Optical fiber sensor mounting structure of natural gas pipeline leakage optical fiber monitoring system

A fiber optic sensor and natural gas pipeline technology, which is applied in the pipeline system, application of light to test fluid tightness, gas/liquid distribution and storage, etc., can solve the problem of unstable installation and connection of fiber optic sensors, leakage fiber optic monitoring system, and single snap-in locking And other problems, to achieve the effect of stable installation structure, convenient use and convenient operation of optical fiber sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

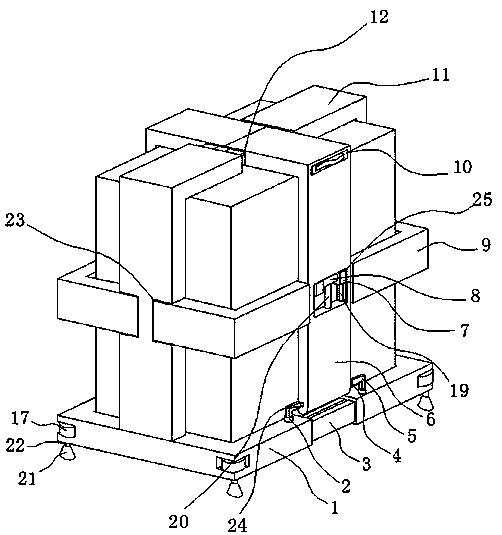

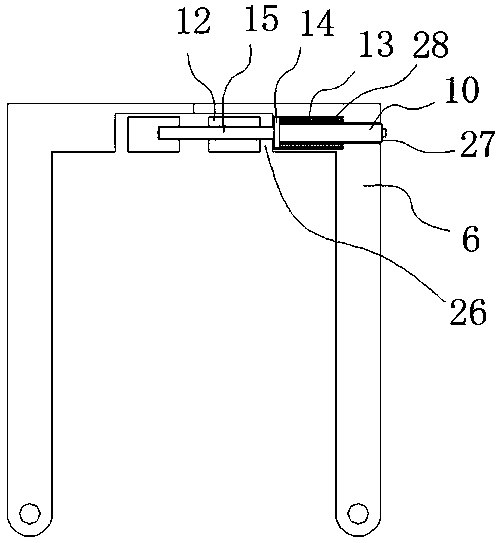

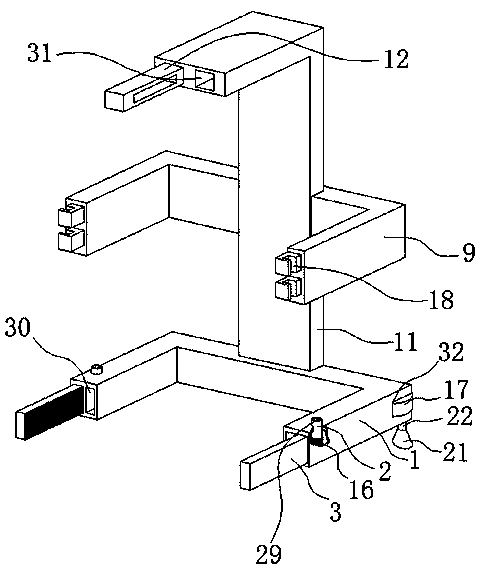

[0020] An optical fiber sensor installation structure for a natural gas pipeline leakage optical fiber monitoring system, including support frames 1 installed on both sides of the optical fiber sensor, two support frames 1 are clamped on the lower side of the optical fiber sensor, and both ends of the support frame 1 are provided with a second A rack bar 3 , the two ends of the support frame 1 are also provided with first slots 30 , and the first slots 30 are located on one side of the first rack bar 3 .

[0021] Rotation is connected with gear 16 in the first slot 30, and one end of gear 16 is connected with rotation bar 2, and the top of support frame 1 is provided with the rotation opening that communicates with first slot 30, and one end of rotation bar 2 passes through rotation opening, One end of the first rack bar 3 away from one of the support frames 1 is inserted into the first slot 30 of the other support frame 1, and one side of the first rack bar 3 is meshed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com