Chemical cleaning system and method for oxide skin of power station superheater or reheater

A chemical cleaning and superheater technology, which is applied in the field of superheater and reheater scale removal in power stations, can solve the problems of low reliability, high cost, and inability to completely remove it, so as to alleviate the problem of pipe plugging, wide cleaning range, and prolong Effect of scale growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

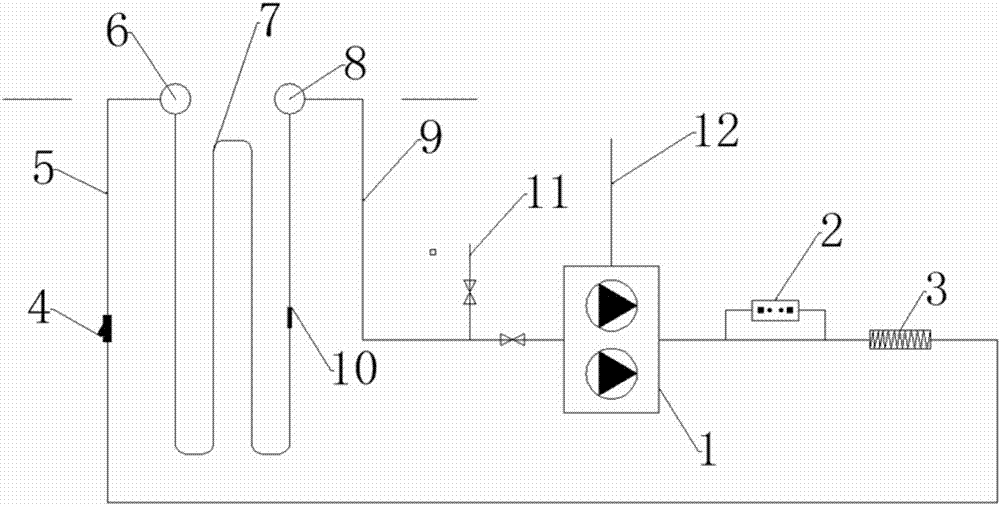

[0035] Such as figure 1As shown, the present invention is a system and method for chemical cleaning of superheater and reheater scale in a power station, which removes the scale of the superheater through chemical cleaning. The cleaning liquid is delivered to the system inlet 6 of the superheater of the power station through the dosing pipeline 12, the cleaning power platform 1 and the liquid inlet pipeline 5. After the cleaning liquid reacts with the scale of the superheater of the power station, it returns to the cleaning system through the return pipeline 9 from the system outlet 8. The power platform 1 performs circular cleaning, and the waste liquid is discharged through the discharge pipe 11 . In order to ensure the cleaning effect, an online corrosion monitoring device 2, a heater 3, a filter 4 and an online monitoring device 10 for dead pipes are installed in the cleaning system.

[0036] The implementation steps are as follows

[0037] Step 1: Water flushing, add d...

Embodiment 2

[0048] Such as figure 1 As shown, the present invention is a system and method for chemically cleaning scales of superheaters and reheaters of power plants, and removes scales of reheaters through chemical cleaning. The cleaning liquid is delivered to the system inlet 6 of the reheater of the power station through the dosing pipeline 12, the cleaning power platform 1 and the liquid inlet pipeline 5. After the cleaning liquid reacts with the scale of the reheater of the power station, it returns from the system outlet 8 through the liquid return pipeline 9. To the cleaning power platform 1, the cycle cleaning is carried out, and the waste liquid is discharged through the discharge pipe 11. In order to ensure the cleaning effect, an online corrosion monitoring device 2, a heater 3, a filter 4 and an online monitoring device 10 for dead pipes are installed in the cleaning system.

[0049] The implementation steps are as follows

[0050] Step 1: Water flushing, add desalted wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com