Method for plating chromium on molybdenum core rod

A core rod, rectangular technology, applied in the field of chemical electroplating, molybdenum core rod electrochrome plating, can solve the problems of chromium layer peeling, thick ends of molybdenum core rod, chromium layer is not dense, etc., to achieve adhesion without peeling, Good process consistency and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

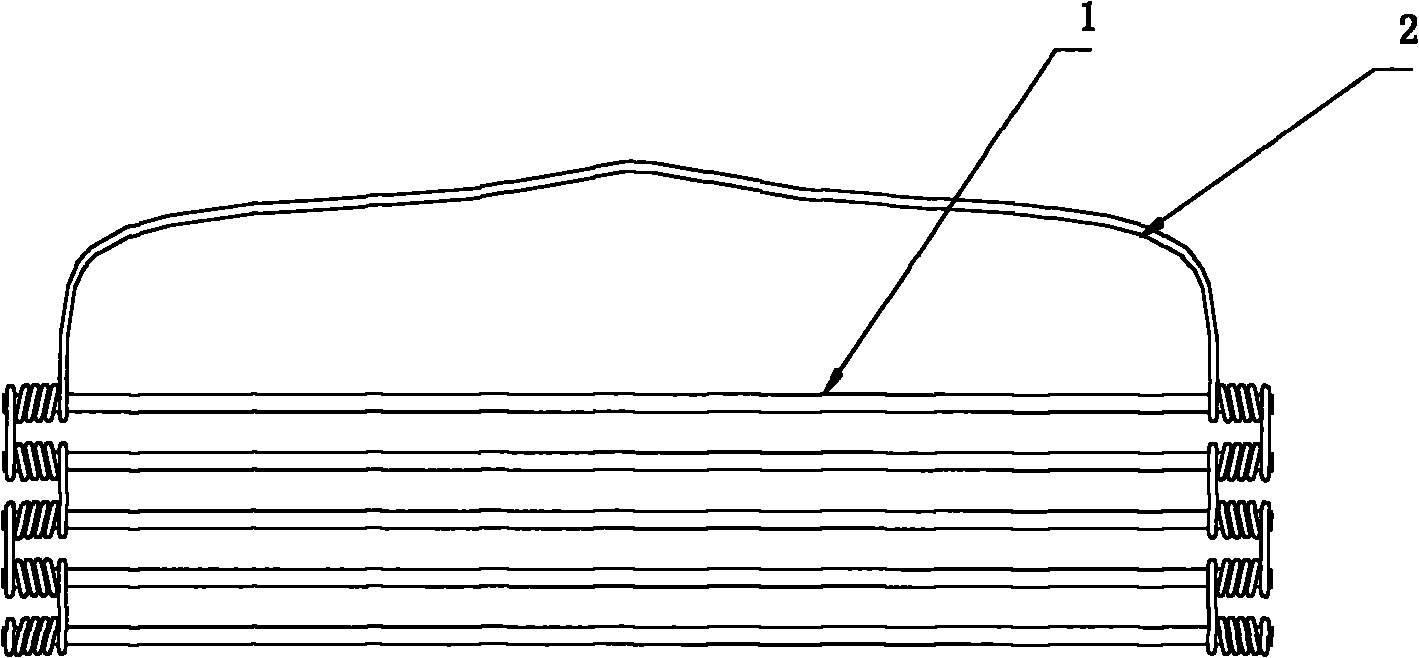

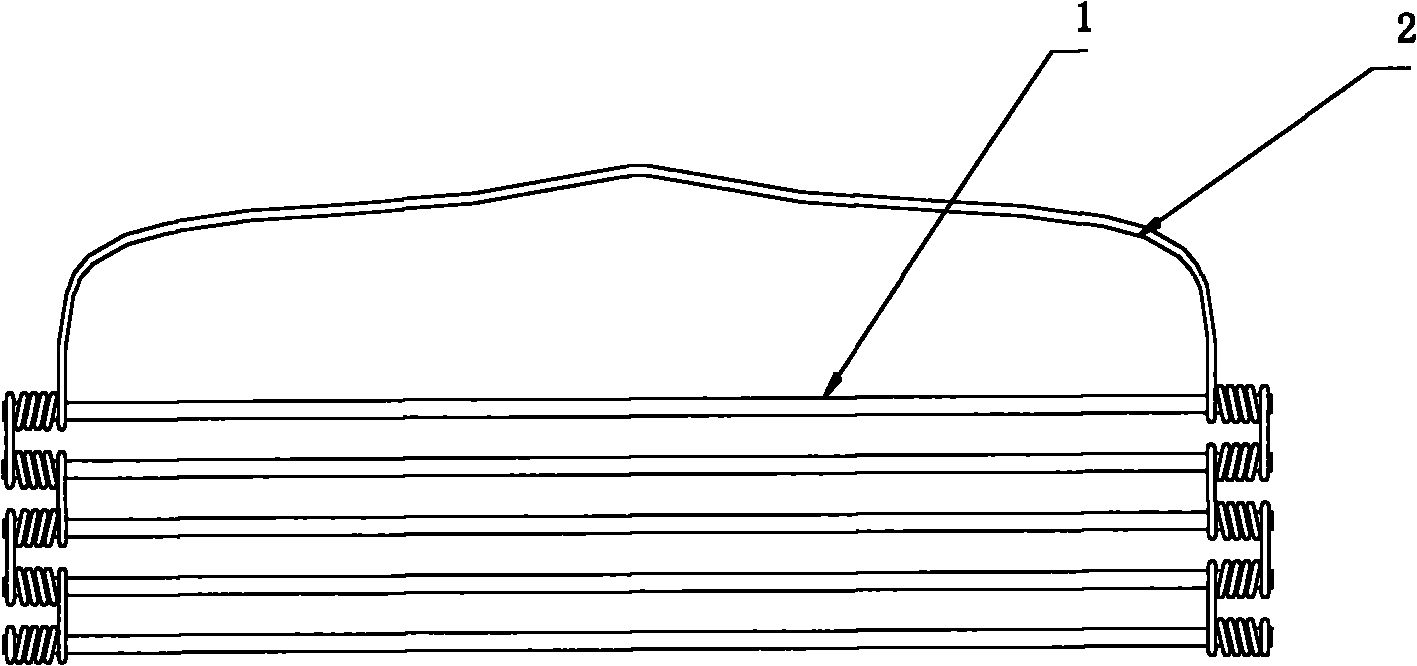

[0022] As can be seen from Figure 1, the method for chrome plating of this molybdenum core rod specifically includes:

[0023] 1) The two ends of the metal wire 2 are respectively tightly wound on the two ends of the molybdenum core rod 1, and fully chemically cleaned;

[0024] 2) Turn on the electroplating power supply, immediately connect the molybdenum core rod 1 to the negative electrode of the electroplating power supply and put it into an electroplating tank containing a chromium plating solution to start electroplating. The material of the anode is a lead-antimony alloy containing 10% antimony;

[0025] 3) During electroplating, the temperature of the chromium plating solution is controlled within the range of 40°C-70°C, and the power cannot be cut off during the electroplating process;

[0026] 4) After the electroplating is finished, take out the molybdenum core rod 1 first, and then turn off the electroplating power supply.

[0027] The composition of the chrome pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com