Paint removing equipment for enameled wire production

An enameled wire and paint stripping technology, applied in metal processing equipment, grinding/polishing equipment, recycling technology and other directions, can solve problems such as affecting normal use, slow overall process, paint peeling, etc. Efficiency, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

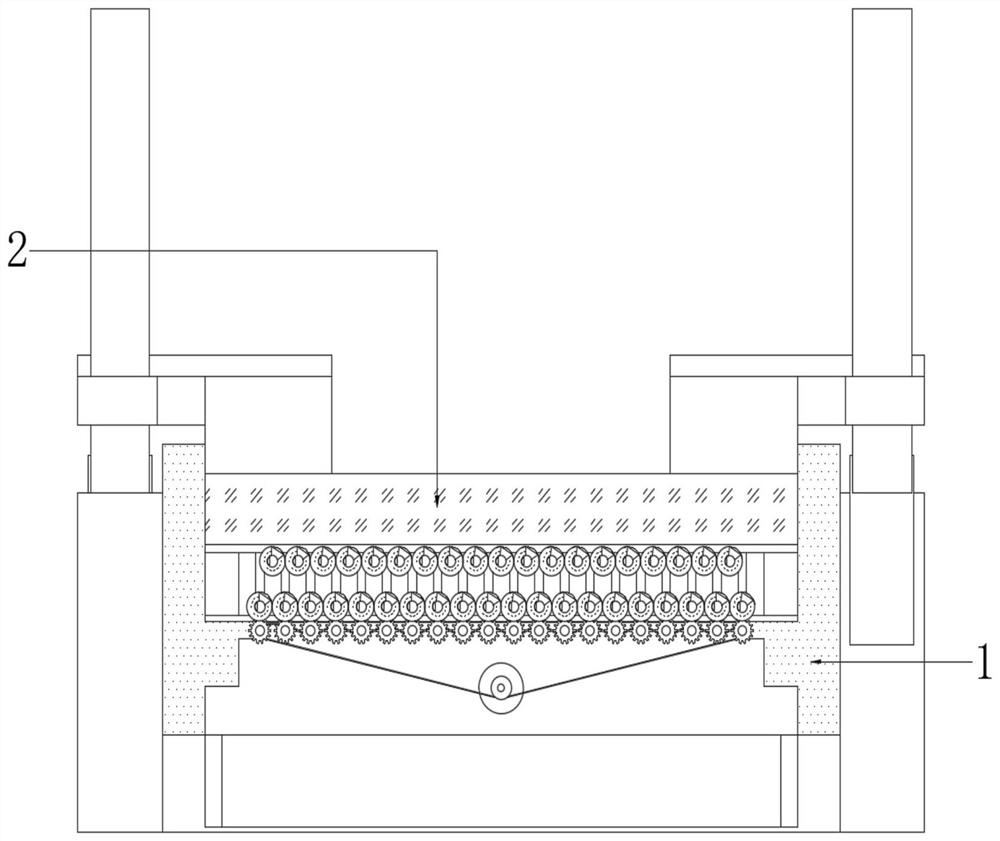

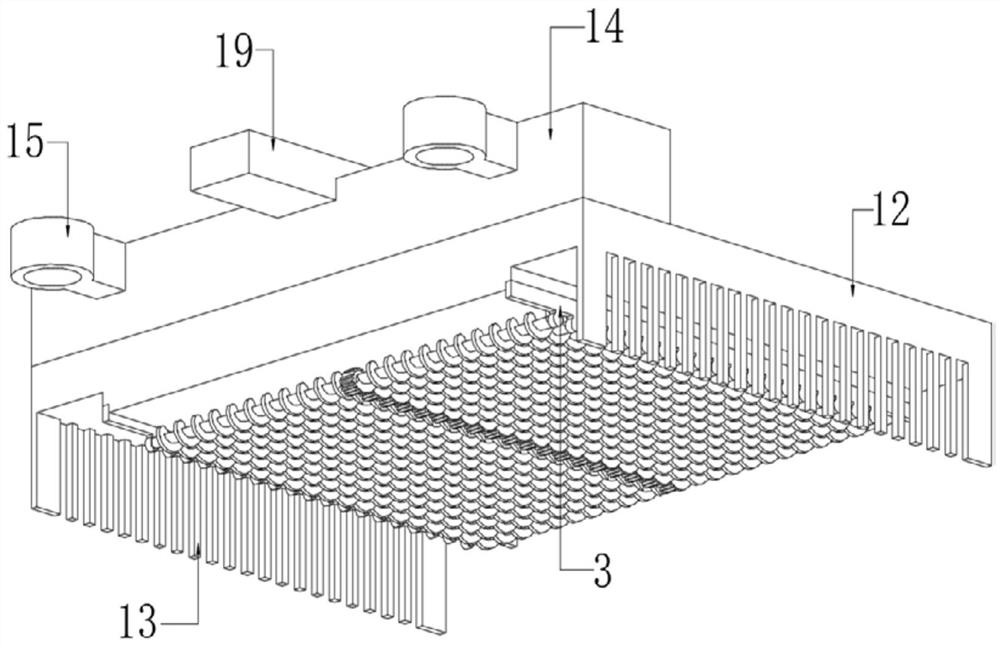

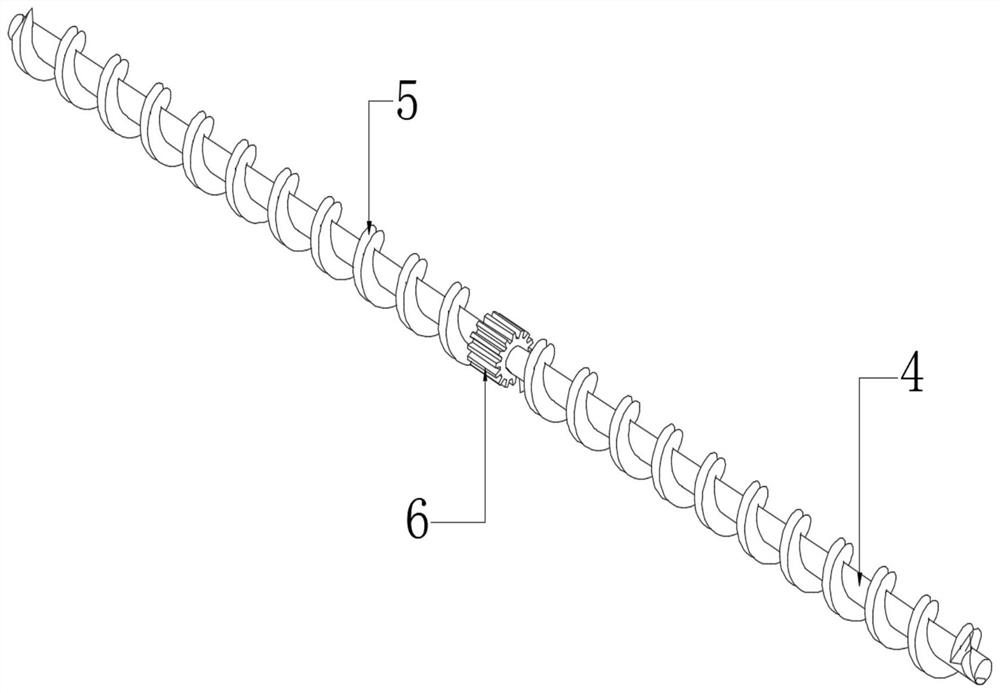

[0033] Demadelazing equipment used in the production of enameled wires, such as figure 1 , figure 2 , image 3 and Figure 4As shown, including the utensilizing pool 1 and the compartment 2, the compartment 2 is located above the undulating pool 1, and the outer outer wall of the upper outer wall and the lower outer wall of the skinned tank 1 is connected by two symmetrical The side plate 3, between the two side panels 3, by the bolt, there is a plurality of equidistant denteline rods 4, and the lacquer rod 4 is opened, and the inner wall of the spiral groove is connected by a bolt. 5, and the middle outer wall of the paint rod 4 is connected to the center gear 6 by bolts, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com