Annular differential-mode inductor and production method thereof

A technology of differential mode inductors and production methods, which is applied in the field of magnetoelectricity, can solve the problems of reducing the service life of downstream products, increasing the magnetic core, and losing application performance, so as to improve the anti-electromagnetic interference performance, reduce the parasitic capacitance value, and product Apply performance-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

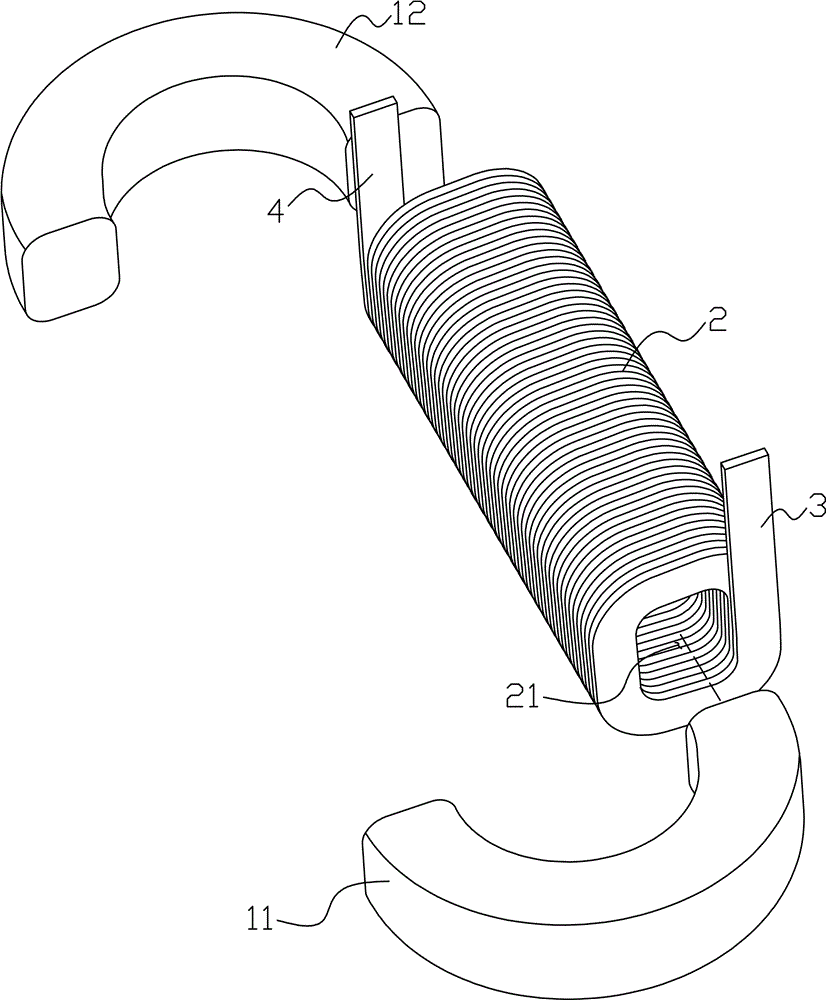

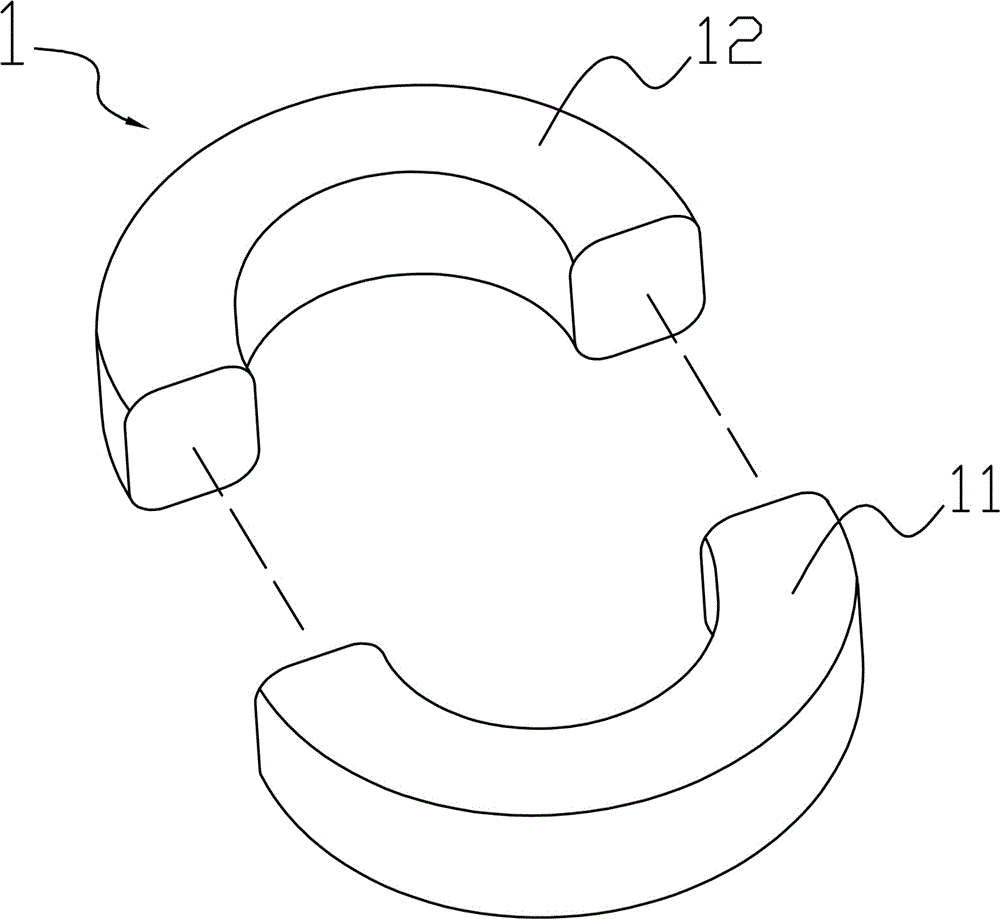

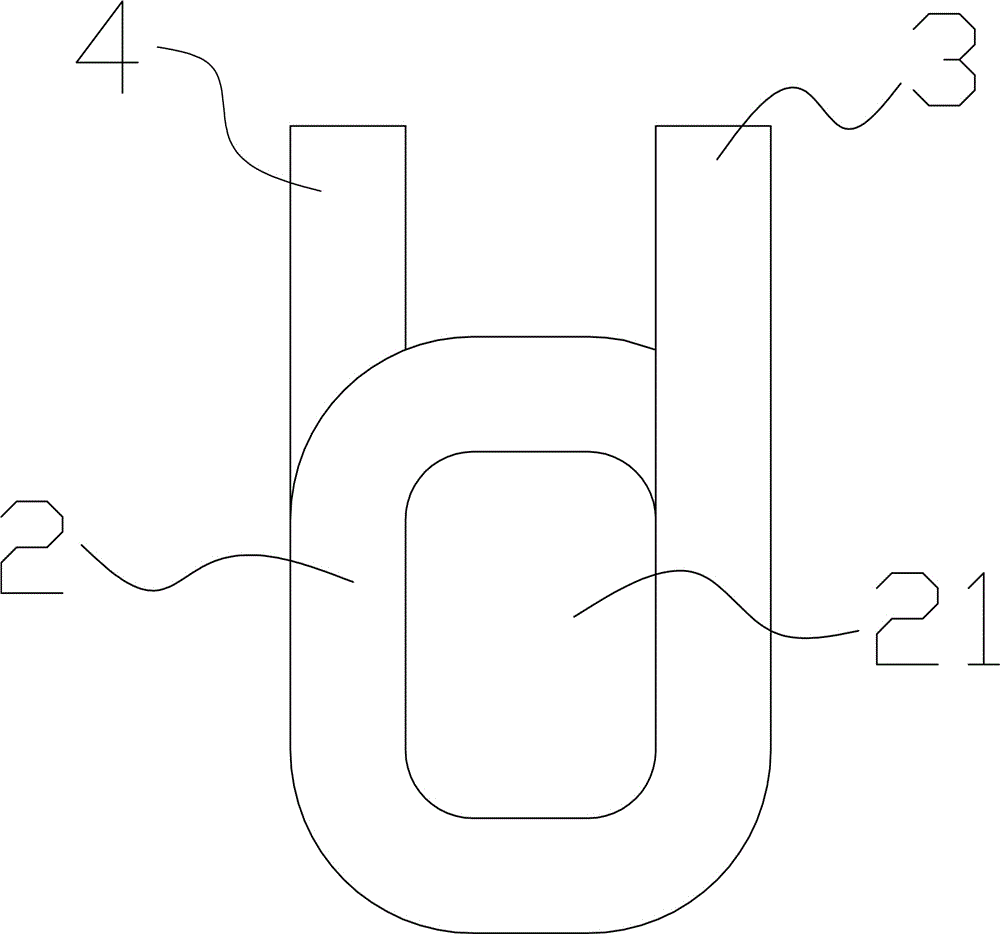

[0029] see Figure 1-Figure 4 .

[0030] The invention discloses an annular differential mode inductor, which comprises an annular magnetic core 1 and a coil 2. The annular magnetic core 1 is formed by butting a first magnetic core 11 and a second magnetic core 12. The window 21 forms a magnetic core channel, and the first and second magnetic cores are inserted into the magnetic core channel and then docked. In this case, the coil 2 is wound in advance with a winding machine as required, and the annular differential mode inductor passes through the first and second The magnetic core is formed by butting after passing through the wound coil. The winding process is simple, which solves the problem that the wire diameter is too large and cannot be wound. At the same time, it reduces the labor intensity of the workers and improves the production efficiency; The copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com