Integrated gas-liquid separator

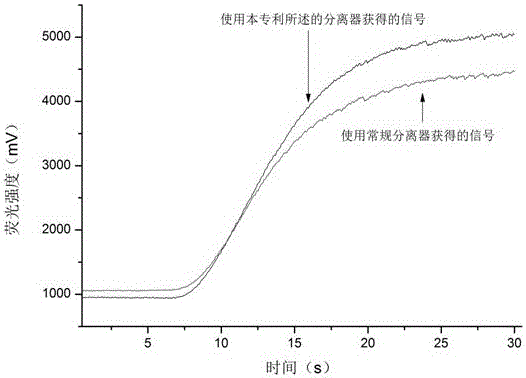

A gas-liquid separator, an integrated technology, applied in separation methods, dispersed particle separation, instruments, etc., can solve the problems of gaseous hydride loss, lower instrument sensitivity, and difficult fixation, and achieve improved sensitivity, lower detection limit, The effect of facilitating the use of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

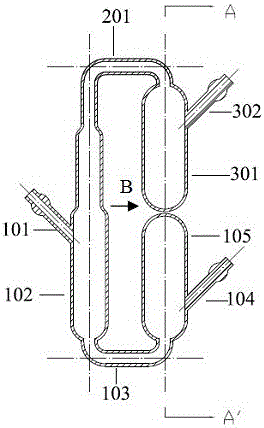

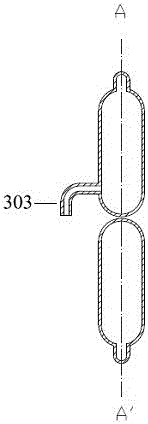

[0020] like figure 1 As shown, the integrated gas-liquid separator of the present invention includes a primary gas-liquid separator and a secondary gas-liquid separator 301 . The primary gas-liquid separator is composed of two arms, that is, two separation bottles A102 and B105. The gas-liquid mixture inlet 101 is connected to the separation bottle A102. The U-shaped sinking tube 103 is located between the separation bottle A102 and the separation bottle B105. The lower end of the liquid outlet 104 is connected to the separation bottle B105, and the upper end of the separation bottle A102 is connected to the secondary gas-liquid separator 301 through an inverted U-shaped connecting pipe 201. Due to the existence of the U-shaped sinking tube 103, after the gas-liquid mixture enters the separator of the present invention, there will always be liquid retained in the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com