Heat-supply network failure quick detection system

A heating pipe network and detection system technology, applied in the direction of measuring devices, liquid tightness measurement using liquid/vacuum degree, instruments, etc., can solve the lack of, difficult to burst pipes and leakage, failure to timely and accurately grasp fault location and Fault level and other issues, to improve processing capacity, improve management level and service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

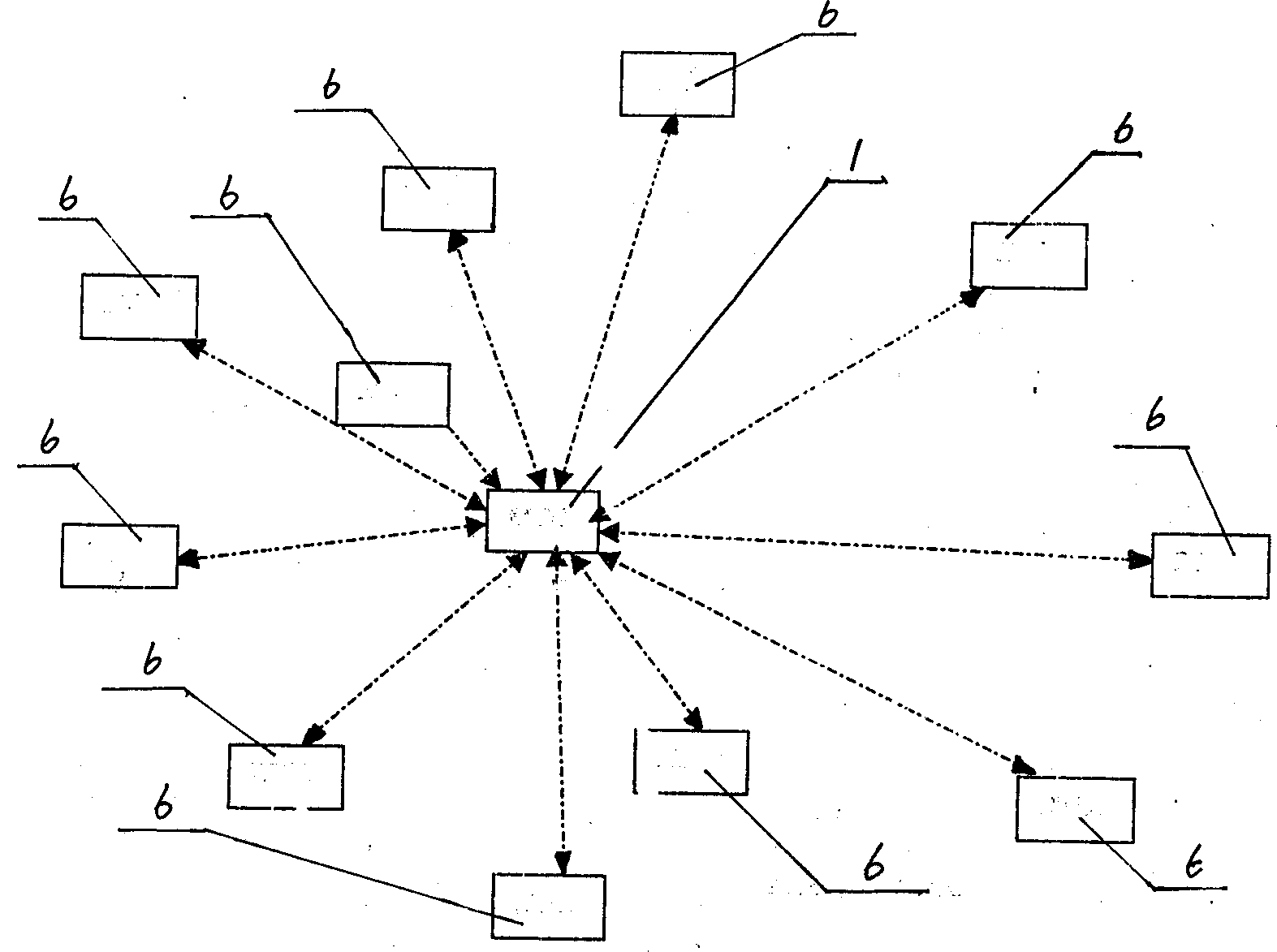

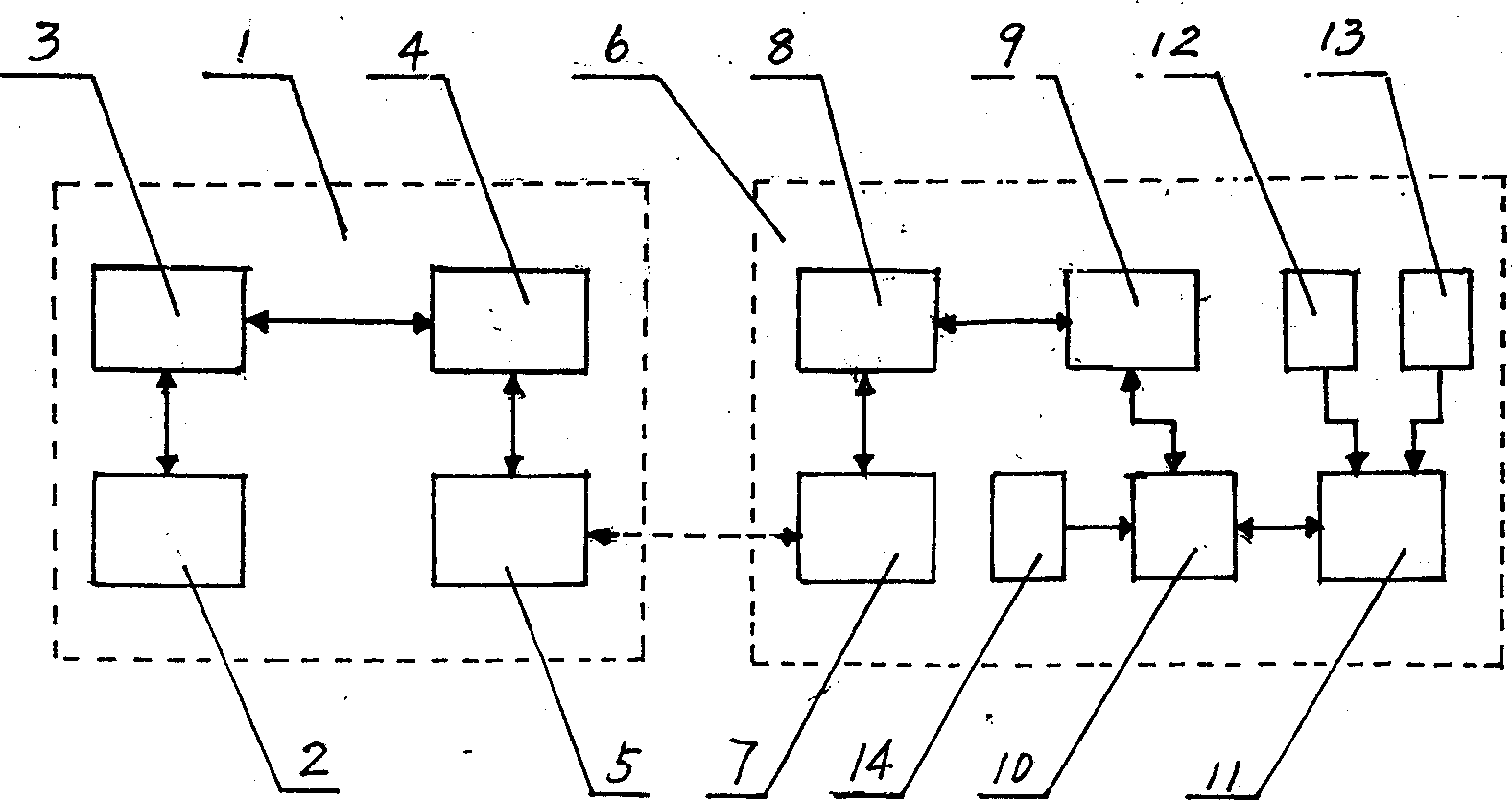

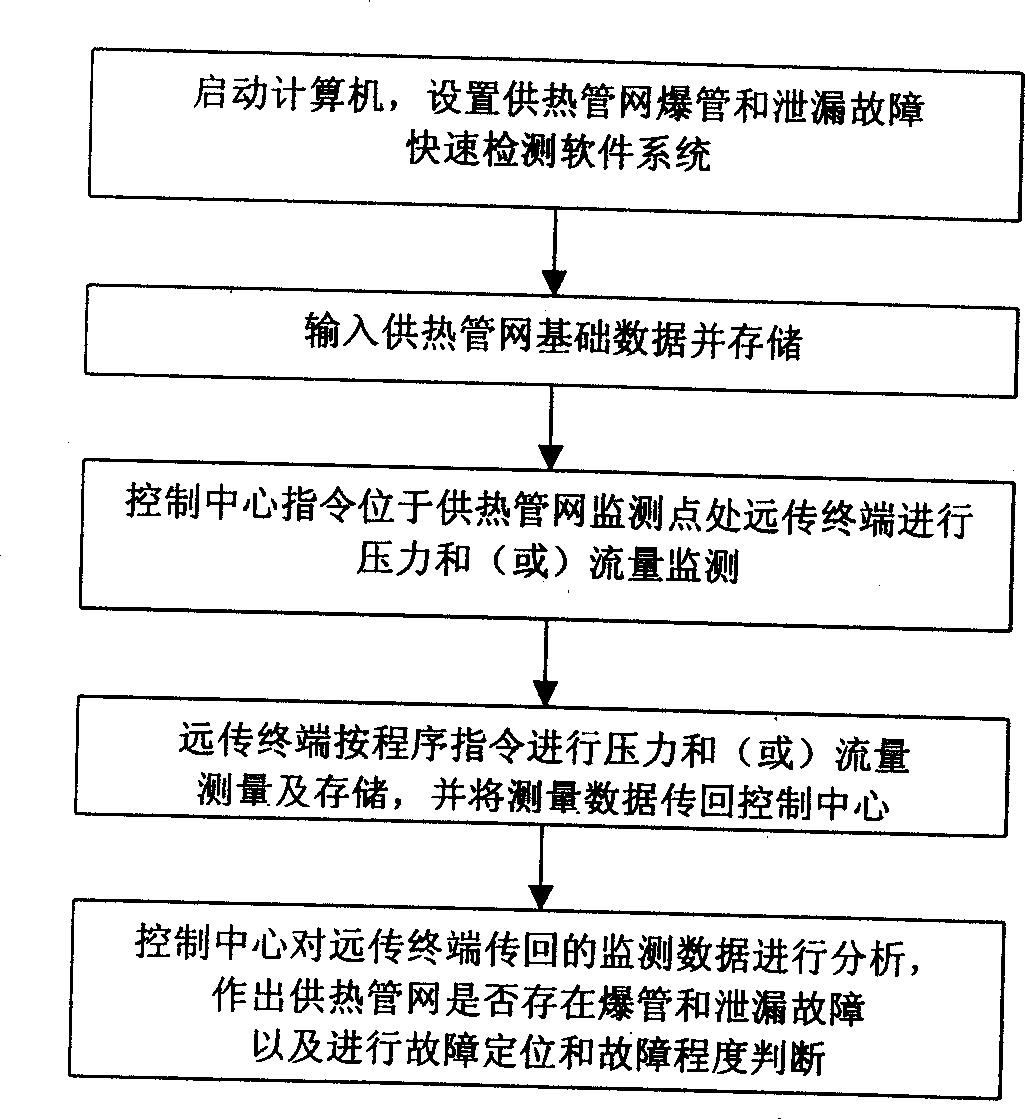

[0039] exist figure 1 Among them, the pipe burst and leakage fault detection system of the heating pipe network is composed of a control center 1 and a number of telemetry and remote transmission terminals 6 . Wherein, the control center 1 may be located in a heat supply station or a heat supply dispatching room or the like. The remote transmission terminals 6 are respectively installed at various heating stations, pressurization stations, and several nodes of the heating pipe network to monitor the heating pressure and (or) the heating flow on-line. The control center 1 and the remote transmission terminal 6, which transmit the execution instructions by the digital transmission machine 5 and the terminal digital transmission machine 7 that transmit wireless signals, or send back the monitoring data of heating pressure and heating flow; and the control center 1 conducts The processing of monitoring data can quickly and accurately make online detection of failures such as pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com