Large cross-section tunnel supporting system construction method applicable to steep dip layered rock mass

A construction method and large-section technology, which can be used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve problems such as vaulting, prone to engineering accidents, and untargeted effects of steeply sloping surrounding rocks. Guaranteed effect of rock mass, reinforcement strength and deformation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

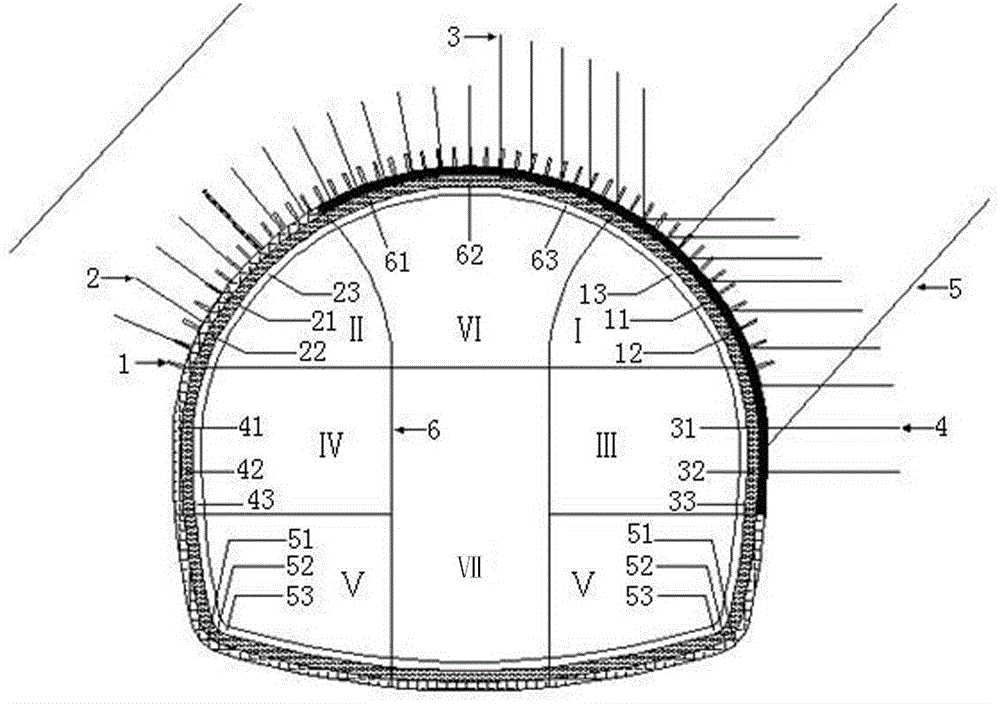

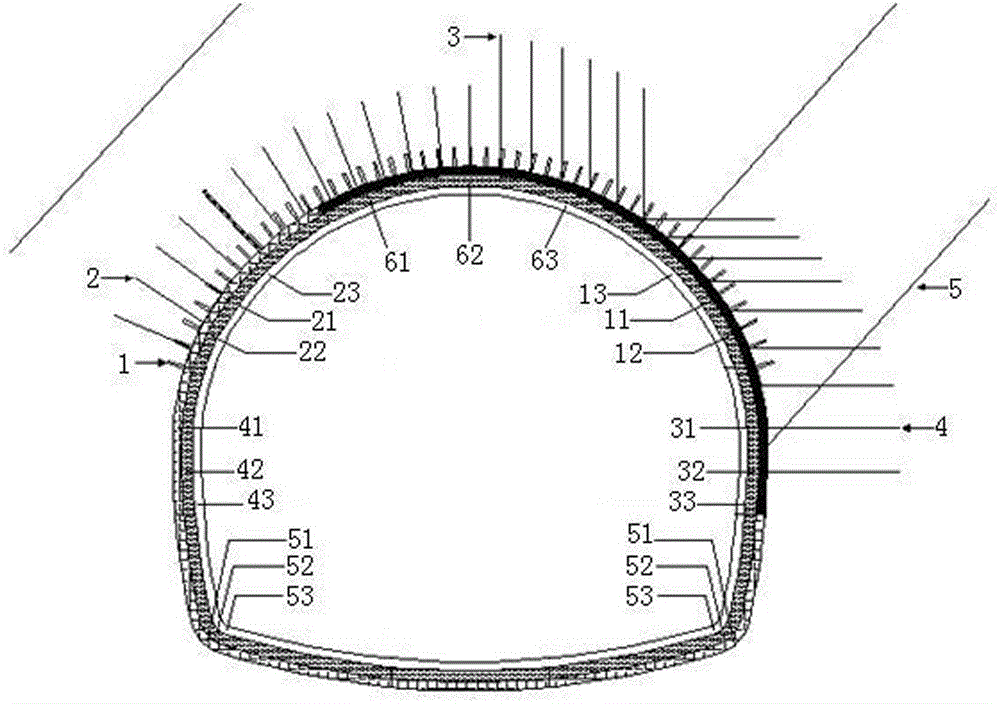

[0035] Example: such as figure 1 As shown, in this embodiment, the large-section tunnel support system suitable for steeply inclined layered rock mass is divided into: the upper guide tunnel I in the down-inclined layer, the guide tunnel II in the upper reversed-dip layer, and the middle part in the down-dip layer. Pilot tunnel III, pilot tunnel IV in the middle anti-inclined layer, lower pilot tunnel V, upper middle pilot tunnel VI, and core soil area VII. All are the relative positions between the pilot tunnel and the steep layered surrounding rock 5.

[0036] The construction method of support system in the present embodiment comprises the following steps:

[0037] ① Excavate the pilot tunnel I in the upper oblique layer first, and construct the grid steel frame reinforcement layer 11, temporary support 6, the grid steel frame reinforcement layer 11 in the upper oblique layer and the second lining 12 in the upper oblique layer, in which the upper oblique layer The layer g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com