High-efficiency workpiece handling device

A technology for handling equipment and workpieces, applied in the field of high-efficiency workpiece handling equipment, can solve the problems of not being able to find handling tools, affecting the use and appearance of workpieces, and taking time and effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

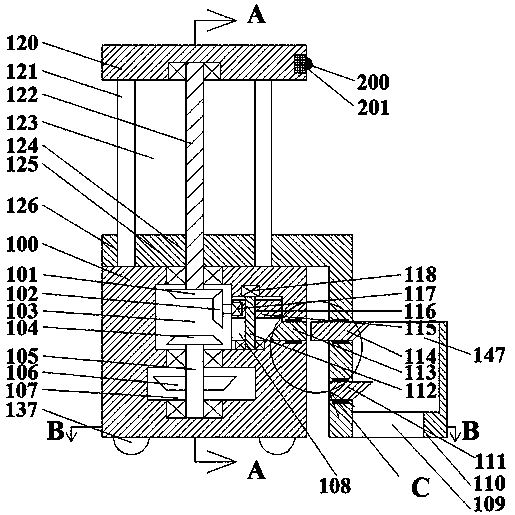

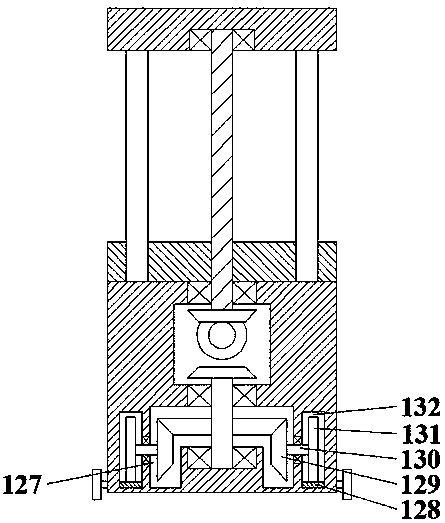

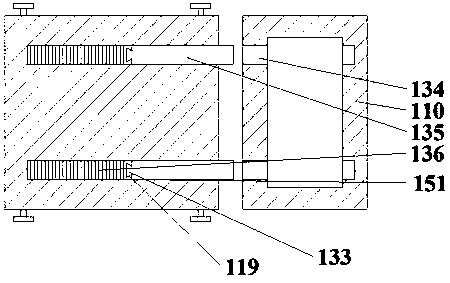

[0017] Such as Figure 1-Figure 4As shown, a high-efficiency workpiece handling device of the present invention includes a fuselage 100 and a fixing plate 120 arranged on the top of the fuselage 100, and a first sliding cavity 123 is arranged between the fuselage 100 and the fixing plate 120 , the first sliding block 125 can slide up and down in the first sliding cavity 123, and the right end of the first sliding block 125 is fixedly installed with a lifting device, and the front and rear symmetry and left and right symmetry of the first sliding block 125 are arranged up and down. Through the first through hole 126, the polished rod 121 extending up and down can be slidably connected to the first through hole 126, and the two ends of the polished rod 121 are fixedly arranged in the upper and lower end walls of the first sliding cavity 123. The middle part of the first sliding block 125 is provided with a first threaded hole 124 that penetrates up and down. The first threaded h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com