Method for enlarging diameter varying range of adjustable winding mould of transformer coil

A technology for transformer coils and winding molds, applied in the field of transformer manufacturing, can solve the problems of inability to meet the requirements of large-capacity transformer tooling, and achieve the effects of shortening the production cycle, strong practicability, and increasing the size of the reducing diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

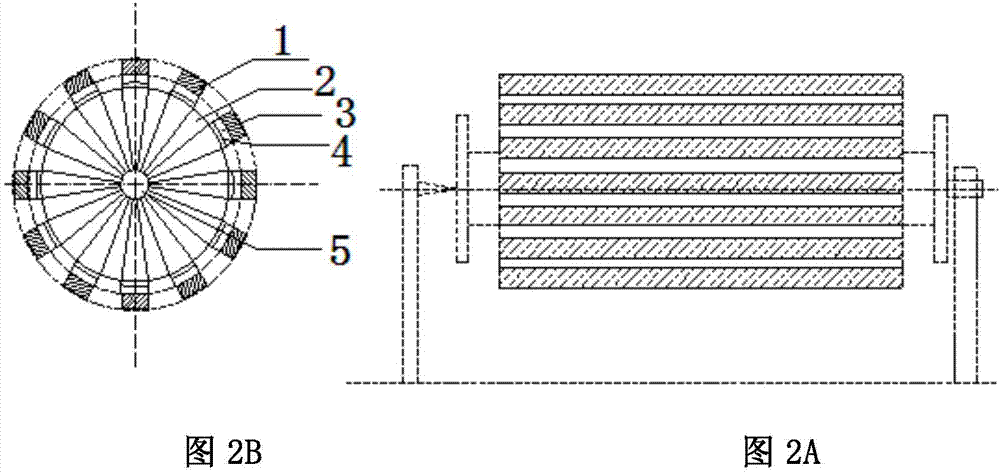

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0027] The method for enlarging the variable diameter range with an adjustable winding die for a transformer coil of the present invention comprises the following steps:

[0028] Prepare a number of wooden stays 1, shaped like Figure 1A , 1B shown;

[0029] Determine the threaded hole size spacing of the wooden stay 1 and the stay gap and length of the mold by the bolt hole pitch on the existing mould, the width and length of the mold support plate; the threaded hole spacing of the present embodiment is 400mm;

[0030] According to the position of the bolt hole on the mould, drill stepped holes at the corresponding position on the wooden stay 1, such as Figure 1B shown;

[0031] Remove the screw on the mould, which is used to install the original mold support plate 3, and replace the wooden support bar with an extended screw to the outside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com