An easy-to-detachable aluminum alloy formwork structure

A technology of aluminum alloy formwork and formwork, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame connectors, building structures, etc., which can solve the cumbersome installation of the entire set of equipment, affect the beauty of the formwork structure, and expose the connectors Problems such as outside, to achieve the effect of quick disassembly and assembly, ensuring reliability, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

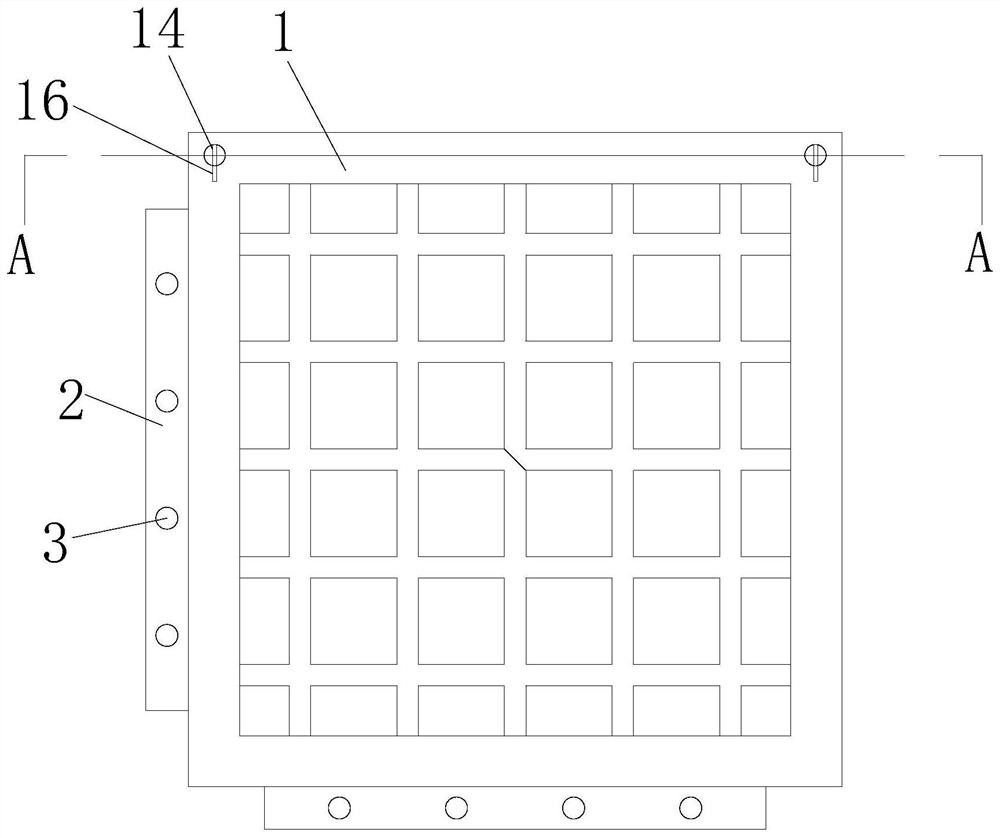

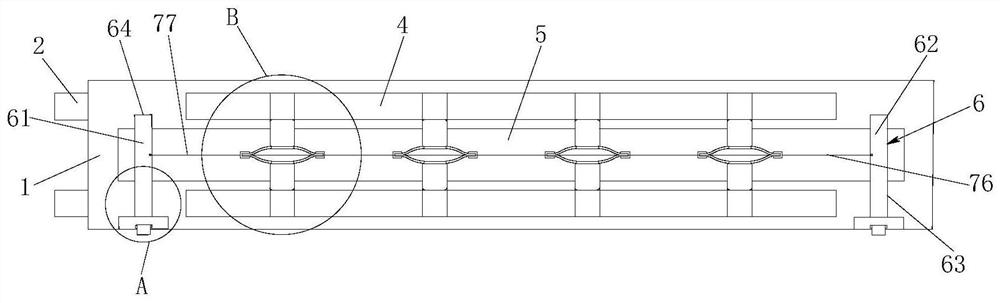

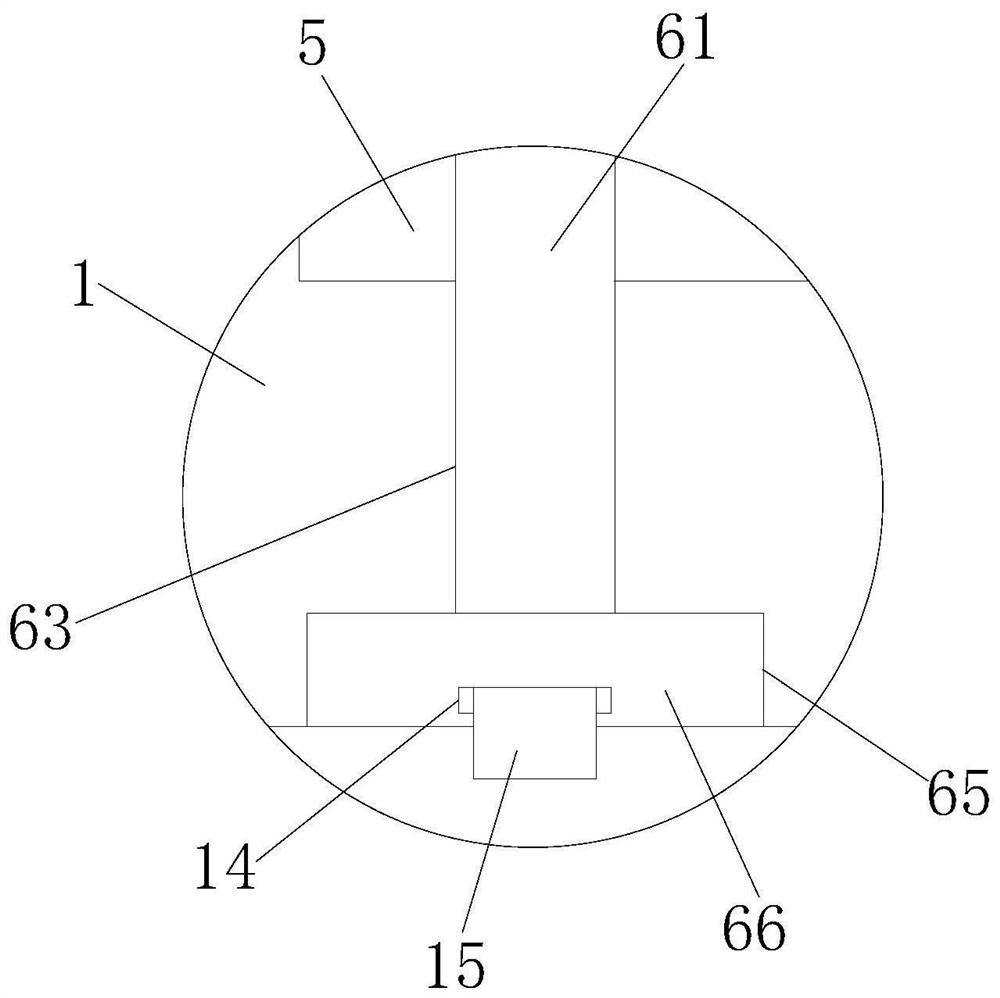

[0026] see Figure 1-7 , The present invention provides a technical solution: an easily dismantled aluminum alloy template structure, comprising a rectangular template base 1, the left side and the lower surface of the template base 1 are fixedly connected with two mutually parallel plug boards 2, The plate 2 is provided with four equidistantly arranged sockets 3, the upper surface and the right side of the template base 1 are provided with two parallel slots 4, and the top and the right end of the template base 1 are provided with cavities. 5, and the cavity 5 is in the corresponding two slots 4, the slot 4 is provided with a quick clamping mechanism 6, the length of the slot 4 is greater than the length of the insertion rod 2 and the difference between the two is the width of the insertion rod 2 It can ensure the smooth installation of the formwork base 1 during the installation process.

[0027] The quick clamping mechanism 6 includes a movable rod 61, a movable rod 2 62, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com