Winding mechanism of direct-current motor rotor

A technology of winding mechanism and motor rotor, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of cumbersome winding process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

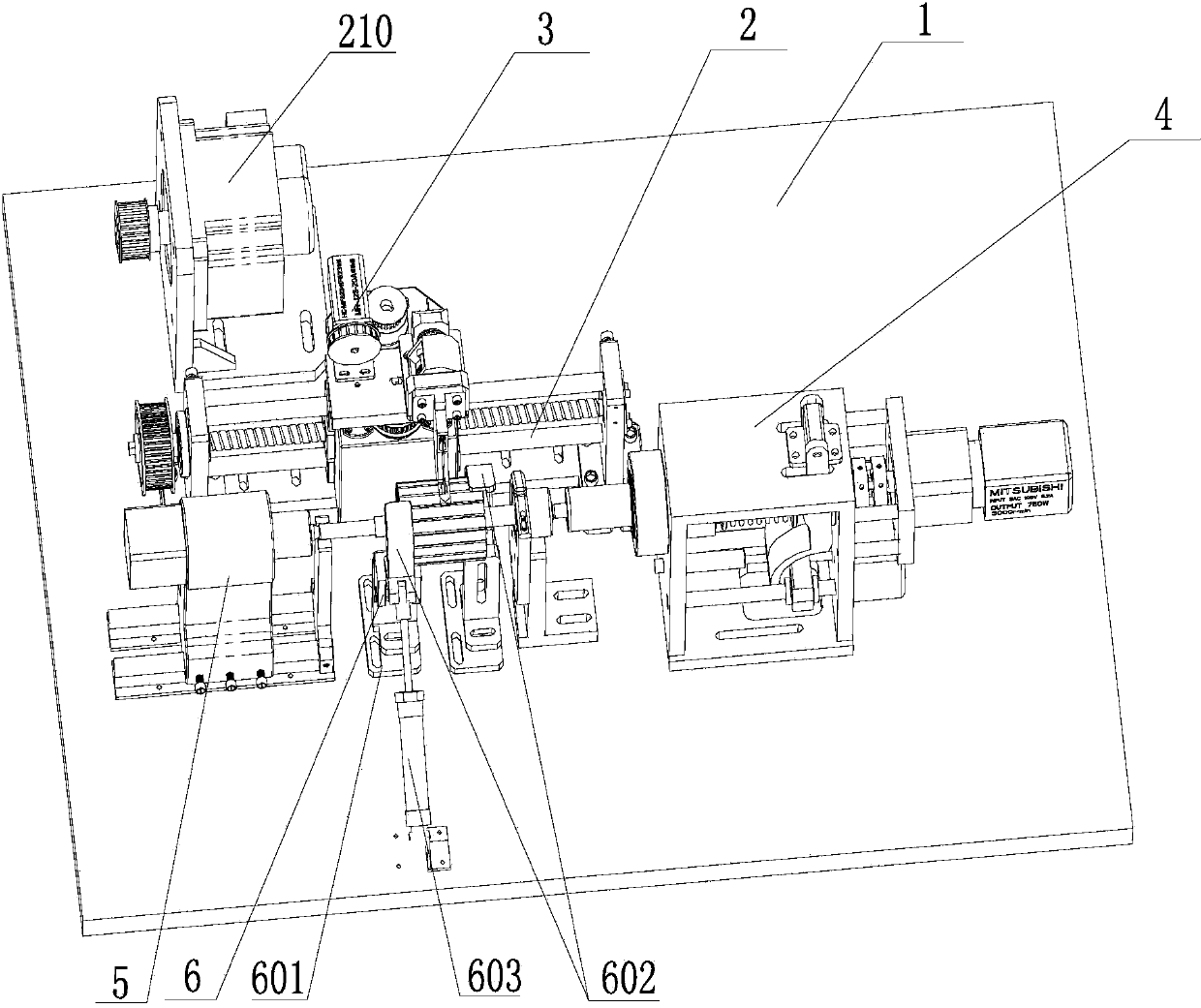

[0056] Such as Figure 1 to Figure 4 The DC motor rotor winding mechanism shown includes a workbench 1, a winding main body mechanism 2, a paint stripping mechanism 3, a clamping mechanism 4 for clamping the motor rotor, and a clamping mechanism 4 that can be positioned on the workbench 1. The tailstock 5 that moves back and forth, the paint stripping mechanism 3 is arranged on the top of the winding body mechanism 2, and the clamping mechanism 4, the tailstock 5 and the winding body mechanism 2 are all arranged on the workbench 1.

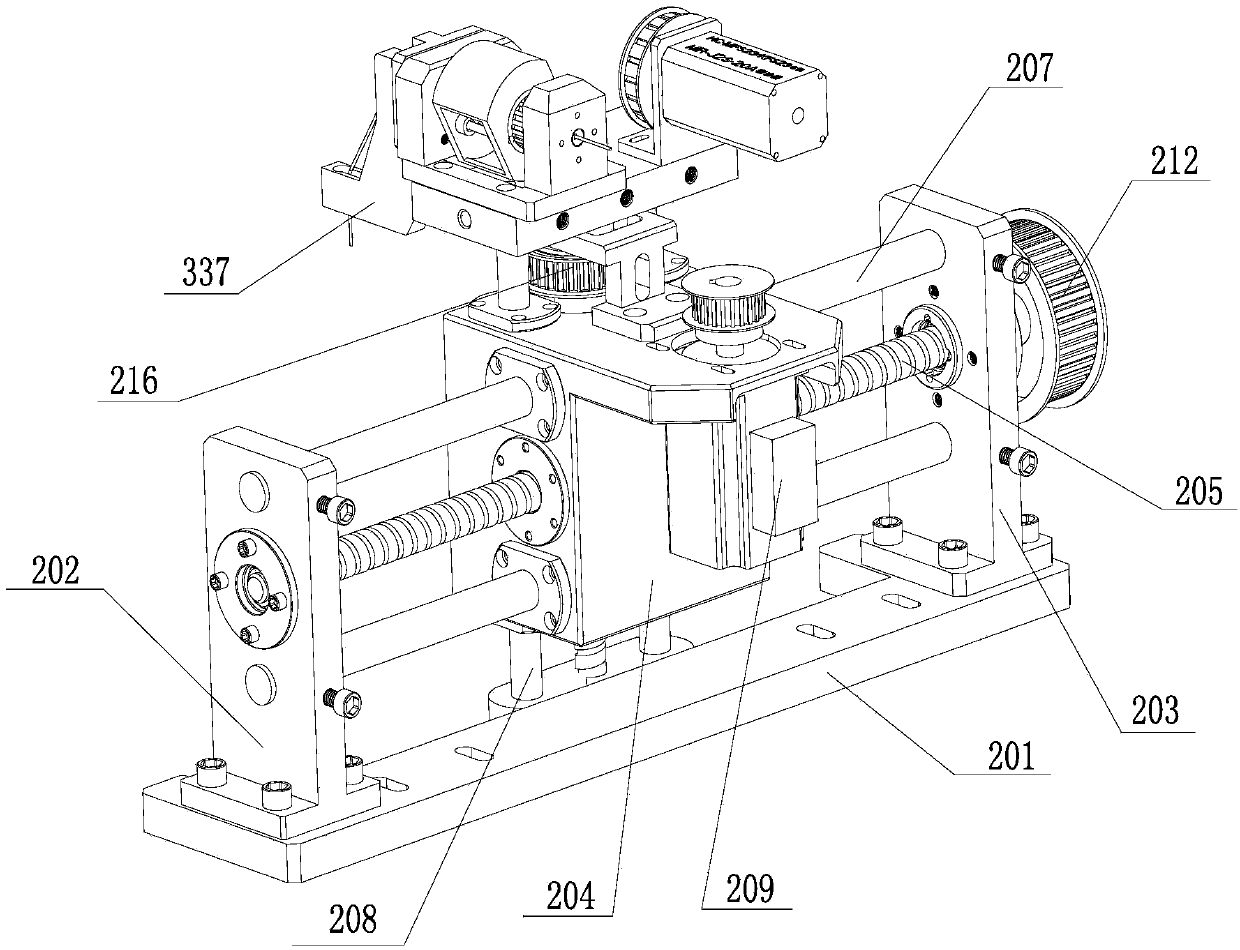

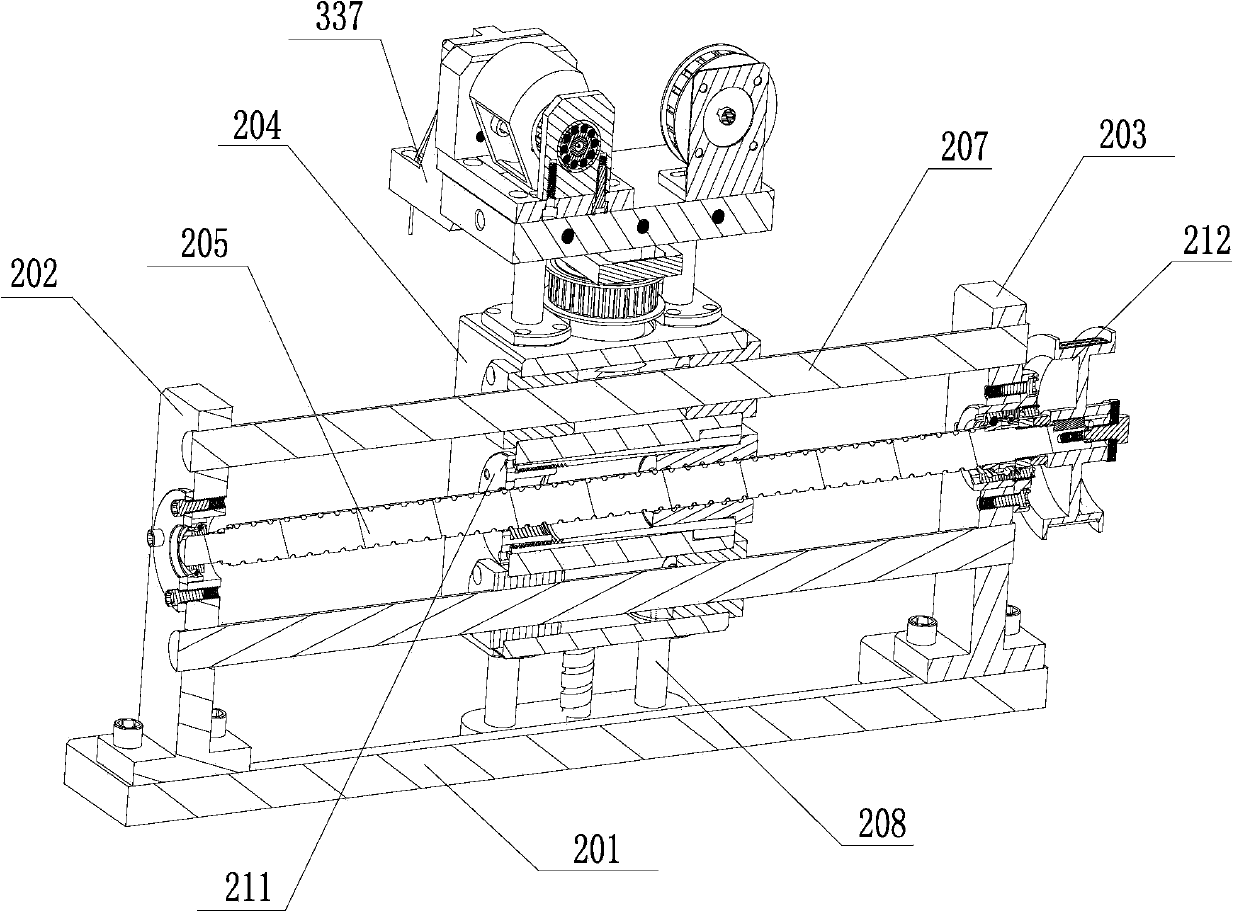

[0057] The winding body mechanism 2 includes a first base 201 arranged on the workbench 1, a first vertical plate 202 and a second vertical plate 203 respectively arranged at both ends of the first base 201, a block 204, and a horizontally arranged first ball Lead screw 205, a vertically arranged second ball sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com