Connecting structure for seat body and working head of electric tool and electric tool

A connection structure and electric tool technology, which is applied in the direction of manufacturing tools and portable mobile devices, etc., can solve the problems of single function of electric tools and poor matching of electric tools, and achieve the effects of easy promotion, ensuring connection stability, and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

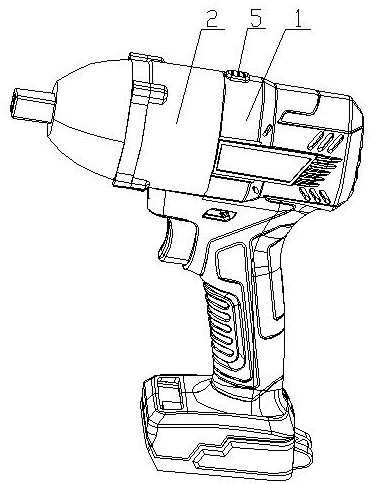

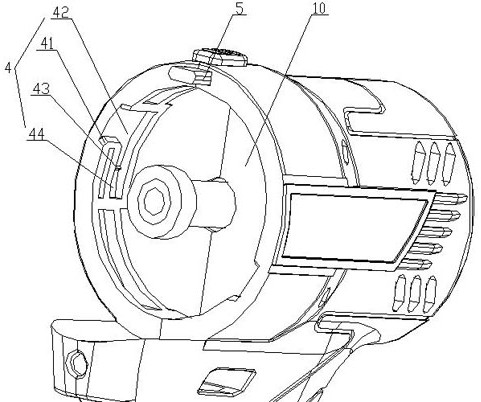

[0027] Such as figure 1 It shows the first embodiment of the connection structure between the power tool base and the working head in the present invention. The power tool base and the working head are detachably connected through the connection structure. The connection structure includes placing the working head 2 close to The two corresponding projections 3 on the side end surface of the seat body 1 also include two card slots 4 placed on the side end surface of the seat body 1 close to the working head 2 and a limit card placed on the side end surface of the seat body 1 close to the working head 2 Block 5, the position limiting card block 5 is placed between the two card slots 4, and the two protrusions 3 are matched with the two card slots 4;

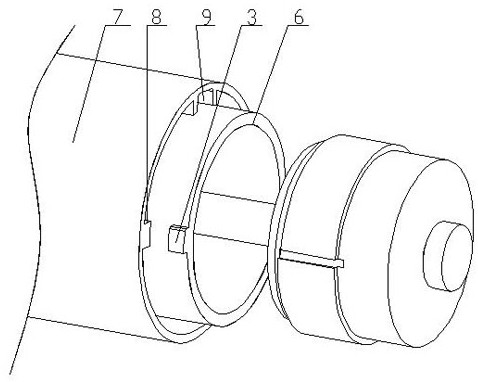

[0028] Such as image 3 As shown, the side of the working head 2 close to the seat body 1 has an inner ring body 6 and an outer ring body 7, and there are a plurality of connecting columns 8 between the inner ring body 6 and the o...

Embodiment 2

[0036] Such as Figure 4 Shows the second embodiment of the present invention, both sides of the bump 3 have elastic pieces 11, when the bump 3 snaps into the cavity 44 formed by the limit bar 43 and the inner wall of the L-shaped recess 42, the bump 3 The elastic sheet 11 on one side of the block 3 is in close contact with the L-shaped recess 42 , and the elastic sheet 11 on the other side of the protruding block 3 encloses the limiting strip 43 in the elastic sheet 11 .

[0037] Further, the elastic piece 11 includes a longitudinal portion 111 fixedly connected to the side end surface of the protrusion 3, a circular arc portion 112 placed at the upper end of the longitudinal portion 111, and an inclined portion 113 placed at one end of the circular arc portion 112. The opening of the circular arc portion 112 It is arranged downward and smoothly transitions the longitudinal part 111 and the inclined part 113. The limit bar 43 is clamped between the inclined part 113 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com