Construction method for improving shield soil in composite sand gravel stratum

A construction method and shield soil technology, which is applied to earth drilling, mining equipment, tunnels, etc., can solve the problems of shield machine cutter head not rotating, main bearing sintering, and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

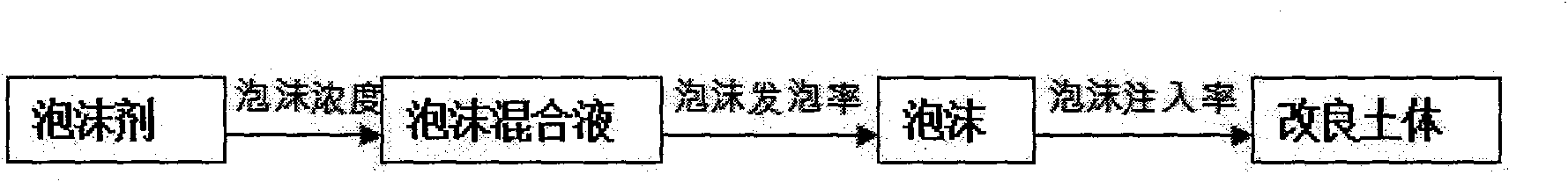

Method used

Image

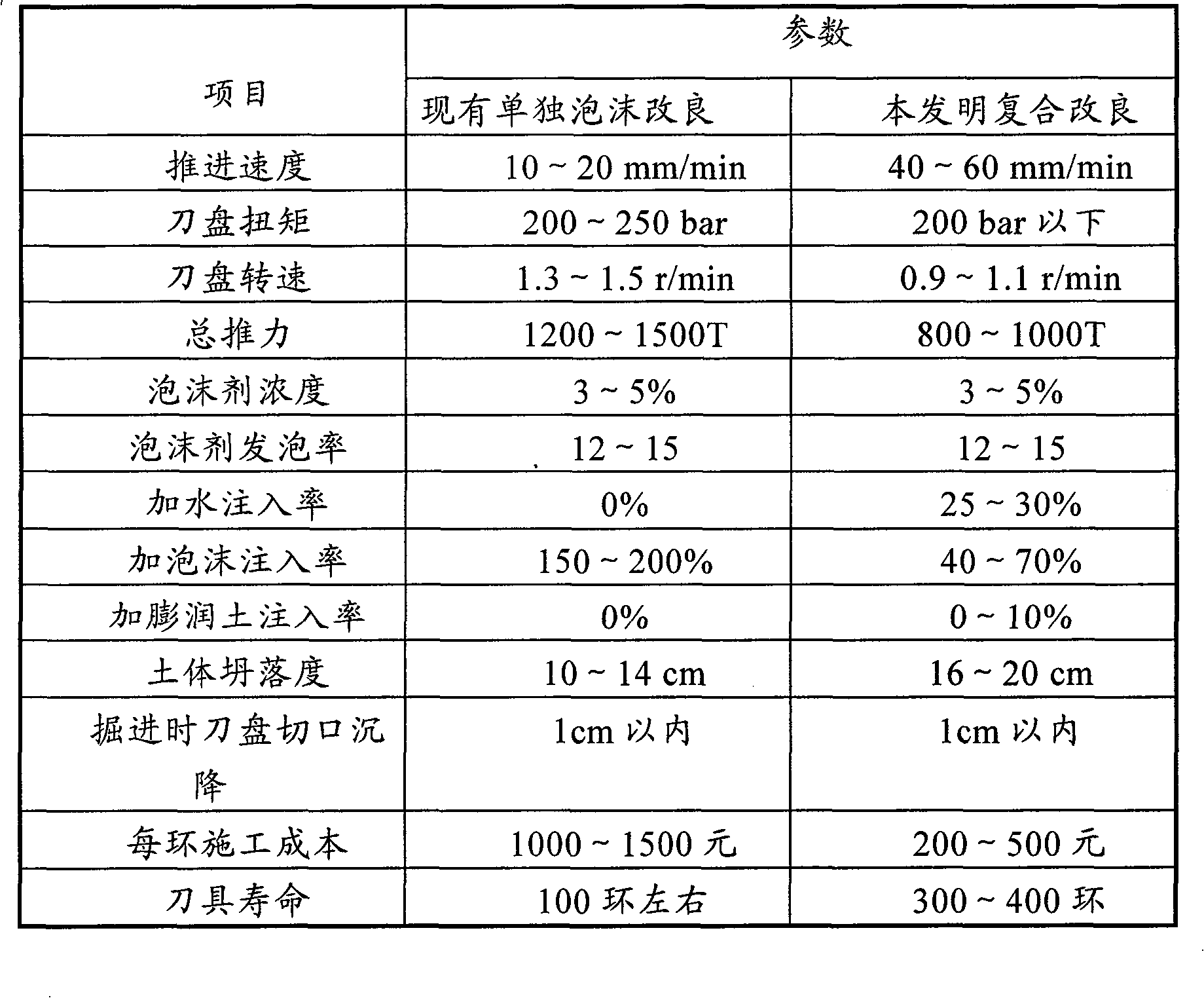

Examples

Embodiment Construction

[0023] The following is a further detailed description in conjunction with specific engineering embodiments on which the present invention is based.

[0024] Take the soil improvement process of a subway section tunnel in Chengdu as an example. The maximum diameter of the earth pressure balance shield machine cutter head used in the tunnel is 6.28m, the total configuration power is 1577kW, the maximum excavation torque is 5300KN·m, and the maximum propulsion force is 36400kN. The maximum tunneling speed can reach 8cm / min, and the opening rate of the cutter head is about 28%. The lining adopts prefabricated reinforced concrete segments with an outer diameter of 6000mm and an inner diameter of 5400mm. The section adopts two kinds of tube slices with 1.2m and 1.5m width, the radius of curvature is less than or equal to 400m and the reinforced section, the 1.2m width tube slice is adopted; when the curvature radius is greater than 400m, the 1.5m width tube slice is adopted. The buri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com