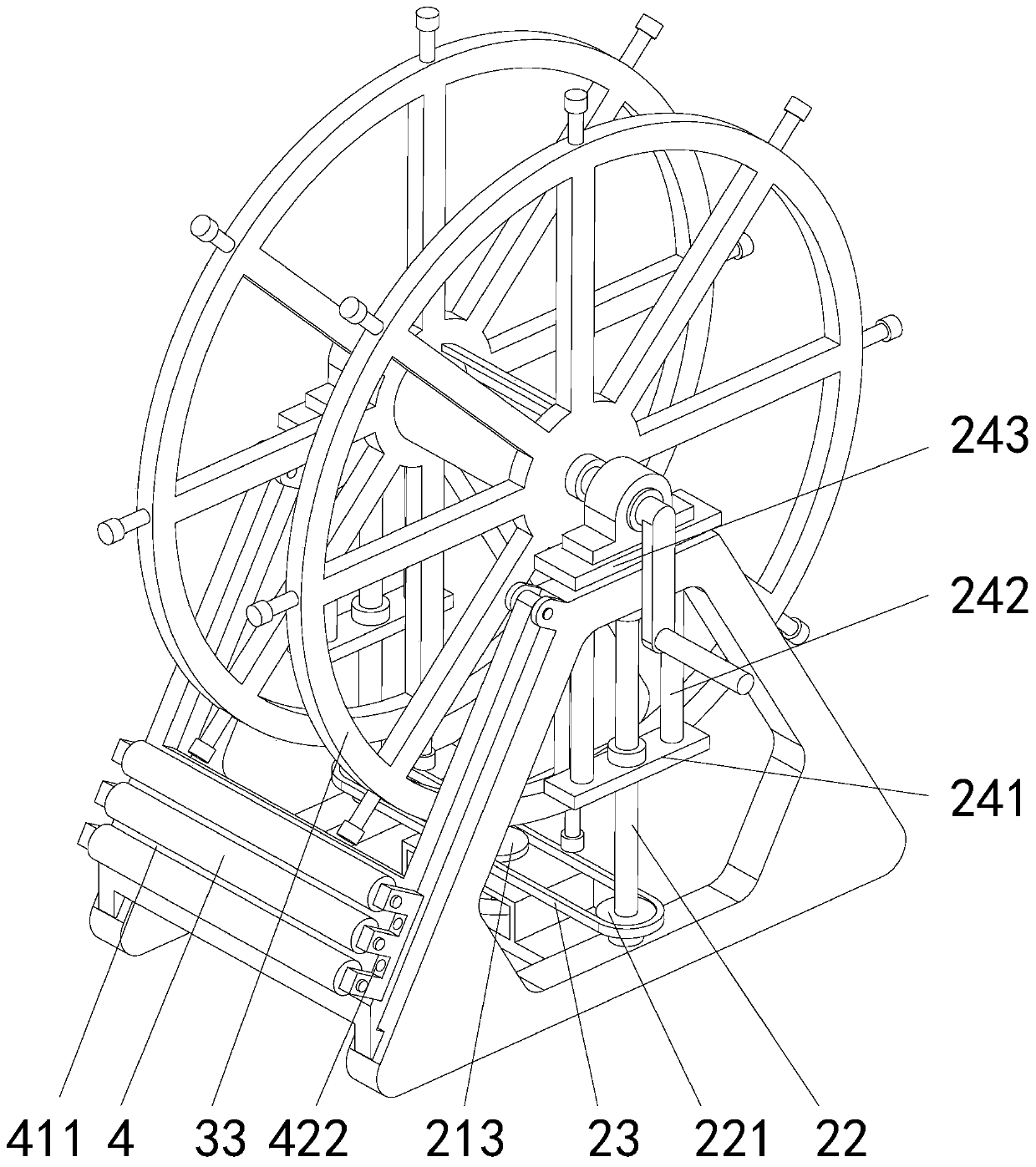

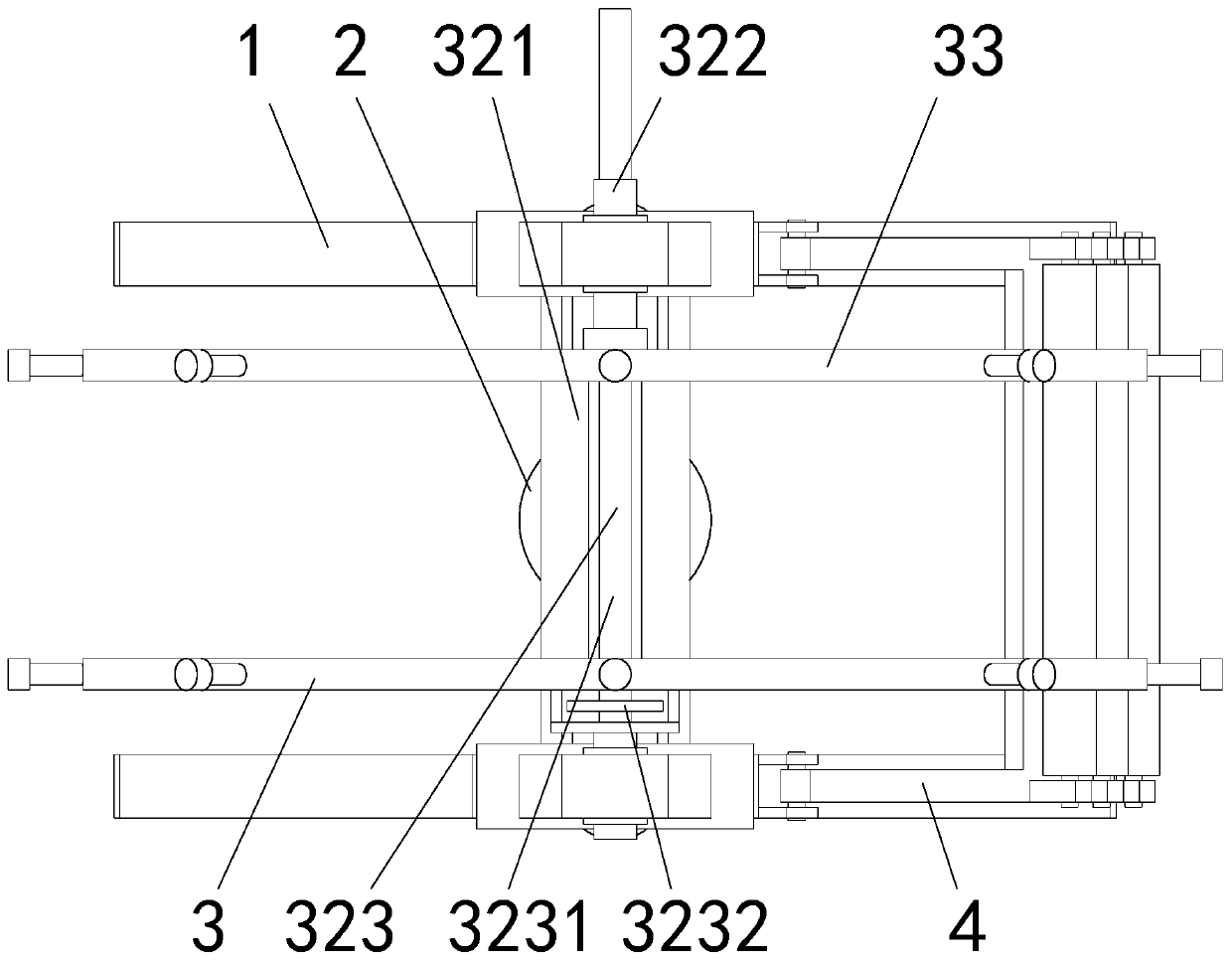

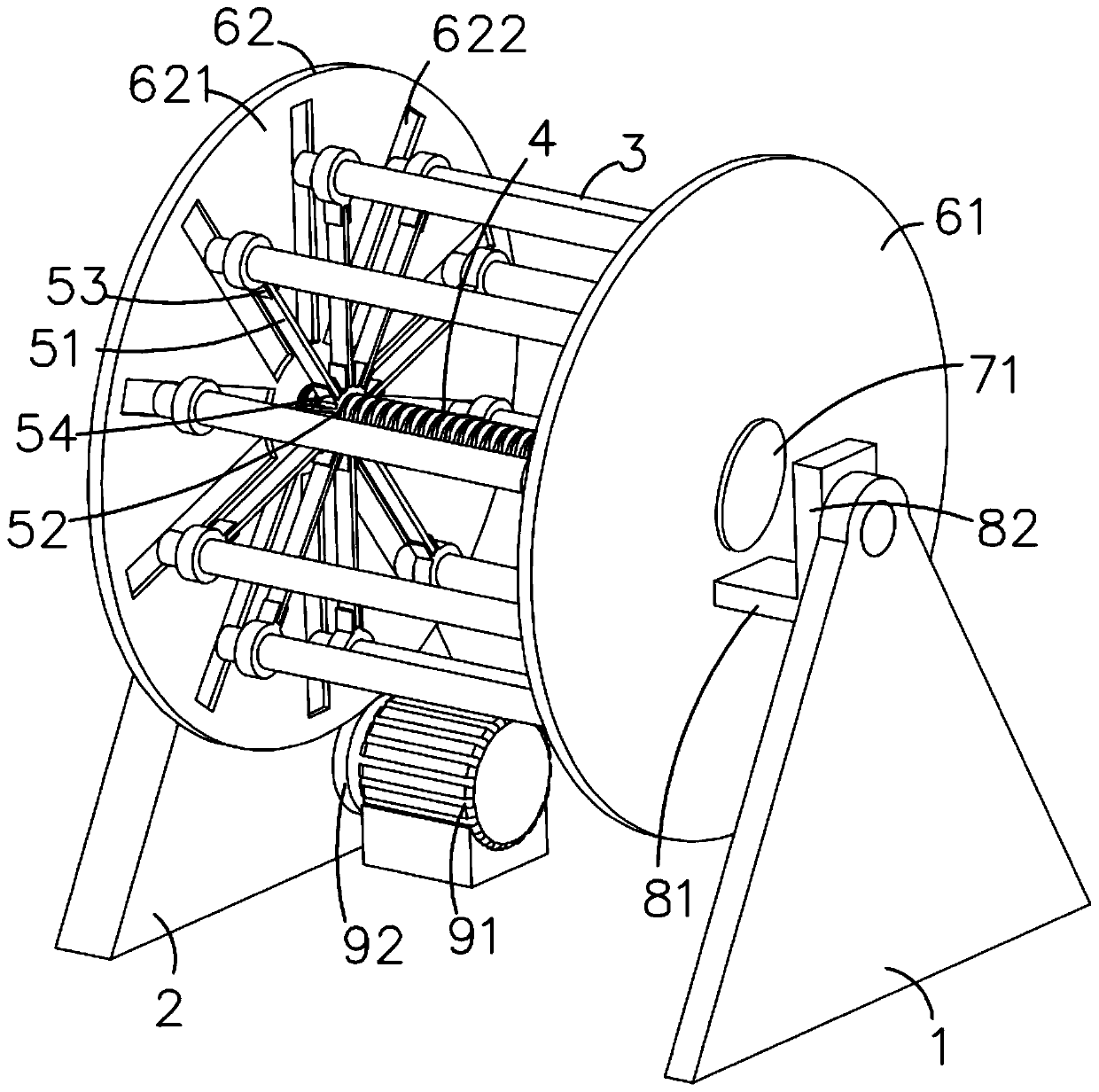

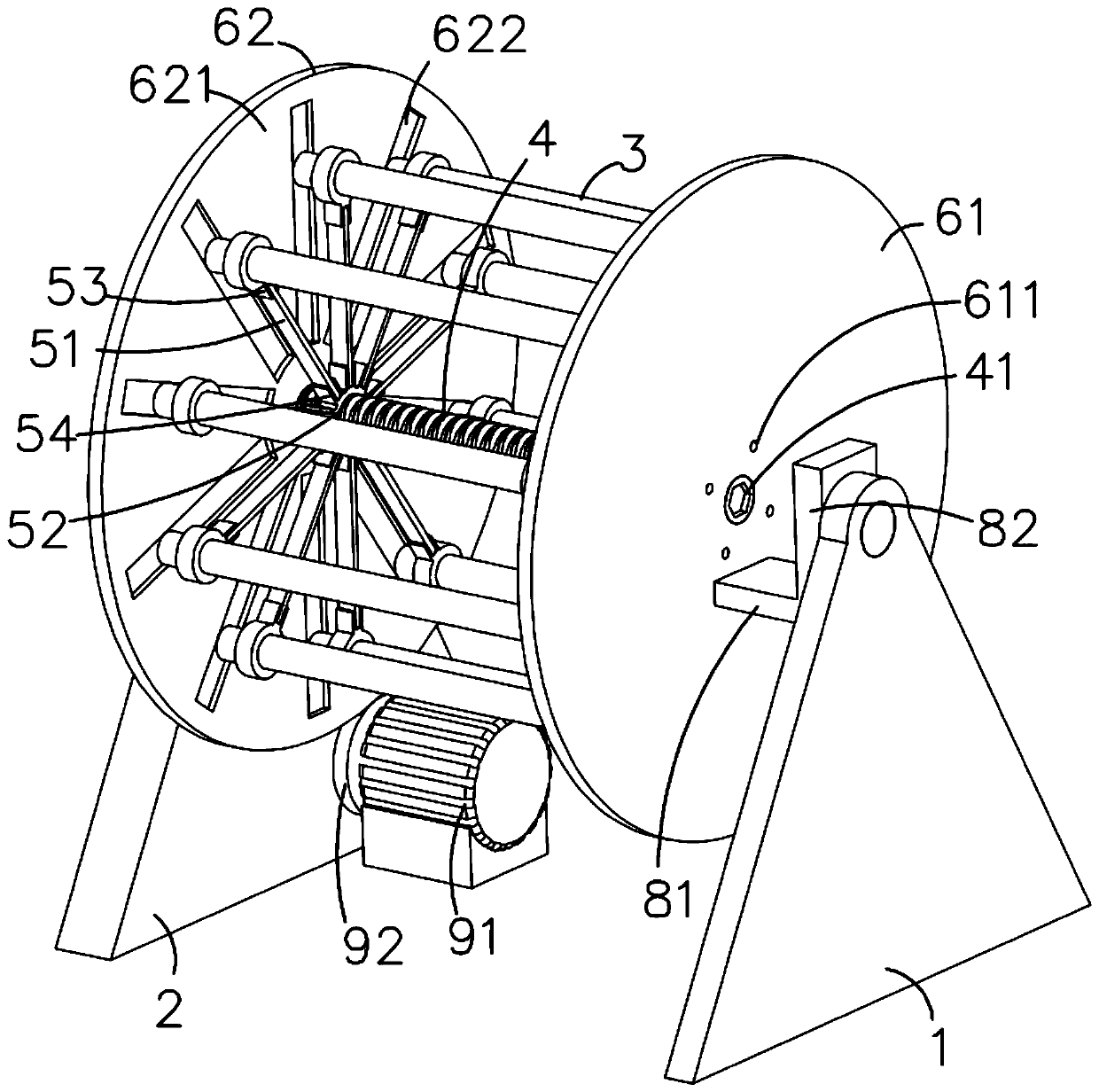

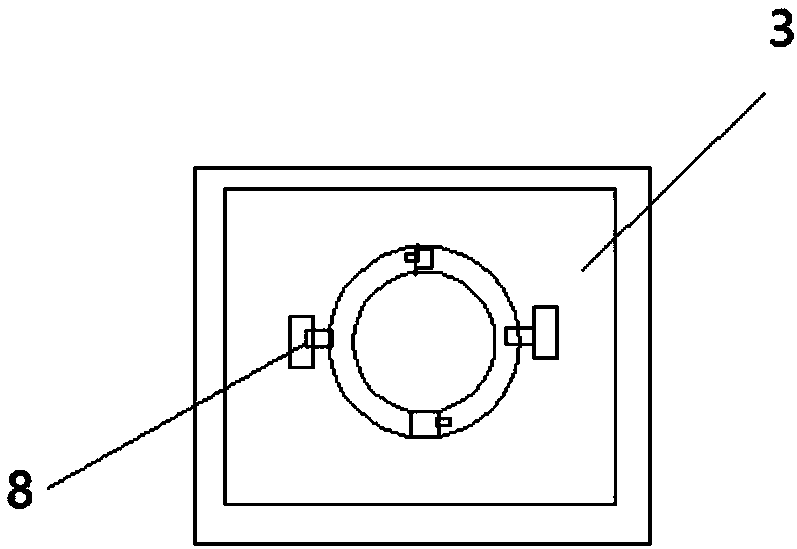

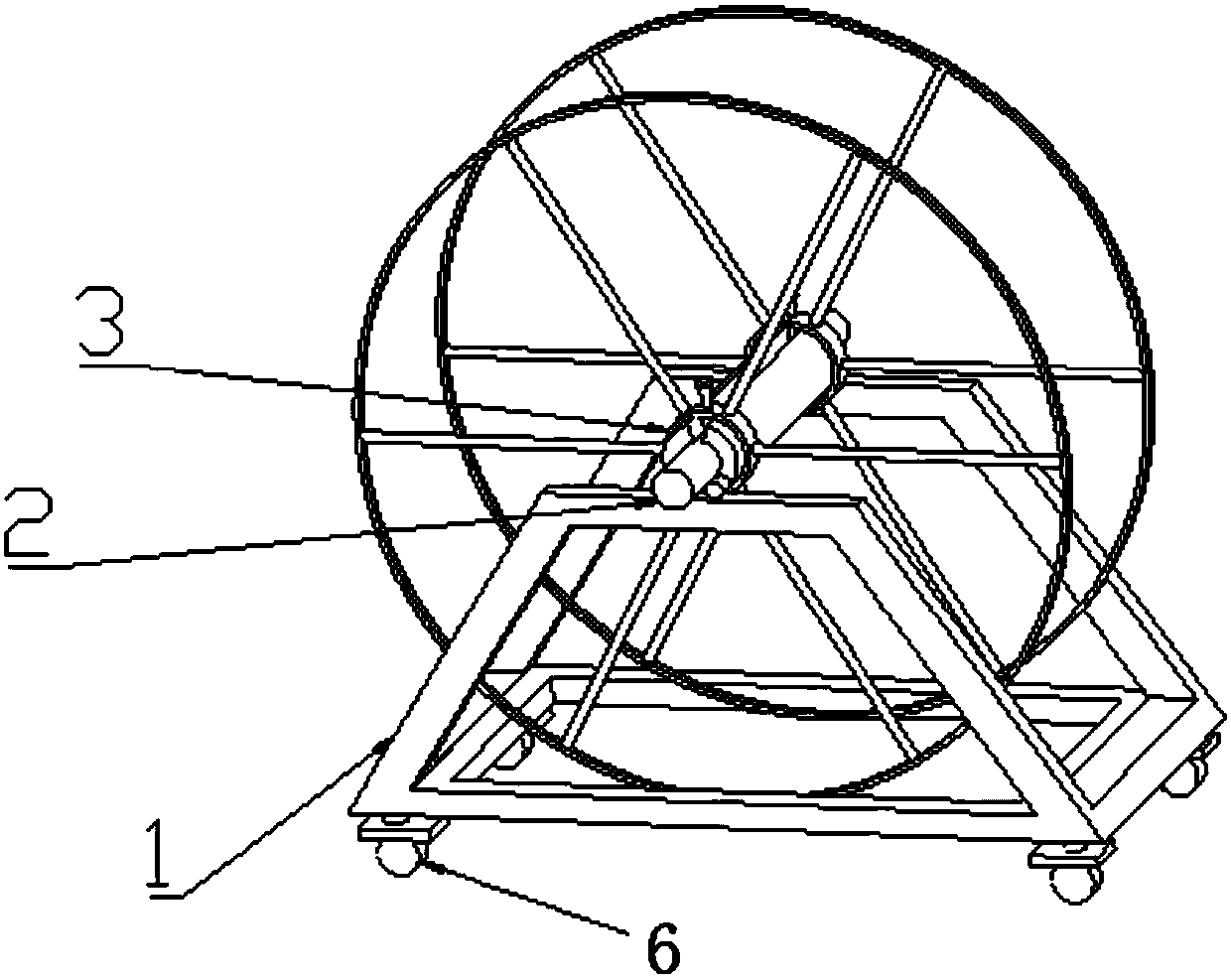

Anti-intertwining winding device for fire hydrant water hose of fire-fighting equipment

The invention relates to an anti-intertwining winding device for a fire hydrant water hose of fire-fighting equipment. The device comprises a winding supporting frame and further comprises a lifting adjusting mechanism arranged on the winding supporting frame, a winding mechanism arranged on the lifting adjusting mechanism and an extruding emptying assembly arranged on the winding supporting frame. According to the device, after the water hose is used, the water hose emptying treatment is automatically completed while the water hose is wound, so that the device is extremely convenient, and water hose winding is convenient; and in addition, the winding amount of the device for the water hose can be adaptively adjusted, so that the device can meet the requirement of winding the water hoses with different lengths.

Owner:NANJING FORESTRY UNIV

Cable tube type stranding device for hardware alternating current equipment processing

InactiveCN111599534AImprove twist effectEasy to disassembleCable/conductor manufactureStructural engineeringElectric machine

The invention discloses a cable tube type stranding device for hardware alternating current equipment processing. The device comprises a box body, wherein a second motor is arranged on the outer wallof the top of the box body, a bush is arranged on the outer wall of one end of the output shaft of the second motor, a spring is arranged on the inner wall of one side of the bush, a connecting disc is arranged on the outer wall of one end of the spring, second sliding blocks are arranged on the outer walls of the two sides of the connecting disc, and a clamping column is arranged on the outer wall of the one side of the connecting disc. According to the invention, when people strand cables, a plurality of cables penetrate through a through groove, a second motor is started after the cables penetrates through the through groove, and the second motor drives a stranding disc to rotate, so that stranding work of the cables can be completed; and people can start an electric push rod when stranding the cables, and the electric push rod drives a clamping ring to move, so that the multiple cables can be close, the stranding effect of the multiple cables is improved, and the situation that thecables are loosened after being stranded is avoided.

Owner:烟台中连智能科技有限公司

Winding device for cables

The invention discloses a winding device for cables. The winding device comprises a first bracket, a second bracket, winding rollers, an axis screw, a first adjusting assembly and a second adjusting assembly, wherein the first bracket and the second bracket support the axis screw, the first adjusting assembly comprises a plurality of first connecting parts and first screw sleeves, the second adjusting assembly comprises a plurality of second connecting parts and second screw sleeves, the first connecting parts, the first screw sleeves, the second connecting parts, the second screw sleeves andthe winding rollers have the same number, the first screw sleeves and the second screw sleeves are arranged on the axis screw in a sleeving manner and matched with the axis screw, one end of each first connecting part is rotationally connected with the corresponding screw sleeve, the other end of each first connecting part is rotationally connected with one winding roller, one end of each second connecting part is rotationally connected with the corresponding screw sleeve, and the other end of each second connecting part is rotationally connected with one winding roller. Compared with the prior art, the winding device adjusts the size of a winding outline formed by the plurality of winding rollers through the first adjusting assembly and the second adjusting assembly so as to meet the winding requirements of different specifications of cables.

Owner:湖南容大之光通信设备有限责任公司

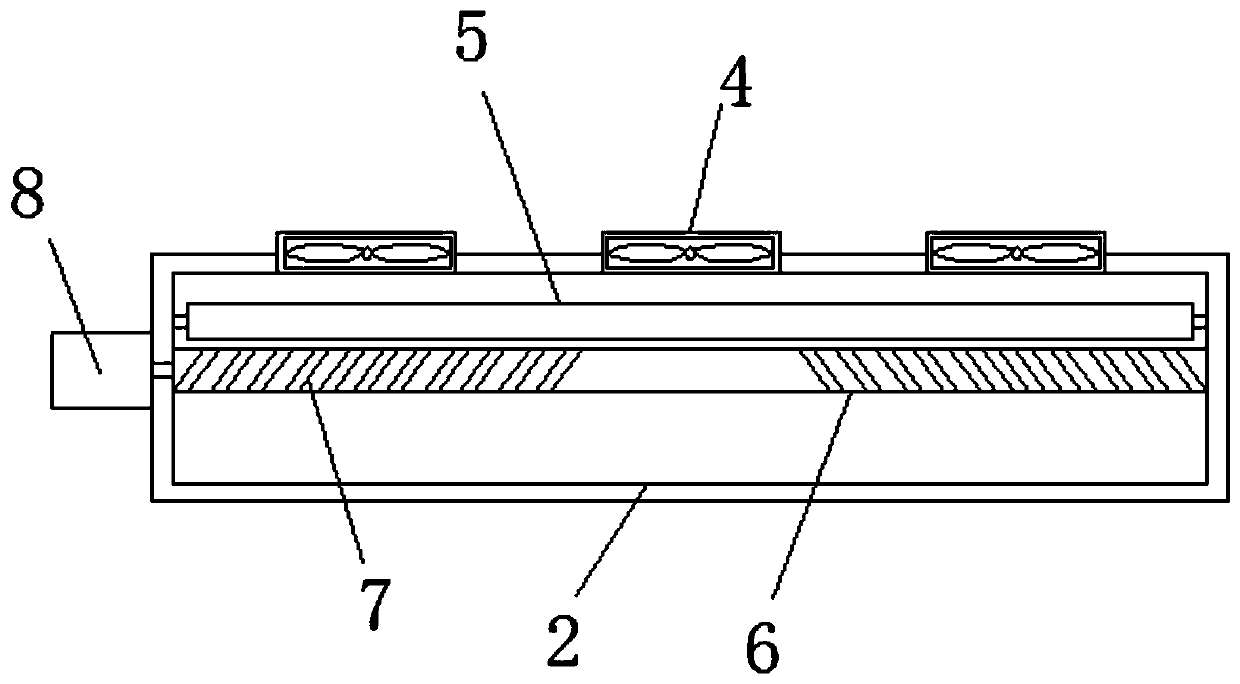

Film rolling mechanism

The invention discloses a film rolling mechanism, and belongs to the field of film machining devices. The film rolling mechanism comprises a fixed support, a horizontal movement support, a horizontal movement supporting plate, rolling supports and a rolling roller. The middles of the two sides of the horizontal movement support are rotationally connected to the fixed support. A rotation motor drives the horizontal movement support. Horizontal movement guiding plates are horizontally arranged on the two sides of the horizontal movement supporting plate respectively. The rolling supports are arranged on the two sides of the horizontal movement support respectively. A rolling motor drives the rolling roller. The rolling supports can horizontally move along the horizontal movement guiding plates. Horizontal movement drive plates are horizontally arranged at the two ends of one sides of the rolling supports respectively. Two horizontal movement motors drive two horizontal movement lead screws respectively. The two horizontal movement lead screws are in horizontal threaded connection with the horizontal movement drive plates on one sides of the two rolling supports respectively. The film rolling mechanism is simple in structure and convenient to use, films can be continuously rolled, the film rolling efficiency and quality are improved, and the requirements for production and usage are met.

Owner:浙江耀阳新材料科技有限公司

Synchronous winding device

Owner:苏州博天纺织有限公司

Waste foil rolling device

The invention discloses a waste foil rolling device which comprises a motor (2), a reduction gear box (2) and a support (3) and further comprises a rolling disk (6) and a friction device. The motor (1) and the reduction gear box (3) are connected into a whole through a coupler, and are fixed on the support (3). The friction device is connected with an output shaft of the reduction gear box (2), at least one rolling disk (6) is arranged on the friction device, and the friction device drives the rolling disk (6) to roll waste foil (5) through friction force generated by friction. The waste foil rolling device can use a servo motor, realizes rolling of multiple strips of waste foil (5) simultaneously, and is simple in structure, low in cost and high in commonality.

Owner:CHANGDE JINPENG PRINTING

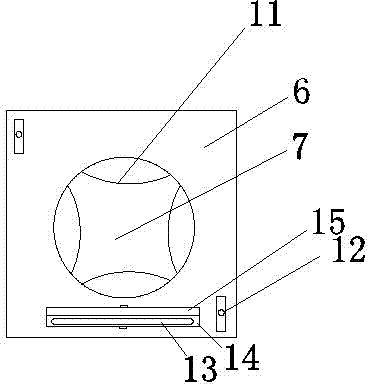

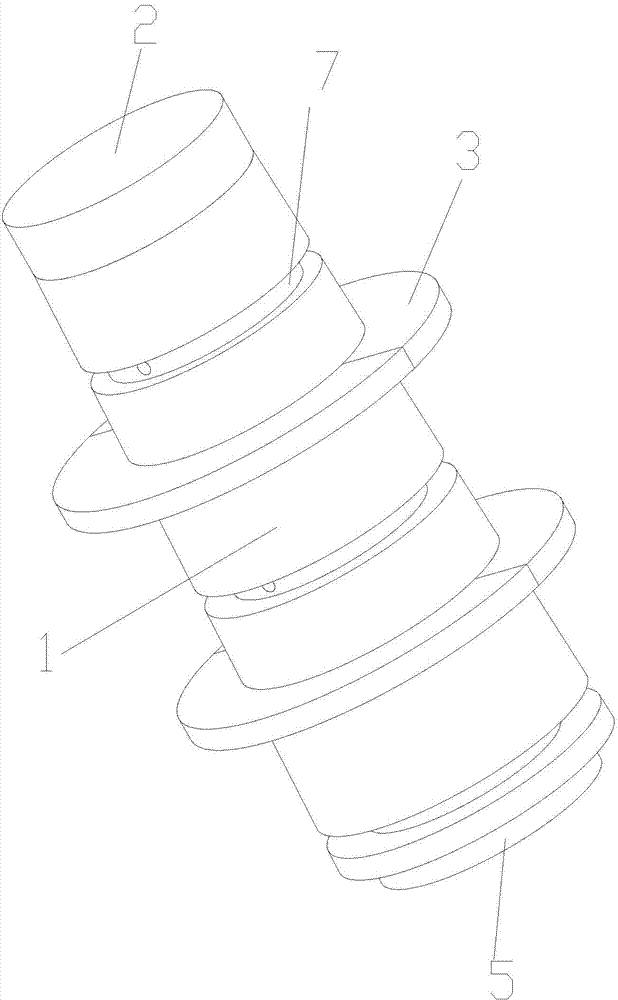

Multipurpose yarn drum

The invention relates to a multipurpose yarn drum which comprises a drum body, a top cover, semicircular retaining plates, locking bolts and a round positioning plate. The drum body is conical, a through hole is formed in the center of the drum body, the top cover in threaded connection is arranged above the through hole, multiple parallel grooves are formed in the drum body, two semicircular retaining plates which are arranged symmetrically are arranged in any two grooves, the locking bolts are arranged on the semicircular retaining plates which are fixedly arranged in the grooves of the drum body through the locking bolts, and the round positioning plate is arranged at the bottom of the drum body. The multipurpose yarn drum is simple in structure, positions of the semicircular retaining plates can be adjusted according to length of yarn different in color to meet winding needs of the yarn, and shaking of the drum body during rotating can be prevented.

Owner:SUZHOU CITY WUZHONG DISTRICT GUOXIANG XUYU WOOLENSWEATER PROCESSING PLANT

Thread splitting and winding device for textile

InactiveCN112125055AGuaranteed stabilityEasy to disassembleFilament handlingElectric machineryScrew thread

The invention discloses a thread splitting and winding device for textile. The thread splitting and winding device comprises a bottom plate, the outer wall of the top of the bottom plate is connectedwith a first supporting plate and a second supporting plate through bolts, and a top plate is arranged on the outer walls of the tops of the first supporting plate and the second supporting plate. A third motor is arranged on the outer wall of one side of the second supporting plate, and the outer wall of one end of an output shaft of the third motor is fixedly connected with a pay-off roller. Textile threads are wound on the outer wall of the circumference of the pay-off roller. A thread guide barrel on the outer wall of one side of a fixing plate can guide and wind the split textile threads.Meanwhile, the guide barrel can slide a sliding block before guiding the textile threads, so that the position of the thread guide barrel is adjusted, and the tightness of the textile threads is adjusted. After the sliding block slides, people can make a fixing screw rod penetrate through a through groove and insert the fixing screw rod into a threaded groove formed in the outer wall of one sideof the sliding block, so that the sliding block can be limited and fixed, and the stability of the sliding block and the guide barrel is guaranteed.

Owner:尹冬岩

Dust-proof winding device for water pumping pipe belts for water conservancy project

InactiveCN112158659AQuick snap-onMeet the needs of windingFilament handlingElectric machineDust control

Owner:朱化书

Metal film cooling and winding device

ActiveCN111674982AEliminate adverse effectsImprove winding efficiencyDomestic cooling apparatusLighting and heating apparatusElectric machineryComposite material

The invention relates to the technical field of metal film processing, in particular to a metal film cooling and winding device. The invention aims at providing the metal film cooling and winding device, which is capable of performing cooling operation on a metal film and eliminating the adverse effect of temperature on the metal film winding, high in winding efficiency, wide in application rangeand high in practicability. The metal film cooling and winding device comprises a base, a carrying plate, supporting plates, positioning plates, a bidirectional motor and the like, wherein the carrying plate is fixedly arranged on one side surface of the base; the bidirectional motor is fixedly arranged on one side surface of the carrying plate; the two positioning plates are fixedly arranged on one side surface of the base; and the supporting plates are fixedly arranged on the two positioning plates respectively. According to the metal film cooling and winding device, through cooperative workof two blades and a fan drum, the newly-produced metal film with a certain stability can be subjected to cooling operation, the adhesion of the metal film during winding can be effectively prevented,the winding effect is good, and the efficiency is high.

Owner:中山市国辉五金实业有限公司

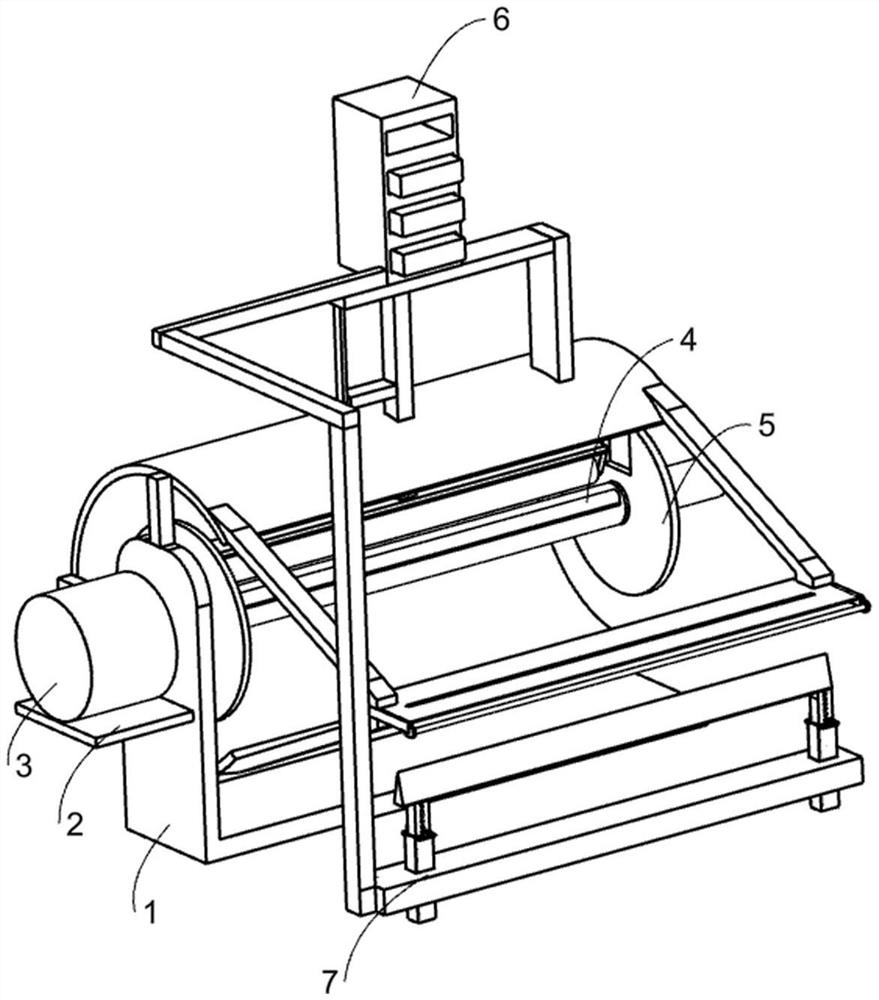

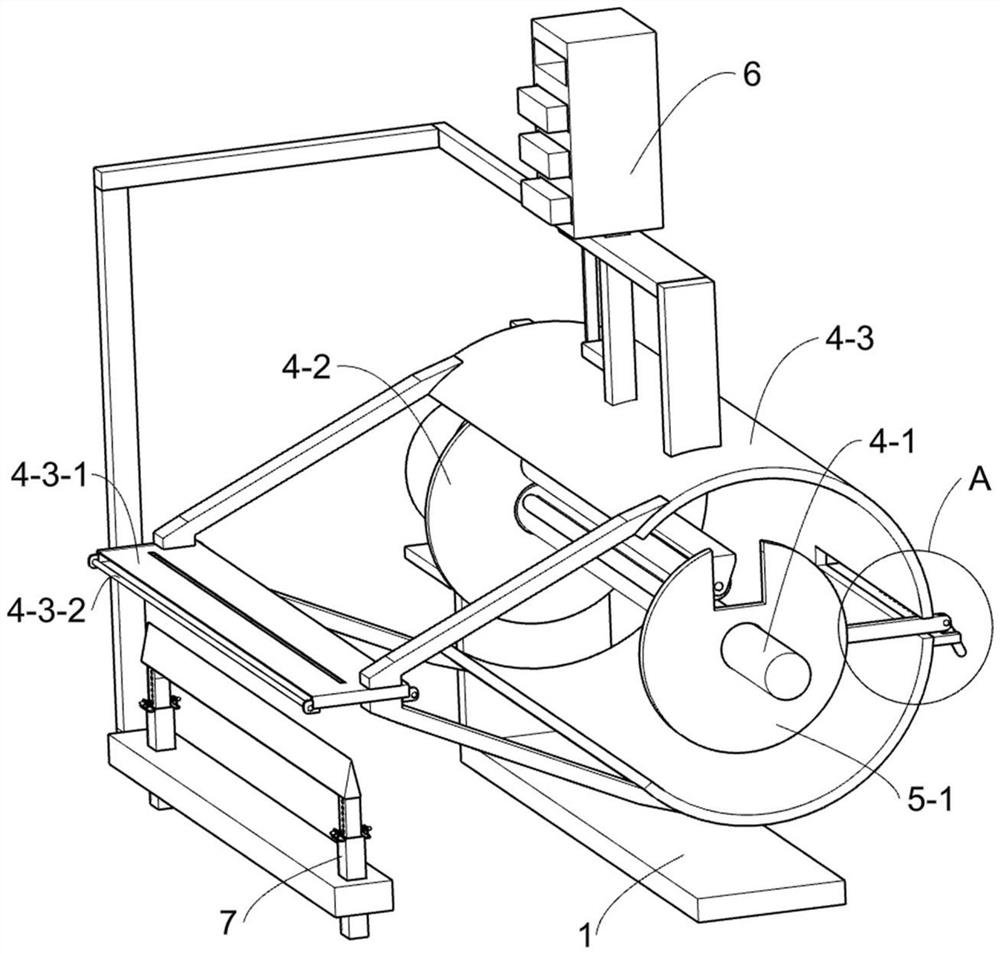

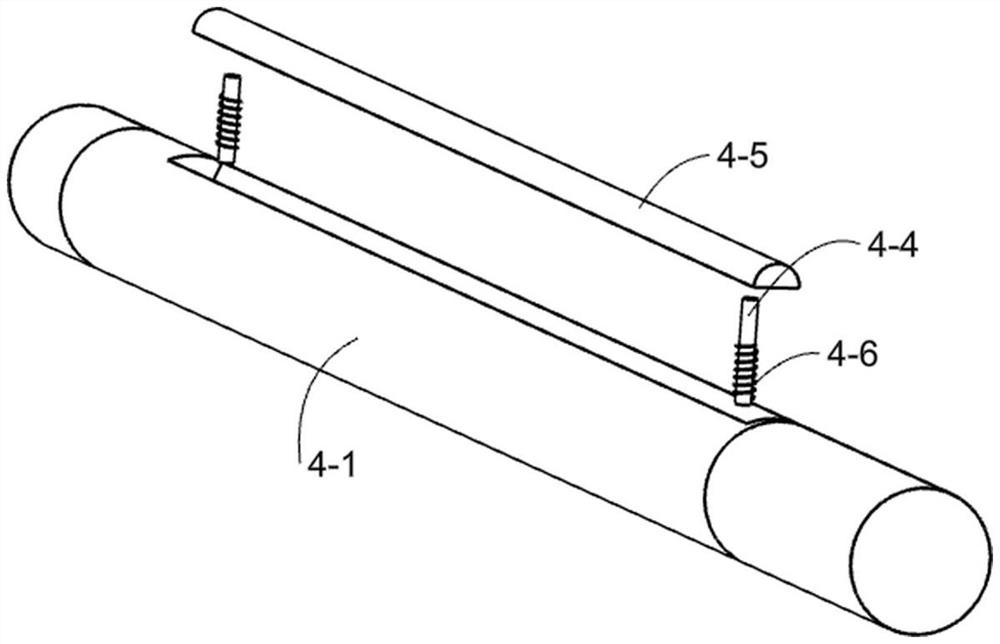

Chunk type strip winding equipment

ActiveCN102009876ASolve the problem of difficult windingImprove winding efficiencyEngineeringMechanical engineering

The invention relates to chunk type strip winding equipment for package of an insulating belt of a container. The equipment consists of a motor, a transmission mechanism, a fixed support, a rotating support and a winding container; the transmission mechanism comprises two transverse rotating shafts and two longitudinal rotating shafts, wherein the transverse rotating shafts are positioned at the same line with a transverse center line of the winding container and positioned on two sides of the winding container; the longitudinal rotating shafts are positioned at the same line with a longitudinal center line of the winding container and positioned on two sides of the winding container; the transverse rotating shafts and the longitudinal rotating shafts are in transmission connection with the motor respectively; and the transverse rotating shafts are arranged on the fixed support. When the chunk type strip winding equipment is used, the winding container can rotate along the transverse shafts and rotate along the longitudinal shafts simultaneously, so that the problem that the insulating belt of the container is difficult to wind during package, and the efficiency of winding the insulating belt is greatly improved.

Owner:HANGZHOU FUSHIDA SPECIAL MATERIAL

Aluminum foil winding device having adjustable tightness

ActiveCN112093527AAct as a clampMeet the needs of windingWebs handlingElectric machineStructural engineering

The invention relates to an aluminum foil winding device, in particular to an aluminum foil winding device having the adjustable tightness, and aims to solve the problems that existing aluminum foil winding equipment cannot adjust the tightness of aluminum foil winding and cannot meet requirements for different winding thicknesses of aluminum foil. The aluminum foil winding device having the adjustable tightness comprises a base, a supporting plate, a motor, a clamping mechanism, an adjusting mechanism, a tightening mechanism and the like; the supporting plate is fixedly arranged on one side surface of the base; the motor is fixedly arranged on one side surface of the supporting plate; the clamping mechanism is arranged on the base; and the adjusting mechanism and the tightening mechanismare both arranged on the clamping mechanism. According to the aluminum foil winding device, clamping rods can play a role in clamping winding drums with different diameters, so that the aluminum foilcan be wound on the winding drums in different models; through adjustment of the position of a movable disc, a power shaft can be sleeved with the winding drums with different lengths to wind the aluminum foil, and thus the winding requirements of the aluminum foil with different widths can be met.

Owner:张浩合

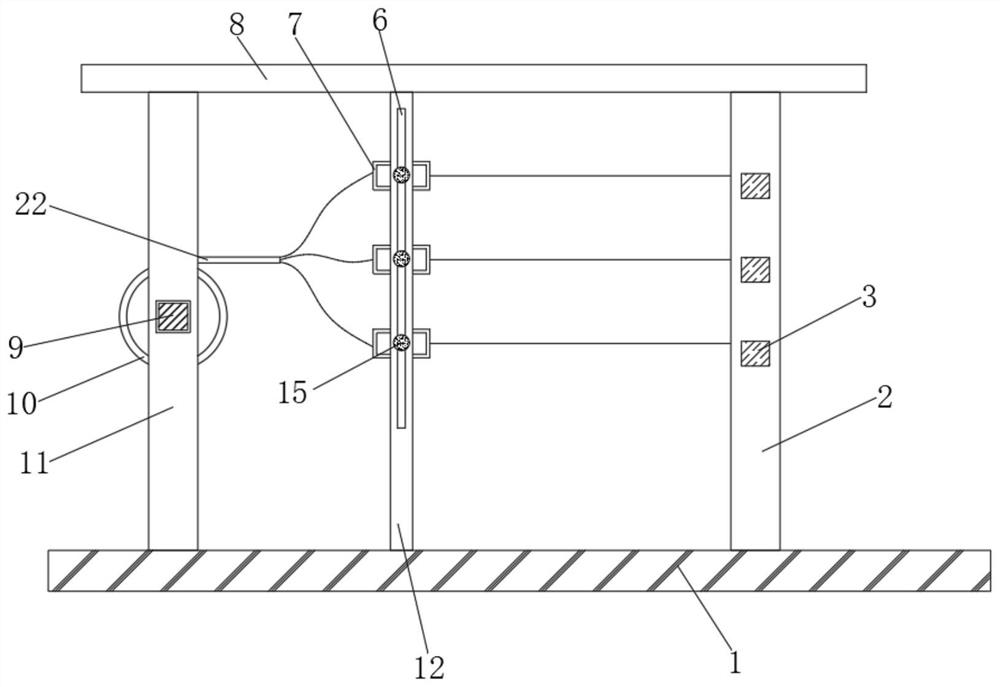

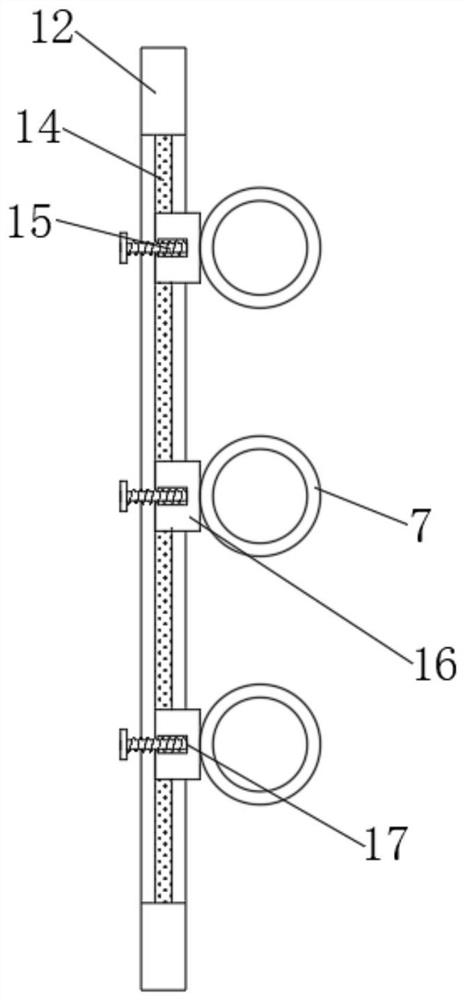

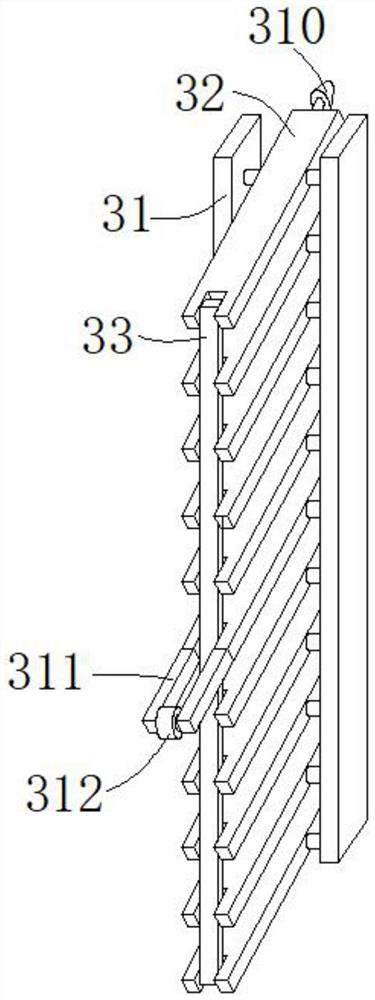

Winding device with pressing structure for optical fiber manufacturing

PendingCN114476832AIncrease volumeImprove compactnessFilament handlingGlass productionEngineeringStructural engineering

The invention discloses a winding device with a pressing structure for optical fiber manufacturing, and relates to the technical field of optical fiber manufacturing. Optical fibers are pressed down in real time in the winding process through the pressing structure, it is ensured that the phenomenon of protrusion or looseness cannot occur in the winding process, the winding compactness of the optical fibers is improved, and the winding amount of a single winding roller is increased. Comprising a base and a pressing structure, a transmission roller is rotationally embedded in the upper end of the base, two stand columns distributed front and back are vertically arranged at the upper end of the base, the pressing structure comprises two supporting back plates and a plurality of hinge rods, and the two supporting back plates are fixedly installed on the side wall of the side, away from the other stand column, of one stand column; the hinge rods are evenly distributed in the vertical direction at intervals, one ends of the hinge rods extend into the adjusting holes and are rotationally connected with the supporting back plates on the two sides through pin shafts, torsional springs are arranged at the rotating positions of the hinge rods, and connecting rods are hinged between the other ends, away from the supporting back plates, of the hinge rods.

Owner:江苏华晟鑫烨智慧城市科技有限公司

Glass fiber woven roving winding device

ActiveCN114348728AFit tightlyMeet the needs of windingMechanical cleaningPressure cleaningGlass fiberFiber

The invention discloses a glass fiber woven roving winding device, and relates to the technical field of glass fiber collection, the glass fiber woven roving winding device comprises a main body, an inner cavity at one end of the main body is rotatably connected with a pressing wheel, one side of the main body is provided with an impurity removal assembly, one end, away from the impurity removal assembly, of the main body is provided with a flattening assembly, and the inner wall of the main body is provided with a leveling assembly. According to the winding device, it can be guaranteed that glass fiber woven roving cloth is tightly attached while the glass fiber woven roving cloth is wound into a large package, the left end and the right end of the glass fiber woven roving cloth can be aligned all the time, the breadths of the glass fiber woven roving cloth are equal, and the glass fiber woven roving cloth can be wound into a large package. The winding requirement is met; and fiber lines attached to the outer surface can be removed, disassembly is convenient after winding is completed, the winding speed is increased, and winding and winding can be conducted on the outer surfaces of collecting rolls with different diameters.

Owner:浙江艾森新材料股份有限公司

Efficient intelligent winder and working method thereof

The invention discloses a working method of an efficient intelligent winder. The efficient intelligent winder comprises a machine frame, at least one group of wire winding rollers, a group of wire feeders and a control device; a separation plate is arranged on each wire winding roller, a driving mechanism used for driving the wire winding rollers and a control mechanism are arranged in the controldevice, the wire winding rollers are arranged on the machine frame, and the wire feeders are arranged on the machine frame; a wire feeding hole is formed in each wire feeder, and the wire winding rollers, the wire feeders and the driving mechanism are all connected with the control mechanism. According to the working method of the efficient intelligent winder, a plurality of the wire winding rollers can be combined to be used and the separation plates can also be arranged on the wire winding rollers so that the winding requirements of a variety of electric wires and cables can be met at the same time, the effect that one wire winding roller is wound with the various wires can be realized, a lot of convenience is brought to construction and production, and the carrying problem of a plurality of the wire winding rollers is well solved.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

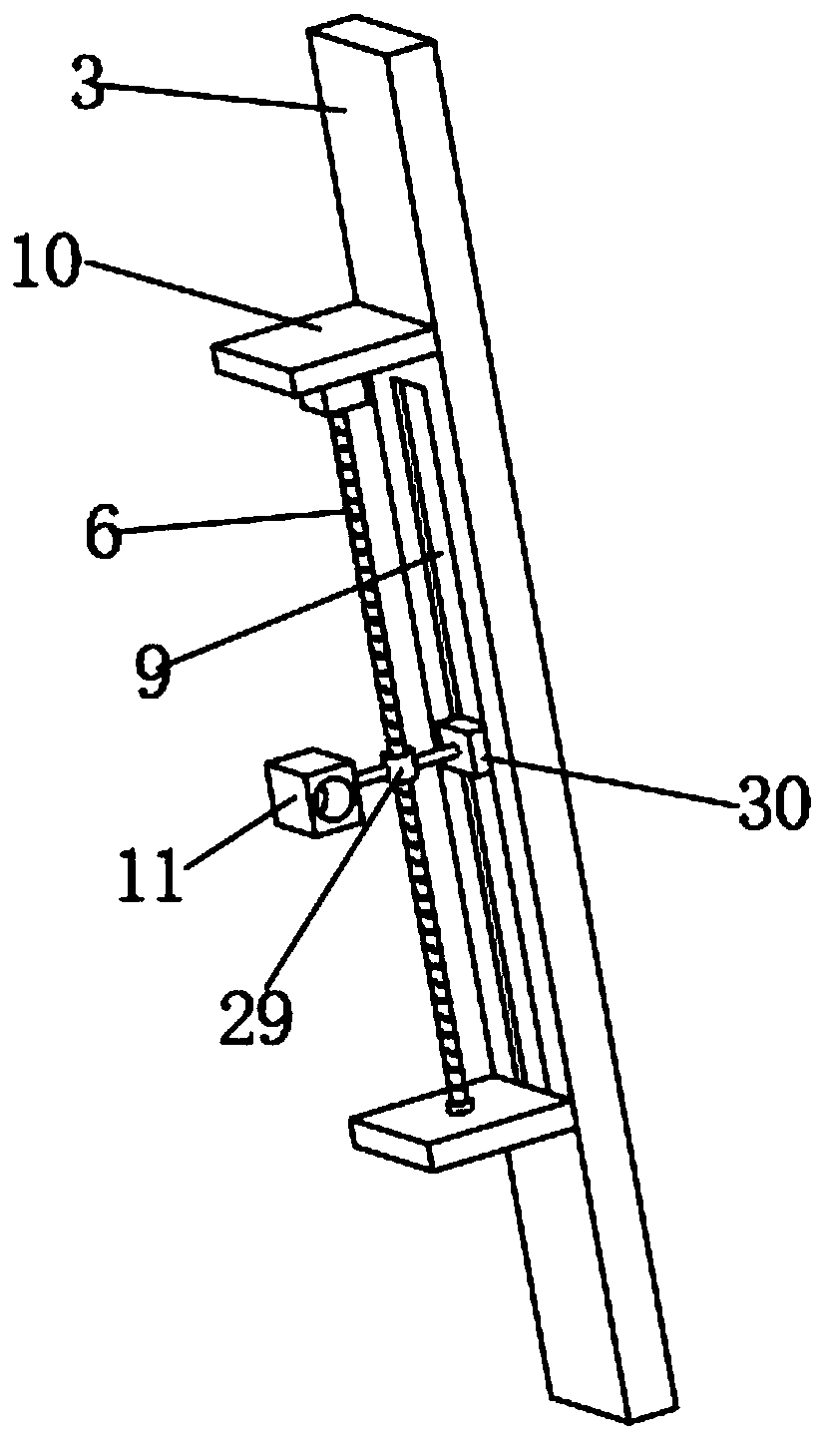

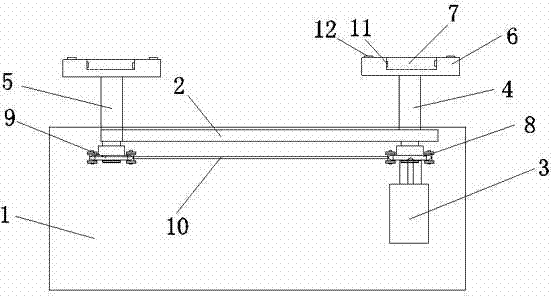

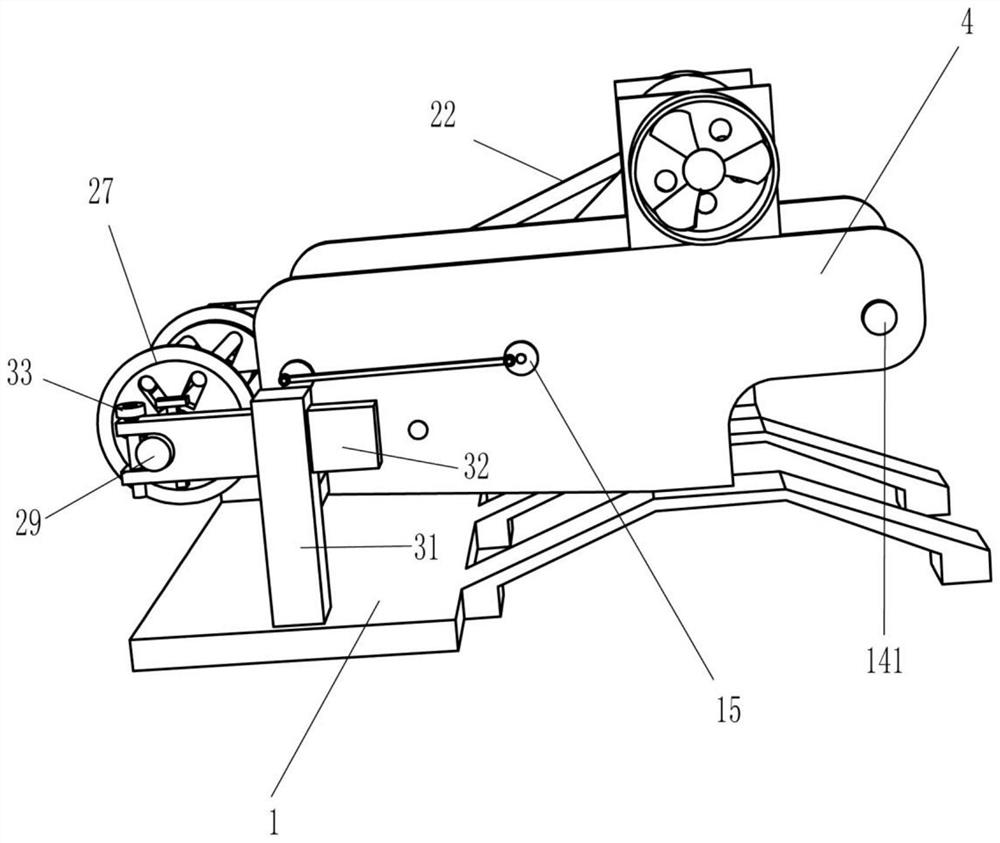

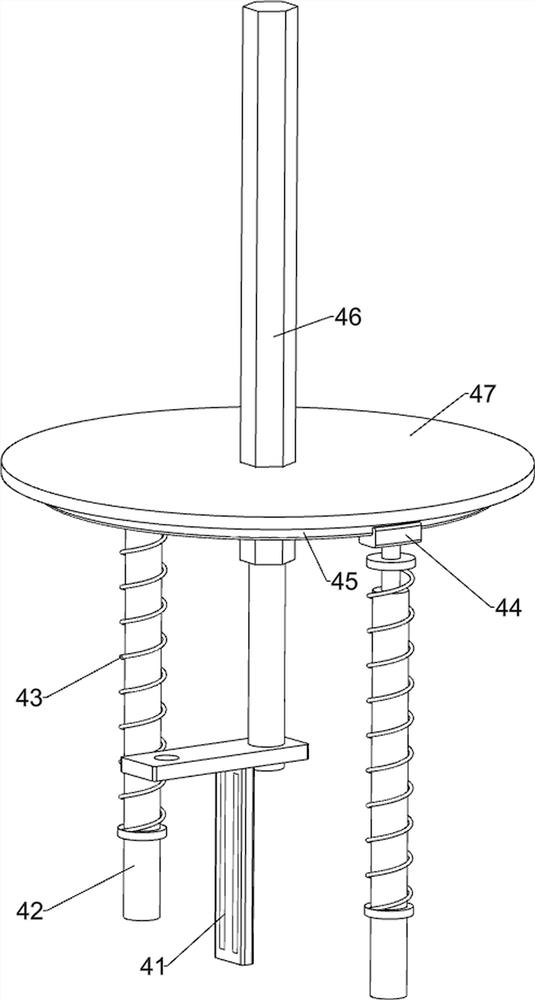

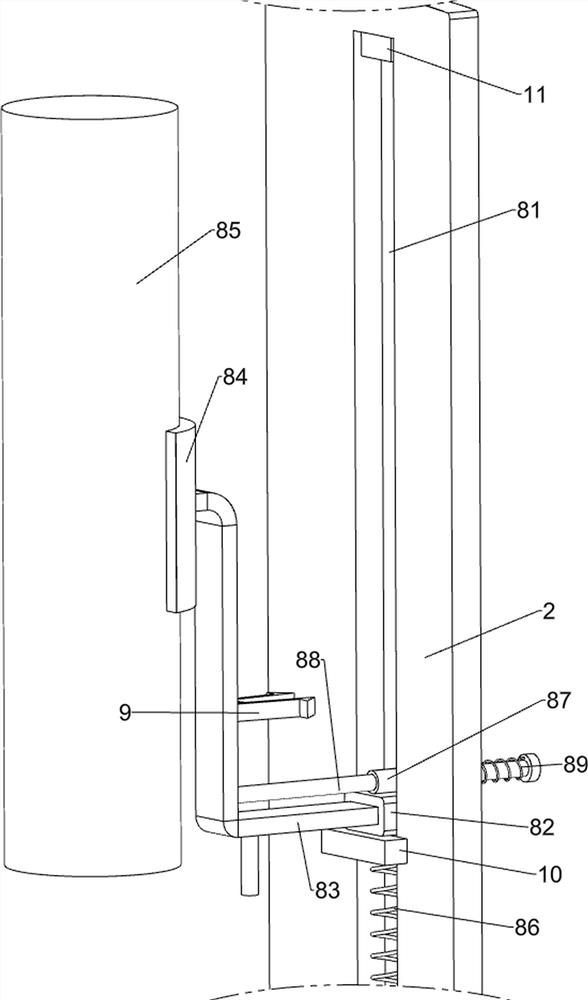

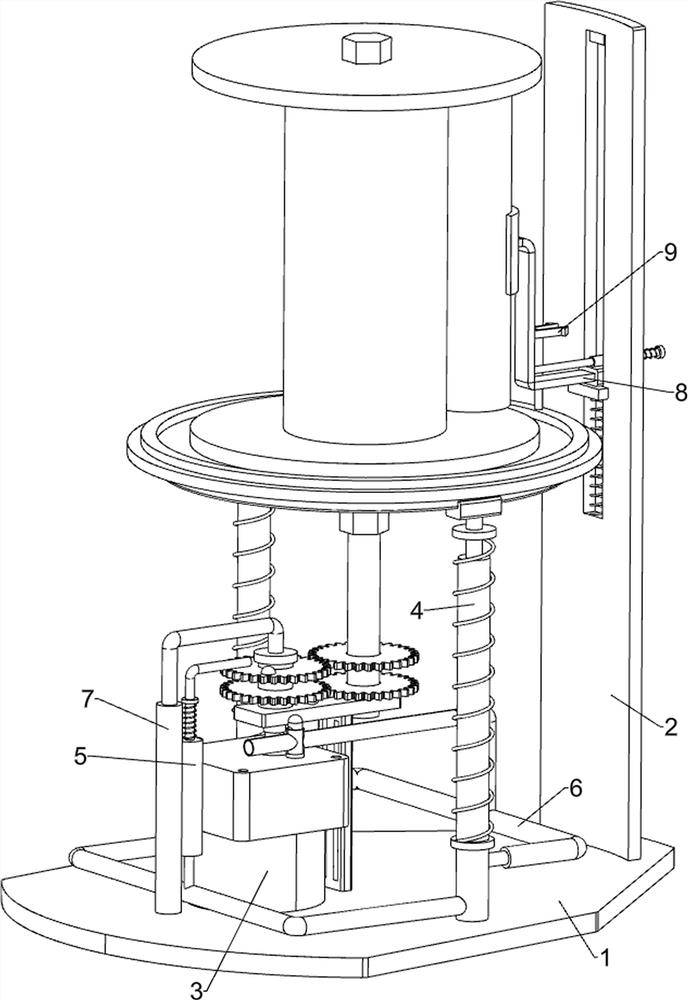

Wire winding device for power transmission and distribution engineering construction

InactiveCN112320464AMeet the needs of windingWind evenlyFilament handlingElectric machineConstruction engineering

The invention relates to a winding device, in particular to a wire winding device for power transmission and distribution engineering construction. According to the wire winding device for power transmission and distribution engineering construction, a wound wire can be conveniently taken out, and the wire winding amount can be accurately controlled. The wire winding device for power transmissionand distribution engineering construction comprises a bottom plate, a support plate arranged on the bottom plate, a gear motor arranged on the bottom plate, a lifting placement component arranged on the bottom plate, a control component arranged on the bottom plate, an air inlet component arranged on the lifting placement component, and a deflation component arranged on the lifting placement component. Through cooperation of the lifting placement component, the control component, the air inlet component and the deflation component, uniform winding of the wire through up-down movement is achieved, and the requirement for wire winding is well met; and by means of a compacting component, a cylinder can compact the wound wire in the whole process, and the wire can be wound more compactly.

Owner:黄永红

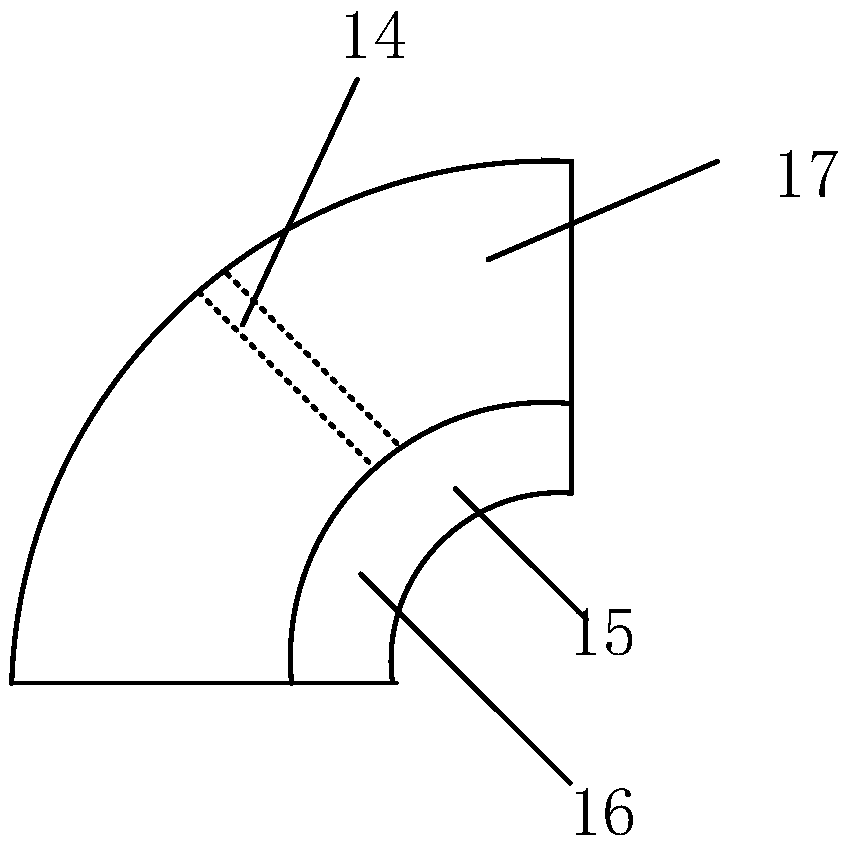

Method for enlarging diameter varying range of adjustable winding mould of transformer coil

InactiveCN104752050AIncrease the reducer sizeMeet winding needsCoils manufactureEngineeringConductor Coil

The invention relates to a method for enlarging a diameter varying range of an adjustable winding mould of a transformer coil. The method for enlarging the diameter varying range of the adjustable winding mould of the transformer coil includes following steps: preparing a plurality of wood struts; confirming the size and the distance of threaded holes of the wood struts and intervals and the length of struts of an existing mould according to the distance of bolt holes, and the width and the length of bracing plates of the existing mold; drilling stepped holes in positions of the wood struts, corresponding to the bolt holes in the existing mold; replacing screws used to install the bracing plates on the existing mold with lengthened screws so as to install the wood struts on the outer sides of the existing mold bracing plates, and thereby achieving the purpose of enlarging the diameter varying range of the adjustable winding mould. The method for enlarging the diameter varying range of the adjustable winding mould of the transformer coil enlarges the diameter varying size of the adjustable winding mould, not only meets demands of coil winding, but also simultaneously saves cost used by purchasing another coil mold, shortens a production period of a product, does not damage the existing mould, facilitates installation and dismantlement, and is strong in practicability and remarkable in economical benefit.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

Gluing device for lithium battery winding machine

InactiveCN108461825AReduce maintenance frequencyReduce downtimeFinal product manufactureSecondary cellsWinding machineEngineering

The invention provides a gluing device for a lithium battery winding machine. The gluing device for the lithium battery winding machine comprises a gluing device body, a rotating shaft, a bracket anda driving mechanism; the gluing device body comprises a fixing piece, a suction mechanism and at least one suction nozzle; the suction nozzle is arranged on the fixing piece; a suction port is formedat one end, far away from the fixing piece, of the suction nozzle; the suction nozzle is connected and communicated with a gas outlet of the suction mechanism through a hose; the other end of the fixing piece is connected with the middle part of the rotating shaft; the rotating shaft is transversely rotatably arranged on the bracket and is in transmission connection with the driving mechanism; andthe driving mechanism drives the rotating shaft and drives the gluing device body to rotate. The gluing device for the lithium battery winding machine, which is provided by the invention, solves theproblems that winding gluing is uneven and adhesive tape debugging consumes long time, reduces rejection rate and increases battery manufacturing qualification rate.

Owner:SHENZHEN RUILONG NEW ENERGY TECH

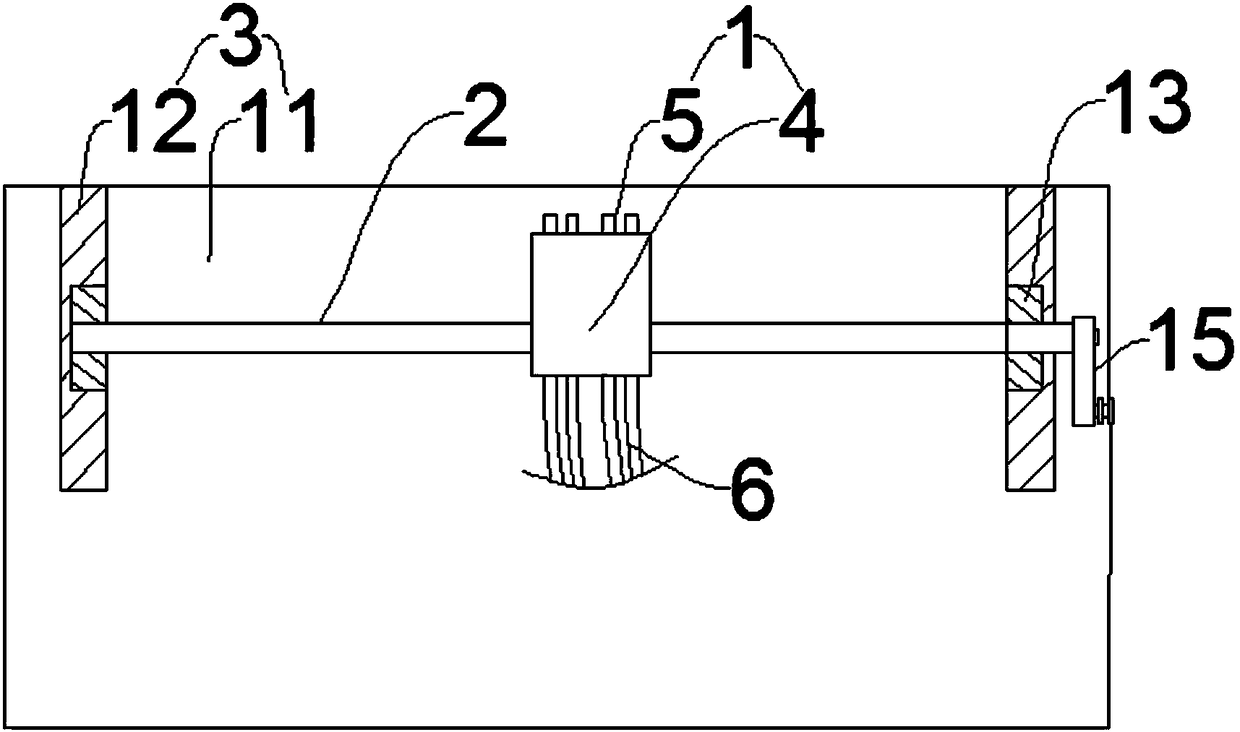

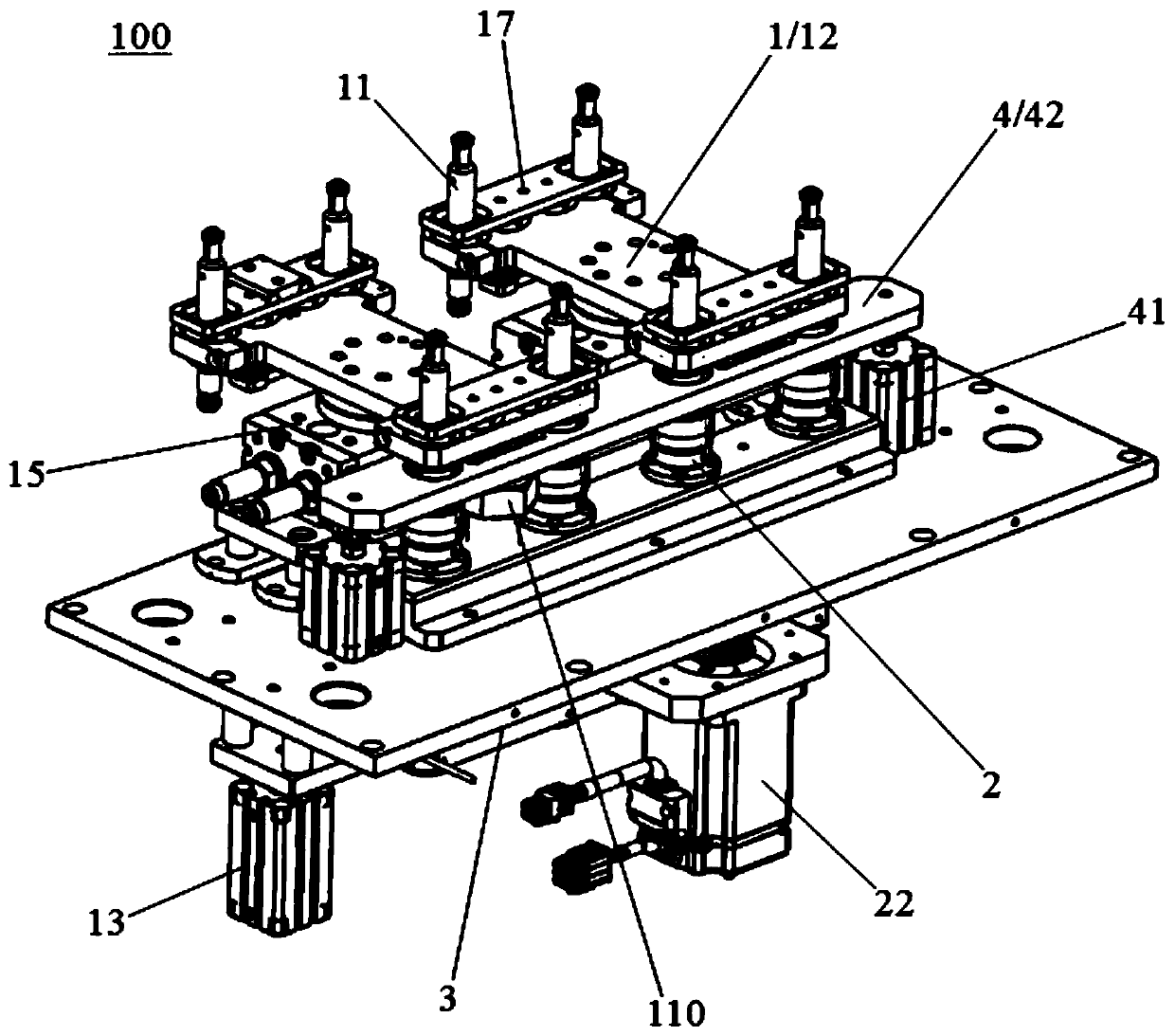

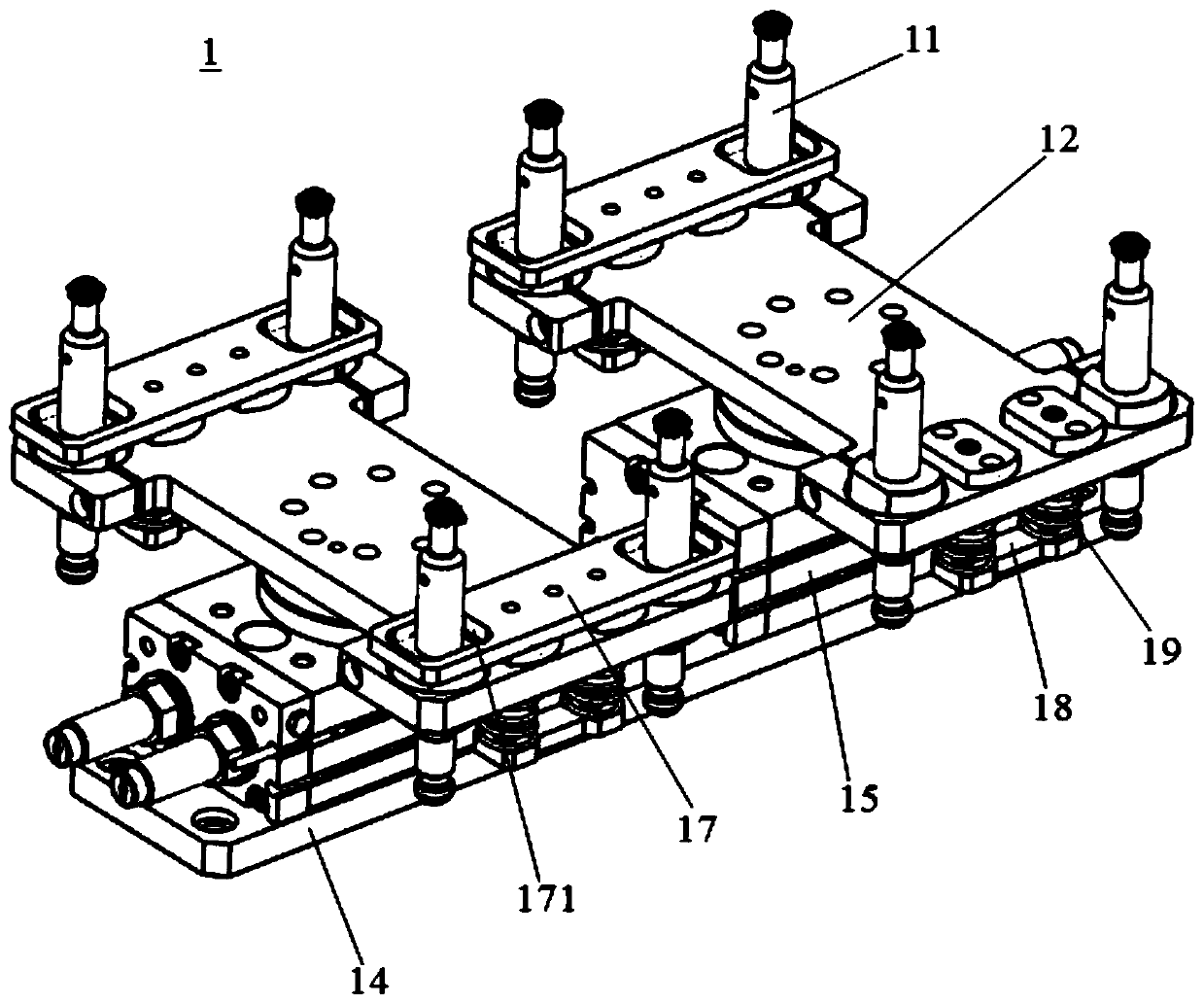

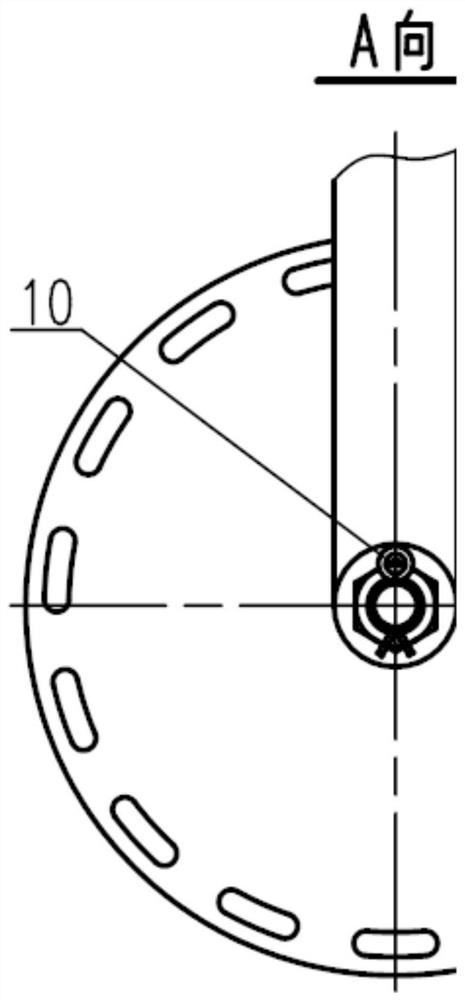

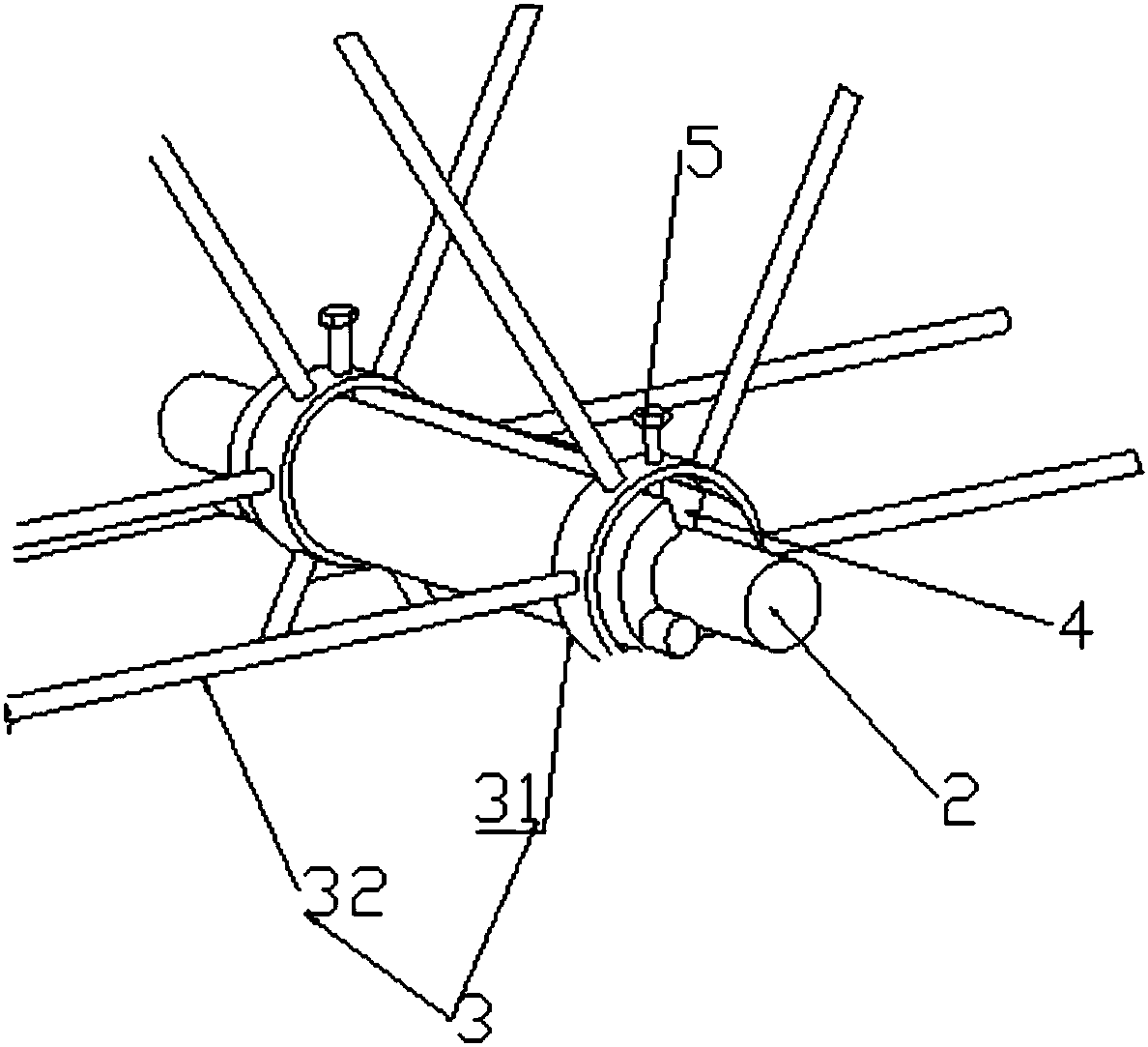

Main shaft mechanism for winding machine with multi-angle rotation

PendingCN110233554ASatisfy the fixed position requirementMeeting Synchronous Rotation NeedsManufacturing dynamo-electric machinesCoils manufactureWinding machineEngineering

The invention discloses a main shaft mechanism for a winding machine with multi-angle rotation. The main shaft mechanism comprises a rotary feeding jig, a main shaft driving unit for driving a jig shaft in the rotary feeding jig to rotate, an anti-rotation unit for preventing a rotary main shaft in the main shaft driving unit from rotating, and an unlocking unit for unlocking a clamping structureof the jig shaft and the rotary main shaft to separate the jig shaft from the rotary main shaft. According to the main shaft mechanism, a series of automatic operations of automatic positioning, compressing, angle adjustment and the like after product feeding can be realized.

Owner:苏州恊合自动化科技有限公司

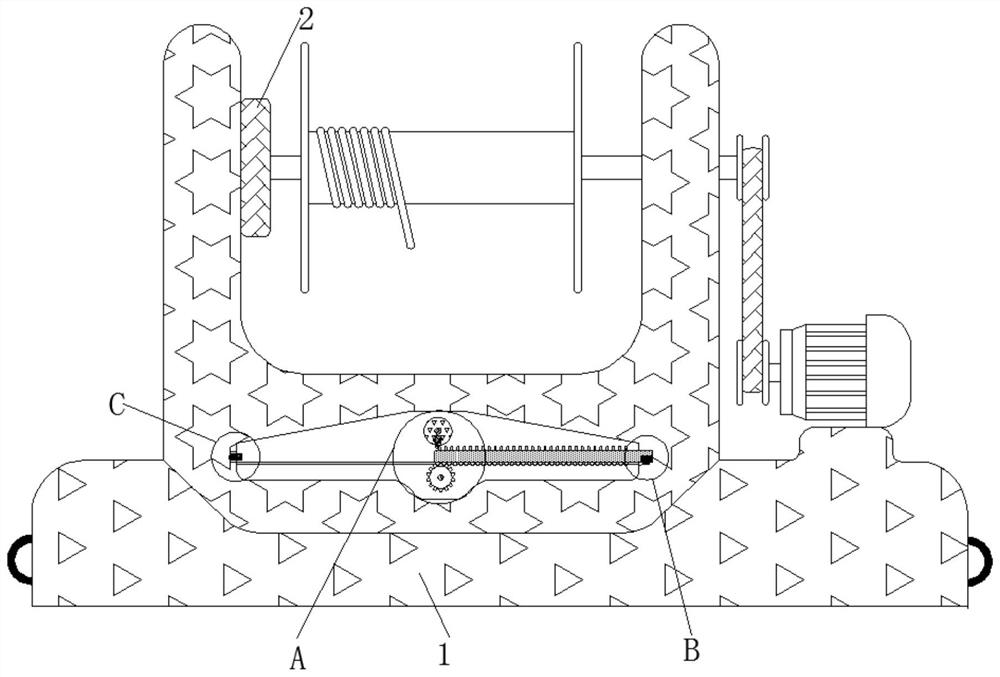

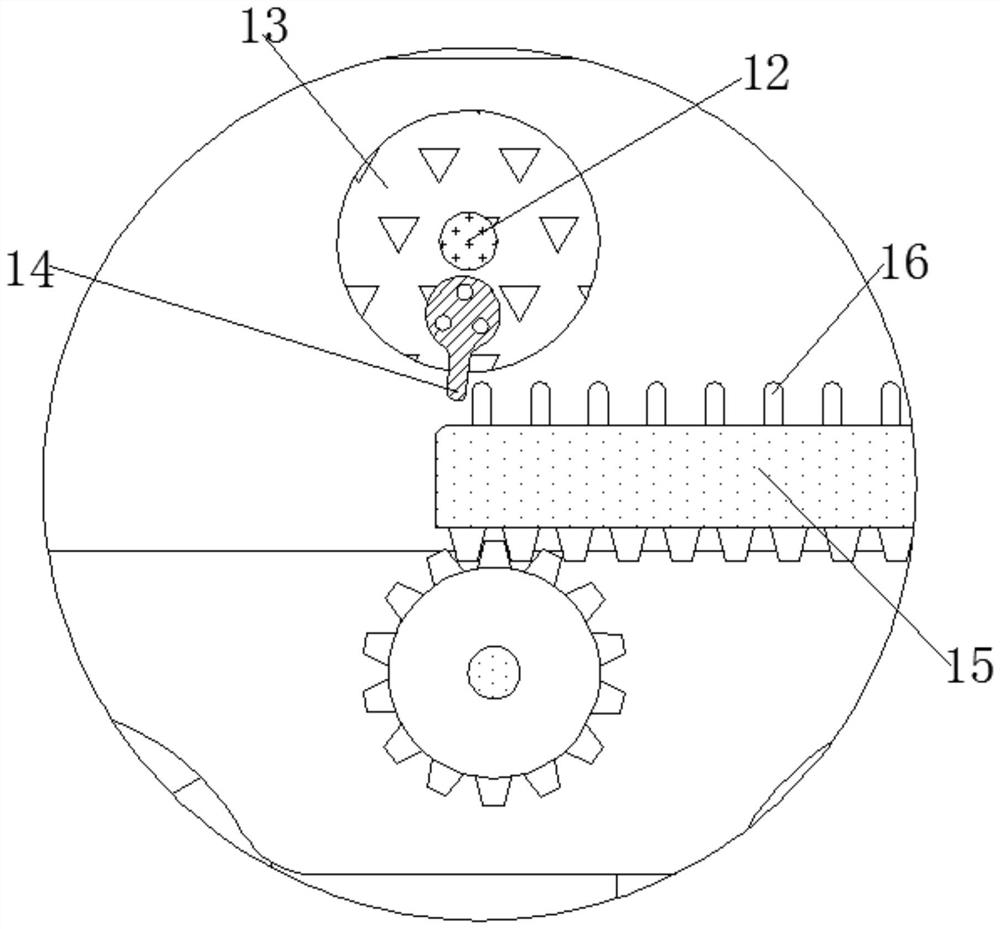

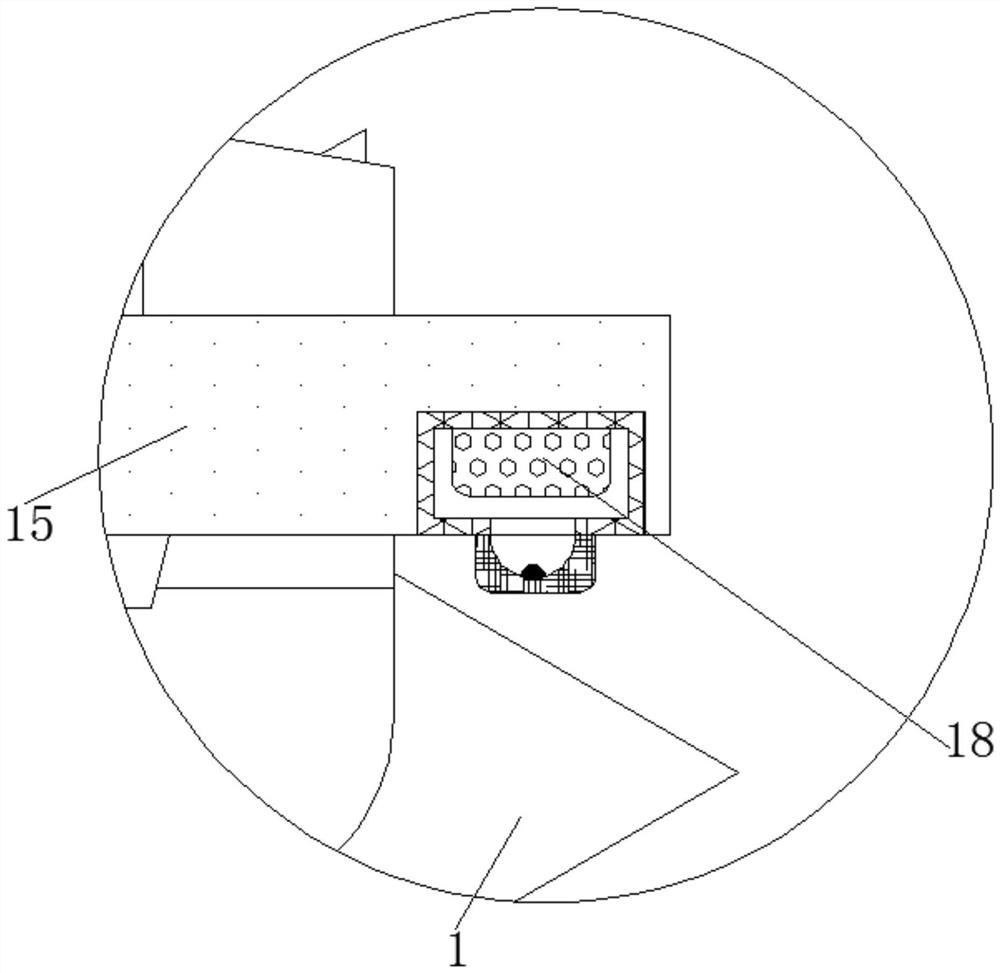

Cable production winding device with fixed-length winding function

InactiveCN112623874AImprove efficiencyWith fixed-length winding functionFilament handlingWinding functionRack and pinion

The invention relates to the technical field of cable production related equipment, and discloses a cable production winding device with a fixed-length winding function. A bracket is included, a shell is fixedly connected to the outer part of the bracket, a rotating shaft is movably connected to the inner part of the shell, a gear I is fixedly connected to the outer part of the rotating shaft, and a rack II is engaged to the outer part of the gear I. A guide rod is fixedly connected in the shell, sliding sleeves are movably connected to the exterior of the guide rod, connecting rods are movably connected to the tops of the sliding sleeves, lifting blocks are movably connected to the tops of the connecting rods, and a speed reducing plate is movably connected to the tops of the lifting blocks. Through interaction of a rotation shaft, a swing rod, a first rack, a short rod, a control assembly and a reset assembly, a cable can be quantitatively wound in the cable winding process, the situation that the specification difference between cable rollers obtained after winding is large due to manual subjective control over the cable winding amount is avoided, and therefore the cable winding requirement is met, and meanwhile subsequent selling of the cable is facilitated.

Owner:刘松林

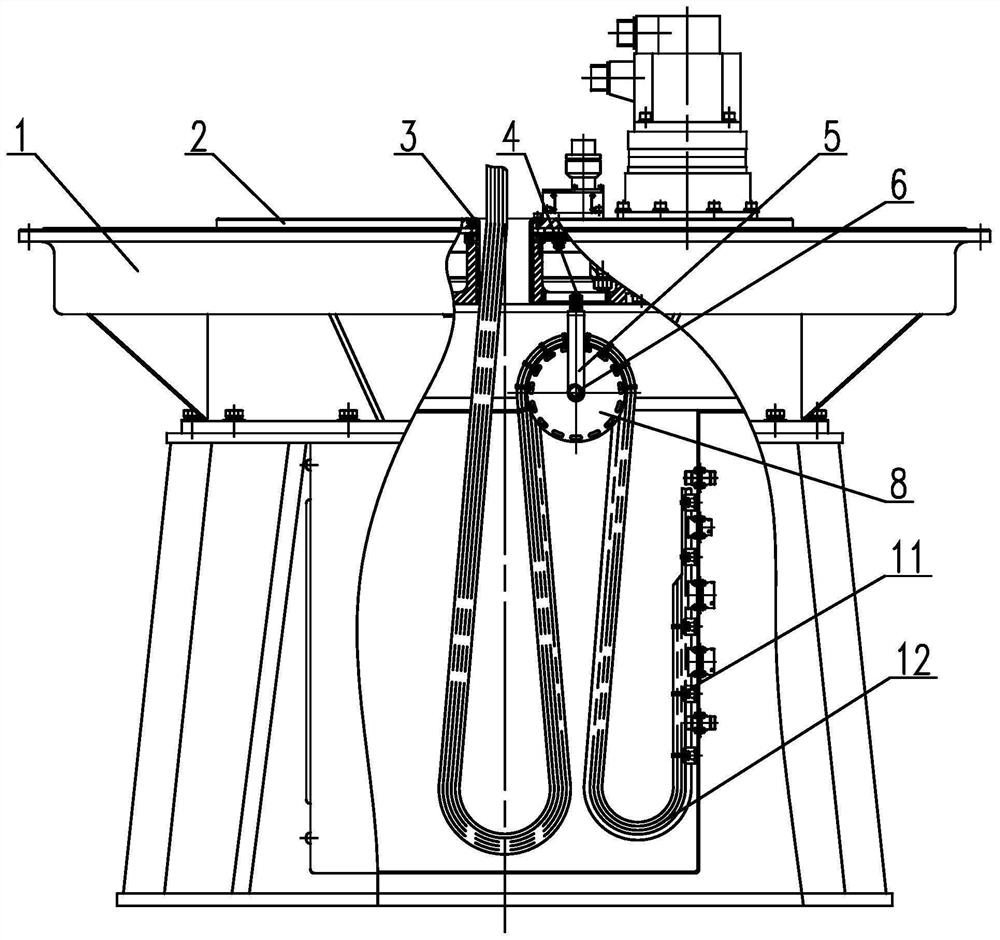

Overhanging type cable winding mechanism and method applied to reciprocating type rotary table

InactiveCN113233262AReduce torsional deformationRealize the winding processFilament handlingArrangements using take-up reel/drumTorsional deformationMechanical drive

The invention discloses an overhanging type cable winding mechanism and method applied to a reciprocating type rotary table, and belongs to the technical field of mechanical transmission. The reciprocating type rotary table comprises a rotary table fixing part and a rotary table rotating part, wherein the rotary table rotating part is rotationally installed on the rotary table fixing part. The winding mechanism comprises: a central sleeve, arranged on the rotary table rotating part; and a suspension bracket, rotatably mounted around a rotating shaft, wherein the axis of the rotating shaft is parallel to the axis of the central sleeve and is not collinear with the axis of the central sleeve; and the suspension bracket is provided with a reel, and the reel and the center sleeve jointly form a cable winding path. Through mutual cooperation of the central sleeve and the reel, when the rotary table rotates, torsion deformation of the cable can be reduced through torsion of the cable and rotation of the reel, the cable winding and protecting functions with the limit rotating angle range not smaller than + / -360 degrees are achieved, and the whole winding mechanism is simple in structure, low in manufacturing cost, reliable in use, convenient to maintain, high in environmental adaptability and high in universality.

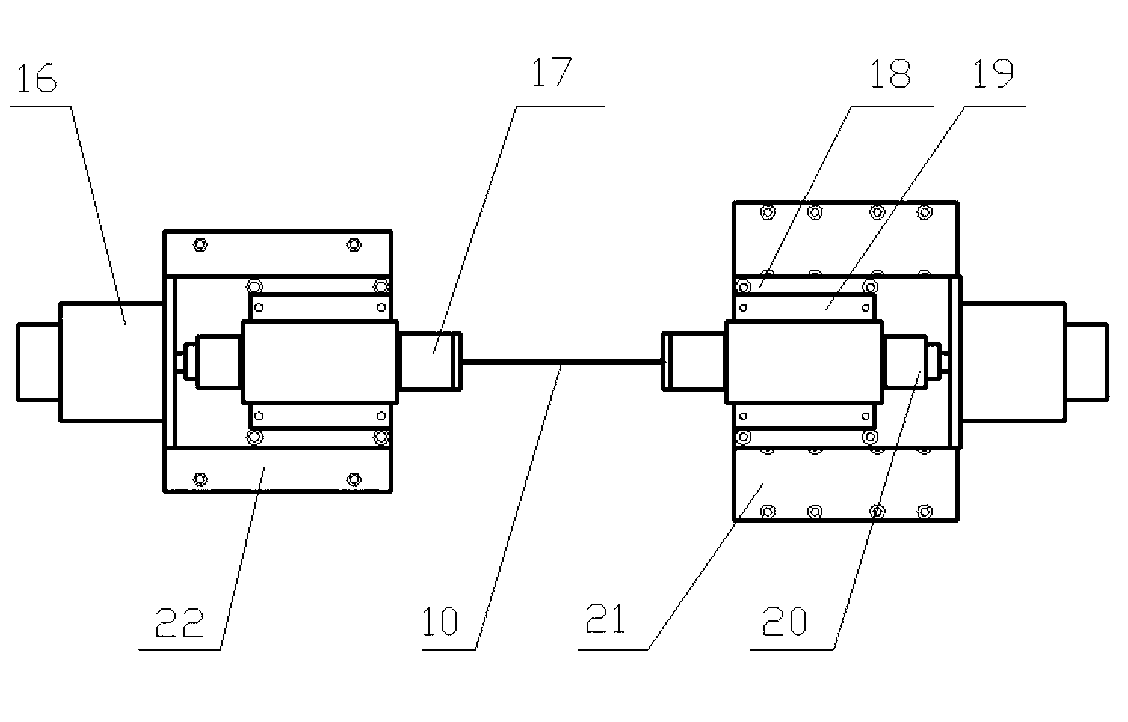

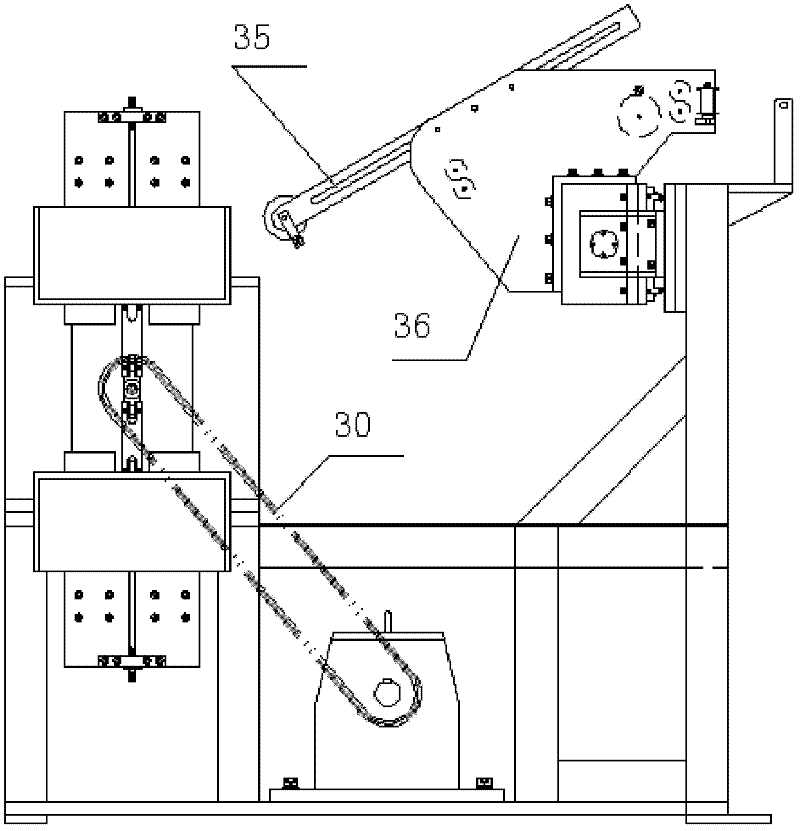

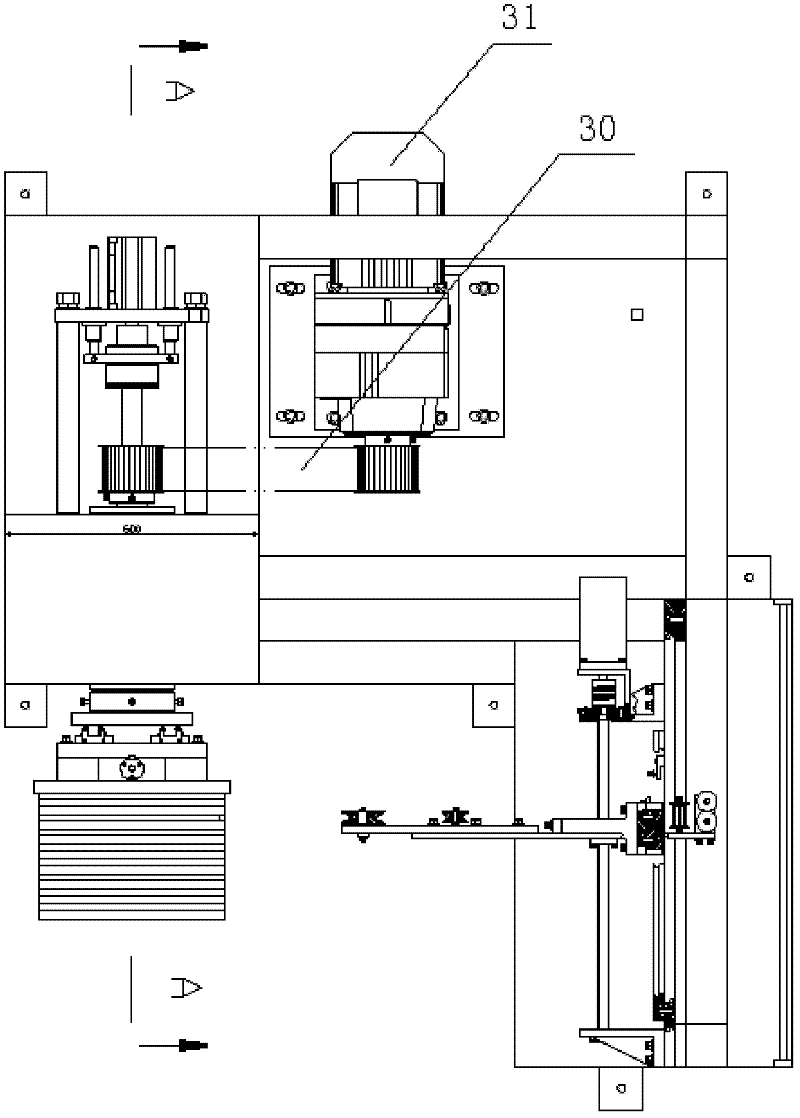

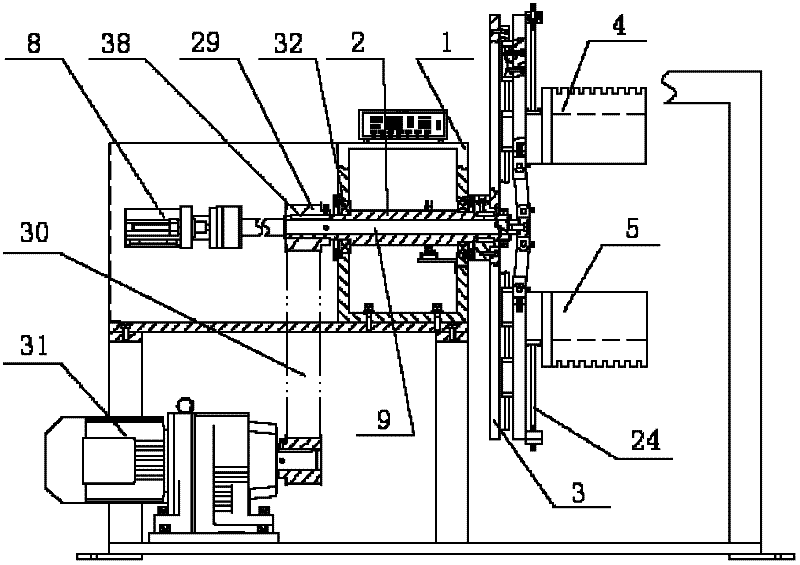

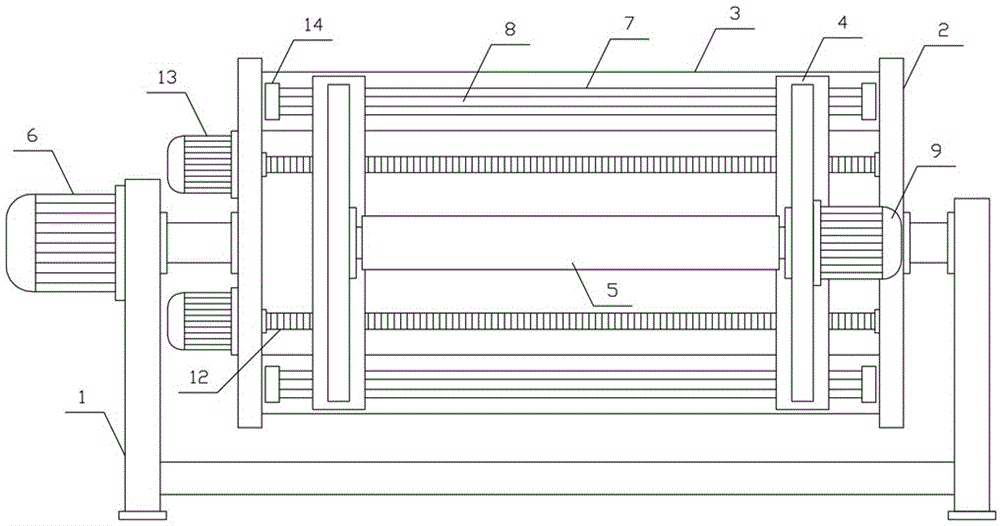

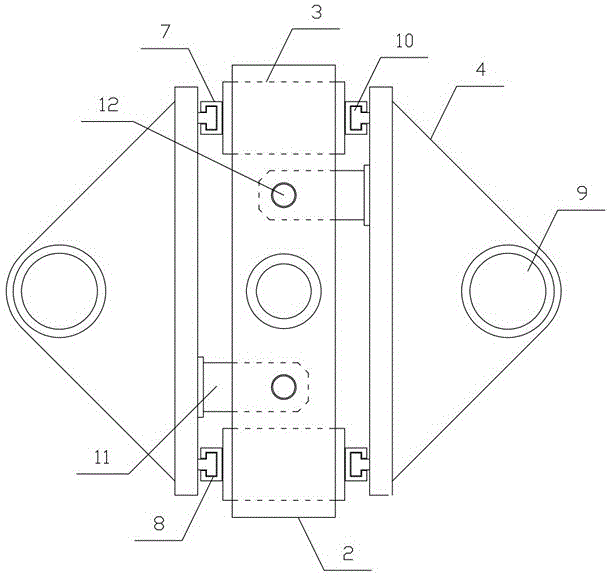

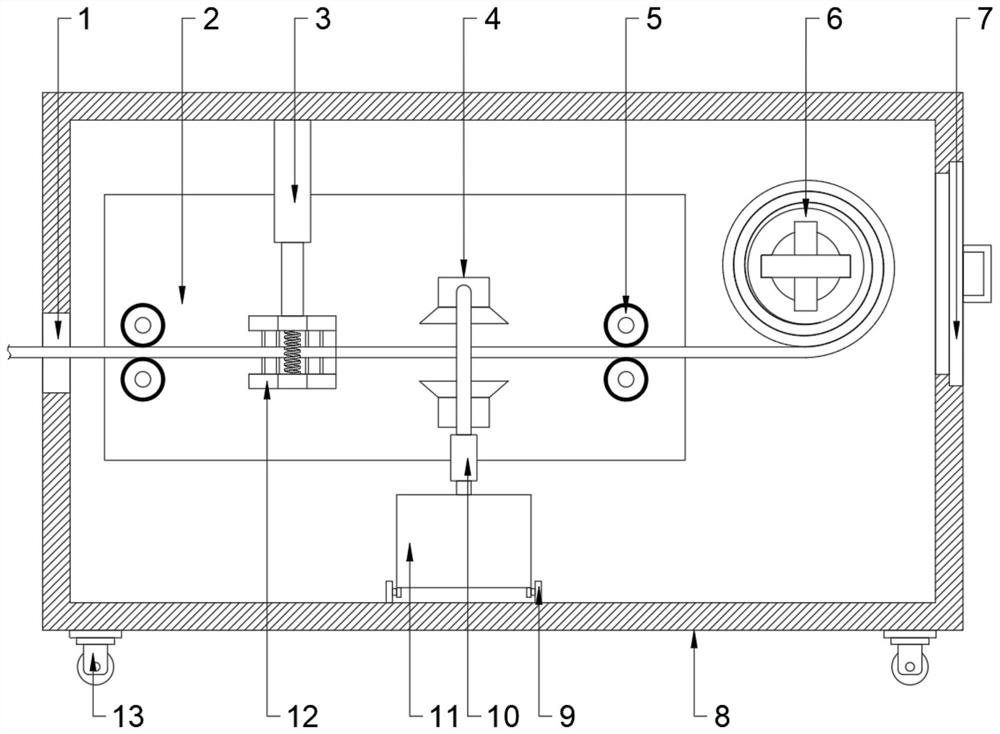

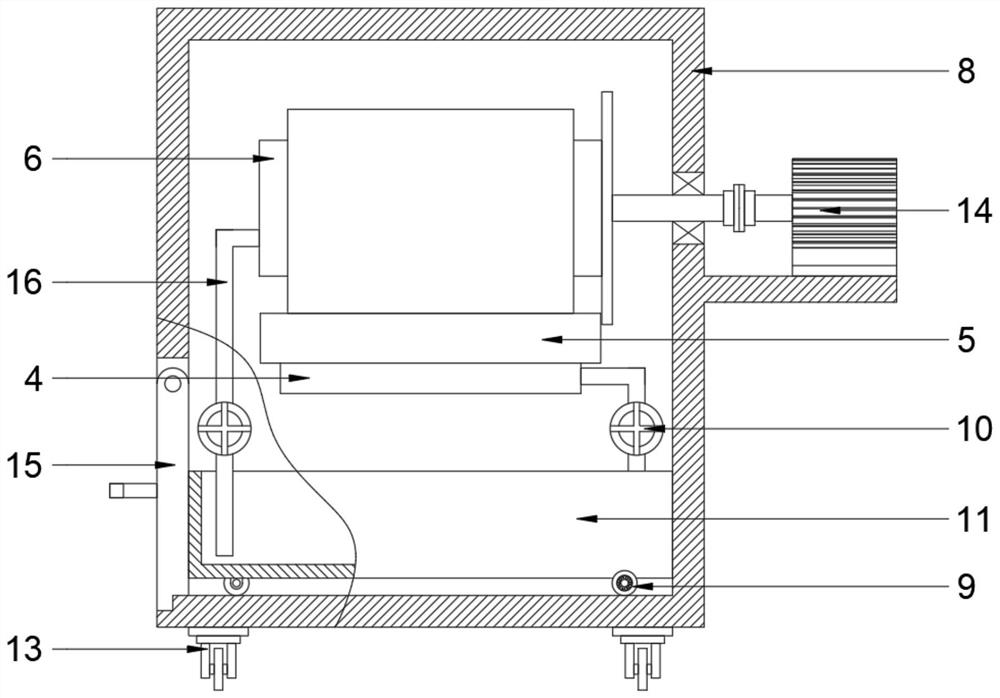

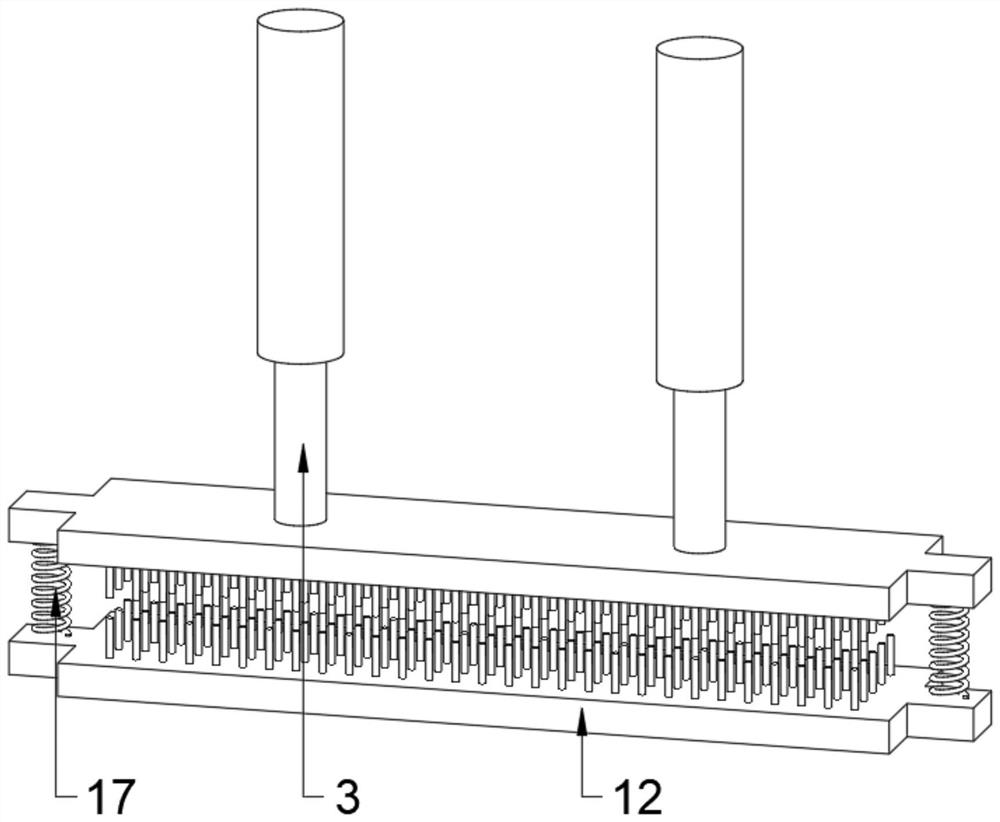

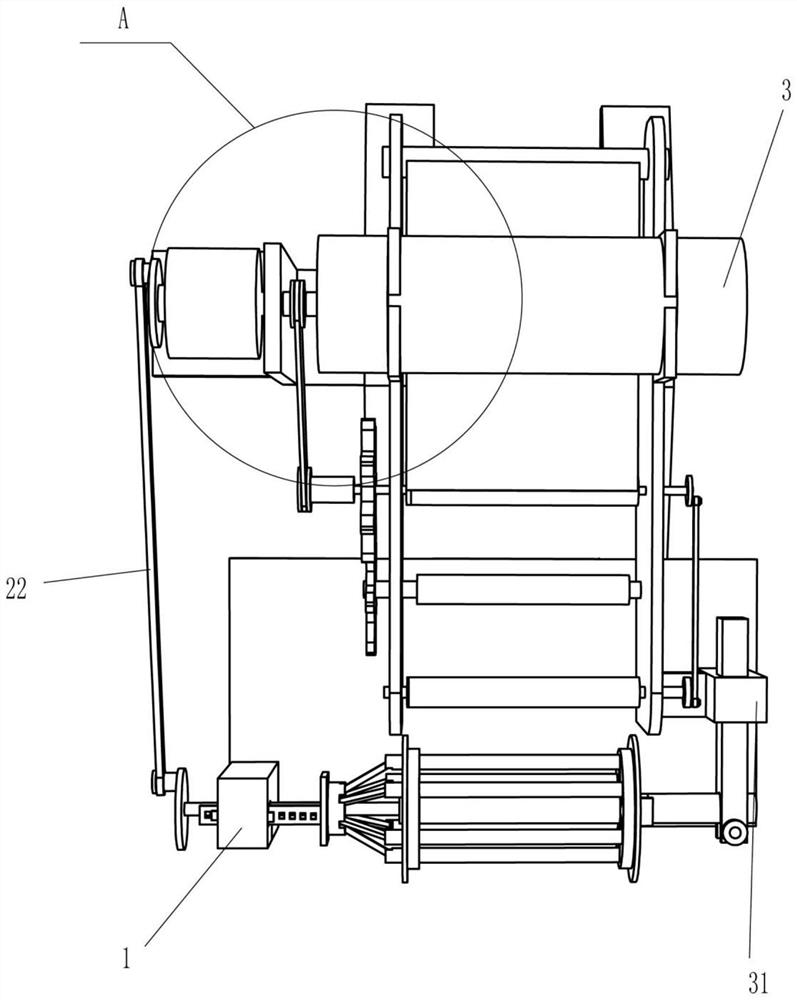

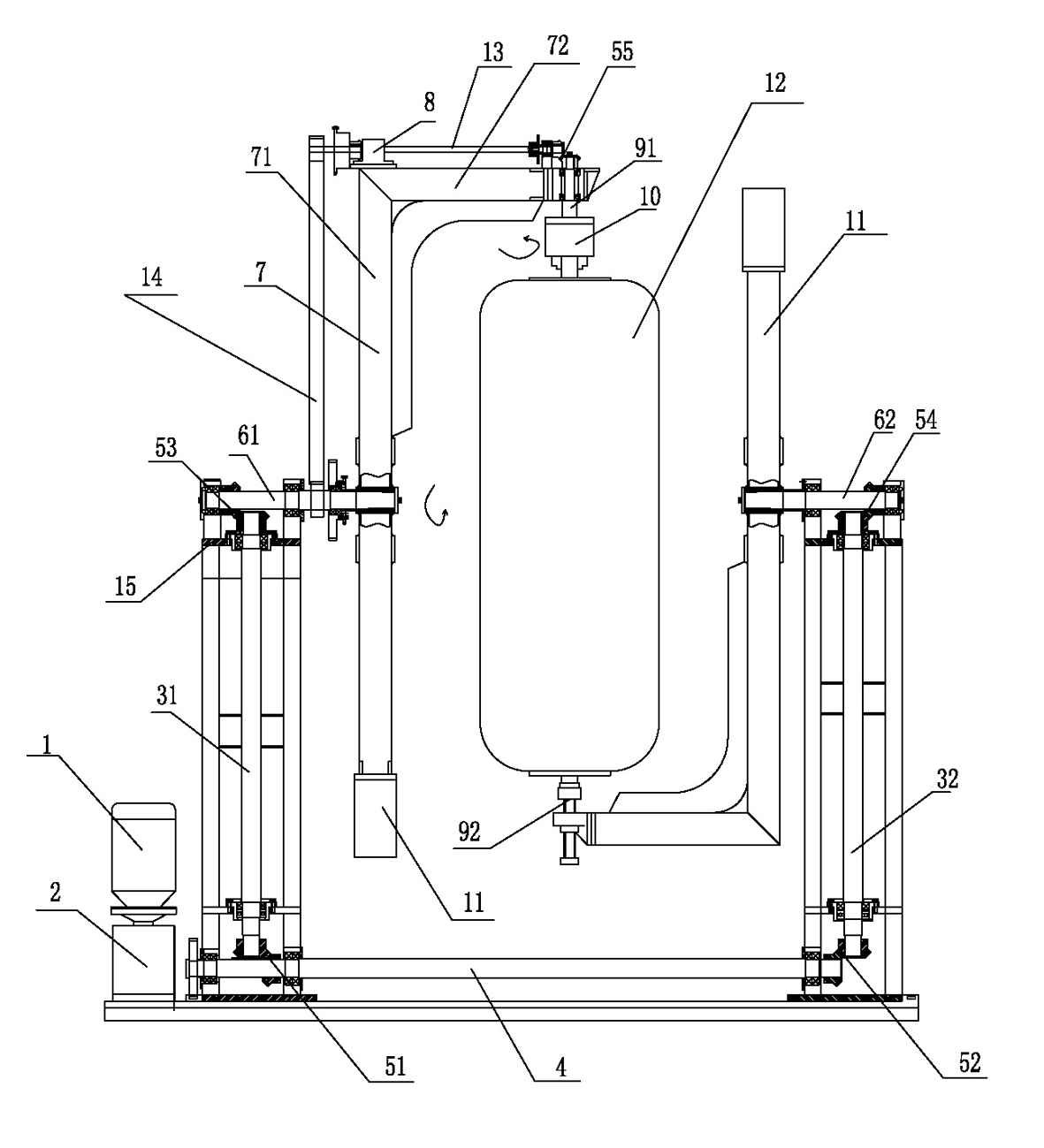

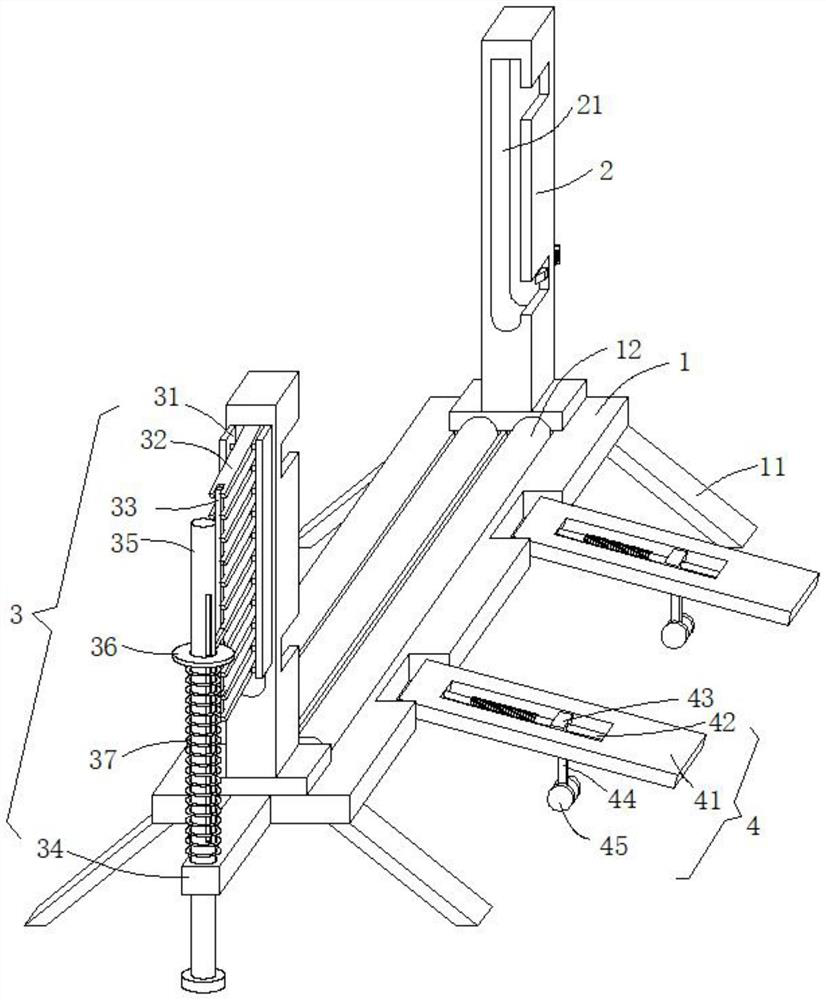

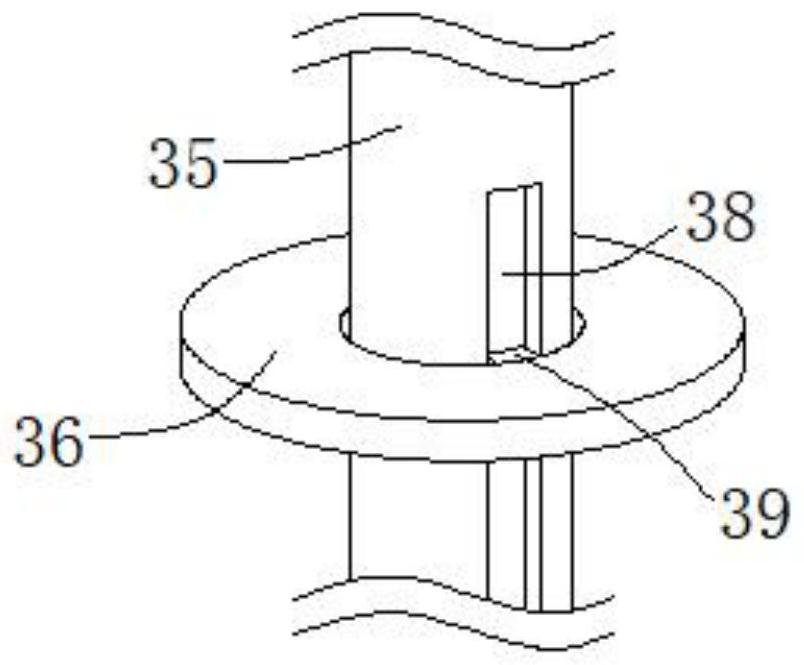

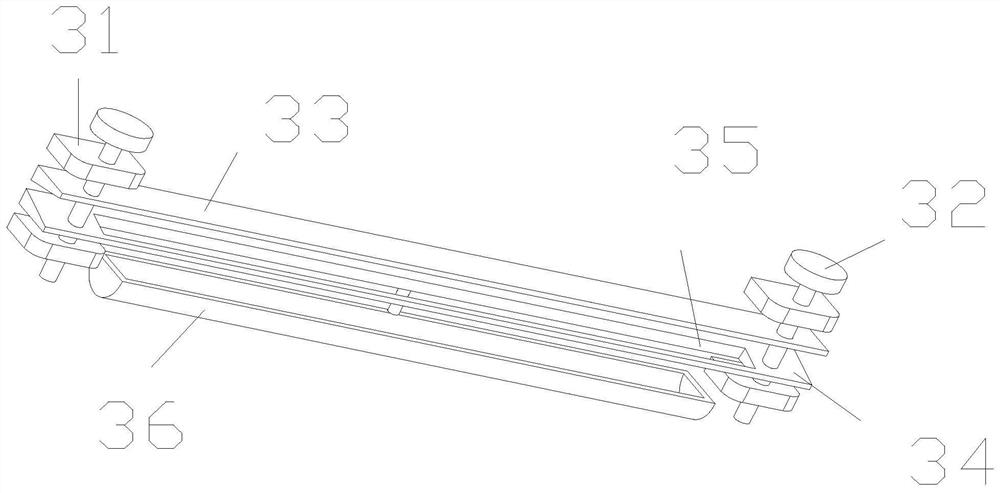

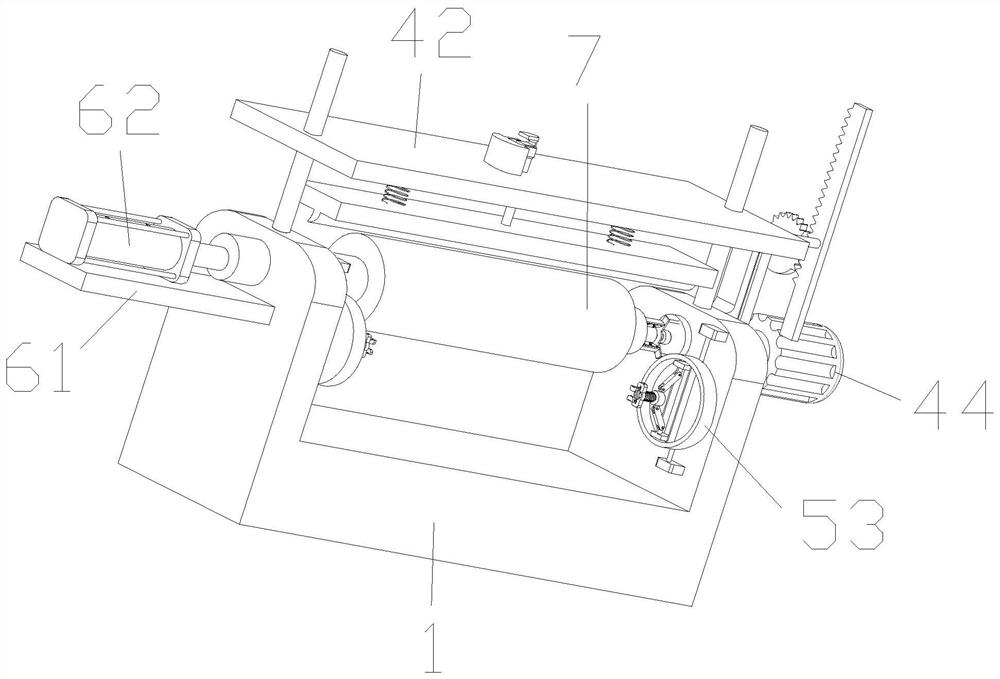

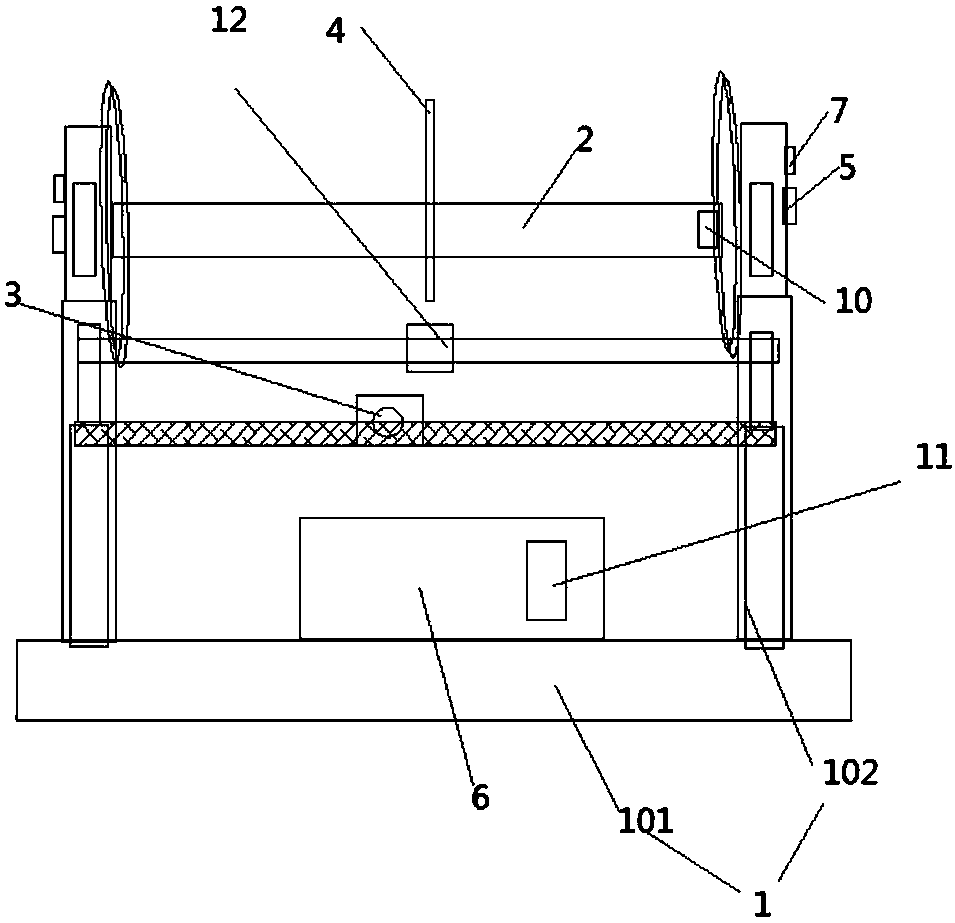

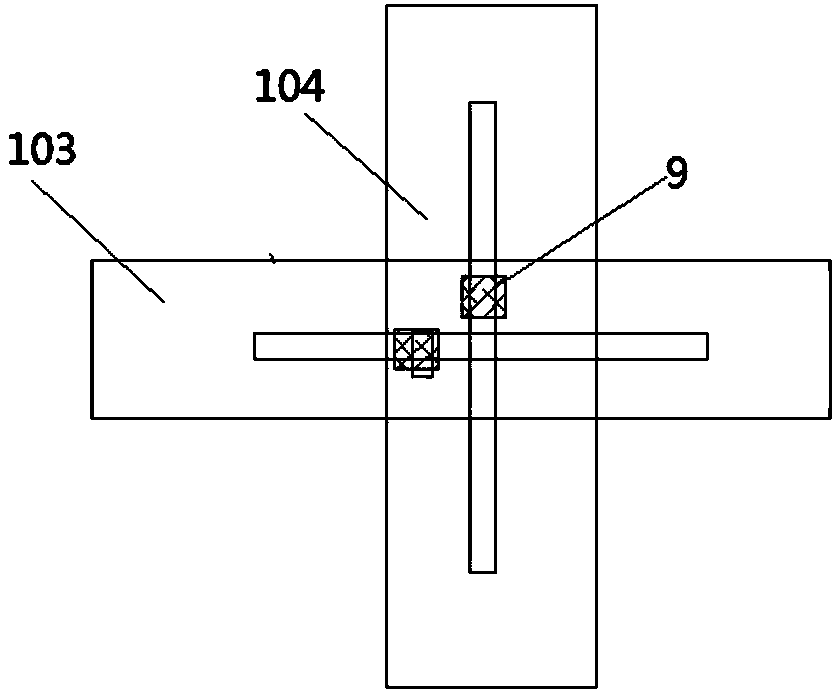

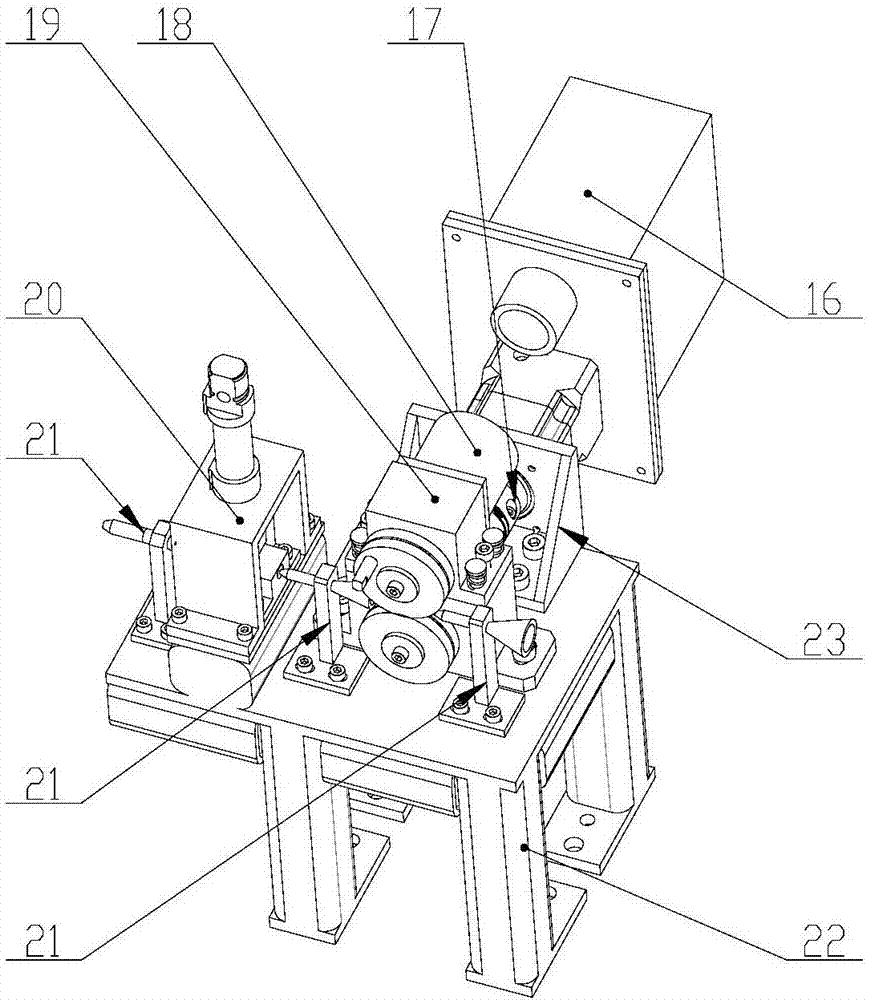

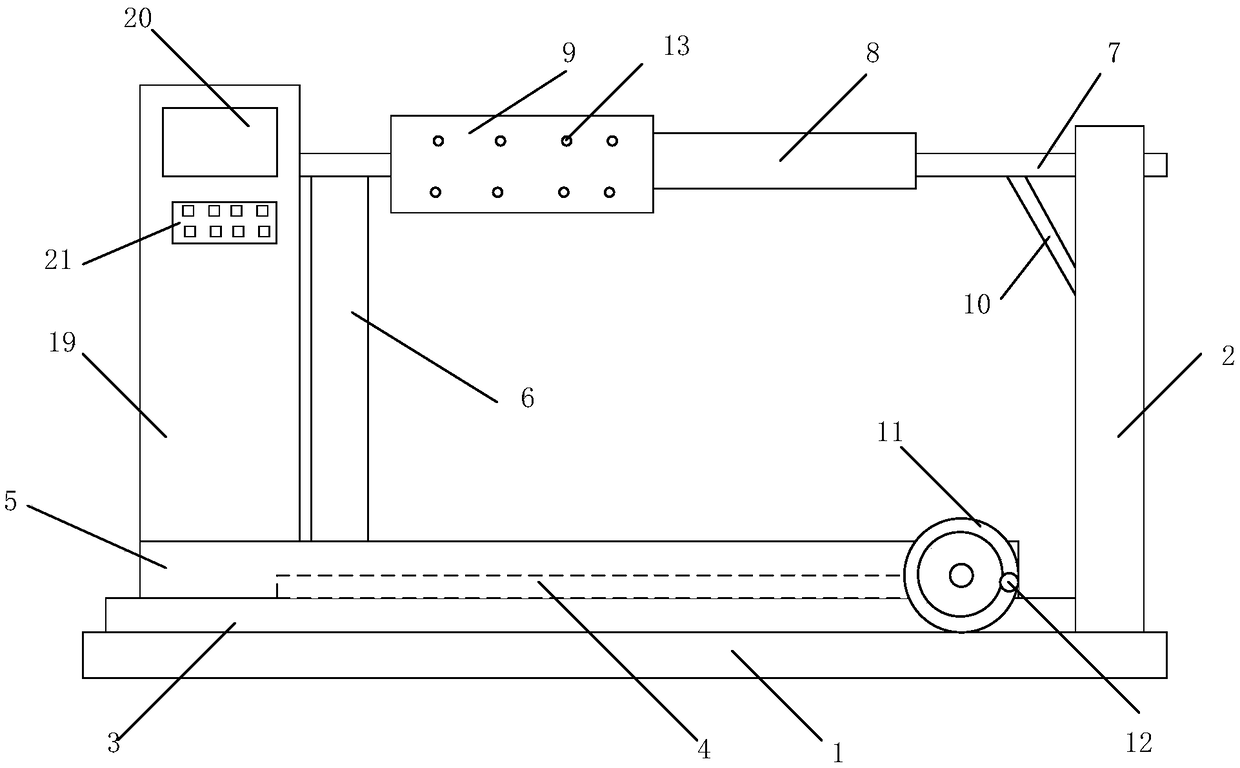

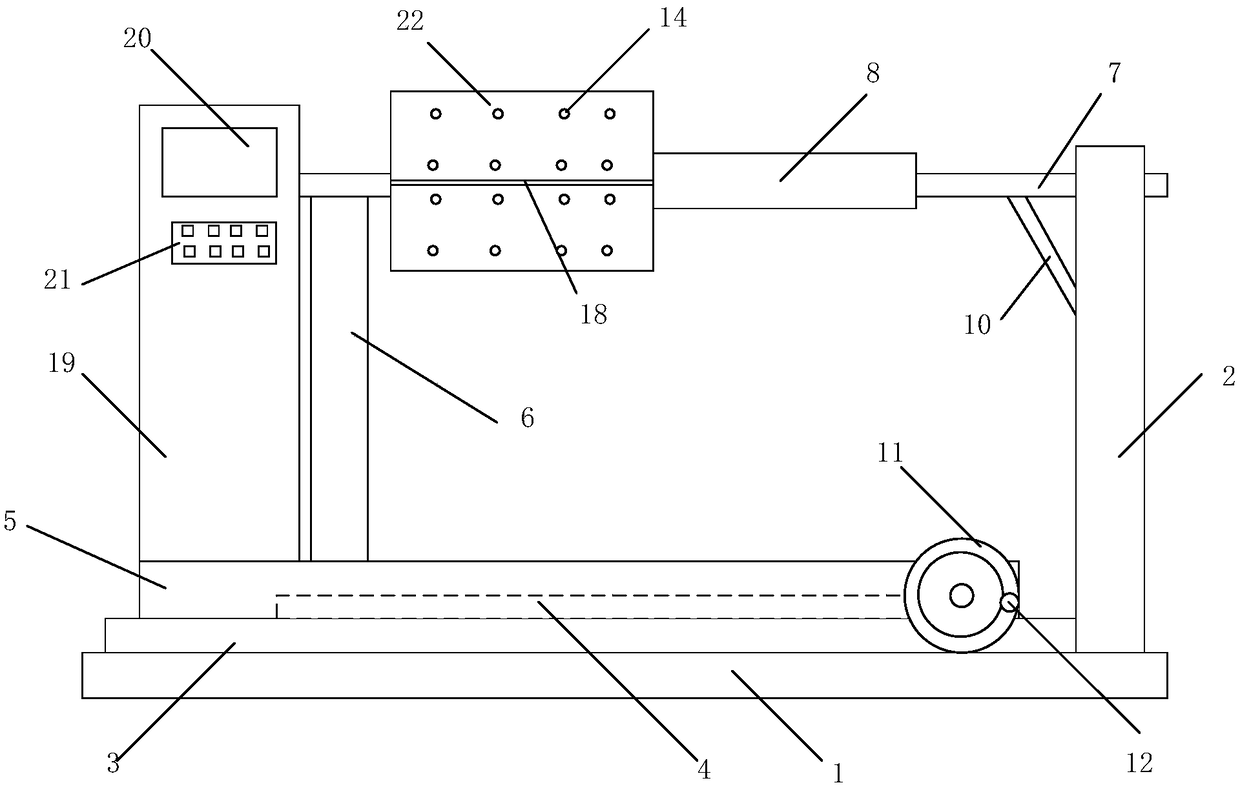

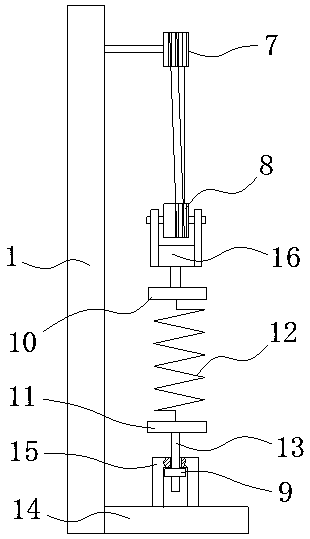

Fixed-length metal wire winding device

ActiveCN107309367AMeet the needs of windingGuarantee the quality of windingProduction scheduleEngineering

The invention relates to equipment for metal wire winding in explosion-proof occasions, particularly to a metal wire fixed-length winding device utilized in the explosion-proof occasions. The metal wire fixed-length winding device comprises a passive end coil winding group, a wire feeding device, a jacking moving device, a wire winding device and a mounting rack body, wherein the passive end coil winding group is positioned at the right end of the mounting rack body, and is mounted on the mounting rack body through bolts; the wire feeding device is mounted on the mounting rack body through holts, and is positioned between the passive end coil winding group and the jacking moving device; the jacking moving device is mounted on the mounting rack body and is below the wire winding device; and the wire winding device is mounted on the mounting rack body through bolts. According to the metal wire fixed-length winding device, the capacity of winding metal wires at fixed length is achieved, winding quality of the metal wires can be further guaranteed, the requirement of fixed-length metal wire winding is met, the automatic operation level is improved, manpower is saved, production cost is reduced, and the production schedule is quickened.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Slitting machine winding equipment suitable for plate and strip processing

PendingCN109502383AImplement lateral movement switchingMeet the needs of windingWebs handlingEngineeringMechanical engineering

The invention relates to slitting machine winding equipment suitable for plate and strip processing. The slitting machine winding equipment suitable for plate and strip processing comprises a bearingbase. An equipment support is arranged on one side of the bearing base. A base rail is mounted above the bearing base. The base rail comprises a base body. A guide rail is erected on the base body. The guide rail is connected with a traction sliding block. A manual adjusting device is mounted on one side of the traction sliding block. A mounting support is arranged on the traction sliding block. Awinding assembly is arranged on the mounting support. A winding assembly is connected with a driving device. The winding assembly comprises a winding shaft. A main winding drum is mounted on the winding shaft. An adjustable winding drum is arranged on one side of the main winding drum. An extension block is mounted on the adjustable winding drum. An auxiliary supporting arm is further connected to the equipment support. One end of the auxiliary supporting arm is connected with the winding shaft. Thus, through arrangement of the independent traction sliding block, transverse movement switchingof the winding assembly can be realized.

Owner:苏州东南铝板带有限公司

Winding device for synchronous belt

The invention discloses a winding device for a synchronous belt. The winding device comprises a winding roller, two ends of the winding roller are provided with limiting assemblies used for limiting axial displacement of the synchronous belt respectively, and the limiting assemblies are detachably and fixedly connected with the winding roller; and the limiting assemblies can move in the axial direction of the winding roller so that the distance between the limiting assemblies can be adjusted according to the width of the synchronous belt. According to the winding device for the synchronous belt, the axial displacement of the synchronous belt is limited through the limiting assemblies so that the phenomena of dislocation and the like of the synchronous belt during winding can be prevented;the limiting assemblies are detachably and fixedly connected with the winding roller, the limiting assemblies can move in the axial direction of the winding roller so that when the widths of the synchronous belts are different, the distance between the limiting assemblies can be adjusted according to the widths of the synchronous belts, and therefore the winding needs of the different synchronousbelts can be met; and the winding device has the advantages of being simple in structure and low in production cost;

Owner:GUANGDONG UNIV OF TECH

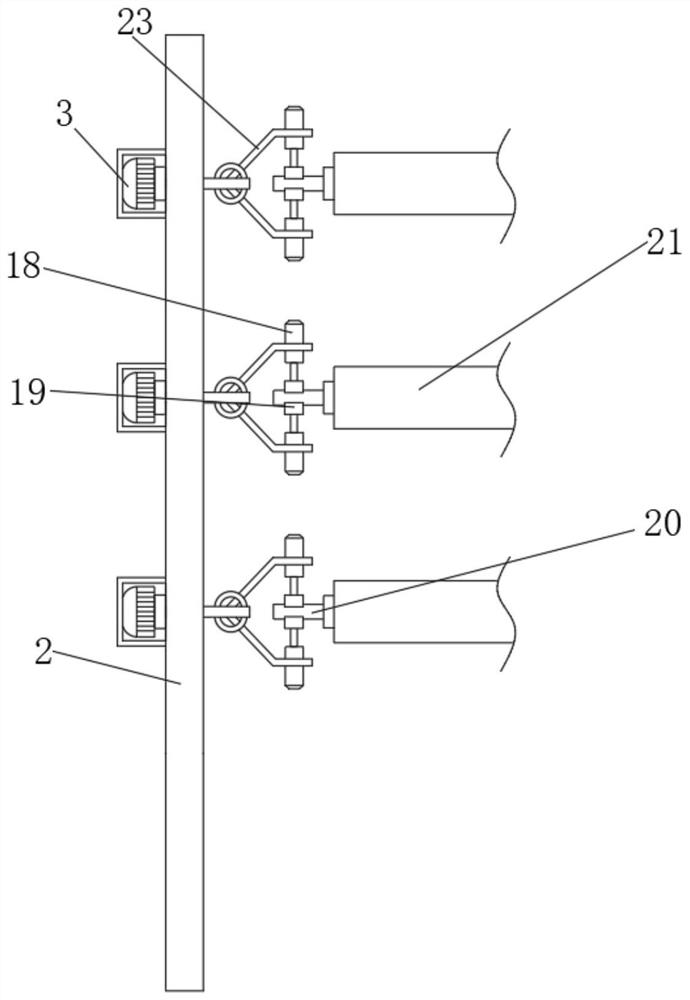

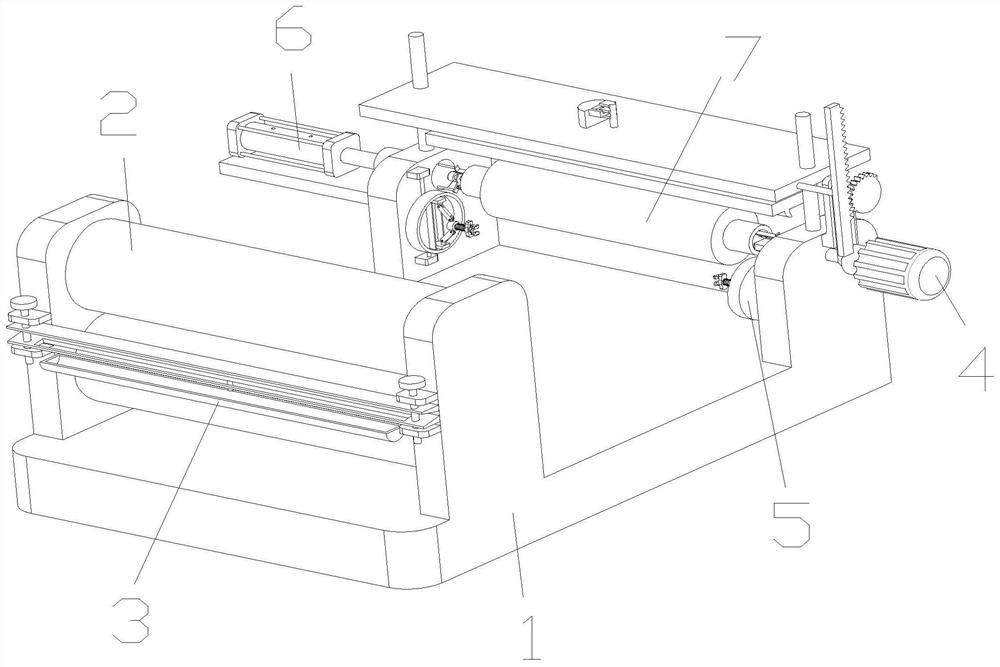

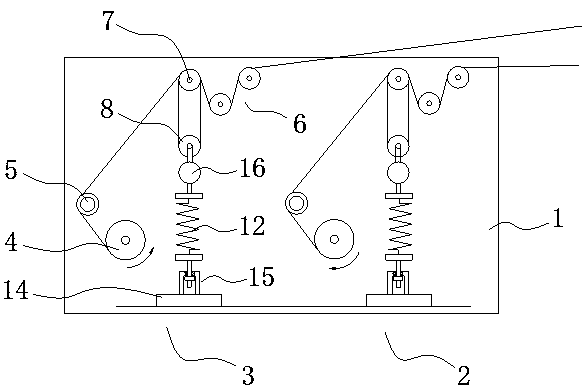

Industrial belt glass fiber wire winder capable of performing stepless adjustment on tensioning force

The invention provides an industrial belt glass fiber wire winder capable of performing stepless adjustment on a tensioning force so as to meet the winding requirement of a glass fiber wire. The winder provided by the invention comprises a vertical substrate; the side wall of the substrate is provided with a wire-feeding winding device and a take-up winding device; each of the wire-feeding windingdevice and the take-up winding device comprises a wire roller, a guide roller, a tensioning roller set and a wire pressing roller set; each tensioning roller set comprises an upper fixed roller, a lower movable roller, a fixed seat and an elastic mechanism; the upper fixed rollers are rotatably arranged on the substrate each elastic mechanism consists of an upper spring seat, a lower spring seatand a spring connected between the upper spring seat and the lower spring seat; the bottom part of each lower spring seat is provided with a vertical stud; each fixed seat consists of a base and a limiting frame arranged on the base; a through hole in the vertical direction is formed in each limiting frame; the rotating shaft of each lower movable roller is connected with the corresponding upper spring seat; the stud of each lower spring seat extends downwards into the through hole of the corresponding limiting frame; and a nut is arranged at a position, under the limiting frame, of each stud.

Owner:茂名市腾龙工业皮带有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com