A control method of a motor driving system

A technology of a motor drive system and a control method, which is applied in the field of motors and can solve problems such as unreliable performance, high cost, and poor fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] This embodiment 1 proposes an electric vehicle, including an electric vehicle installation frame and a motor drive system that are installed and connected as one. Specifically, in this embodiment, the electric vehicle is an electric motorcycle, and its input power ranges from 400W to 10KW. Preferably, the input power range is 1KW-10KW, and within the range of medium and high-power electric vehicles, the technical effect of the present invention will be even greater;

[0103] See Figure 14 As shown, the motor drive system in this embodiment includes a three-phase AC motor and a controller group for controlling the three-phase AC motor. Specifically, preferably, in Embodiment 1, the three-phase AC motor is a permanent magnet motor, More specifically, in this embodiment, a permanent magnet synchronous hub motor is used;

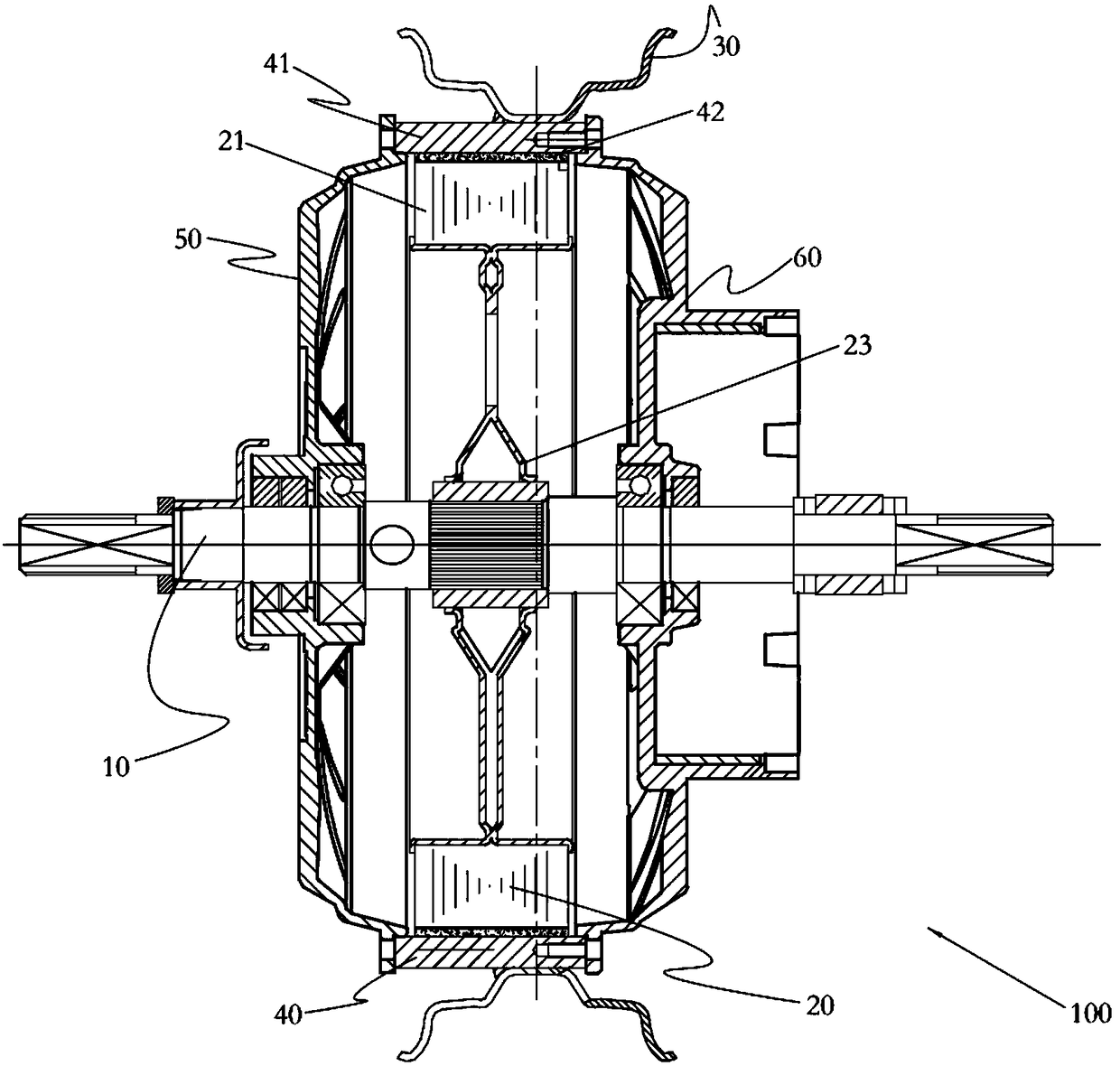

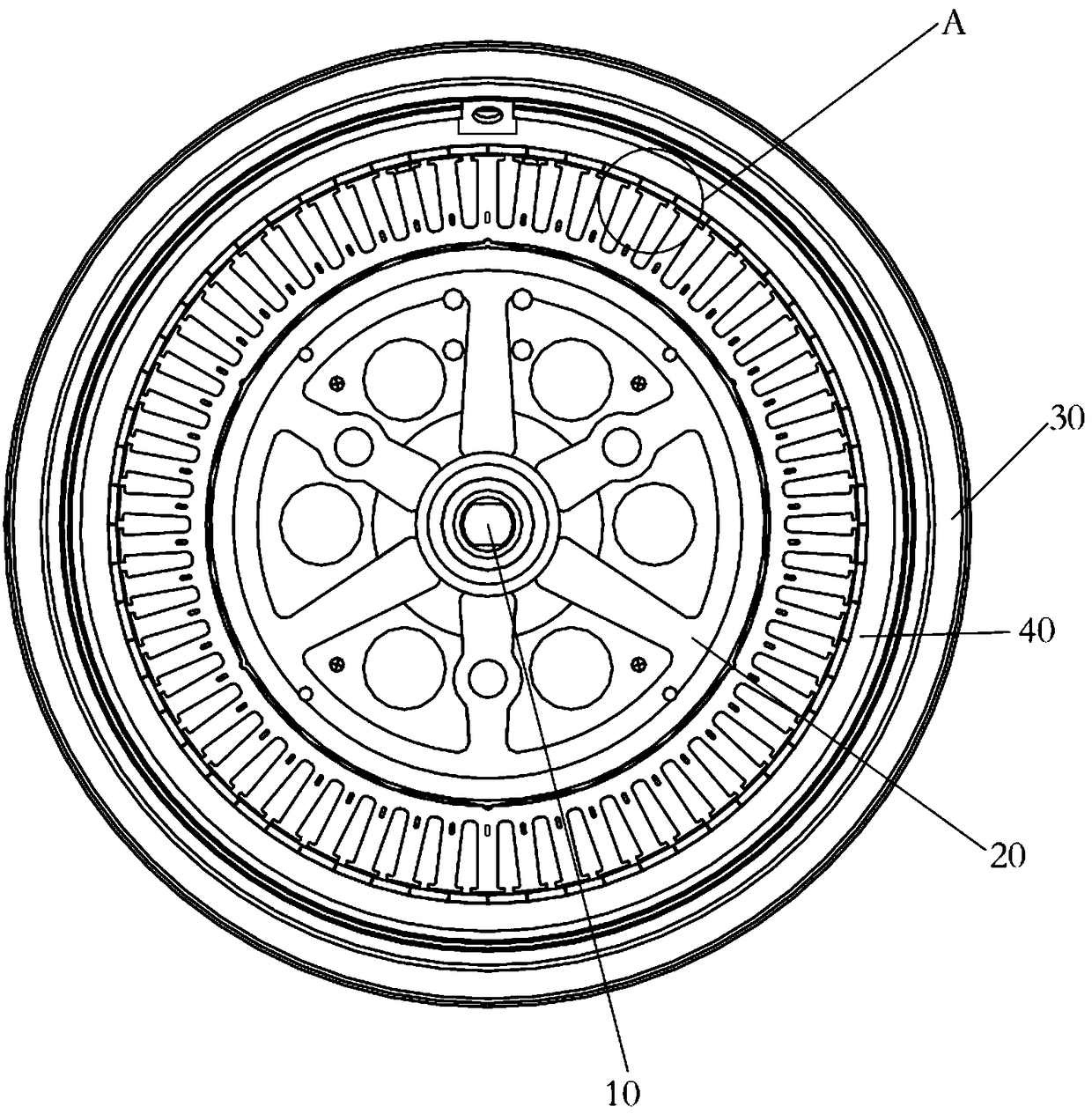

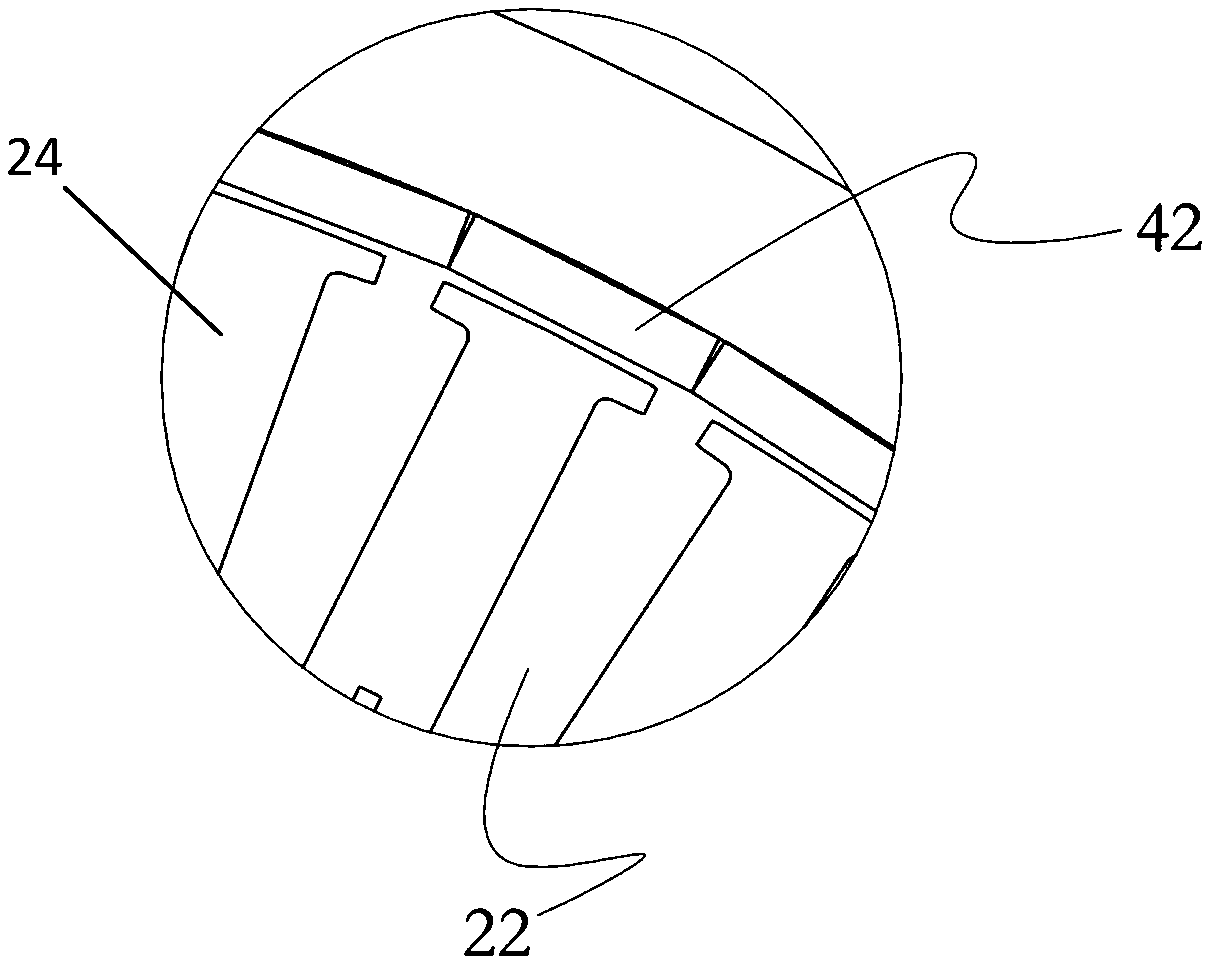

[0104] See figure 1 The shown permanent magnet synchronous hub motor 100 includes a stator 20 integrally connected with the motor shaft 10, a permanen...

Embodiment 2

[0132] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference being that: in this embodiment 2, the electric vehicle is an electric two-wheeled vehicle; wherein, the output power range of the permanent magnet synchronous hub motor is 180W-1.5 KW, the speed range of normal operation is 500-1000 rpm, and the input current range of each winding unit is 1-100A; the specific size specification, number of stator slots and number of permanent magnet steel pieces of permanent magnet synchronous hub motor can be determined according to The above-mentioned functional parameters of the permanent magnet synchronous hub motor required by this embodiment 2 are used to make a specific selection, specifically, the permanent magnet synchronous hub motor for electric two-wheeled vehicles of the prior art can be selected;

[0133]Although this embodiment 2 can also reduce the capacity of the motor driver, since the input power of...

Embodiment 3

[0134] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, the difference being that: in this embodiment 3, the electric vehicle is an electric tricycle; wherein, the output power range of the permanent magnet synchronous hub motor is 250W-15KW, More preferably, the output power range is 1KW-15KW, the speed range during normal operation is 500-2000 revolutions per minute, and the input current range of each winding unit is 10-200A; specifically preferably, in this embodiment, the permanent The output power of the magnetic synchronous hub motor 100 is 10KW, the speed range during normal operation is 800-1200 revolutions per minute, and the input current of each winding unit is 30A, wherein, the specific dimensions and specifications of the permanent magnet synchronous hub motor of the present embodiment 3 Specific selections can be made according to the above-mentioned functional parameters of the permanent magnet synchrono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com