Dust-proof winding device for water pumping pipe belts for water conservancy project

A water conservancy project and winding device technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of poor practicability, small application range, and inability to adjust, and achieve strong practicability, Improve work efficiency and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

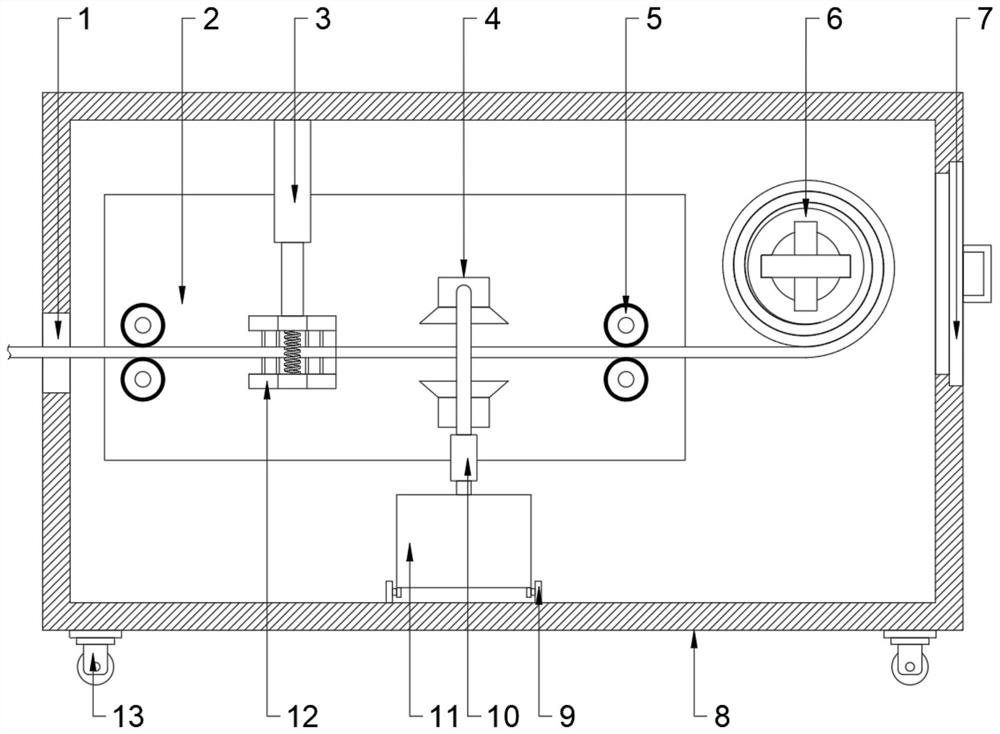

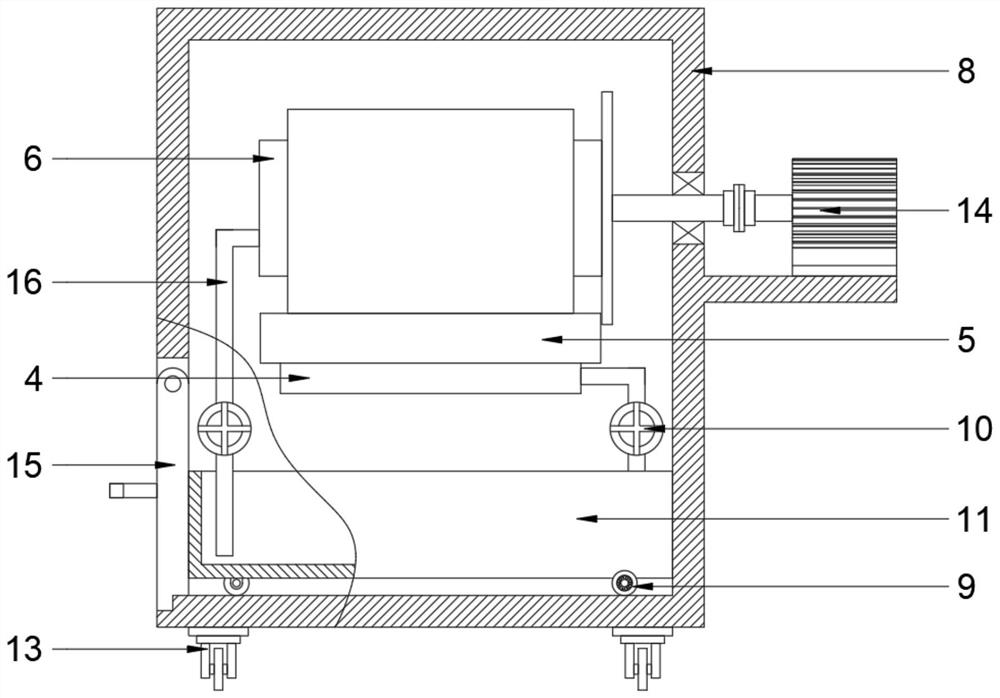

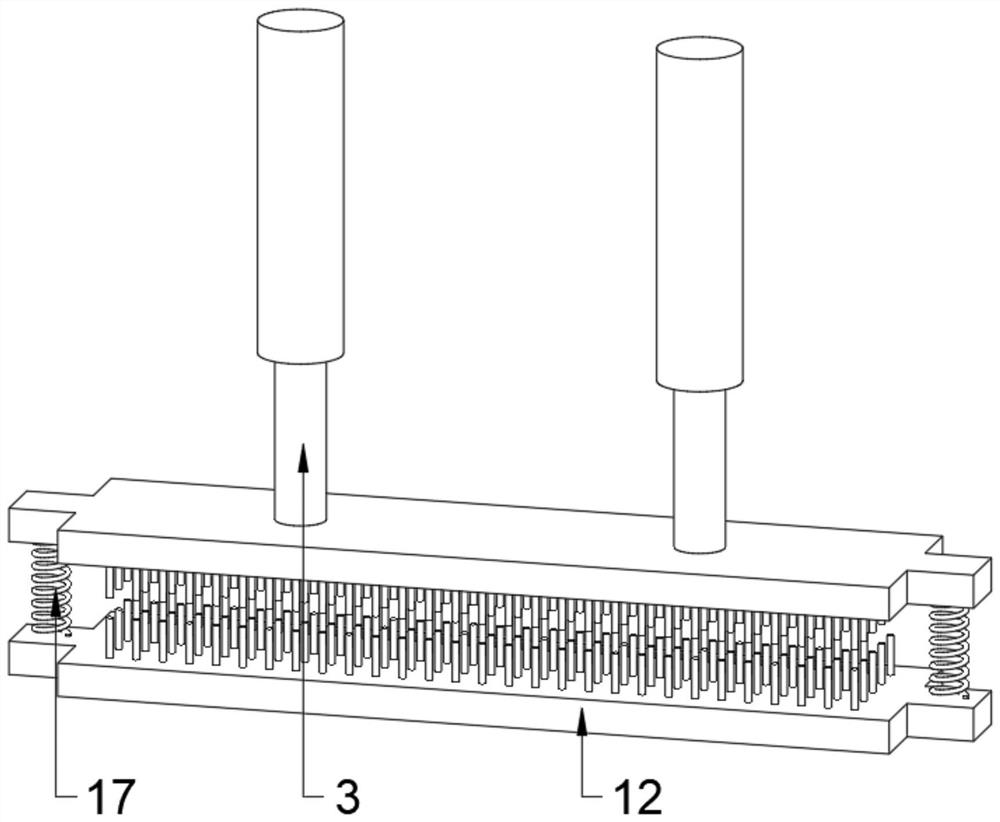

[0027] see Figure 1-6 , in an embodiment of the present invention, a water conservancy project with a dust-proof rewinding device for a suction pipe belt, comprising a box body 8 and a dust removal assembly and a rewind assembly arranged inside the box body 8, and the two sides of the box body 8 are respectively provided with The feed port 1 and the discharge door 7 are convenient for the input and output of the suction pipeline; the dust removal assembly includes a scrubbing device and a dust suction device, and the scrubbing device and the dust suction device are installed side by side inside the casing 8 and the scrubbing device is close to the inlet The side where the material opening 1 is located; the winding assembly includes a fixing device and a winding sleeve 6 sleeved on the periphery of the fixing device. One end of the fixing device is rotatably mounted on the side wall of the box body 8 and is located near the discharge door 7 One side of the winding shaft sleeve...

Embodiment 2

[0036] see Figure 1~2, in an embodiment of the present invention, a water conservancy project with a dust-proof winding device for the suction pipe belt, in order to facilitate the scrubbing device and the dust cleaning device to better remove the dust on the suction pipe belt, and to better rewind the suction pipe of the winding assembly belt, to improve the working efficiency of the device. On the basis of Embodiment 1, multiple sets of feeding rollers 5 are arranged inside the box body 8, and the feeding rollers 5 are rotatably mounted on the side wall of the box body 8 and form a For the layout, place the suction pipe belt between two sets of feeding rollers 5, use the two sets of feeding rollers 5 to hold up the suction pipe belt, and lay it flat at the same time, so as to facilitate subsequent brushing, vacuuming and winding work. Enhance dust removal effect and improve winding efficiency.

[0037] The outer periphery of the feeding roller 5 is also provided with a pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com