An enameled wire stripping aid for transformer assembly

An enameled wire and transformer technology, applied in the field of auxiliary devices, can solve the problems of cumbersome procedures, easy to spill, and the length of enameled wires cannot be unified in length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

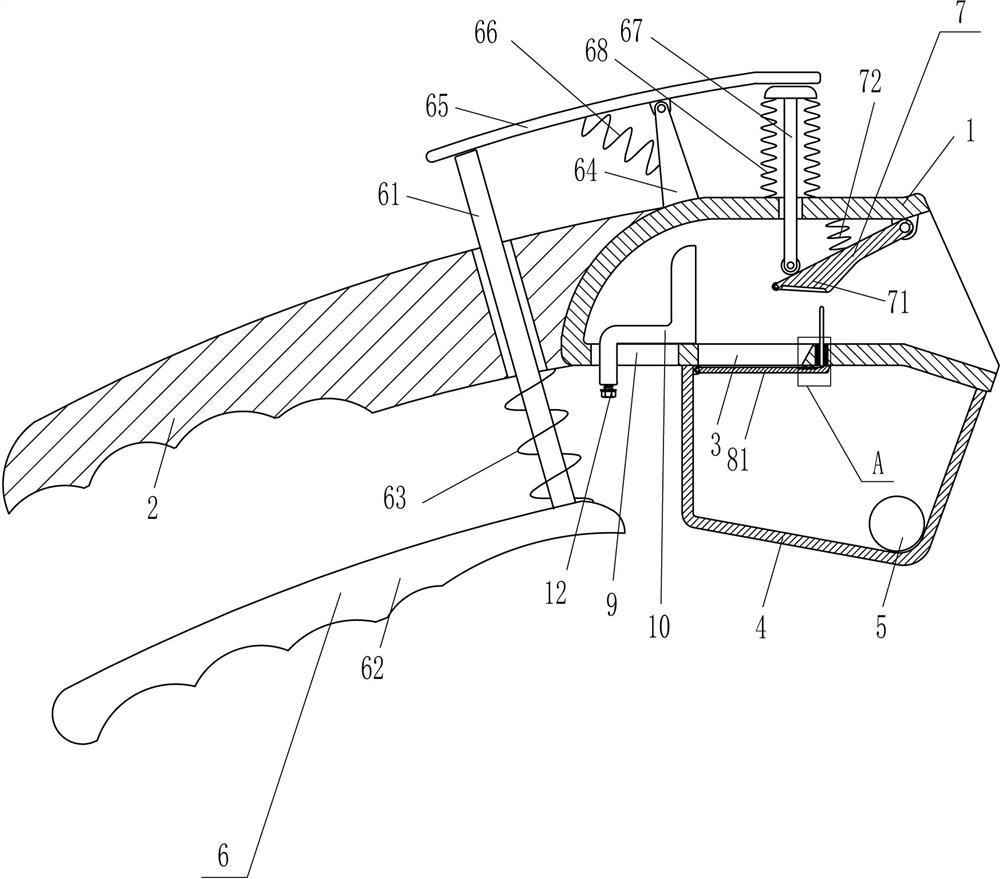

[0024] An enameled wire stripping aid for transformer assembly, such as figure 1 As shown, it includes a frame body 1, a fixed handle 2, a liquid storage tank 4, a liquid storage tube 5, a driving mechanism 6 and a pressing mechanism 7. There is an opening 3, a liquid storage tank 4 is installed on the outer bottom of the frame body 1, the top of the liquid storage tank 4 is open, the liquid storage tank 4 communicates with the opening 3, and the front and rear sides of the liquid storage tank 4 are sealed with a liquid storage tube 5, The fixed handle 2 is provided with a driving mechanism 6, and the top of the frame body 1 is provided with a pressing mechanism 7, wherein the driving mechanism 6 is used to drive the pressing mechanism 7 to operate and drive the enameled wire to bend into the liquid storage tank 4, wherein the The pressing mechanism 7 is used for pressing the enameled wire.

[0025] The drive mechanism 6 includes a sliding bar 61, a movable handle 62, a first...

Embodiment 2

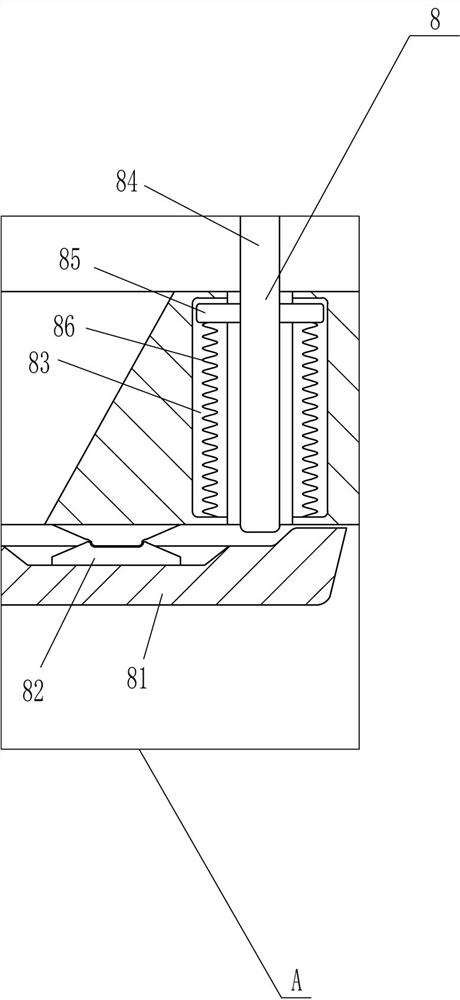

[0029] On the basis of Example 1, such as figure 1 , figure 2 and image 3As shown, a sealing device 8 is also included, and the sealing device 8 includes a cover plate 81, a fixed strong magnet 82, a movable rod 84, a sliding block 85 and a fourth spring 86, and the fixed strong magnet 82 includes a first fixed strong magnet And the second fixed strong magnet, the upper left side of the liquid storage tank 4 is installed with a cover plate 81 through a hinged connection, the first fixed strong magnet is installed on the right part of the cover plate 81, and the second fixed strong magnet is installed In the middle of the outer bottom of the frame body 1, the first fixed strong magnet and the second fixed strong magnet attract and cooperate with each other, and there are special-shaped sliding holes 83 evenly spaced in the middle of the bottom of the frame body 1, and the special-shaped sliding holes 83 are equipped with movable Bar 84, sliding block 85 is all installed on ...

Embodiment 3

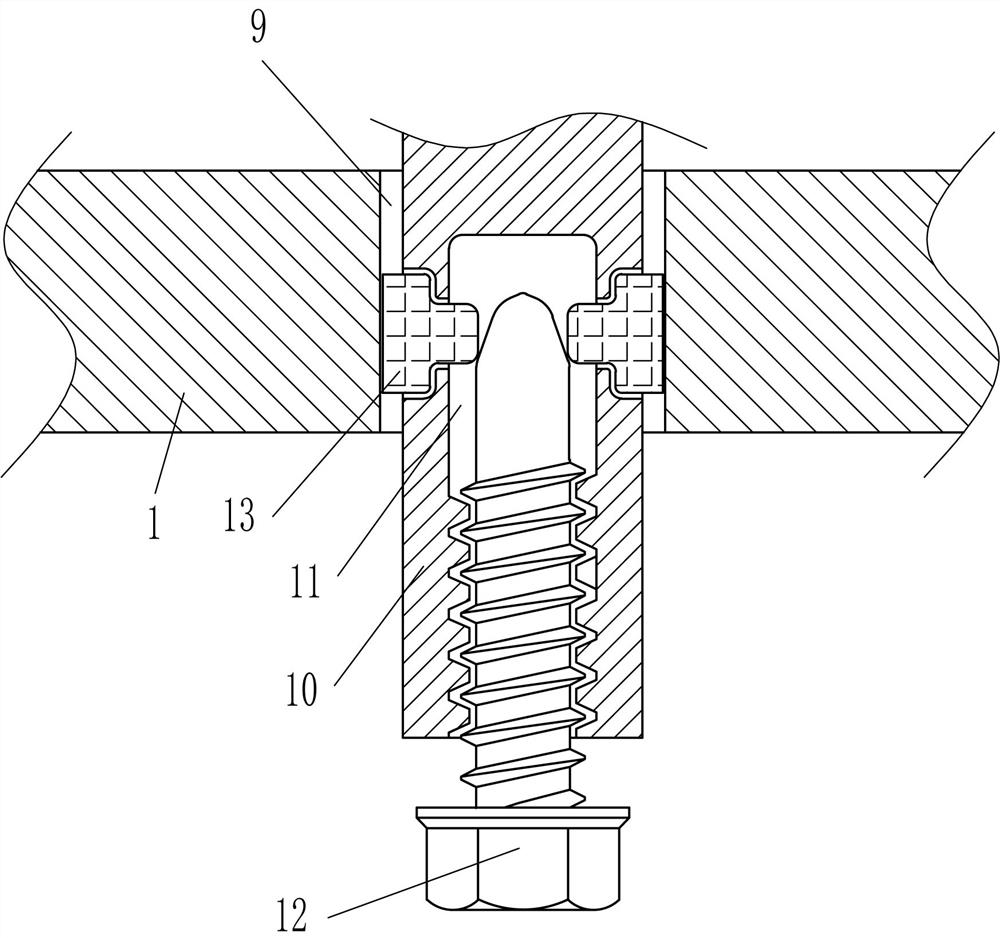

[0032] On the basis of Example 1 and Example 2, as figure 1 , Figure 4 and Figure 5 As shown, it also includes a special-shaped limiting plate 10, bolts 12 and rubber friction blocks 13. There is a horizontal chute 9 on the left side of the bottom of the frame body 1, and the sliding type in the horizontal chute 9 is provided for limiting the enameled wire put in. There are threaded holes 11 at the bottom of the special-shaped limiting plate 10, and bolts 12 are screwed inside the threaded holes 11. The front and rear sides of the special-shaped limiting plate 10 are movable and equipped with rubber that rubs against the horizontal chute 9. Friction block 13, the inner end of rubber friction block 13 contacts and fits with the top of bolt 12.

[0033] Also include rolling ball 14, movable magnet rod 15, the fifth spring 16, movable magnet plate 18 and the sixth spring 19, the movable type is provided with rolling ball 14 in the liquid storage pipe 5, and the left side in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com