Hook-type electromagnetic field device of full-diameter single crystal furnace

An electromagnetic field, single crystal furnace technology, applied in the direction of single crystal growth, post-processing device, crystal growth, etc., can solve the problems of troublesome assembly of the upper and lower coils, large overall mass of the integral shield, difficult to assemble and maintain, etc. Material saving, continuously adjustable magnetic field strength, simple installation and commissioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

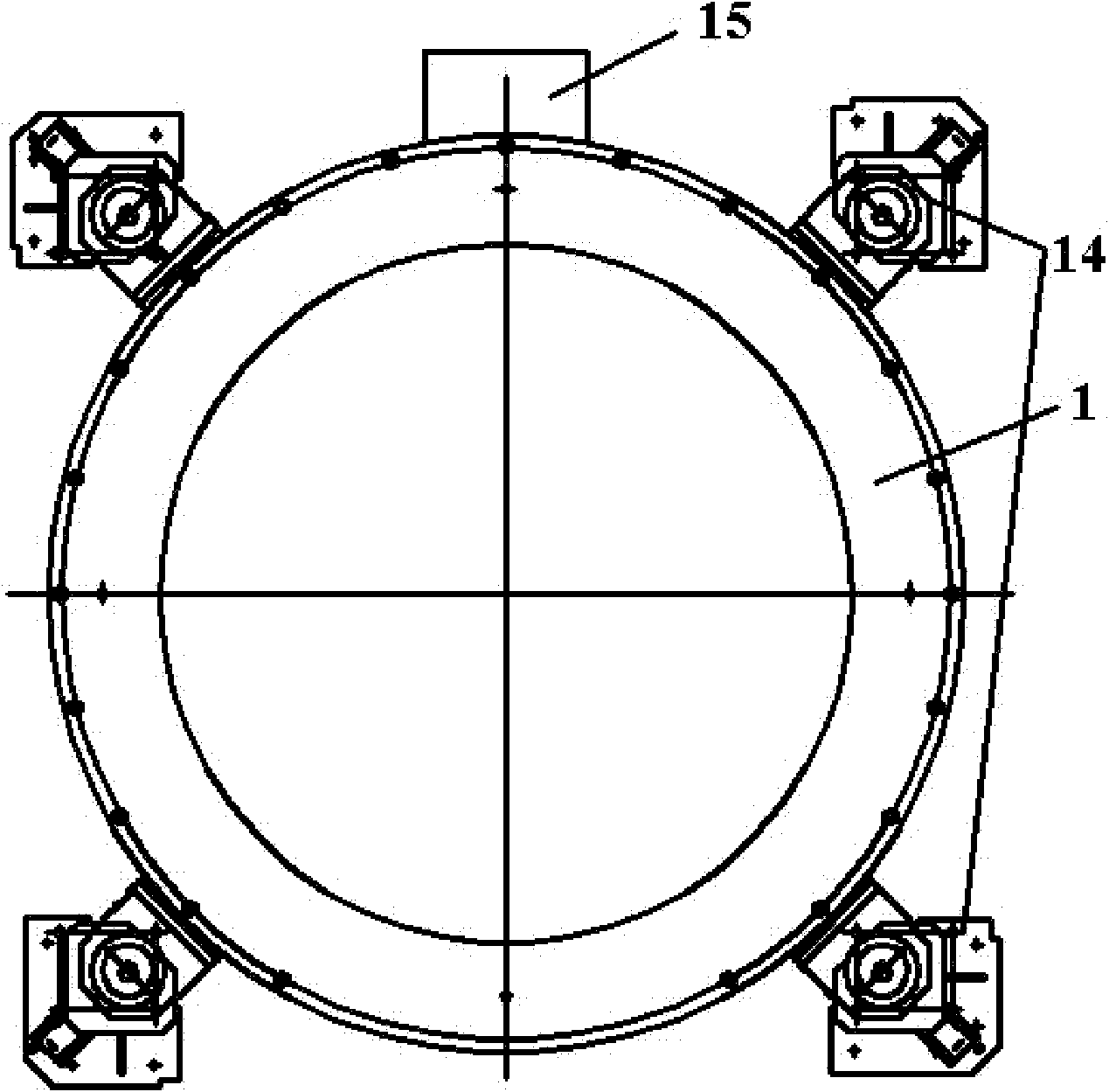

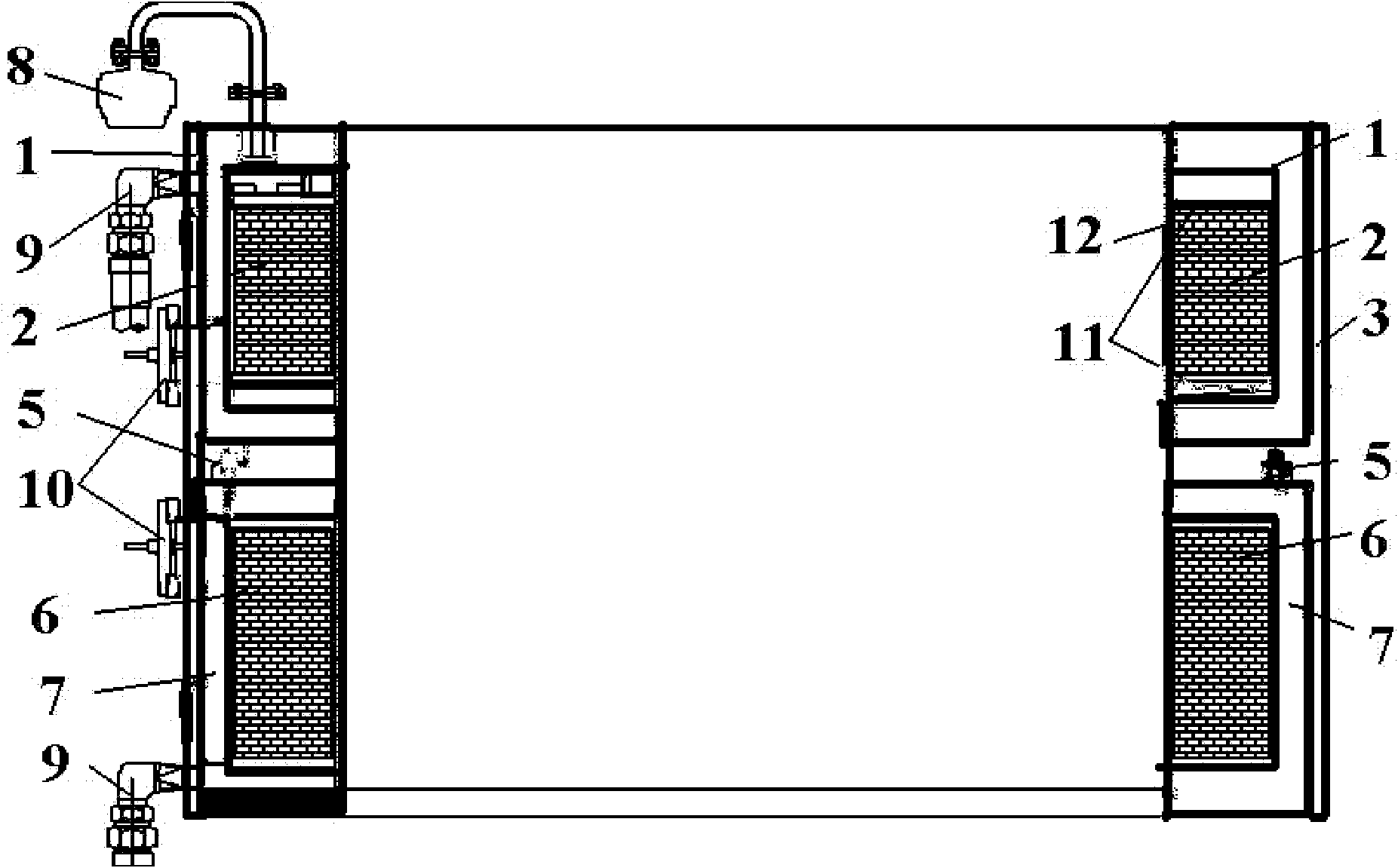

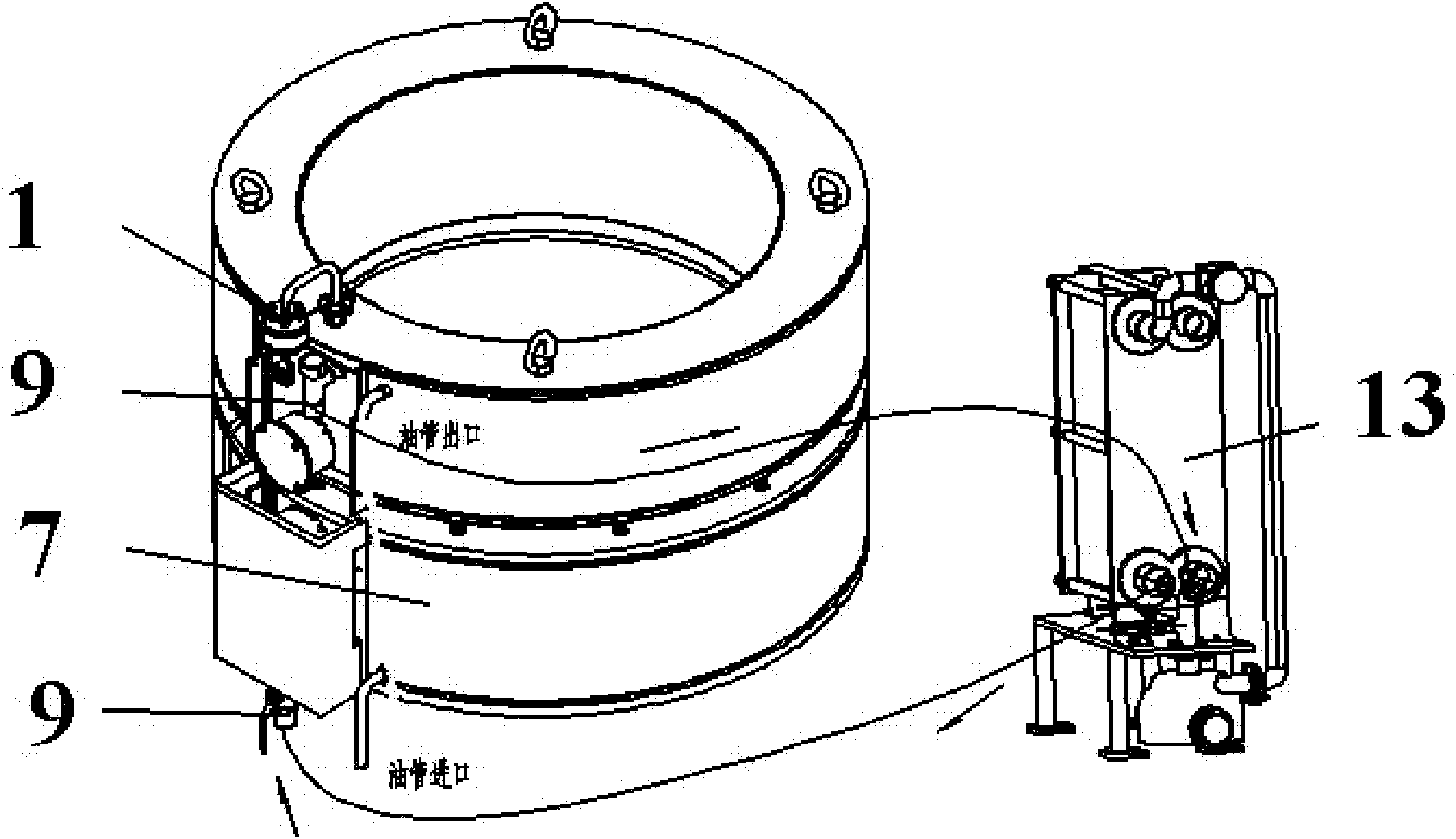

[0026] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0027] The large-diameter single crystal furnace hook-type electromagnetic field device in this embodiment includes two annular airtight chambers filled with cooling oil, and the annular airtight chambers are stacked up and down to form a hollow cylinder; each airtight chamber is located on the outside The semi-enclosed shielding body (upper coil shielding body 1 or lower coil shielding body 7), the inner cylinder 12 and two Er plates 11 are connected to each other in the form of welding, and are connected to the oil pump and oil cooler through pipelines. 13 together form a forced oil cooling system, and a water cooling jacket 3 is installed on the periphery of the shield body. The oil cooler 13 in this embodiment is a plate heat exchanger. The device has a positioning device for fixed installation, and the upper and lower airtight chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com