Flange structure convenient to install and using method thereof

A technology for flanges and fixed flanges, which is applied to mechanical equipment, couplings, etc., can solve the problems of reduced efficiency, trouble, and reduced sealing performance, and achieve the effects of quick installation, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

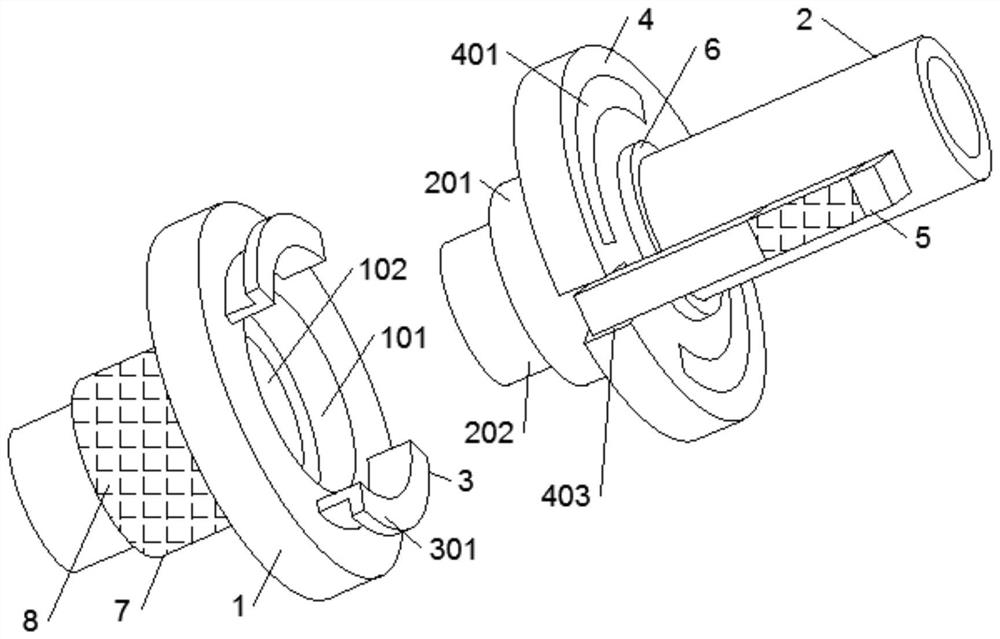

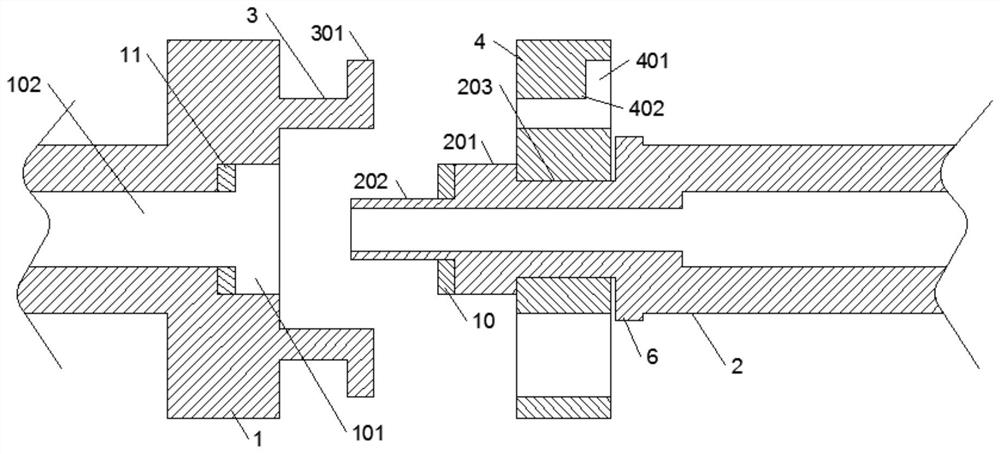

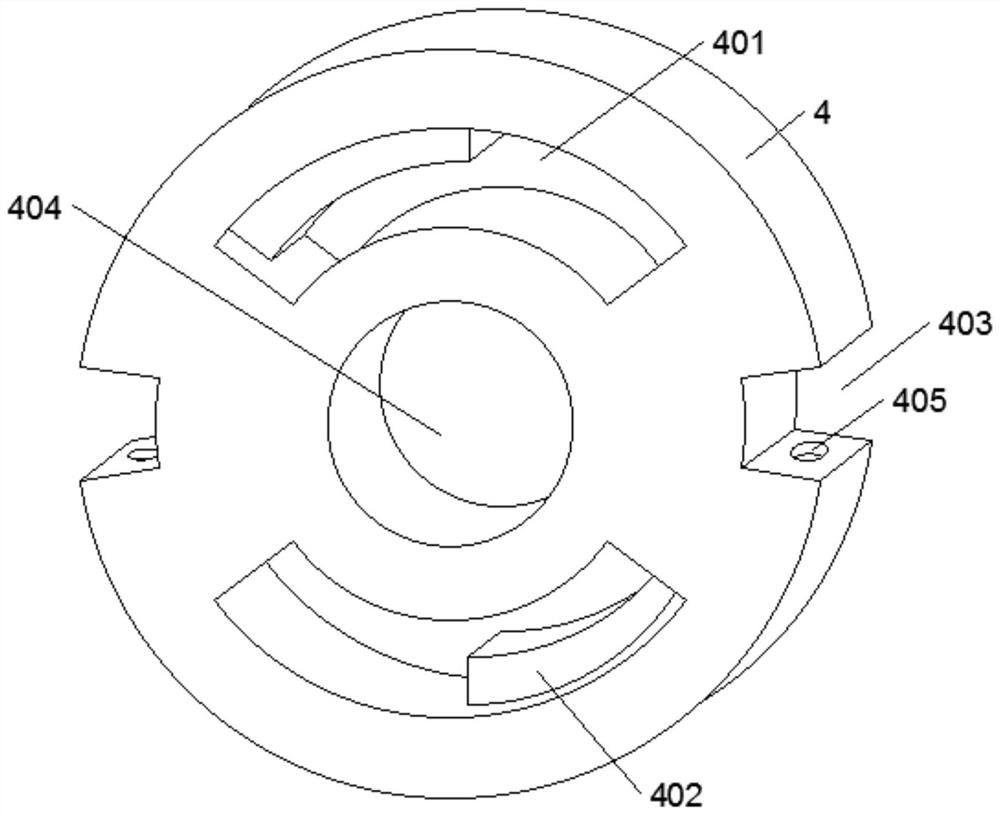

[0045] like Figure 1-Figure 7 As shown, the easy-to-install flange structure provided by this embodiment includes a fixed flange 1 and a connecting flange 2. The fixed flange 1 is provided with symmetrically distributed locking pieces 3, and the locking pieces 3 are fixedly provided with convex The ear 301, the lock head piece 3 and the lug 301 are perpendicular to each other, the connecting flange 2 is provided with a runner lock groove 203, and the runner lock groove 203 is rotated to be provided with a runner lock 4, and the runner lock 4 rotates Afterwards, it is used to engage and connect with the lock piece 3. The rotary lock piece 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com