Electrostatic spraying array system and optimizing method thereof

A technology of electrostatic spraying and optimized control, applied in spraying device, spray discharge device, etc., can solve the problems of poor film uniformity, affecting uniformity, affecting spraying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

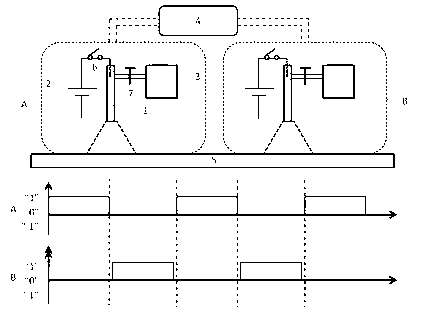

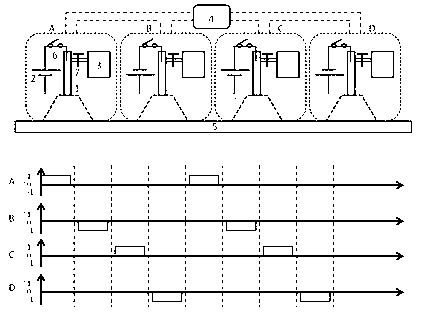

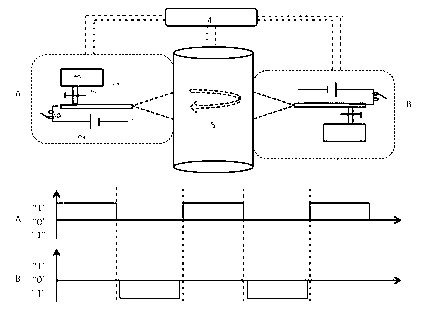

[0021] As shown in the figure, an electrostatic spray array containing two or more electrostatic spray units, each of which can include some or all of the following devices: an electrostatic spray nozzle 1, a charge generation and injection device 2 , A liquid storage and transport device 3, an automatic control device 4 for realizing a specific switching pattern, an ejection substrate 5, a switch 6 that controls charge generation or injection paths, and a switch that controls a liquid storage or delivery path 7. Different electrostatic spraying units can be independent of each other, they can share part of the devices or form parts of each other; the devices can be physically separated or have no clear boundaries; some devices can be omitted according to the situation; and so on.

[0022] The typical form of spray head 1 is tubular, or capillary tube, cavity, surface with raised points or other shapes that can realize electrostatic spraying; the liquid sprayed by each spray head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com