Large-span subway station underground excavation construction method for hard rock stratum

A technology for subway stations and construction methods, which is applied to earth-moving drilling, underground chambers, and shaft equipment, etc., can solve the problems of long construction period, large vault settlement, and affecting pipelines under the road.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

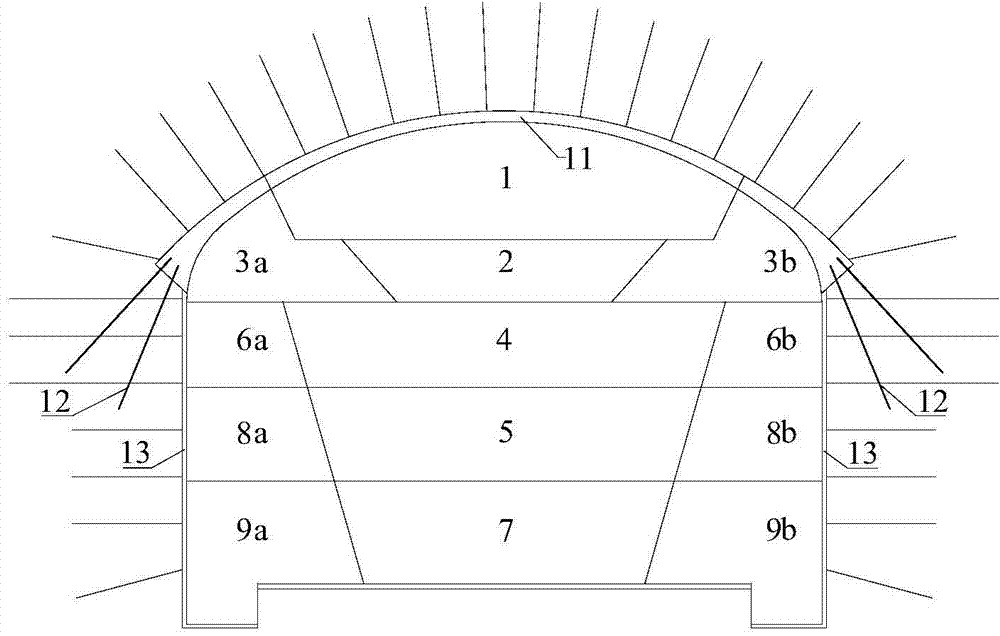

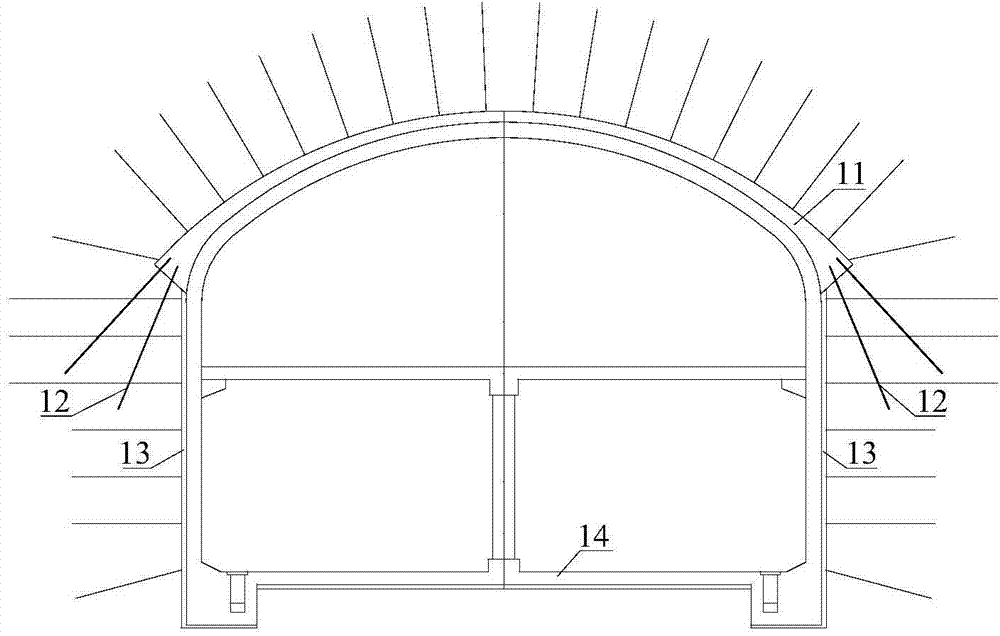

[0018] refer to figure 1 and figure 2 , the underground excavation construction method of large-span subway station in hard rock formation of the present invention, comprises the following steps:

[0019] 1. The middle of the arch of the station is excavated by two steps. First, the upper step 1 in the middle of the arch of the tunnel is excavated, and the initial arch cover 11 is constructed.

[0020] 2. Excavate the lower step 2 in the middle of the tunnel arch.

[0021] 3. Excavate the left part 3a of the tunnel arch and the right part 3b of the tunnel arch, install the anchor bolt 12 at the arch foot position, connect the initial arch cover 11 of the long vault, and complete the construction of the initial arch cover 11. The primary support arch cover 11 is composed of shotcrete layer, grid steel frame, steel mesh, system anchor rod and locking foot anchor rod 12, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com