evaporative radiator

A heat sink, evaporative technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of high-performance graphics card radiators such as bulky size, poor heat dissipation effect, easy to accumulate dust, etc., to achieve heat dissipation Remarkable effect, simple structure and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

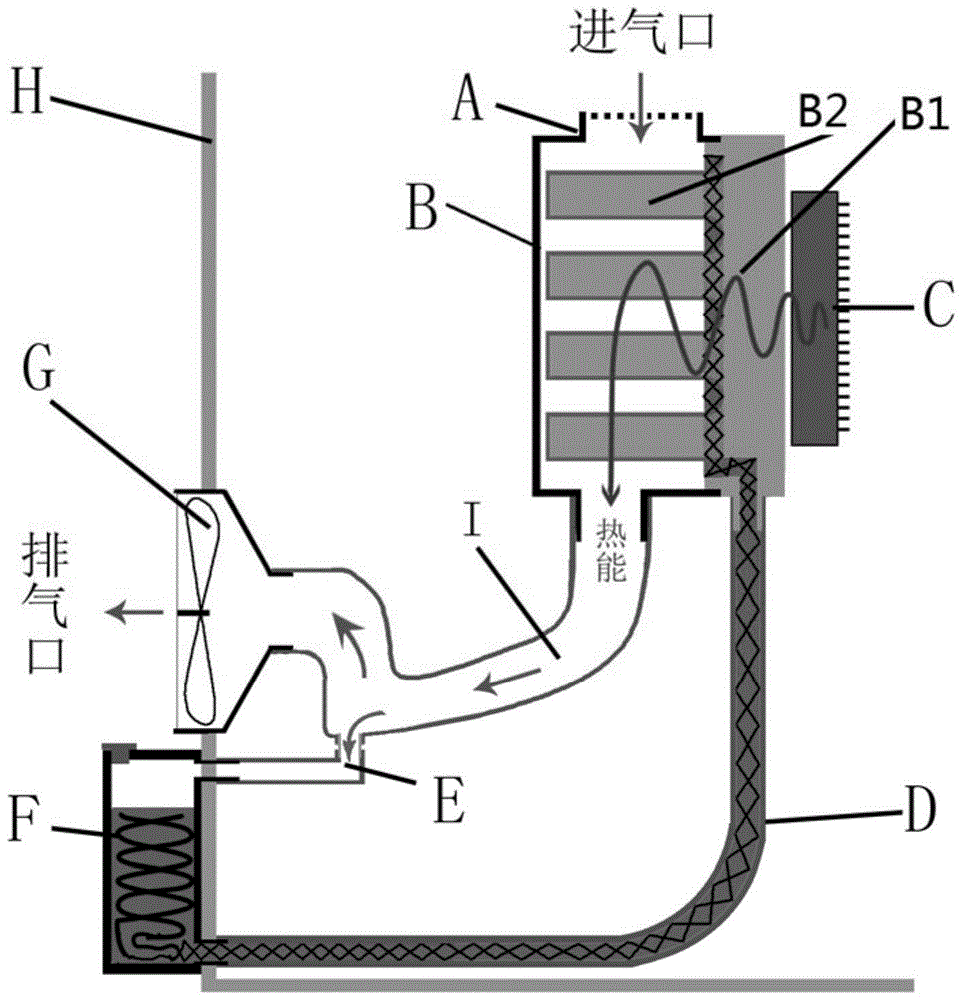

[0018] see figure 1 As shown, the evaporative heat sink is fixed in the chassis. The metal heat sink B includes a metal heat sink base B1, and a plurality of heat dissipation columns B2 are arranged on the metal heat sink base B1; Component C, heat dissipation column B2 surface is provided with a hydrophilic material layer, metal radiator B is a semi-sealed structure, its top is provided with a top cover and an air inlet filter A, and the bottom end is connected to an exhaust pipe I. There is an exhaust port in the chassis shell H on the opposite side of B, and an exhaust fan G is arranged at the exhaust port. A water tank F is arranged on the outer surface of the chassis shell H below the exhaust port. The exhaust pipe I is divided into two branches. One branch is connected to the exhaust port, and the other branch is the condensed water return channel E, which is connected to the upper part of the water tank F; the heat generated by the heating electronic component C communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com