Linear guide track functional pulley group for bundle-like winding machine

A technology of linear guide rail and winding machine, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc. It can solve the problems of large power consumption and uneven tension of strip materials, and achieves high degree of automation, convenient operation, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

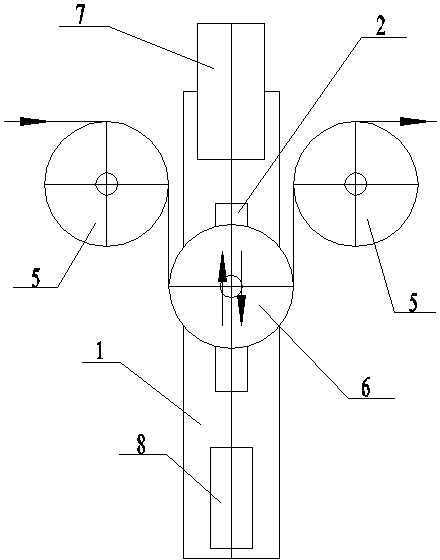

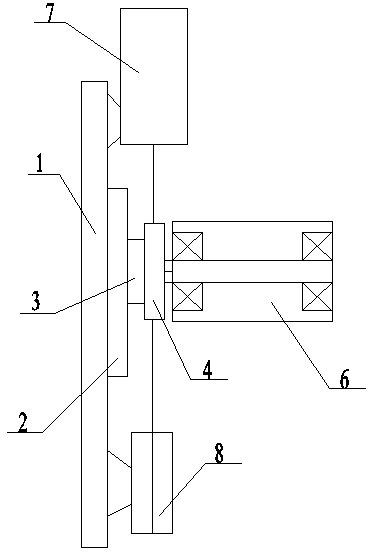

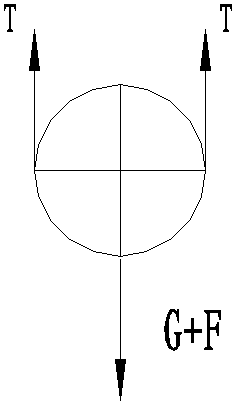

[0026] A linear guide rail-type functional pulley block for bundle winding machines, including a movable pulley 6 for guiding materials to be wound and fixed pulleys 5 arranged on both sides of the movable pulley 6, the movable pulley 6 is arranged on a linear track 2 and can reciprocate along the linear track 2, the movable pulley 6 is connected with a displacement sensor 8, the displacement sensor 8 is connected with the control system, and the control system controls the speed of the winding shaft in the winding machine according to the displacement measured by the displacement sensor 8 .

[0027] A counterweight device is connected to the movable pulley 6, and counterweight weights are installed in the counterweight device.

[0028] The movable pulley 6 is also connected with a force application mechanism 7, and the force application mechanism 7 is any one of a spring, an air cylinder or an oil cylinder, and the air cylinder or oil cylinder is connected with the control sy...

Embodiment 1

[0049] A linear guide rail type functional pulley block for a bundle winding machine, comprising a linear rail 2 arranged on a bed 1, a guide rail slider 3 capable of arbitrarily sliding on the linear rail 2, a PLC control system and at least two fixed The pulley 5 and a movable pulley 6 arranged between the fixed pulley 5, the movable pulley 2 is arranged on the guide rail slider 3 through the transition plate 4, the movable pulley 6 is also connected with a force applying mechanism 7 and a displacement sensor 8, the described Both the force applying mechanism 7 and the displacement sensor 8 are arranged on the bed 1 and connected with the PLC control system.

[0050] The force applying mechanism 7 is an air cylinder.

[0051] The displacement sensor 8 is a linear displacement sensor.

[0052] The linear track 2 includes two limit positions and an intermediate position, the intermediate position is provided with a travel switch, and the travel switch is connected with the co...

Embodiment 2

[0055] A linear guide rail type functional pulley block for a bundle winding machine, comprising a linear rail 2 arranged on a bed 1, a guide rail slider 3 capable of arbitrarily sliding on the linear rail 2, a PLC control system and at least two fixed The pulley 5 and a movable pulley 6 arranged between the fixed pulley 5, the movable pulley 2 is arranged on the guide rail slider 3 through the transition plate 4, the movable pulley 6 is also connected with a force applying mechanism 7 and a displacement sensor 8, the described Both the force applying mechanism 7 and the displacement sensor 8 are arranged on the bed 1 and connected with the PLC control system.

[0056] The force applying mechanism 7 is an oil cylinder.

[0057] The displacement sensor 8 is an incremental grating ruler displacement sensor.

[0058] The linear track 2 includes two extreme positions and an intermediate position. The intermediate position and the two extreme positions are respectively provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com