Method for manufacturing optical fiber current sensor sensitivity coil

A technology of sensitive coils and fiber optic currents, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of fiber brittleness, long time, difficult processing such as welding, etc., to achieve easy processing, uniform speed, The effect of simple winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

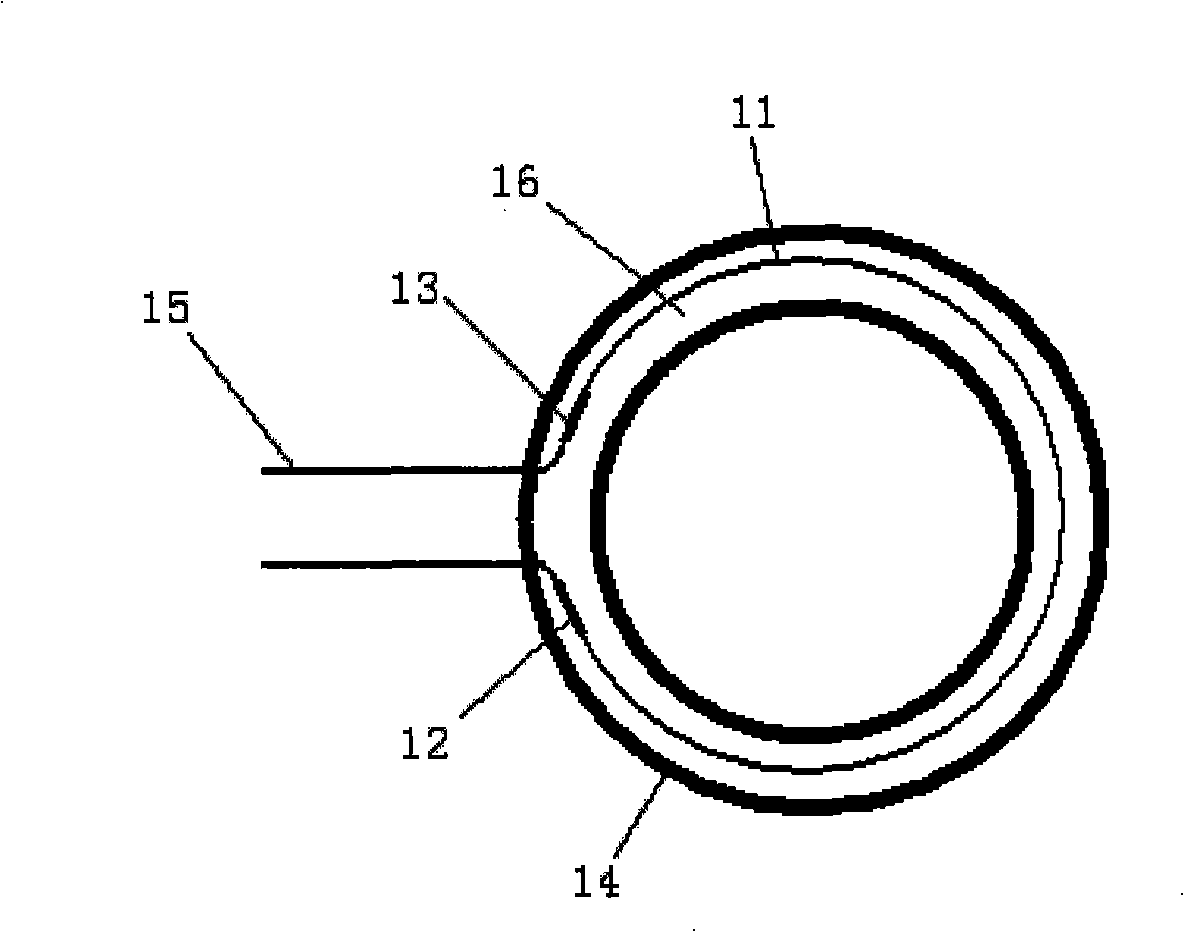

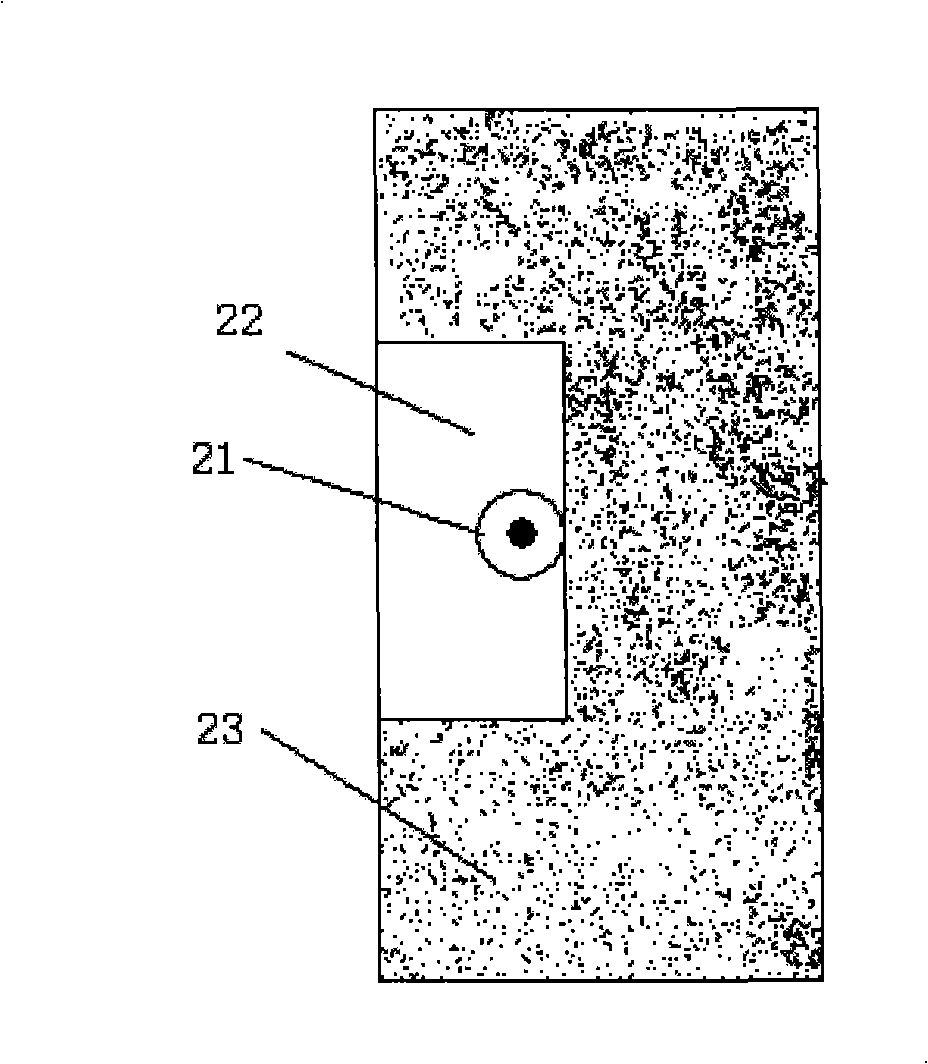

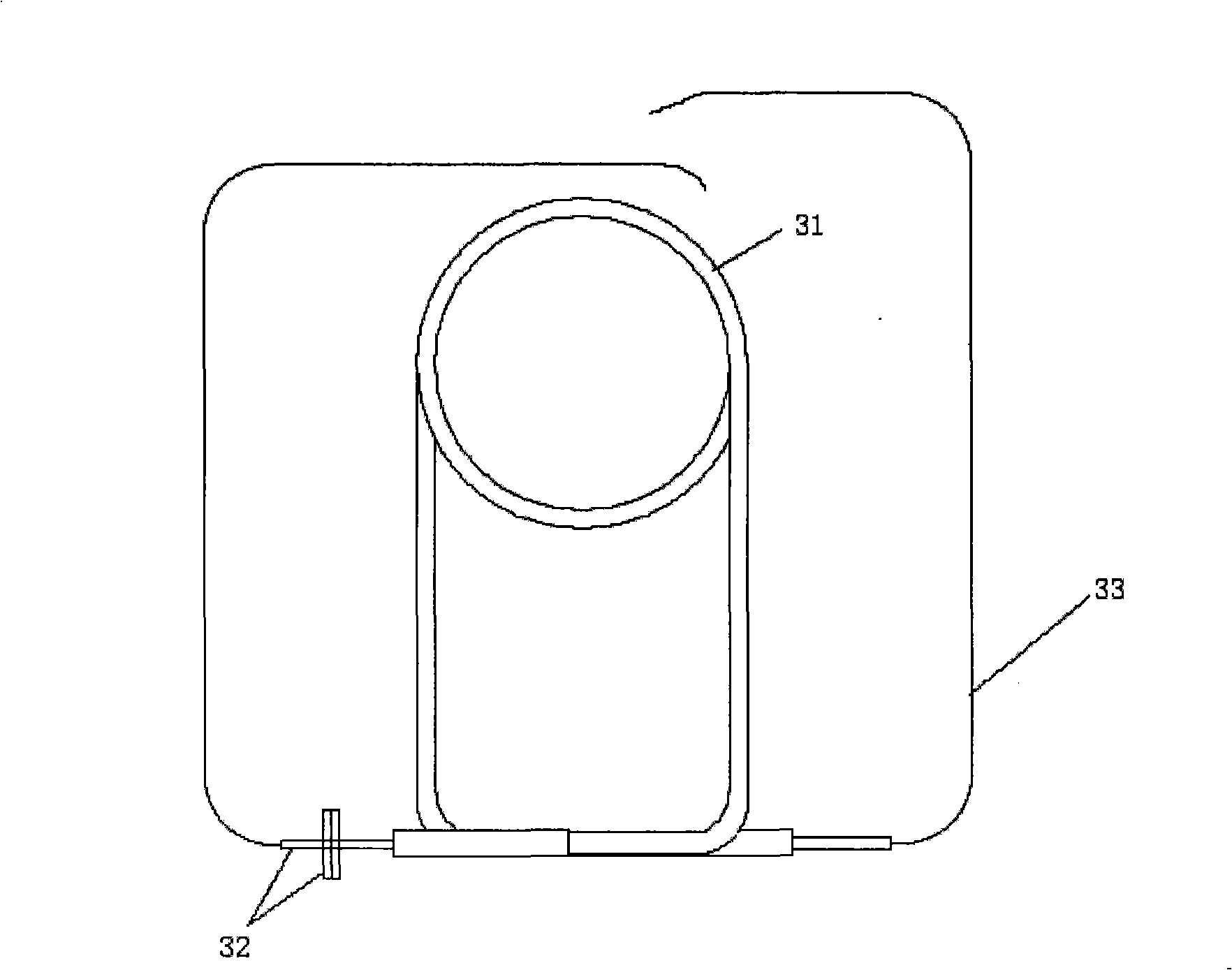

[0037] Such as Figure 5 As shown, it is a schematic diagram of the preparation method of the sensitive coil of the optical fiber current sensor of the present invention, among which 1 is a coil bobbin, 2 is an optical fiber, 3 is a symmetrical distribution point selected in the circumferential direction of the coil bobbin 1, 4 is the first quartz tube, 5 is the second quartz tube, 6 is the bracket, and 7 is the polarization-maintaining optical fiber.

[0038] First, the expansion coefficient is less than 10 -6 Or a material close to the optical fiber 2, such as quartz or Invar, prepares a ring-shaped coil bobbin 1, the outer diameter of the coil bobbin 1 is 20-200 cm, the inner diameter of the skeleton is 3-20 cm smaller than the outer diameter, and the height of the skeleton in the normal direction of the circle is 1-10 cm. In the embodiment of the present invention, the outer diameter of the coil frame 1 is selected to be 150 cm, the inner diameter is 140 cm, and the heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com