Production apparatus and oxidative combustion method of organic tritium carbon sample

An organic tritium and sample technology, applied in the field of radioactive detection, to achieve high oxygen content, improve recovery rate, and prevent open flames from burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

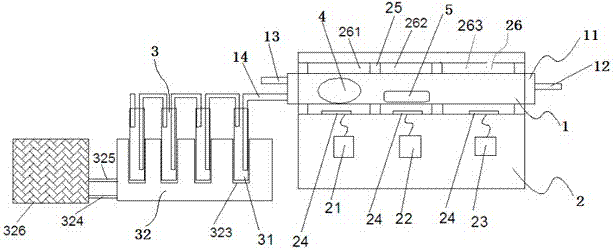

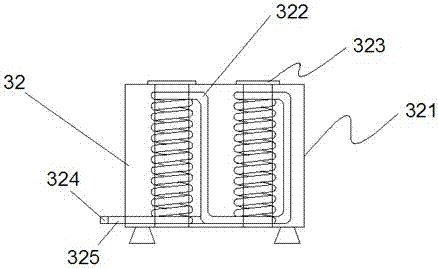

[0028] A combustible tritium, carbon-14 sample preparation system, the combustible tritium, carbon-14 sample preparation system is an open or closed structure, including a reaction working tube 1 for oxidation reaction of combustible samples; The oxidation combustion furnace 2 that provides heating for the reaction working tube 1 and the absorption device 3 used for recovering and sampling the gas generated by the oxidation reaction of combustibles.

[0029] The reaction working tube 1 includes a pipe body 11 and a first air inlet 12, a second air inlet 13, and an air outlet 14 provided on the pipe body 11; the oxidation combustion furnace 2 includes a first temperature controller 21, a second Thermostat 22, the 3rd thermostat 23, heating wire 24, thermal insulation material plate 25 and heating zone 26, described thermal insulation material plate 25 divides heating zone 26 into catalytic reaction zone 261, sample stacking zone 262, sample The recovery area 263 , the sample st...

example 2

[0032] According to another preferred example 2 of the present invention, the organic tritium carbon oxidation combustion method provided comprises the following steps:

[0033] a. Edit the heating program of the catalytic zone: 10°C / min to 750°C and maintain.

[0034] b. Edit the heating program in the recovery area: 5.3°C / min to 400°C and maintain.

[0035] c. Sample heating program editing: Generally speaking, different samples can be heated and burned with different programs. Facing the following table of plant sample procedures in this column:

[0036] temperature (°C) time / rate Room temperature—350 1°C / min 350 keep for 30min 350—700 4℃ / min 700 keep for 120min

[0037] d. Simultaneously open the catalytic area and the recovery area, and flush from the first air inlet and the second air inlet respectively for 10 minutes. Make the oxygen volume of the first air inlet 0.05L / min, the nitrogen volume 0.15L / min, and the oxygen volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com