Aluminum alloy formwork structure easy to disassemble

A technology of aluminum alloy formwork and formwork, which is applied in the direction of formwork/formwork member, formwork/formwork/work frame connector, building structure, etc., which can solve the problem of exposed connectors, cumbersome and time-consuming installation of the whole set of equipment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

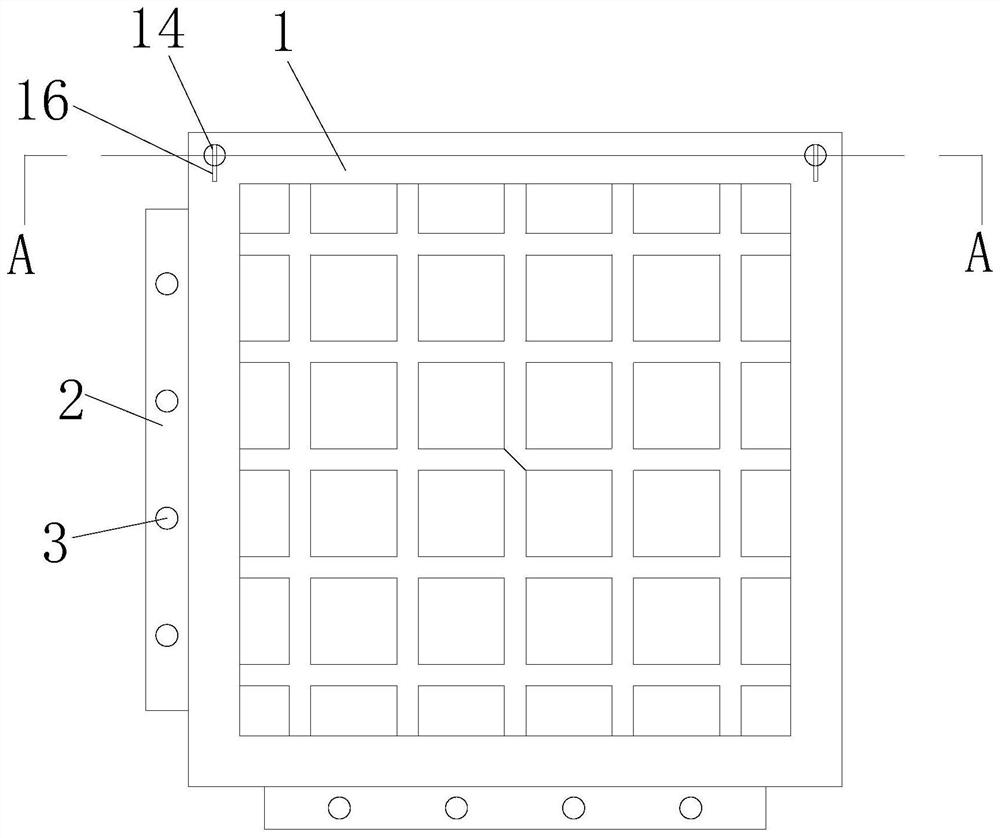

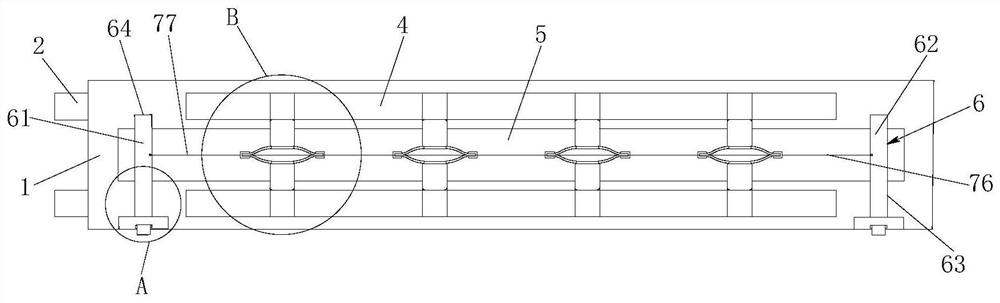

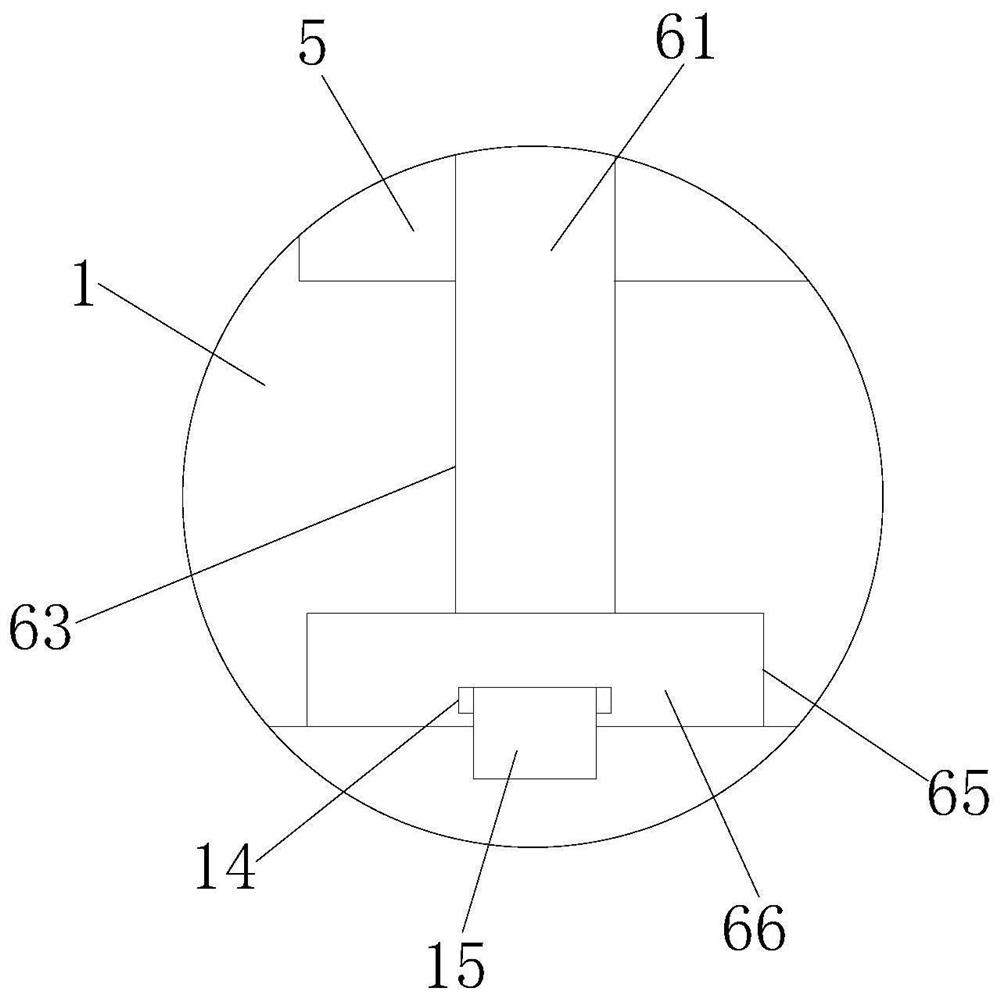

[0026] see Figure 1-7 , the present invention provides a technical solution: an easy-to-detach aluminum alloy formwork structure, including a rectangular formwork base 1, the left side and the lower surface of the formwork base 1 are fixedly connected with two parallel inserting plates 2, and the inserting There are four equidistantly arranged sockets 3 on the plate 2, two parallel slots 4 are provided on the upper surface and the right side of the formwork base 1, and cavities are provided on the top and right side of the formwork base 1 5, and the cavity 5 is in the corresponding two slots 4, and the slot 4 is provided with a quick snap-in mechanism 6, the length of the slot 4 is greater than the length of the insertion rod 2 and the difference between the two is the width of the insertion rod 2 Twice of that, it can ensure the smooth installation of the formwork base 1 during the installation process.

[0027] The fast clamping mechanism 6 includes movable rod one 61, mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com