Impact-resistant modified polyvinyl chloride (PVC-M) pipe material for coal mine

A polyvinyl chloride, impact-modified technology, applied to rigid pipes, pipes, pipes/pipe joints/fittings, etc., to achieve the effects of ensuring impact resistance, eliminating the possibility of safety accidents, and being easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

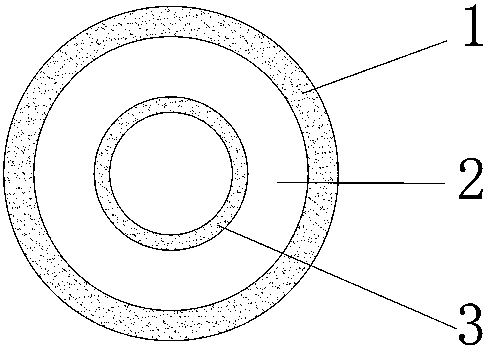

[0052] An impact-resistant modified polyvinyl chloride (PVC-M) pipe for coal mines, the inner layer 3 of the pipe wall and the outer layer 1 of the pipe wall are extruded to prepare raw materials according to the following ratio:

[0053] 100 parts of polyvinyl chloride (PVC) resin, 2.5 parts of organic tin (more than 12% tin content) as stabilizer, 0.8 parts of synthetic polyethylene wax lubricant 627A, 1.2 parts of synthetic oxidized polyethylene wax lubricant AC629, Add 0.5 parts of AC316 to add a total of 2.5 parts, add 1.2 parts of processing aid to PA20 processing aid, add 5.0 parts of plasticizer to dioctyl phthalate, add 8.0 parts of impact modifier to MBS type B564, Add 6.5 parts of the electrostatic agent to nano-scale conductive carbon black (particle size 10nm), add 1.5 parts to nano-scale calcium carbonate (particle size 15nm) as the reinforcing agent, add 1.0 parts to TDCPP as the flame retardant, and add 1.0 parts to the antioxidant agent β-(3 , 1.5 parts of 5-d...

Embodiment 2

[0056] An impact-resistant modified polyvinyl chloride (PVC-M) pipe for coal mines, the inner layer 3 of the pipe wall and the outer layer 1 of the pipe wall are extruded to prepare raw materials according to the following ratio:

[0057] 100 parts of polyvinyl chloride (PVC) resin, 2.3 parts of organic tin stabilizer (tin content above 12%), 0.86 parts of synthetic polyethylene wax lubricant 627A, 1.14 parts of synthetic oxidized polyethylene wax lubricant AC629, Add 0.5 parts of AC316 to a total of 2.5 parts, add 1.5 parts of processing aid to PA20 processing aid, add 5.0 parts of plasticizer to dioctyl phthalate, add 8.5 parts of impact modifier to MBS type B564, Add 7.0 parts of the electrostatic agent to nano-scale conductive carbon black (particle size 10nm), add 2.0 parts to nano-scale calcium carbonate (particle size 15 nm) as the reinforcing agent, add 1.1 parts to TDCPP as the flame retardant, and add 1.1 parts to the antioxidant agent β-( Add 1.7 parts of n-octadecy...

Embodiment 3

[0060] An impact-resistant modified polyvinyl chloride (PVC-M) pipe for coal mines, the inner layer 3 of the pipe wall and the outer layer 1 of the pipe wall are extruded to prepare raw materials according to the following ratio:

[0061] 100 parts of polyvinyl chloride (PVC) resin, 2.5 parts of organic tin (more than 12% tin content) as stabilizer, 0.8 parts of synthetic polyethylene wax lubricant 627A, 1.2 parts of synthetic oxidized polyethylene wax lubricant AC629, Add 0.5 parts of AC316 to 2.5 parts in total, add 1.2 parts to PA20 processing aid, add 4.5 parts to plasticizer dioctyl phthalate, add 10.0 parts to ACM as impact modifier, and add 10.0 parts to antistatic agent Add 6.5 parts for nano-scale conductive carbon black (particle size 10nm), add 1.5 parts for nano-scale calcium carbonate (particle size 15nm), add 1.2 parts for flame retardant, and add 1.2 parts for bromocyclododecane, and add β- Add 1.5 parts of (3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecanol propi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com