Efficient intelligent winder and working method thereof

A working method and technology of a wire winder, applied in the field of electric power, can solve the problems of increasing the difficulty and workload of carrying, loose span of wires and cables, and inability to adjust, so as to reduce equipment energy waste, improve adaptability, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

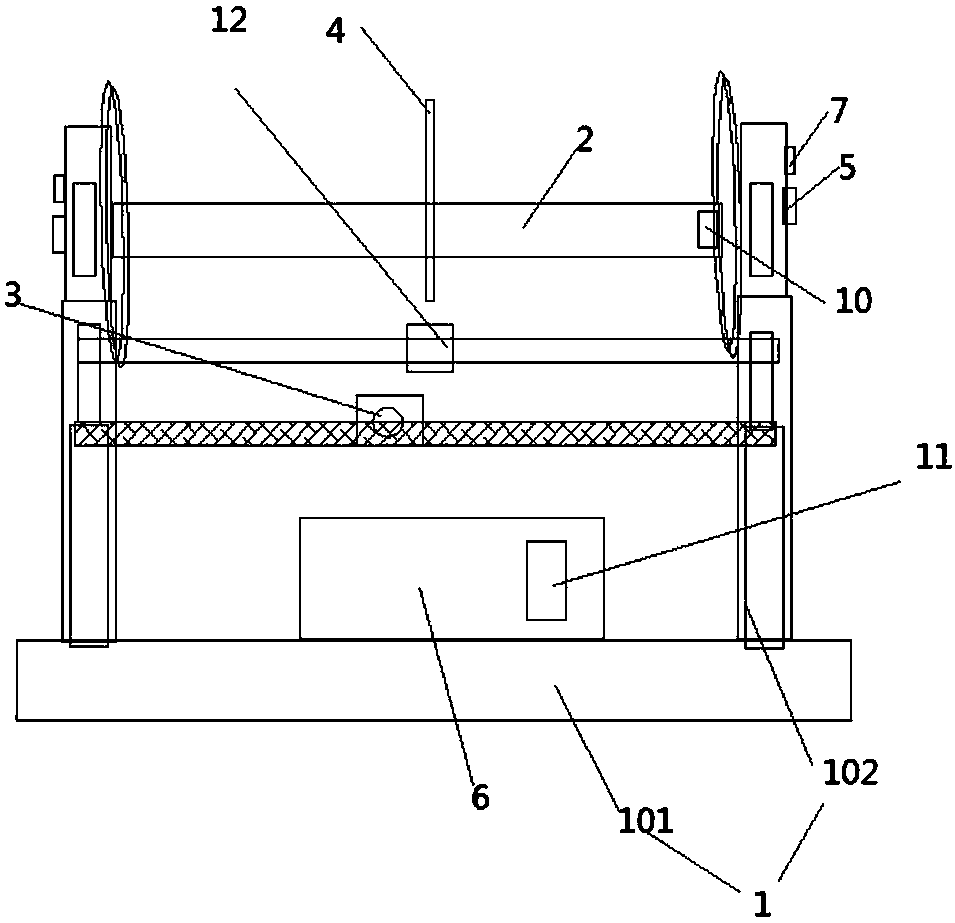

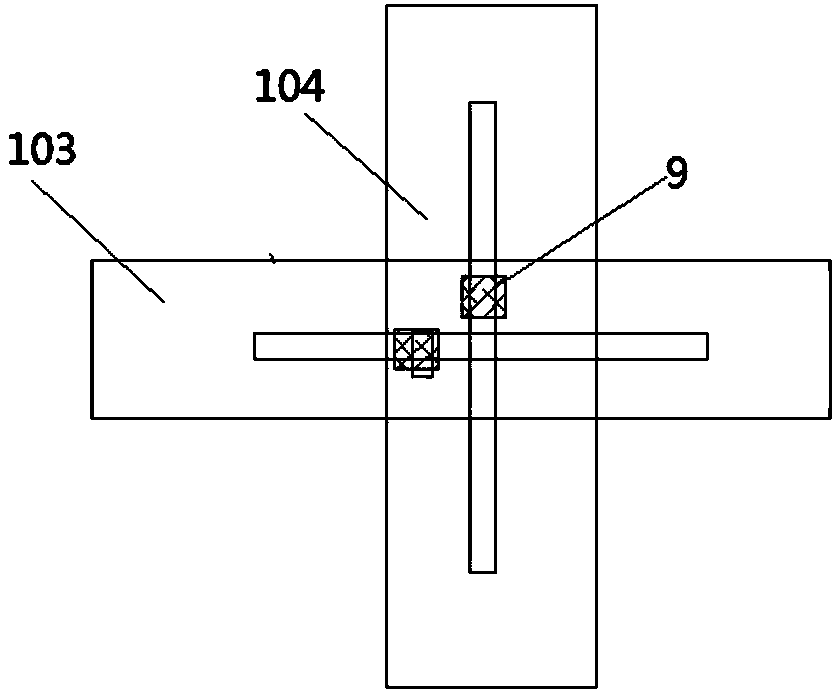

[0040] As shown in the figure, a working method of an efficient and intelligent wire winder, wherein the high-efficiency intelligent wire winder includes: a frame 1, at least one set of winding rollers 2, a set of wire guides 3 and a control device, wherein, The winding roller 2 is provided with a partition plate 4, and the control device is provided with a driving mechanism 5 and a control mechanism 6 for driving the winding roller 2, and the winding roller 2 is arranged on the frame 1, and the The wire guide 3 is arranged on the frame 1 , and the wire guide 3 is provided with a wire routing hole 31 , and the wire winding roller 2 , the wire guide 3 and the driving mechanism 5 are all connected to the control mechanism 6 .

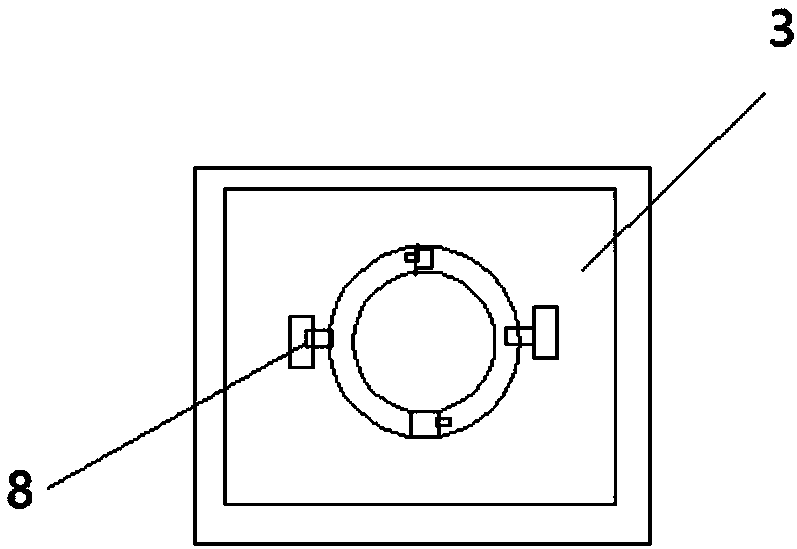

[0041] In this embodiment, the control device is also provided with a rotational speed adjustment mechanism 7 and an aperture adjustment mechanism 8, the rotational speed adjustment mechanism 7 is arranged on the winding roller 2, and the aperture adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com