Novel high tension coil for dry transformer and manufacturing method for novel high tension coil

A technology of dry-type transformers and high-voltage coils, which is applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., which can solve the problems of long production cycle and difficult coil winding, and achieve short production cycle, low cost, and increased The effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

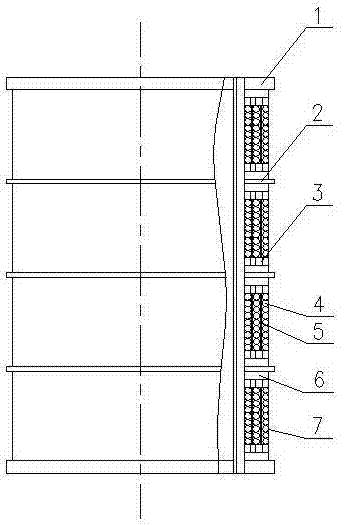

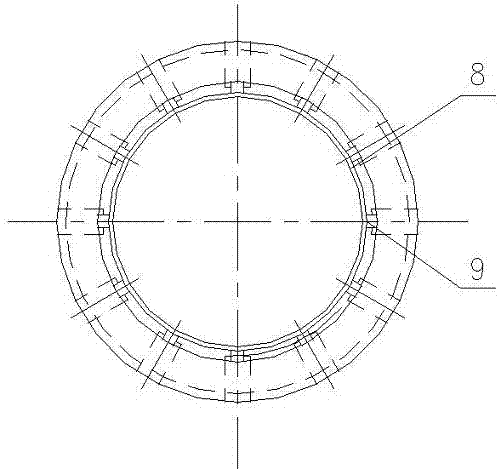

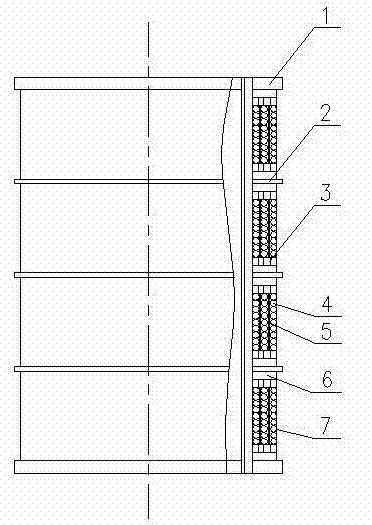

[0015] see figure 1 , figure 2 , this embodiment is a typical 10kV high-voltage coil, and it is a 4-section cylindrical structure, consisting of an insulating end ring 1, an annular insulating plate 2, an end insulating 3, an electromagnetic wire 4, an interlayer insulating 5, and several gaskets 6 , Insulation grid plate 7, insulation cylinder 8 and strut 9 are formed.

[0016] The 4 sections of cylindrical coils are wound on the stays 9 evenly distributed on the insulating cylinder 8, and the ring-shaped insulating plates 2 and the air are clamped between each section of coils by the stays 9 and the gaskets 6 passing on the stays 9. Spaced apart, the annular insulating plate 2 is sandwiched between the two gaskets and forms a radial air passage. The outer surface of each section of coil is wrapped with an insulating grid plate 7, and the upper and lower ends of the coil are all equipped with insulating end rings 1, and are positioned by stays 9 and gaskets 6 worn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com