Combined framework steel structure of jacked subway bridge and method for jacking subway bridge

A combined frame and tunnel bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing construction costs, lack of versatility, labor and time-consuming, etc., saving steel and construction costs, excavating surface Stabilizing, reducing the effect of speed limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

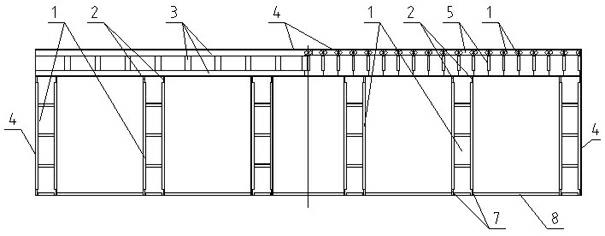

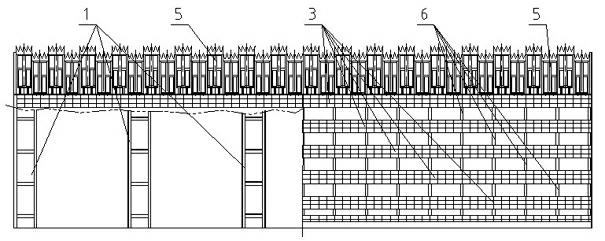

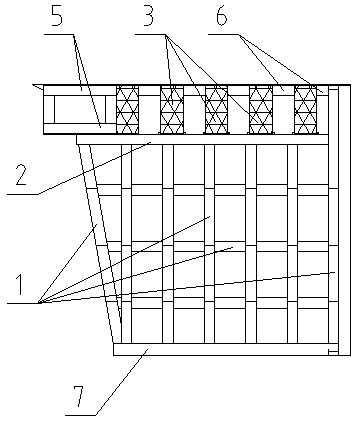

[0022] Example 1 as attached Figure 1-5 Shown: A combined frame steel structure jacked into the tunnel bridge, the frame steel structure is located at the front end of the square reinforced concrete tunnel bridge jacked by hydraulic jacks; the upright rectangular vertical frame 1 relies on the longitudinal upper joist 2 at the top The horizontal top beam 3, the spacer beam 6, the longitudinal lower joist 7 and the horizontal bottom beam 8 at the bottom are fastened and connected by bolts to form an integral square main frame structure; the upright rectangular vertical frame 1 is six A steel frame with the same external dimensions, side parallel to each other, the upper front end inclined forward, the rear end abutting against the front end of the square reinforced concrete tunnel bridge 11, and spaced evenly; in the overall square main frame structure Soil-retaining steel plates 4 are installed on the top surface and both sides, and a row of sub-frame structures 5 that are ...

Embodiment 2

[0023] Example 2 as attached Figure 1-6 Shown: a method for jacking a tunnel bridge with a combined frame steel structure jacking into the tunnel bridge, the steps are:

[0024] [1] Select standard rectangular vertical frame 1, upper joist 2, top beam 3, spacer beam 6, lower joist 7 and bottom beam 8 according to the design size of the tunnel bridge, and select according to the width of the tunnel bridge and the load on the upper floor. Determine the number and spacing of the rectangular vertical frames 1, and install the square main frame structure with bolts in the open trench dug in advance on one side of the tunnel bridge; The surrounding dimensions of the tunnel bridge are the same.

[0025] [2] Soil-retaining steel plates 4 are installed on the top and both sides of the overall square main frame structure, and a row of mutually tight steel plates is installed on the upper front end of the overall square main frame structure that is inclined forward and in front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com