Constant-tension winding machine for niobium titanium-copper superconducting solenoid coils

A solenoid coil, constant tension technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of high labor intensity of operators, complicated winding process, and low utilization of equipment space. Achieve the effect of low labor intensity, simple winding process and compact space arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

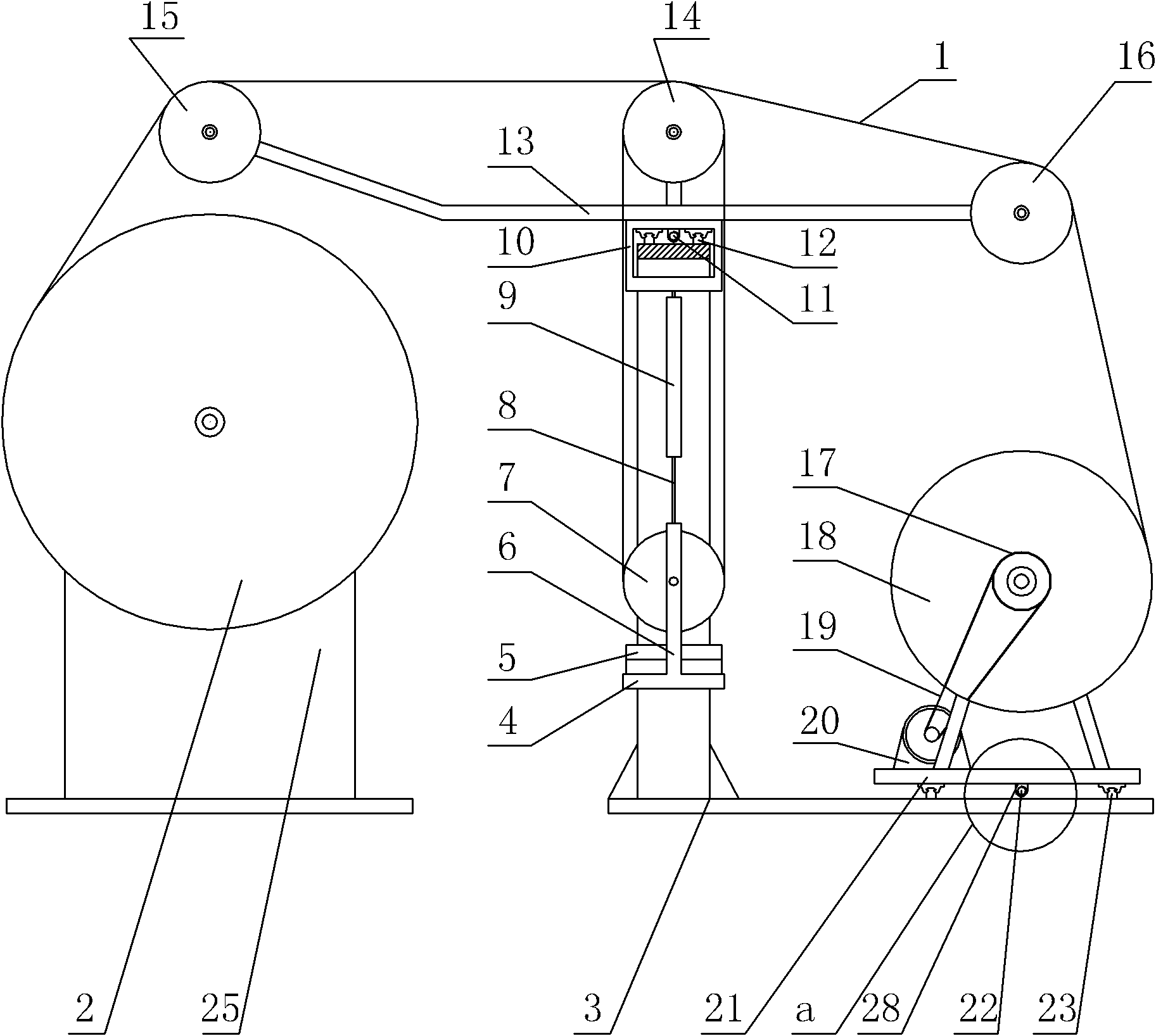

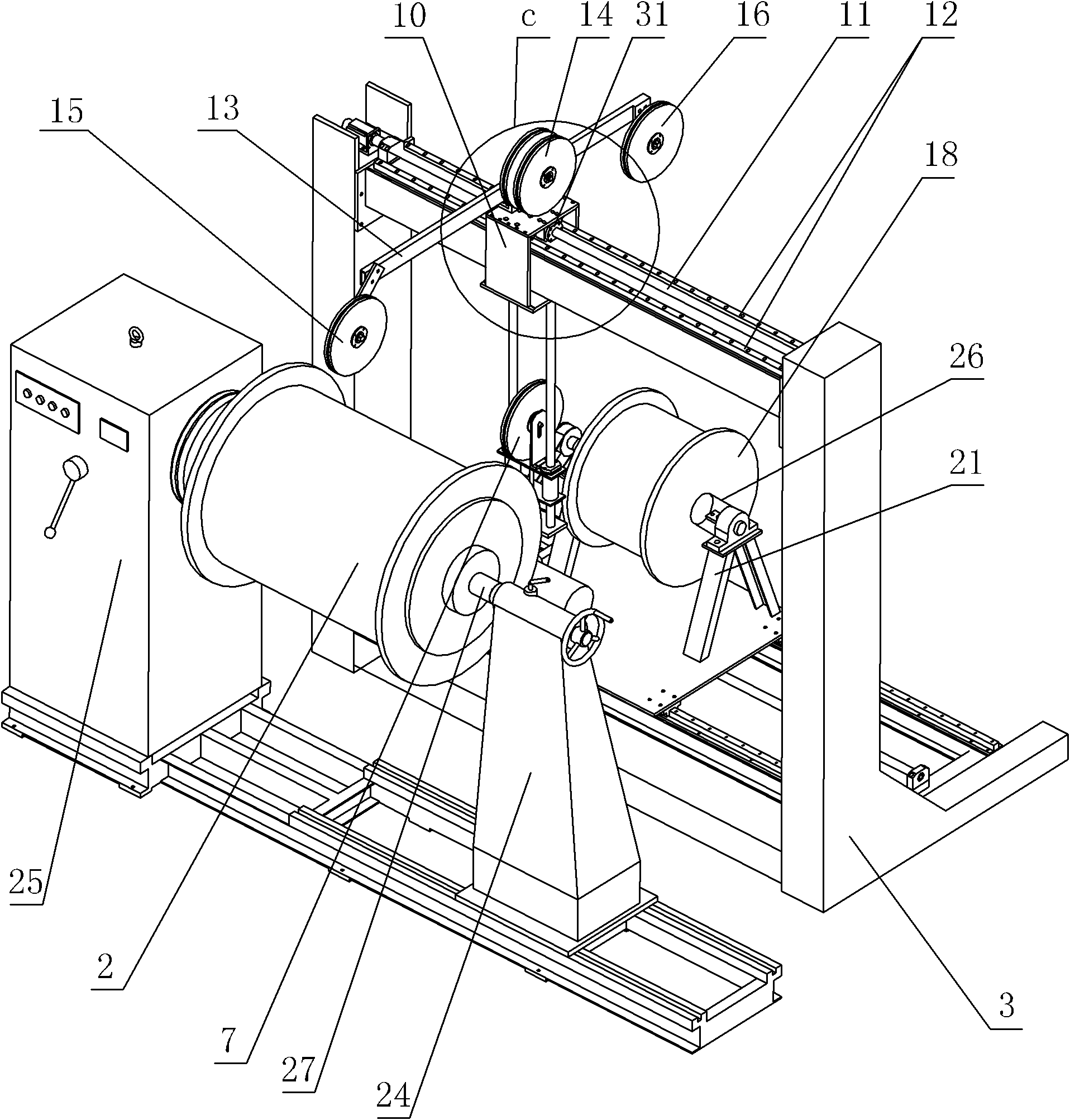

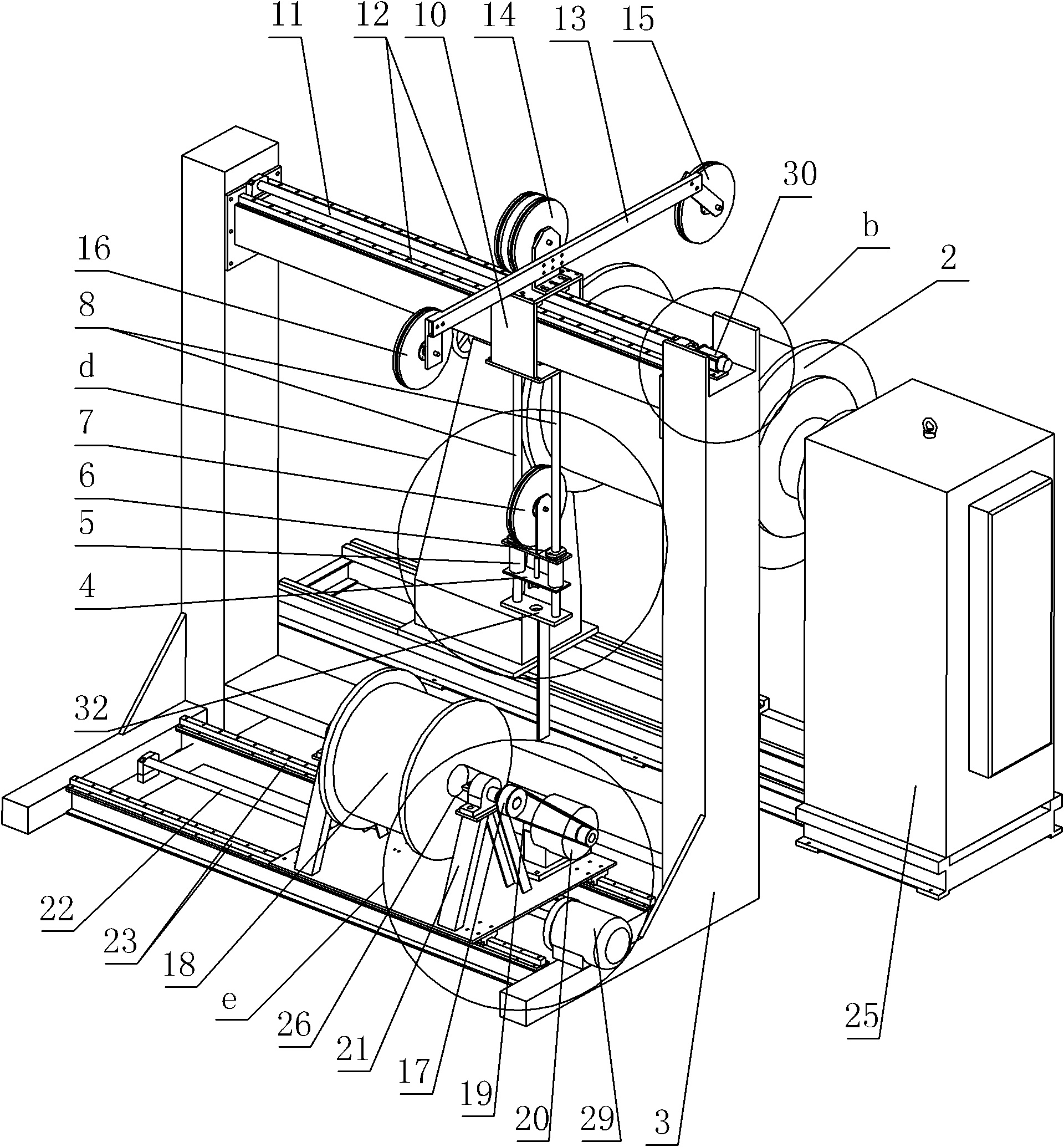

[0016] Specific implementation mode one: combine Figure 1-Figure 11 Describe this embodiment, the niobium-titanium-copper superconducting solenoid coil constant tension winding machine of this embodiment includes a superconducting solenoid coil 2 to be wound, an L-shaped gantry support 3, a counterweight plate 4, and a counterweight 5. Moving pulley axis support 6, moving pulley 7, linear displacement sensor 9, cable trolley 10, first ball screw 11, first drive motor 30, first sleeve 31, bracket 32, cable arm 13, double Track pulley 14, cable pulley 15, pay-off pulley 16, belt pulley 17, pay-off reel 18, transmission belt 19, reducer 20, pay-off bracket 21, second ball screw 22, winding bracket 24, winding Drive controller 25, first rotation shaft 26, second rotation shaft 27, second sleeve 28, second drive motor 29, two slide arms 8, two first slide block linear guides 12 and two second slides block linear guide 23;

[0017] The upper end face of the vertical part of the L...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination image 3 The present embodiment will be described. The diameter of the movable pulley 7 in this embodiment is equal to the diameter of the double track pulley 14 , and the movable pulley 7 is located directly below the double track pulley 14 . Such arrangement facilitates coil winding. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination image 3 The present embodiment will be described. The pay-off reel 18 of the present embodiment is located directly below the pay-off pulley 16 . Such arrangement facilitates coil winding. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com