Winding device with pressing structure for optical fiber manufacturing

A technology of compaction structure and winding device, which is applied in the field of optical fiber manufacturing, can solve the problems of less winding volume of winding rollers, unfavorable optical fiber winding and finishing, and reduced optical fiber winding efficiency, so as to increase winding volume and improve The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

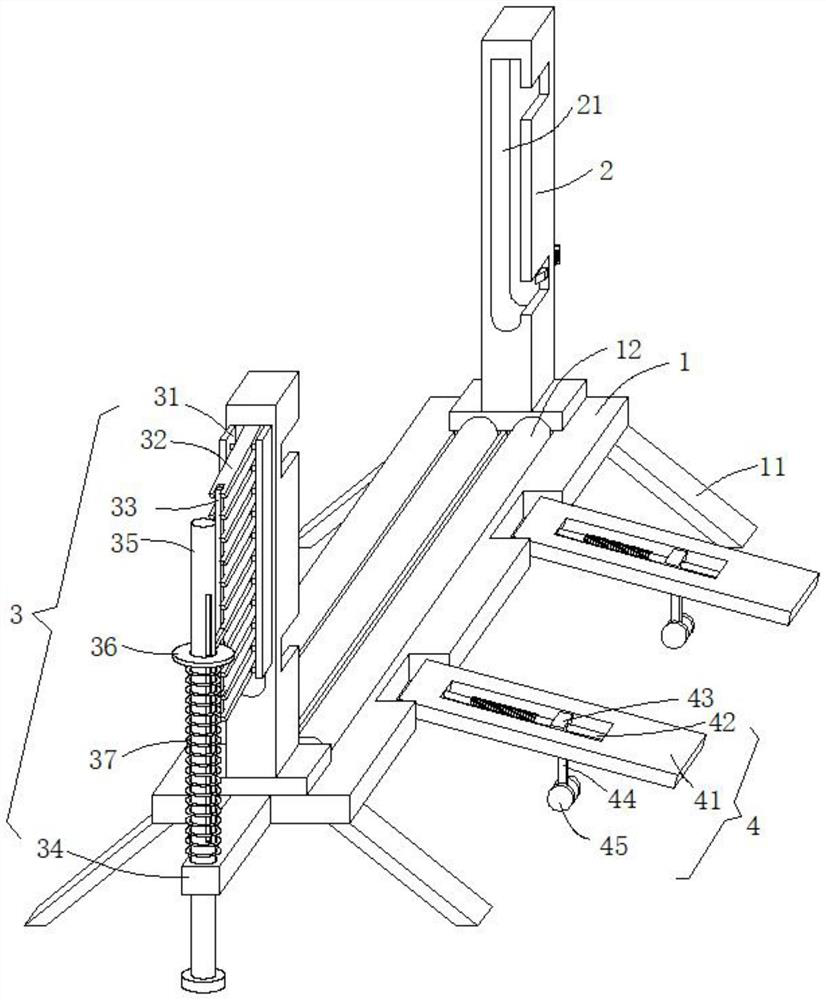

[0032] see figure 1 and image 3 , the present embodiment provides a winding device for optical fiber manufacturing with a pressing structure, including a base 1 and a pressing structure 3, the bottom corner of the base 1 is provided with a leg 11, and the leg 11 is used to The base 1 is stably supported so as to support the winding shaft of the optical fiber to be wound.

[0033] The upper end of the base 1 is vertically provided with two uprights 2 distributed front and back, and the opposite side walls of the two uprights 2 are provided with adjustment holes 21, and the side walls of the two uprights 2 close to each other are provided with feeding gaps distributed up and down. and the feeding gap, the blanking gap is connected with the inner top of the adjustment hole 21, the feeding gap is connected with the inner bottom of the adjustment hole 21, and the end pin shaft of the winding roller is rolled from the feeding gap of the two columns 2 Into the bottom position inside...

Embodiment 2

[0045] see Figure 1-4 , further improvements have been made on the basis of Example 1:

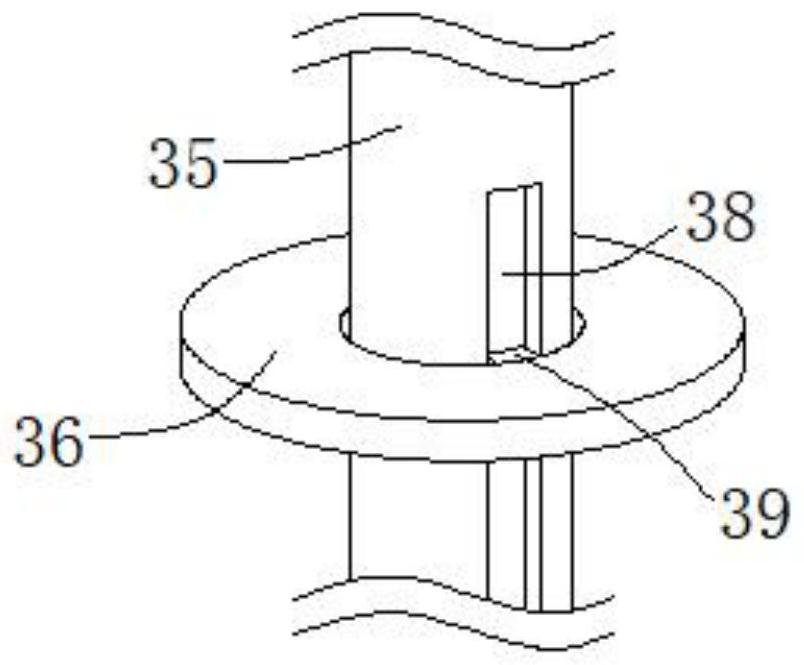

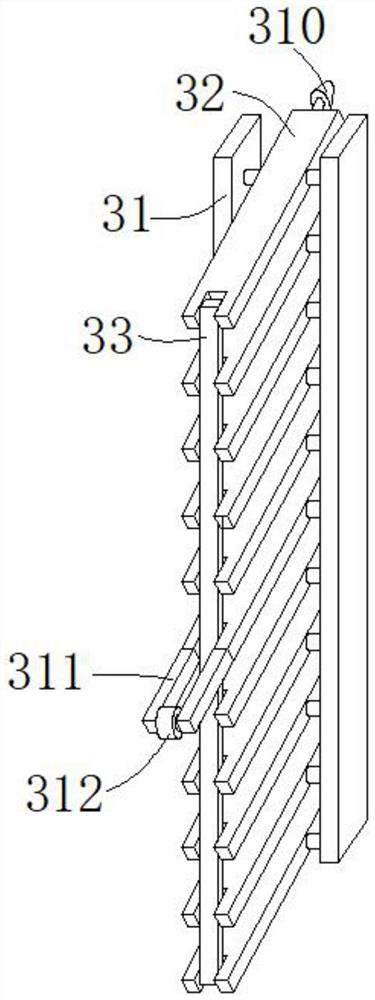

[0046] The compression structure 3 also includes an extension block 34 and an adjustment rod 35, the extension block 34 is fixedly arranged on the front side wall of the base 1, the end of the extension block 34 is rotatably inserted into the adjustment rod 35 through a threaded hole, and the upper end of the adjustment rod 35 Rotate and extend to the top of the extension block 34. The outer wall of the adjustment rod 35 is slidably sleeved with a support plate 36 and a first spring 37. The hinged rod 32 at the position is fixedly provided with two extension rods 311 away from one end of the upright column 2, and the end of the extension rods 311 slides and fits with the upper end surface of the support plate 36, utilizes the extension rods 311 to support the adjusting rod 35, and the first spring 37 The elastic potential energy can push the support plate 36 up in real time along the out...

Embodiment 3

[0053] see figure 1 , Figure 5 and Image 6 , further improvement is made on the basis of embodiment 2:

[0054] During the winding process of the rewinding shaft, it is gradually raised from the innermost end position of the adjustment hole 21. When the pin shaft at the end of the collecting shaft is adjusted to the same height as the feeding gap, it is easy to roll out from the feeding gap, which affects the winding shaft. For normal collection operation, a stopper 5 that can prevent the pin shaft at the end of the rewinding shaft from rolling out of the feed gap is provided inside the feeding gap of the pin shaft at the end of the rewinding shaft, and the pin at the end of the collection shaft is prevented by using the stopper 5. The shaft breaks away from the adjustment hole 21 to ensure that the winding shaft normally winds up the optical fiber.

[0055] The stopper 5 includes a stop rod 51, the stop rod 51 is located inside the feed gap and one end slides through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com